I feel your pain brother. On the positive side, this is a nudge to get the re-gearing done!Regearing just bumped up in priority. View attachment 313693

The sniff test tells me it's gear oil. If I'm gonna pull the cover, I might as well do the whole thing!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A rebuild of #miRustyJeep...

- Thread starter Mike_H

- Start date

I too am not ready for an outboarding. However, I would love to squeeze out another 1-2" of shock travel out back, without having to install a lower mount that hangs down even more than the stock mount.I'm actually looking at doing something a little different. I was working on my MH last weekend and noticed how they welded on the shock mounts. It looks like something I could duplicate pretty easily on the jeep...

View attachment 314699

Now, I haven't crawled under there to see if I have the room, but something like that, coming off the frame rail in the same general vicinity of the cross member would kinda bridge the gap between a full outboard and the crummy lengths that the factory mounts force on us.

If you do mess with relocating the lower mounts, just pay attention to clearance issues at full stuff. I made a piss poor attempt with some Clayton brackets and assed up some shocks.

Stupid Motorhome is chewing up all my free time. Working on installing a new front end on that old beast and its been fighting me (well, I've been fighting myself). Its coming together, but its been slow and filled with set-backs. I'll post a bigger update on my thread about the motorhome. However...this is keeping me from regearing my jeep now!

old

New

old

New

Boooooo ... I was looking forward to hearing about your  as to how it feels to drive after the gears went in.

as to how it feels to drive after the gears went in.

But you get a pass since that motorhome is way too cool and time spent on it is a good thing

But you get a pass since that motorhome is way too cool and time spent on it is a good thing

Oh man...I have about 8 hours into it today...and if I took a picture when I left...it wouldn't look any different than the one above! Independent front suspension with drive to the wheels is a giant pain in the ass. This has a torsion bar spring too, so everything is fighting for real estate. It goes together one way...and it took me about three tries to get it right!Boooooo ... I was looking forward to hearing about youras to how it feels to drive after the gears went in.

But you get a pass since that motorhome is way too cool and time spent on it is a good thing

But the control arms are torqued now, the brakes lines are new and pad installed, torsion bars are loaded and I'm in good shape to finish tomorrow.

My jeep club is actually doing a ride next weekend, so I may do that instead of gears...If I roach the bearings due to the leak...meh. I have all new stuff going in anyway.

5:13 if you’re NEVER going to 35’s…EVERAbsolutely correct! I’m building for 33s and I still can’t decide between 5.13 and 5.38. I like to gear a step lower than recommended for the manual transmission (around 3k rpm at 75), but I don’t want a ridiculously low first when I’m taking off from lights and such.

My jeep club is actually doing a ride next weekend, so I may do that instead of gears...If I roach the bearings due to the leak...meh. I have all new stuff going in anyway.

I need to find a good club nearby that does more exploring style trips in eastern/southern Oregon Ave SW Washington State. I've been here 10+ years and I've still barely just scratched the surface in terms of seeing places since there is just so much around.

I need to find a good club nearby that does more exploring style trips in eastern/southern Oregon Ave SW Washington State. I've been here 10+ years and I've still barely just scratched the surface in terms of seeing places since there is just so much around.

https://www.pnw4wda.org/clubs-r6.php

Contact a few and see if one fits what you're looking for. Also you can contact the Region director as they might have more information.

Region 6 Director:

Alan Paulson

541-670-1215

https://www.pnw4wda.org/clubs.php

All off-roading isn’t just rock crawling and mud (yuck)., it’s nice to take a leisurely trip on dirt roads on BLM or U S Forest land, even better if its a historical trail. I think joining a club is a great idea.I need to find a good club nearby that does more exploring style trips in eastern/southern Oregon Ave SW Washington State. I've been here 10+ years and I've still barely just scratched the surface in terms of seeing places since there is just so much around.

