Waiting for my welder co-worker to get out to my place to weld the mounts in I did some more positioning and made sure I liked where everything was going. So to start off I moved it up one notch and I am happy with clearence now.

With it now clearing better I worked on the transmission mount. I got the Novak universal mount and it addmittedly confused me with a few things. One being when the bushings are installed in the plate, there is a gap between the shoulder and plate. I am not sure if I was looking at it right but I just got some washers for 1” bolts from the hardware store to fill the gap as well as longer bolts. One thing I noticed is center of frame channels is different from center of original trans mounting holes. I went off center of the mounting holes.

With that said, with a cam sticking out to the grill it looks like either the engine is offset or not parallel to vehicle but I think that will not be an issue. I called Novak and they agreed.

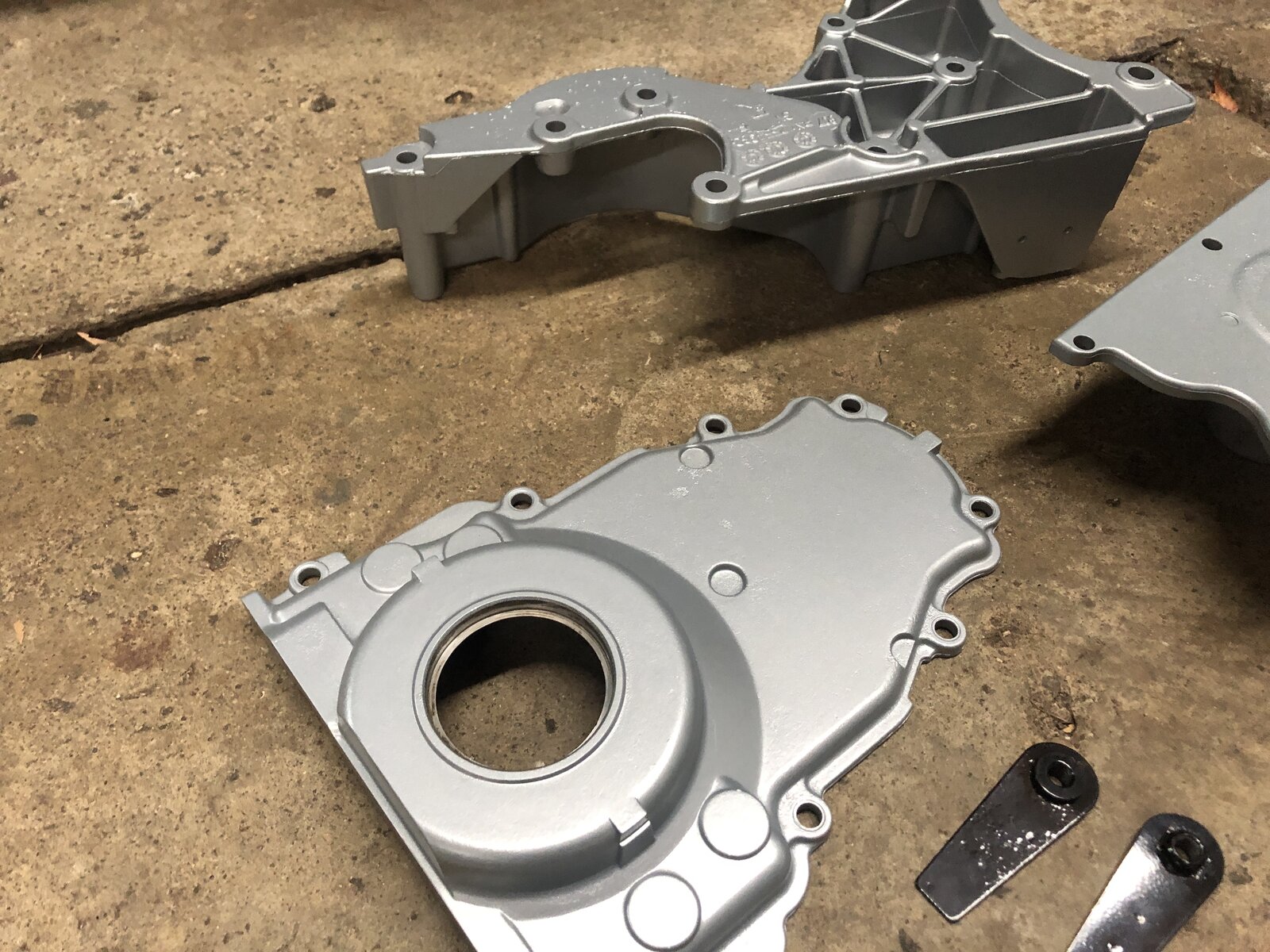

The engine is now completely in place, minus the fully welded mounts. I can only do so much until the horns are welded on, so I did what I could. This week I worked on prepping and powdercoated a bunch of parts, and painted what would not handle the oven. The various brackets and hardware were gloss black, LS covers and accessory bracket were platinum silver and the valve covers satin textured black. I do enjoy powdercoating as a hobby, I just need to get an area better to do powdercoating for easier setup

Now that thoes parts are ready I put togather more of the engine and like where everything sat.

