I saw that and it's on the list!You oughta weld up them divots in the knuckles where the brake pads ride.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A lesson learned—keep it light and nimble!

- Thread starter Irun

- Start date

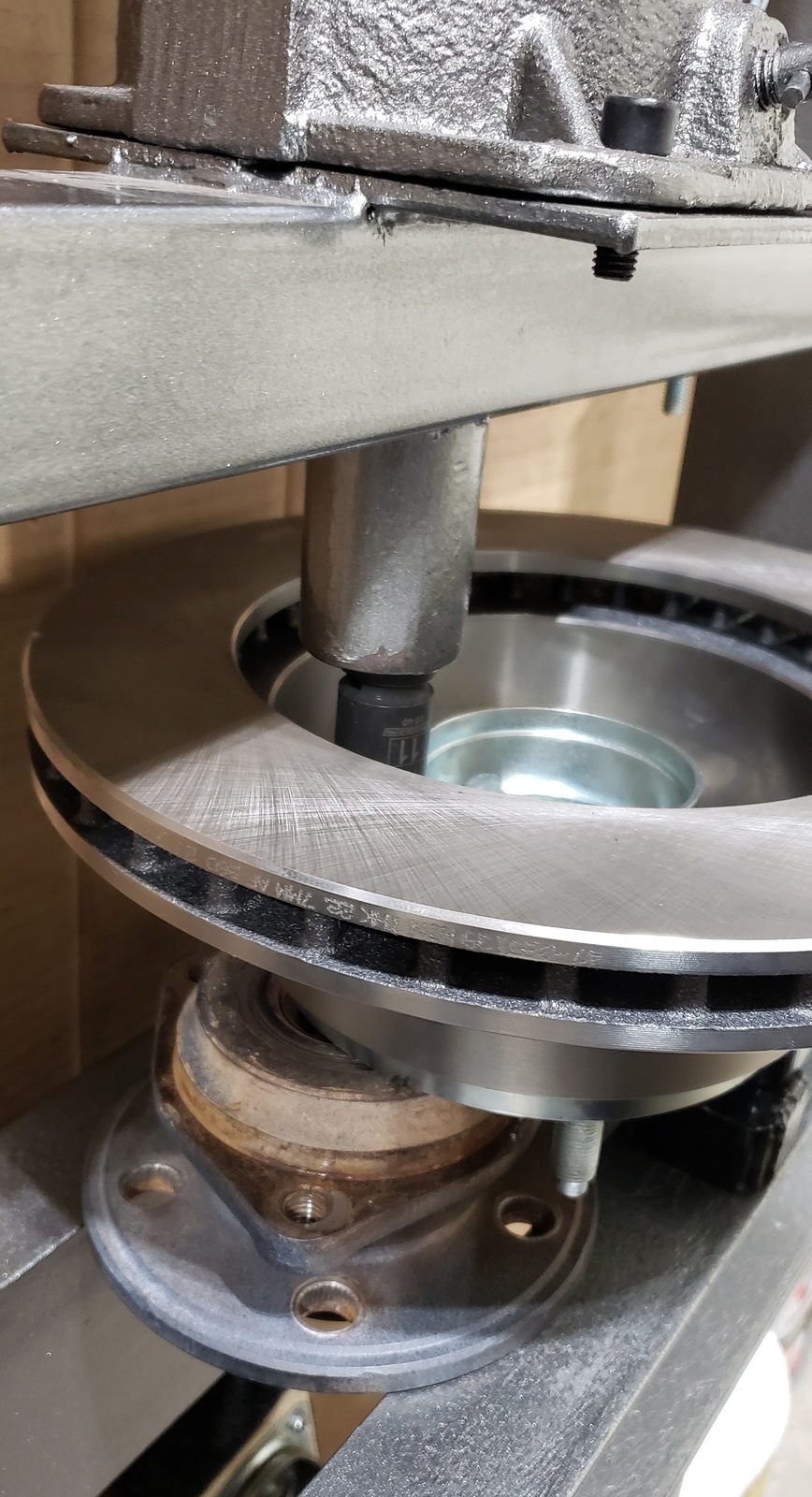

@mrblaine described this, but for those, like me, that sometimes have difficulty visualizing things, here's the difference in the supplied rotors, versus the stock one you buy. I laid the supplied rotor over the stock one and marked it.

This is how much needs to be removed from the stock rotor, if you want to install one on the Yukon hubs. I have a couple 2" stones, so, for future reference, I'm going to see how difficult it is to cut these down. Unless someone has a different recommendation?

This is how much needs to be removed from the stock rotor, if you want to install one on the Yukon hubs. I have a couple 2" stones, so, for future reference, I'm going to see how difficult it is to cut these down. Unless someone has a different recommendation?

Seems something is missingFirst surprise of the install came when I went to install the new u joints, connecting the inner and outer shafts. See the problem here?

View attachment 225948

Yes, one of the needle bearings was missing. I've done lots of u joints, so I know the drill...be careful not to loose them, and double check when installing the caps. In this case, this particular cap came off easy. I'm guessing when it was packaged the cap came off and someone put it back on, not knowing one of the needle bearings had fallen out. Fortunately, I had a spare u joint.Seems something is missing

You need to check the wheel studs and how they fit into the hub flange. The answer is not "get a bigger hammer" like they told Garrett.Yes, one of the needle bearings was missing. I've done lots of u joints, so I know the drill...be careful not to loose them, and double check when installing the caps. In this case, this particular cap came off easy. I'm guessing when it was packaged the cap came off and someone put it back on, not knowing one of the needle bearings had fallen out. Fortunately, I had a spare u joint.