Yeah, @psrivats this. My friends and I were just talking about this. Just getting out and exploring is fun. We call them Two Tracks in Michigan. They are generally seasonal roads here through the national forests. Probably the same as your fire roads out west. Mostly easy, sandy. You'll get what we call michigan pinstriping (which, reading @Wildman's posts, sounds like a thing in the PNW too). That is branches scratching the paint because the trees have grown in on the trail. Fun to explore them though. Just out in the woods, usually along a creek or river, and you just never know what you'll find. Some of my best wheeling memories are that. You "run whatcha brung" and just get outside.All off-roading isn’t just rock crawling and mud (yuck)., it’s nice to take a leisurely trip on dirt roads on BLM or U S Forest land, even better if its a historical trail. I think joining a club is a great idea.

Yeah, @psrivats this. My friends and I were just talking about this. Just getting out and exploring is fun. We call them Two Tracks in Michigan. They are generally seasonal roads here through the national forests. Probably the same as your fire roads out west. Mostly easy, sandy. You'll get what we call michigan pinstriping (which, reading @Wildman's posts, sounds like a thing in the PNW too). That is branches scratching the paint because the trees have grown in on the trail. Fun to explore them though. Just out in the woods, usually along a creek or river, and you just never know what you'll find. Some of my best wheeling memories are that. You "run whatcha brung" and just get outside.

Yep, we have them here too and I have good memories from couple past trips. Wanting to do more of them this year. Some of the FS roads here get pretty adventurous. I've gotten my old Mazda nearly stuck couple times

Go look in the trail ride section for a event called the Creek & Trail. See if they have any spots still open. It's a great event.Yep, we have them here too and I have good memories from couple past trips. Wanting to do more of them this year. Some of the FS roads here get pretty adventurous. I've gotten my old Mazda nearly stuck couple times

Sorry Mike don't mean to be cloggin up your thread.

This weekend was a bust. I wanted to regear my jeep. Got started on Saturday and had the front axle pulled in an hour, up on my bench in a half hour after that. Got the diff pulled and the housing disassembled Saturday before I had to leave for an event we were going to with another Couple (Watched the Princess Bride with a Live orchestra performing the music...It was amazing).

Today was shit. With the parts shortages everywhere, I ended up buying a Rough Country install kit to go with my Revolution Gears. I should have known better...Anyway, when they got here (bought them in August and I'm finally getting around to installation), I noticed that the bearings were no-name, "made in China" bearings. I didn't want to risk that, so I spent a couple hundred more dollars on Timkens from Rock Auto. Figured I could use the chinese bearings as set-up bearings...Nope. More on that later.

So, Following @hosejockey61's guide to re-gearing a TJ rubicon axle, I got all the old bearings cut off the carrier and pinion (I needed the race for a press tool) and I had a buddy helping me that worked on making the inner Pinion bearing race a slip fit in the housing. He got that fitting nice and we went to set the gears up for the first time and get our first pattern at the factory shim settings...this is where the wheels fell off. The Install kit did NOT come with the shims required to go outside the carrier bearings. Actually, it came with two of them about 0.020 thick, and the rest are designed to go under the carrier bearings. This is a problem, because I was an idiot and didn't check before hand that the kit didn't include the correct shims...and my brand new bearings are pressed on the carrier. Ok...I can use the factory ones for an initial backlash measurement. Lets move on.

The pinion depth of the factory gears was 0.0613," and in my factory set-up the single shim was between the pinion head and the bearing cone race. So, that doesn't work installing the shim behind the cup and its basically useless.

How much shim stock did I get in my install kit? Less than 0.05" of an inch. Grrrr....Ok....I have another install kit. I can make this work with BOTH kits and order more shim stock. At this point, I'm just trying to get an initial reading...

So, we install the correct number of shims and put the pinion in...that's weird...it doesn't fit very well. Yeah, the chinese race I used to make my set-up bearing has a different angle on the taper than the timken does...even though they have the SAME NUMBER.

At this point I was so frustrated I called it a night...and snapped at my wife for which I'm still paying the price.