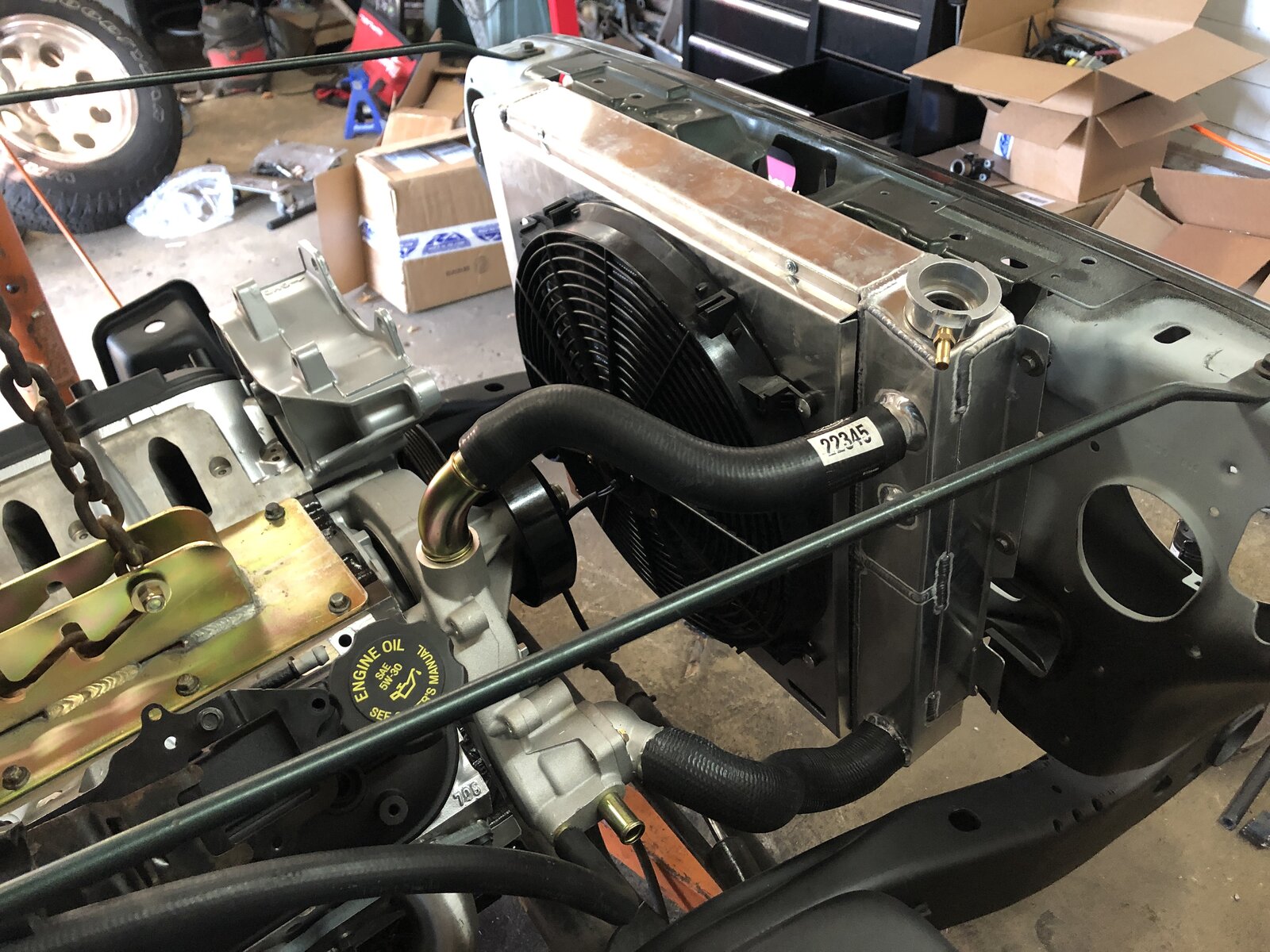

After I got all that done, I worked on cooling hoses. Took some trial and error but through research of what others have posted and other reccomendations I found the winning combo.

For the upper hose I used Gates 22345 which is the lower hose from a Pontiac Sunfire and other models. Only needed to be trimmed one side of it. Looking at it you could probably trim the other side instead at the same spot before the outer bend and it would fit the same.

For the lower hose it took a lot more trimming on both ends. This is a Gates 21615 and is the lower hose for XJs and MJs. Wish I had better pictures where I trimmed but only the middle section wad really used.

Heater core hoses were simple, one is from an 80s Toyota pickup, Gates 28471. The other is a universal hose, 28480 but is the same thing, just bigger ID. Dont have the 28480 yet but is essentially the same process. I cut about 1” from the short leg and routed it to the heater core and trimmed where needed on the long leg. I found a bracket with a clip meant for 2 hoses and I homestly have no idea where it came from. It might have been part of this motor but I bolted it to the valve cover and used that to get the hoses away from the fenders and headers. I will of course be sandblasting and powdercoating the bracket.

With it now clearing better I worked on the transmission mount. I got the Novak universal mount and it addmittedly confused me with a few things. One being when the bushings are installed in the plate, there is a gap between the shoulder and plate. I am not sure if I was looking at it right but I just got some washers for 1” bolts from the hardware store to fill the gap as well as longer bolts. One thing I noticed is center of frame channels is different from center of original trans mounting holes. I went off center of the mounting holes.

With that said, with a cam sticking out to the grill it looks like either the engine is offset or not parallel to vehicle but I think that will not be an issue. I called Novak and they agreed.