Haven't checked those, but they're next on the list. I'm assuming I can use the press to install them? That is my plan.You need to check the wheel studs and how they fit into the hub flange. The answer is not "get a bigger hammer" like they told Garrett.

You have to check the fit at two places. The shoulder under the head should be about a .000-.003 interference fit in the hole in the rotor. The max interference in the hub flange should be .010 down to around .005. Most recognize .008 as proper. If that is not the case, you may have some work to do. Yes on the press. The problem is supporting the flange and not the rotor hat unless you want to see how easy it is to break a rotor.Haven't checked those, but they're next on the list. I'm assuming I can use the press to install them? That is my plan.

Good advice here. Had not considered this. I'll see what I can put together to support it from the bottom!The problem is supporting the flange and not the rotor hat unless you want to see how easy it is to break a rotor.

Had to put down the tools and walk away...Whats wrong with this picture?

Idiots sent me two completely different outers and I installed the wrong one first, before finding out!

Idiots sent me two completely different outers and I installed the wrong one first, before finding out!

That’ll piss you off. Wow.Had to put down the tools and walk away...Whats wrong with this picture?

View attachment 226047

Idiots sent me two completely different outers and I installed the wrong one first, before finding out!

View attachment 226048

Can’t trust yukon.

For me the only issue was that the studs knurl diameter was wayyy too big for the holes in the hub flange. Something like 32 thousandths bigger. I was fortunate enough to take mine to Blaine and he found studs that were smaller in knurl diameter but he also did some reaming to both the hub and rotor holes to make sure they were within the proper interference range.

I can find the part number for the studs we used if you want but you’ll most likely still need to do some machining to get it perfect.

For me the only issue was that the studs knurl diameter was wayyy too big for the holes in the hub flange. Something like 32 thousandths bigger. I was fortunate enough to take mine to Blaine and he found studs that were smaller in knurl diameter but he also did some reaming to both the hub and rotor holes to make sure they were within the proper interference range.

I can find the part number for the studs we used if you want but you’ll most likely still need to do some machining to get it perfect.

As expected, @mrblaine was spot on about installing the wheel studs for the lockout conversion with a press. I could get three installed using the standard press arbor plates. After that, no bueno. Had to get creative, found an old hub bearing, removed the wheel studs from it, and it worked perfect. I could use the center of the hub bearing as a way to push the wheel studs down with no issues!

Pass the part numbers on. I'm going to see if I can get Yukon to send me a new kit. This install has been a huge disappointment so far!Can’t trust yukon.

For me the only issue was that the studs knurl diameter was wayyy too big for the holes in the hub flange. Something like 32 thousandths bigger. I was fortunate enough to take mine to Blaine and he found studs that were smaller in knurl diameter but he also did some reaming to both the hub and rotor holes to make sure they were within the proper interference range.

I can find the part number for the studs we used if you want but you’ll most likely still need to do some machining to get it perfect.

Did you measure the diameter of the holes and knurl on the studs?As expected, @mrblaine was spot on about installing the wheel studs for the lockout conversion with a press. I could get three installed using the standard press arbor plates. After that, no bueno. Had to get creative, found an old hub bearing, removed the wheel studs from it, and it worked perfect. I could use the center of the hub bearing as a way to push the wheel studs down with no issues!

View attachment 226061

Missing needle bearing in one u joint, two different outers, and hubs that are scratched and look used. I've walked away for the evening. I'm pissed as it is, because of poor packaging on Yukon's part!Did you measure the diameter of the holes and knurl on the studs?

I have that conversation at least once a week when folks ask me why I don't have the parts on the shelf to do the conversions with our brake kits. I have to explain that Yukon is all over the map and change dimensions and hole sizes arbitrarily depending on the day that fully negates me building stuff ahead of time. I have about 4 different wheel stud versions around now just to try and get everything to play nice together.Missing needle bearing in one u joint, two different outers, and hubs that are scratched and look used. I've walked away for the evening. I'm pissed as it is, because of poor packaging on Yukon's part!

I will poke you a bit though because you committed the NUMBER 1 installer failure in that you did not check all of the parts before you took the rig apart. I get calls from mechanic shops wanting me to pay a labor claim when my packing guy screws up a part.

First question I ask is did you read the instructions and verify that you had the correct parts before you put it on the lift and tore it down?

No

Okay, then I'm not going to pay a labor claim because I do not reward stupidity and lack of common sense. Do you check other parts to see if they fit before you tear a vehicle down? If you don't, you need to start.

I use 219, 149, 177, and 179 so far IIRC.I believe we used dorman 610-219 studs. But like I said we reamed the holes.

Failure on my part. Went over the instructions several times before starting. and checked that all the parts were there. However, I didn't verify each part numerically. A 33% error is still a 100% failure!I have that conversation at least once a week when folks ask me why I don't have the parts on the shelf to do the conversions with our brake kits. I have to explain that Yukon is all over the map and change dimensions and hole sizes arbitrarily depending on the day that fully negates me building stuff ahead of time. I have about 4 different wheel stud versions around now just to try and get everything to play nice together.

I will poke you a bit though because you committed the NUMBER 1 installer failure in that you did not check all of the parts before you took the rig apart. I get calls from mechanic shops wanting me to pay a labor claim when my packing guy screws up a part.

First question I ask is did you read the instructions and verify that you had the correct parts before you put it on the lift and tore it down?

No

Okay, then I'm not going to pay a labor claim because I do not reward stupidity and lack of common sense. Do you check other parts to see if they fit before you tear a vehicle down? If you don't, you need to start.