I do have another 100 dollars worth of shim stock on order now. Couple carrier kits from amazon and some random shims from McMaster for PInion Depth. The pinion preload shims were the ONLY shims that were correct in the kit...and My master install kit? I'll end up using the flange nut, the gear marking compound, the ring gear bolts and about 10% of the shims for my install.

What a waste.

I do have some good news. I got a really good deal on my gears from another member here. They had very little use and since I wanted to do this myself, I figured I would try with used gears...so if I mess them up, I'm not ruining a good set.

They are in VERY good shape, with so little wear you can still see the original machining marks...

So, I'm going to set them up like they are new. They might make some noise, but after I swap my auto transmission in, I suspect I'll be doing this job again, so this is essentially practice now.

Today was shit. With the parts shortages everywhere, I ended up buying a Rough Country install kit to go with my Revolution Gears. I should have known better...Anyway, when they got here (bought them in August and I'm finally getting around to installation), I noticed that the bearings were no-name, "made in China" bearings. I didn't want to risk that, so I spent a couple hundred more dollars on Timkens from Rock Auto. Figured I could use the chinese bearings as set-up bearings...Nope. More on that later.

So, Following @hosejockey61's guide to re-gearing a TJ rubicon axle, I got all the old bearings cut off the carrier and pinion (I needed the race for a press tool) and I had a buddy helping me that worked on making the inner Pinion bearing race a slip fit in the housing. He got that fitting nice and we went to set the gears up for the first time and get our first pattern at the factory shim settings...this is where the wheels fell off. The Install kit did NOT come with the shims required to go outside the carrier bearings. Actually, it came with two of them about 0.020 thick, and the rest are designed to go under the carrier bearings. This is a problem, because I was an idiot and didn't check before hand that the kit didn't include the correct shims...and my brand new bearings are pressed on the carrier. Ok...I can use the factory ones for an initial backlash measurement. Lets move on.

The pinion depth of the factory gears was 0.0613," and in my factory set-up the single shim was between the pinion head and the bearing cone race. So, that doesn't work installing the shim behind the cup and its basically useless.

How much shim stock did I get in my install kit? Less than 0.05" of an inch. Grrrr....Ok....I have another install kit. I can make this work with BOTH kits and order more shim stock. At this point, I'm just trying to get an initial reading...

So, we install the correct number of shims and put the pinion in...that's weird...it doesn't fit very well. Yeah, the chinese race I used to make my set-up bearing has a different angle on the taper than the timken does...even though they have the SAME NUMBER.

At this point I was so frustrated I called it a night...and snapped at my wife for which I'm still paying the price.

I do have another 100 dollars worth of shim stock on order now. Couple carrier kits from amazon and some random shims from McMaster for PInion Depth. The pinion preload shims were the ONLY shims that were correct in the kit...and My master install kit? I'll end up using the flange nut, the gear marking compound, the ring gear bolts and about 10% of the shims for my install.

What a waste.

I do have some good news. I got a really good deal on my gears from another member here. They had very little use and since I wanted to do this myself, I figured I would try with used gears...so if I mess them up, I'm not ruining a good set.