The engine is now completely in place, minus the fully welded mounts. I can only do so much until the horns are welded on, so I did what I could. This week I worked on prepping and powdercoated a bunch of parts, and painted what would not handle the oven. The various brackets and hardware were gloss black, LS covers and accessory bracket were platinum silver and the valve covers satin textured black. I do enjoy powdercoating as a hobby, I just need to get an area better to do powdercoating for easier setup

Now that thoes parts are ready I put togather more of the engine and like where everything sat.

After I got all that done, I worked on cooling hoses. Took some trial and error but through research of what others have posted and other reccomendations I found the winning combo.

For the upper hose I used Gates 22345 which is the lower hose from a Pontiac Sunfire and other models. Only needed to be trimmed one side of it. Looking at it you could probably trim the other side instead at the same spot before the outer bend and it would fit the same.

For the lower hose it took a lot more trimming on both ends. This is a Gates 21615 and is the lower hose for XJs and MJs. Wish I had better pictures where I trimmed but only the middle section wad really used.

Heater core hoses were simple, one is from an 80s Toyota pickup, Gates 28471. The other is a universal hose, 28480 but is the same thing, just bigger ID. Dont have the 28480 yet but is essentially the same process. I cut about 1” from the short leg and routed it to the heater core and trimmed where needed on the long leg. I found a bracket with a clip meant for 2 hoses and I homestly have no idea where it came from. It might have been part of this motor but I bolted it to the valve cover and used that to get the hoses away from the fenders and headers. I will of course be sandblasting and powdercoating the bracket.

Last edited: