We add a slight amount of bend to the trackbar where the cover hits and then a tad bit where the first bend is from the axle side joint to put it all back where it belongs. Then we trim off the inboard front corner of the spring perch at a 45 to pass by the JJ barrel. Then we do some serious trimming on that goofy gusset. After that, a bit of clearance work of the upper part where the holes are for the case spreader on the diff casting.It definitely wouldn't stop it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A lesson learned—keep it light and nimble!

- Thread starter Irun

- Start date

I'm pretty sure you have the SL links incorrectly attached. The black spacer goes next to the link mount. The nut with the tapered end goes on the bolt with the taper towards the ball on the rod end. The concept is to provide misalignment room.Looks like the Currie problem is solved. Ground the inside edge, per @jjvw, and now can get zero bump stop. I don't yet know the collapsed stack height of the H&R springs, but this is progress in the correct direction!

View attachment 249315

View attachment 249316

You highly fucked up the trackbar bolt. You need to unfuck it. Go back to a grade 8. Find the thick washer Currie supplied. It goes into the counterbore on the top side of the frame side mount. That big washer and lock washer go in the trash. Use red loctite with a graded normal nut. The bolt head goes right against the end of the JJ ball.Looks like the Currie problem is solved. Ground the inside edge, per @jjvw, and now can get zero bump stop. I don't yet know the collapsed stack height of the H&R springs, but this is progress in the correct direction!

View attachment 249315

View attachment 249316

I didn't want to drill the frame side hole until I knew the Currie bar would work. The bolt that's in there is only temporary, until I got it working. Now that everything clears, I'll drill the hole and install the Currie supplied bolt.You highly fucked up the trackbar bolt. You need to unfuck it. Go back to a grade 8. Find the thick washer Currie supplied. It goes into the counterbore on the top side of the frame side mount. That big washer and lock washer go in the trash. Use red loctite with a graded normal nut. The bolt head goes right against the end of the JJ ball.

That's good.I didn't want to drill the frame side hole until I knew the Currie bar would work. The bolt that's in there is only temporary, until I got it working. Now that everything clears, I'll drill the hole and install the Currie supplied bolt.

Temporary as well!I'm pretty sure you have the SL links incorrectly attached. The black spacer goes next to the link mount. The nut with the tapered end goes on the bolt with the taper towards the ball on the rod end. The concept is to provide misalignment room.

I do need you to pay attention! Screwing up is normal for me, but I'm trying to do it less frequently!I'll quit paying attention now.

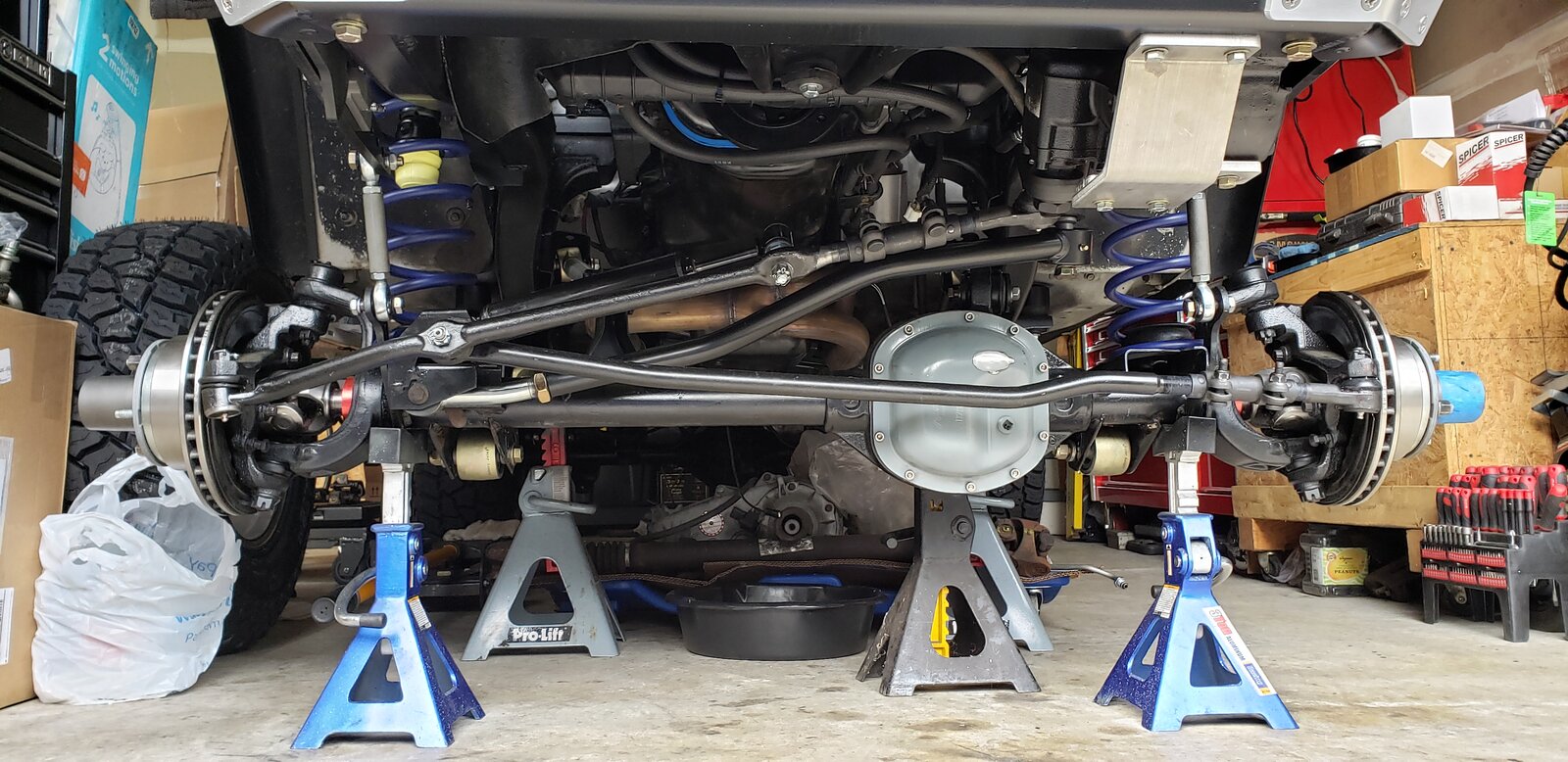

Still need to tighten everything up, but the springs and 3/4" spacers are in.

Can't wait to see the final height once it's back on the ground. Doesn't matter since I can't get springs for mine, but I can dreamStill need to tighten everything up, but the springs and 3/4" spacers are in.

View attachment 249478

View attachment 249479

View attachment 249480

View attachment 249481

How is steering at full bump? With the axle pulled back decreasing wheelbase, do the tires rub the back of the front fenders?

The combination of the 3.75" backspaced wheel, along with the hub kit, works well. The steering all checked out at full bump. Clearance on the back fender well is the same as depicted at the flare.How is steering at full bump? With the axle pulled back decreasing wheelbase, do the tires rub the back of the front fenders?

Here's a list of the parts used for the front end and what I learned:

- Savvy CE-9100SA Control Arms

- Moog DS1430 (1) Drag Link

- Moog DS1312 (1) ZJ Tie Rod

- Moog ES2079S (2) ZJ Tie Rod Terminal

- Moog ES3096L (2) ZJ Tie Rod End

- Monroe SC2928 Steering Damper

- H&R 52107 1" Lift Springs

- Omix-ADA 18280.25 Jounce Bumper

- Moog K160039 Front Spring Insulator

- StreetRays SR-JEEPTJ-FRLIFTCUP1 Billet 1" Spacer

- Currie CE-9120TJS Front Track Bar

- Alloy USA 11200 Dana 30 5/16 HD Cover

- Lube Locker LLR-D030 Dana 30 Gasket

- SwayLLOC SL-TJLV

- Pro Comp 69 Wheel (15x8 with 3.75" BS)

- Mickey Thompson ATZ P3 Tire 31x10.50R15

- Yukon YA WU-07 Small Hub Kit

The Savvy lower control arms had to be adjusted almost all the way in, set to the stock arm length, to work with the small lift. Once this was done, all the parts here played well together, with a couple small exceptions.

The combination of the Alloy USA 5/16 cover and the Currie track bar interfered with each other, when cycling the suspension. This resulted in a hard stop, requiring 2" bumpstop extensions, if left as is. A significant amount of trimming of the Currie track bar gusset, along with minor grinding on the Alloy cover, allowed the suspension to go to full bump, with zero interference. This meant zero (0) bump stop was required. As a note, I had the track bar in and out at least a dozen times while clearancing everything. Only after I was done making sure the Currie track bar would work did I drill the required 5/8" frame side mount hole, and 1/2" axle side mount.

My other top three things I learned:

1. This site continues to be an invaluable resource for those of us that are willing to learn. @Chris does an amazing job of ensuring content is updated and discoverable. Now, whenever I search anything, I preface my google search with "wranglertjforum". This helps ensure I get worthwhile results at the top of my search list first.

2. The experts here are exactly that, experts, and are willing to help. We can help them help us, if we make it simple and clear what we're asking for, with pictures, and are specific with describing where we are in the process. Bottom line, don't assume they can, or want to, read your mind!

3. Cycling the suspension really does show the interference points. In my case I had two areas that required grinding and cutting, along with one stupid positioning I did with the tie rod terminal adjuster bolts. Taking the time to make sure everything works resulted in resolving some issues that could have damaged parts later, and certainly limited useful suspension travel.

All that said, a special thanks to @Chris, @jjvw , and, especially @mrblaine . Their contributions here help all of us put together a better rig, if we're willing to listen and do a little work.

- Savvy CE-9100SA Control Arms

- Moog DS1430 (1) Drag Link

- Moog DS1312 (1) ZJ Tie Rod

- Moog ES2079S (2) ZJ Tie Rod Terminal

- Moog ES3096L (2) ZJ Tie Rod End

- Monroe SC2928 Steering Damper

- H&R 52107 1" Lift Springs

- Omix-ADA 18280.25 Jounce Bumper

- Moog K160039 Front Spring Insulator

- StreetRays SR-JEEPTJ-FRLIFTCUP1 Billet 1" Spacer

- Currie CE-9120TJS Front Track Bar

- Alloy USA 11200 Dana 30 5/16 HD Cover

- Lube Locker LLR-D030 Dana 30 Gasket

- SwayLLOC SL-TJLV

- Pro Comp 69 Wheel (15x8 with 3.75" BS)

- Mickey Thompson ATZ P3 Tire 31x10.50R15

- Yukon YA WU-07 Small Hub Kit

The Savvy lower control arms had to be adjusted almost all the way in, set to the stock arm length, to work with the small lift. Once this was done, all the parts here played well together, with a couple small exceptions.

The combination of the Alloy USA 5/16 cover and the Currie track bar interfered with each other, when cycling the suspension. This resulted in a hard stop, requiring 2" bumpstop extensions, if left as is. A significant amount of trimming of the Currie track bar gusset, along with minor grinding on the Alloy cover, allowed the suspension to go to full bump, with zero interference. This meant zero (0) bump stop was required. As a note, I had the track bar in and out at least a dozen times while clearancing everything. Only after I was done making sure the Currie track bar would work did I drill the required 5/8" frame side mount hole, and 1/2" axle side mount.

My other top three things I learned:

1. This site continues to be an invaluable resource for those of us that are willing to learn. @Chris does an amazing job of ensuring content is updated and discoverable. Now, whenever I search anything, I preface my google search with "wranglertjforum". This helps ensure I get worthwhile results at the top of my search list first.

2. The experts here are exactly that, experts, and are willing to help. We can help them help us, if we make it simple and clear what we're asking for, with pictures, and are specific with describing where we are in the process. Bottom line, don't assume they can, or want to, read your mind!

3. Cycling the suspension really does show the interference points. In my case I had two areas that required grinding and cutting, along with one stupid positioning I did with the tie rod terminal adjuster bolts. Taking the time to make sure everything works resulted in resolving some issues that could have damaged parts later, and certainly limited useful suspension travel.

All that said, a special thanks to @Chris, @jjvw , and, especially @mrblaine . Their contributions here help all of us put together a better rig, if we're willing to listen and do a little work.

Last edited:

if we're willing to listen and do a little work.

I can’t stress this enough. If people are willing to listen and do a little work and some research, you can build a TJ that will meet your every expectation and more.

There are specific people on this forum who know very well what they are doing and what works well. I highly suggest listening to those people and doing the research before just rushing out to buy parts. There is a recipe for a TJ that works really, really well. I know because I happen to own one of those TJs.

.., do the tires rub the back of the front fenders?

Unlikely to be an issue on anything smaller than a 35"

I'm a little anxious to see what the ride height looks like as well. I have my shock measurements at compressed and extended lengths, but not ride height!Can't wait to see the final height once it's back on the ground. Doesn't matter since I can't get springs for mine, but I can dream

I literally spent 8 - 10 hours on the front end. Installing, cycling, removing, clearancing, and repeating until it was correct. Most wouldn't go through that trouble, which is a real shame. I'm an old guy and not afraid to try different things and learn. In fact, as I repeatedly moved to suspension up and down, I got a new appreciation for how simple and elegant it is. It's not that I haven't done this before, but I've never done it this detailed. Watching the geometry, and relationship, of the parts was interesting to see the motion!I can’t stress this enough. If people are willing to listen and do a little work and some research, you can build a TJ that will meet your every expectation and more.

There are specific people on this forum who know very well what they are doing and what works well. I highly suggest listening to those people and doing the research before just rushing out to buy parts. There is a recipe for a TJ that works really, really well. I know because I happen to own one of those TJs.

Unlikely to be an issue on most rigs even with 35's. I make it a point to cycle every rig on 35's that I do front end work on without the springs in and that is just not a common occurrence.Unlikely to be an issue on anything smaller than a 35"

The time investment is why most don't know what interferes and what doesn't. It takes a good level of commitment to figure it out and not throw in the "good enough" towel. I say this repeatedly, I'm not really that special when it comes to figuring things out, what I am is patient and persistent and I'm not afraid to throw it all away, cut it all back out, and/or just walk away for a bit and come back to something that I'm struggling with. When good enough isn't, that is when someone willing to put in the effort winds up with something very special.I'm a little anxious to see what the ride height looks like as well. I have my shock measurements at compressed and extended lengths, but not ride height!

I literally spent 8 - 10 hours on the front end. Installing, cycling, removing, clearancing, and repeating until it was correct. Most wouldn't go through that trouble, which is a real shame. I'm an old guy and not afraid to try different things and learn. In fact, as I repeatedly moved to suspension up and down, I got a new appreciation for how simple and elegant it is. It's not that I haven't done this before, but I've never done it this detailed. Watching the geometry, and relationship, of the parts was interesting to see the motion!