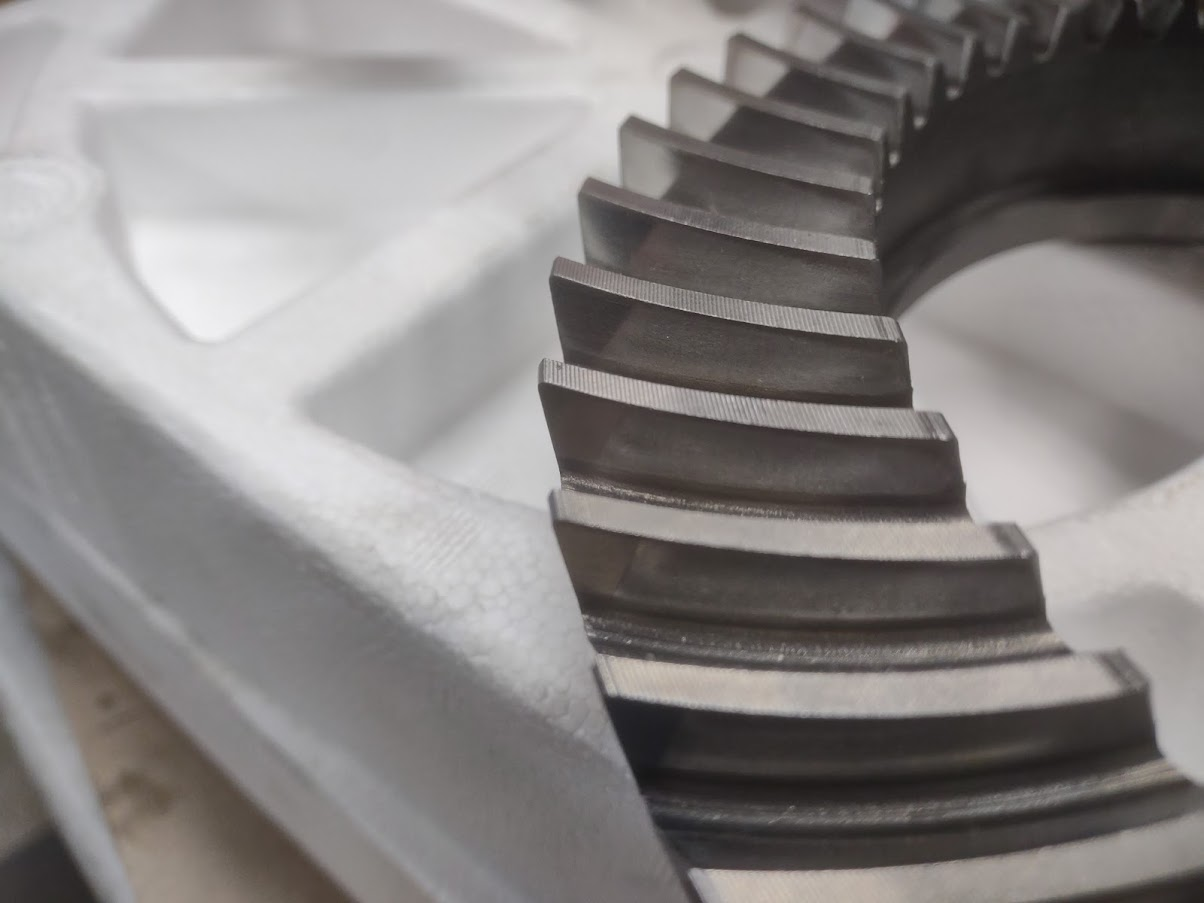

They are in VERY good shape, with so little wear you can still see the original machining marks...

So, I'm going to set them up like they are new. They might make some noise, but after I swap my auto transmission in, I suspect I'll be doing this job again, so this is essentially practice now.

Last edited:

Why are you gearing now if you plan to regear after the swap? Just for learning sake?This weekend was a bust. I wanted to regear my jeep. Got started on Saturday and had the front axle pulled in an hour, up on my bench in a half hour after that. Got the diff pulled and the housing disassembled Saturday before I had to leave for an event we were going to with another Couple (Watched the Princess Bride with a Live orchestra performing the music...It was amazing).

View attachment 317152

Today was shit. With the parts shortages everywhere, I ended up buying a Rough Country install kit to go with my Revolution Gears. I should have known better...Anyway, when they got here (bought them in August and I'm finally getting around to installation), I noticed that the bearings were no-name, "made in China" bearings. I didn't want to risk that, so I spent a couple hundred more dollars on Timkens from Rock Auto. Figured I could use the chinese bearings as set-up bearings...Nope. More on that later.

So, Following @hosejockey61's guide to re-gearing a TJ rubicon axle, I got all the old bearings cut off the carrier and pinion (I needed the race for a press tool) and I had a buddy helping me that worked on making the inner Pinion bearing race a slip fit in the housing. He got that fitting nice and we went to set the gears up for the first time and get our first pattern at the factory shim settings...this is where the wheels fell off. The Install kit did NOT come with the shims required to go outside the carrier bearings. Actually, it came with two of them about 0.020 thick, and the rest are designed to go under the carrier bearings. This is a problem, because I was an idiot and didn't check before hand that the kit didn't include the correct shims...and my brand new bearings are pressed on the carrier. Ok...I can use the factory ones for an initial backlash measurement. Lets move on.

The pinion depth of the factory gears was 0.0613," and in my factory set-up the single shim was between the pinion head and the bearing cone race. So, that doesn't work installing the shim behind the cup and its basically useless.

View attachment 317155

How much shim stock did I get in my install kit? Less than 0.05" of an inch. Grrrr....Ok....I have another install kit. I can make this work with BOTH kits and order more shim stock. At this point, I'm just trying to get an initial reading...

So, we install the correct number of shims and put the pinion in...that's weird...it doesn't fit very well. Yeah, the chinese race I used to make my set-up bearing has a different angle on the taper than the timken does...even though they have the SAME NUMBER.

At this point I was so frustrated I called it a night...and snapped at my wife for which I'm still paying the price.

I do have another 100 dollars worth of shim stock on order now. Couple carrier kits from amazon and some random shims from McMaster for PInion Depth. The pinion preload shims were the ONLY shims that were correct in the kit...and My master install kit? I'll end up using the flange nut, the gear marking compound, the ring gear bolts and about 10% of the shims for my install.

What a waste.

I do have some good news. I got a really good deal on my gears from another member here. They had very little use and since I wanted to do this myself, I figured I would try with used gears...so if I mess them up, I'm not ruining a good set.

They are in VERY good shape, with so little wear you can still see the original machining marks...

View attachment 317156

View attachment 317157

So, I'm going to set them up like they are new. They might make some noise, but after I swap my auto transmission in, I suspect I'll be doing this job again, so this is essentially practice now.

WOW......that totally sucks. Sorry to hear what you are going through.

Setting up used gears can be a pain in the ass. It's best to run a pattern before removing them and then try to match that pattern during setup. Just like my signature line reads, experience is what you get just after you needed it! But hey, at least you're getting after it.

Setting up used gears can be a pain in the ass. It's best to run a pattern before removing them and then try to match that pattern during setup. Just like my signature line reads, experience is what you get just after you needed it! But hey, at least you're getting after it.

Yeah,. Experience is the teacher that gives the test before the lesson.WOW......that totally sucks. Sorry to hear what you are going through.

Setting up used gears can be a pain in the ass. It's best to run a pattern before removing them and then try to match that pattern during setup. Just like my signature line reads, experience is what you get just after you needed it! But hey, at least you're getting after it.

Yeah, and I'm hopeful (but hope isn't a plan) that 4.88s will work with Michigan flatland. I also got all the stuff before I got the transmission, so I figured I'd just get a set under my belt.Why are you gearing now if you plan to regear after the swap? Just for learning sake?

Little bit cooler temperament tonight. I went out to the shop without any real plan, just figured I shuffle stuff around a clean up a little. I ended up pulling the axle seals out of my front axle. Everyone said they were a bad idea...and they are. I found so much rust and crap in my axle tubes...I may as well not have been running them. I actually think it will be cleaner without them, because the stuff can flush through.

For those running upgraded axles...I have some Motive Chromoly ones to install. I picked em up used (I should probably name my jeep "Spare Parts") and noticed that there isn't a lump for the oil slingers to fit on. Does anyone else run the slingers on aftermarket axles, or just risk it as a low risk, low occurrence failure mode (of the gear oil running down the axle and flinging onto the brakes). If you do run them, how do you get them to stay put?

Since I have more parts on order and I was working on the axle tubes, I decided to pop the seal out (that are relatively new) and scrape the tubes clean. Then I used some eastwood internal frame coating to douche the insides of the tubes.

Finally, I finished grinding my new set-up bearing in, so hopefully when my new shims show up, I'll be able to start getting these new gears set-up.

While the axle is on the bench, I've also thought about welding some reinforcement to the pass side UCA mount. Anyone think I can get away with that and not melt the bushing? Just thinking a little piece of metal between the two halves of the mount. I think @mrblaine has a trick or two there. I'll see if I can find some pictures. I guess if I DO melt the bushing...it's as good a time as any to install a johnny joint...LOL

For those running upgraded axles...I have some Motive Chromoly ones to install. I picked em up used (I should probably name my jeep "Spare Parts") and noticed that there isn't a lump for the oil slingers to fit on. Does anyone else run the slingers on aftermarket axles, or just risk it as a low risk, low occurrence failure mode (of the gear oil running down the axle and flinging onto the brakes). If you do run them, how do you get them to stay put?

Since I have more parts on order and I was working on the axle tubes, I decided to pop the seal out (that are relatively new) and scrape the tubes clean. Then I used some eastwood internal frame coating to douche the insides of the tubes.

Finally, I finished grinding my new set-up bearing in, so hopefully when my new shims show up, I'll be able to start getting these new gears set-up.

While the axle is on the bench, I've also thought about welding some reinforcement to the pass side UCA mount. Anyone think I can get away with that and not melt the bushing? Just thinking a little piece of metal between the two halves of the mount. I think @mrblaine has a trick or two there. I'll see if I can find some pictures. I guess if I DO melt the bushing...it's as good a time as any to install a johnny joint...LOL

I take a piece of exhaust tubing that fits snugly on the small side of the bushing, expand it to fit tightly as in press fit to the large part of the bushing, carefully cut that to length to fit between the two sides and then weld that in keeping an eye on the width between the two sides. That restores the press fit for a Clevite bushing which I always prefer over any other joint there.Little bit cooler temperament tonight. I went out to the shop without any real plan, just figured I shuffle stuff around a clean up a little. I ended up pulling the axle seals out of my front axle. Everyone said they were a bad idea...and they are. I found so much rust and crap in my axle tubes...I may as well not have been running them. I actually think it will be cleaner without them, because the stuff can flush through.

For those running upgraded axles...I have some Motive Chromoly ones to install. I picked em up used (I should probably name my jeep "Spare Parts") and noticed that there isn't a lump for the oil slingers to fit on. Does anyone else run the slingers on aftermarket axles, or just risk it as a low risk, low occurrence failure mode (of the gear oil running down the axle and flinging onto the brakes). If you do run them, how do you get them to stay put?

Since I have more parts on order and I was working on the axle tubes, I decided to pop the seal out (that are relatively new) and scrape the tubes clean. Then I used some eastwood internal frame coating to douche the insides of the tubes.

Finally, I finished grinding my new set-up bearing in, so hopefully when my new shims show up, I'll be able to start getting these new gears set-up.

While the axle is on the bench, I've also thought about welding some reinforcement to the pass side UCA mount. Anyone think I can get away with that and not melt the bushing? Just thinking a little piece of metal between the two halves of the mount. I think @mrblaine has a trick or two there. I'll see if I can find some pictures. I guess if I DO melt the bushing...it's as good a time as any to install a johnny joint...LOL

Clevite over the drivers side Johnny Joint? I was looking at this guy...I take a piece of exhaust tubing that fits snugly on the small side of the bushing, expand it to fit tightly as in press fit to the large part of the bushing, carefully cut that to length to fit between the two sides and then weld that in keeping an eye on the width between the two sides. That restores the press fit for a Clevite bushing which I always prefer over any other joint there.

From barnes as a way to reinforce the bracket. I currently don't have a problem so I probably shouldn't fuck with it, but idle hands and all that...I also don't have a way to expand exhaust tubing.