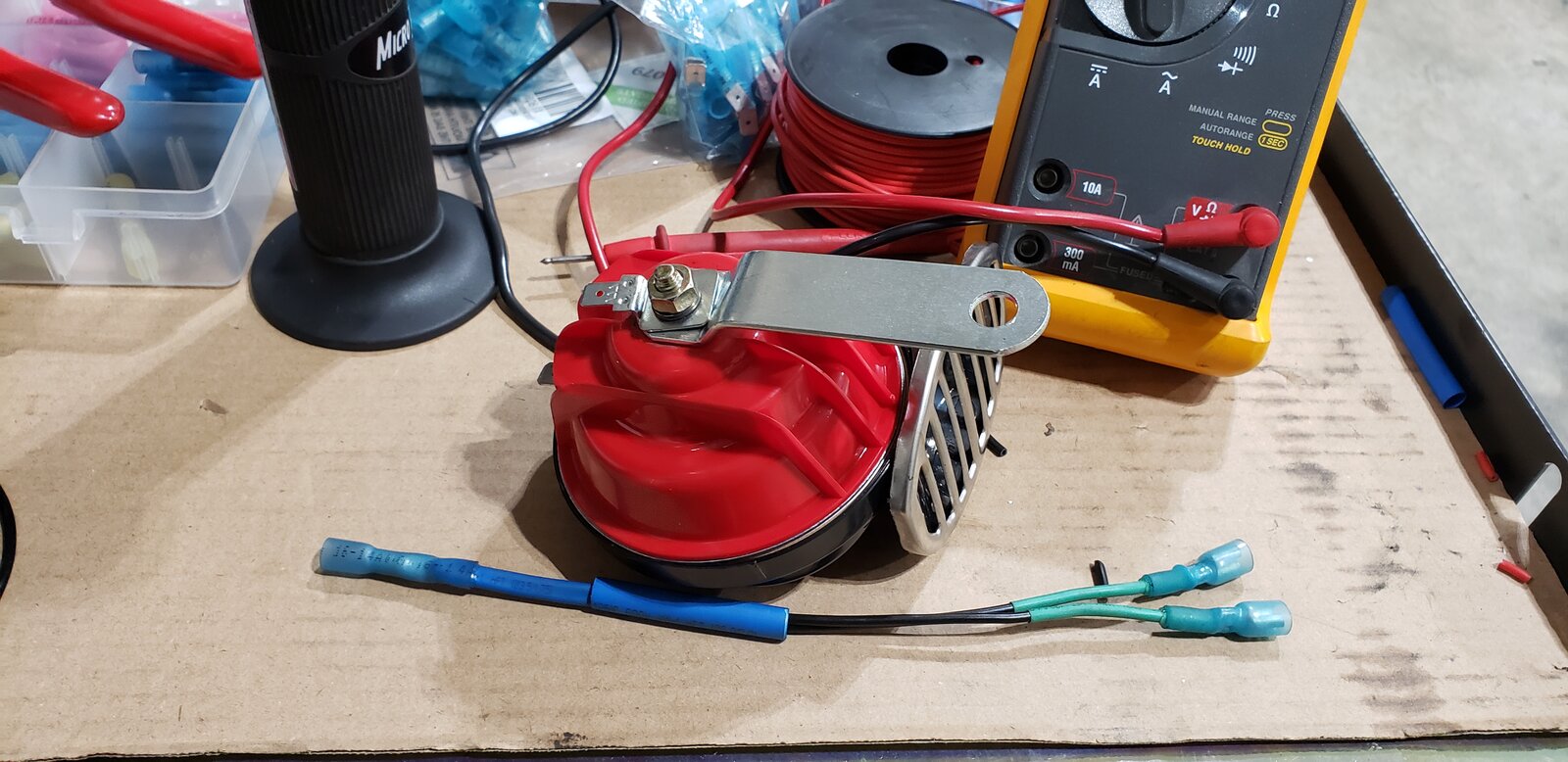

I'm pretty sure these new horns have been with me since the mid 80s. They're made in Italy and are very loud. They make a good replacement for the anemic single horn I had and I didn't have to go buy something else. I thought about throwing these out multiple time, but kept telling myself..."I'll use these one day!".

I also installed a spare fanbelt and idler pulley, which I roll up and attach to the hood support rod.

I also installed a spare fanbelt and idler pulley, which I roll up and attach to the hood support rod.