They are pretty firm, not much compression. The rock krawler pucks have a little lip the compresses some. I might just leave it here.How squishy are the hockey pucks? If they squish at all then you may want to leave the 1/2” of shock shaft showing. I’ve just honestly never played with a hockey puck lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PRNDL's Green One

- Thread starter PRNDL

- Start date

Just have to imagine what it will be like in a hard hit. With the front, typically the bump stop extension will not limit articulation. Articulate the axle and see if the shock or bump stop hits. I bet shock will still be the limit which is goodThey are pretty firm, not much compression. The rock krawler pucks have a little lip the compresses some. I might just leave it here.

Even though the jounce bumpers will mostly compress in the cup, they still will give you 1/2" or so of cushion.

Had the Jeep out at BMRA yesterday and brought my son. He had a blast. Next time we'll camp and make a weekend out of it. The Jeep did great. The addition of the hand throttle this time out made all the difference.

Suspension travel looks good here. The driver is full drop limited by the shock. The tire is almost hanging, but just touching the ground. Spring is just about to unseat and the brake line has slack. Passenger side, there's still 1.5" of shock showing and no tire clearance concerns.

Suspension travel looks good here. The driver is full drop limited by the shock. The tire is almost hanging, but just touching the ground. Spring is just about to unseat and the brake line has slack. Passenger side, there's still 1.5" of shock showing and no tire clearance concerns.

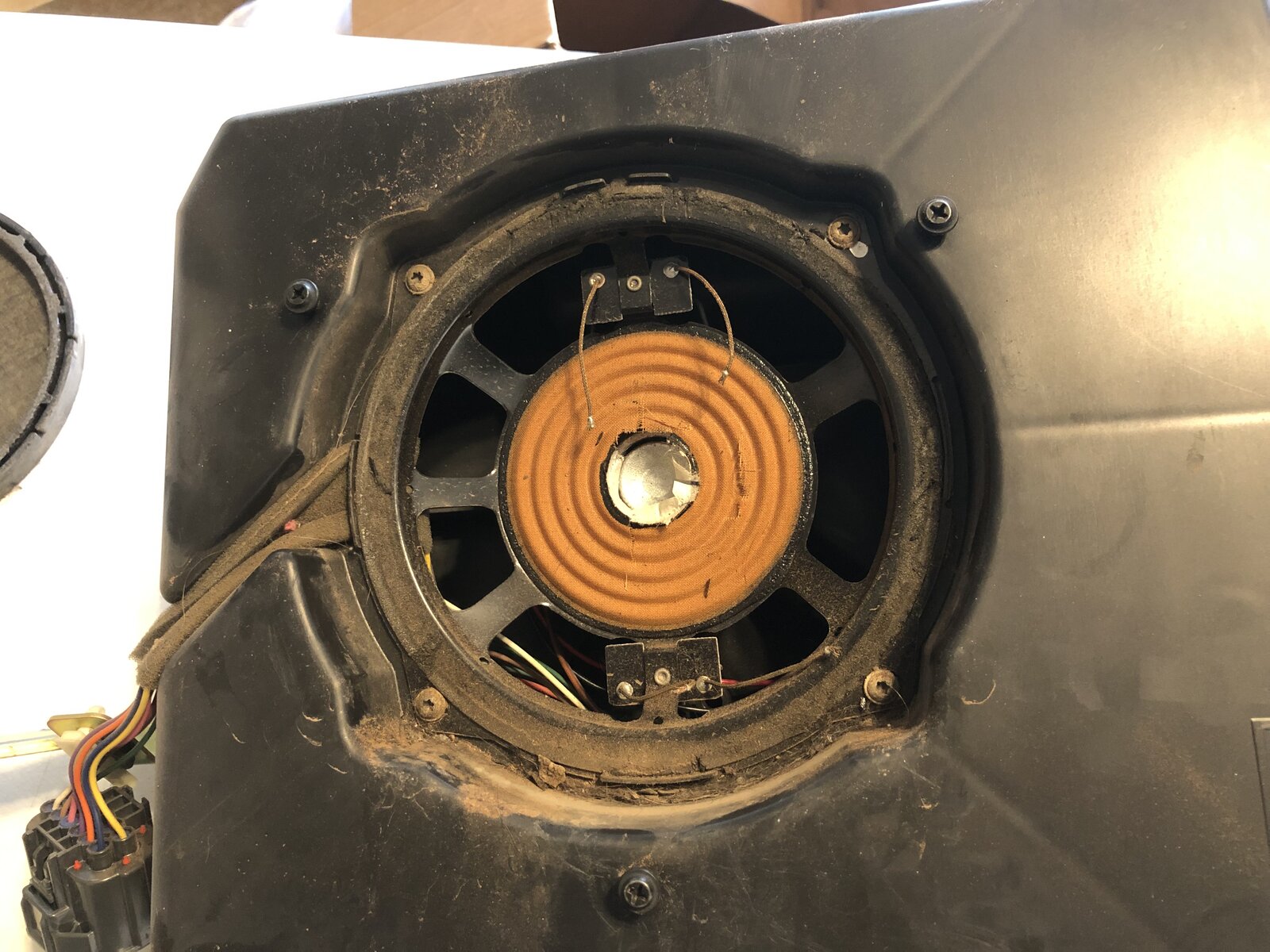

The factory sub is working after messing with the wiring and head unit... I think it was just not connected well under the console. Its blown to pieces, so I ordered the $25 Goldwood. The ohms aren't exactly right, but I'm not sure how much I'll notice or care. I'll eventually move to a powered 8" in the console cavity.

Let us know how it turns out running off of the factory amp. Years ago I did the kicker sub replacement off of the factory amp and the amp always went into protection mode. So I had to opt for the external amp.

I replaced mine with the factory Quadratec one because I don’t want extra wires and amps. It’s actually extremely bassy at high volumes. I’m more concerned about longevity, but it seems sturdy.

I think mine has yours beat

I replaced mine with the factory Quadratec one because I don’t want extra wires and amps. It’s actually extremely bassy at high volumes. I’m more concerned about longevity, but it seems sturdy.

I think mine has yours beat

Swapped the sub over the weekend. I ran a couple of errands around town and its (obviously) a massive improvement. It's not cutting out, but I've only had it running for 10-15 minutes at a time. I'll keep an eye on it. My expectations were and are low for a $25 sub, but it sounds fine and the bass is at least present now. Still need to tweak the EQ and settings a bit more.Let us know how it turns out running off of the factory amp. Years ago I did the kicker sub replacement off of the factory amp and the amp always went into protection mode. So I had to opt for the external amp.

I replaced mine with the factory Quadratec one because I don’t want extra wires and amps. It’s actually extremely bassy at high volumes. I’m more concerned about longevity, but it seems sturdy.

I think mine has yours beat

View attachment 320534

Now that the sub works and I can actually turn up the volume a bit with out the dramatic clipping from the sub, the front speakers (probably the rears too) are distorting at what I subjectively do not consider to be a high volume. My fronts are Polk DB522s and the rears are still factory. I might be able to compensate for this a bit in the head unit settings, but its probably just the factory amp showing its colors. Now I'm thinking a 5 channel amp might be in my future. I'm not a huge fan of the Pioneer head the PO installed either. We shall see where I land.

6.5" - same (or close enough) to the factory size.Question: What size is the sub-woofer?

Thanks.

Great. Thanks.6.5" - same (or close enough) to the factory size.

Nothing new to report, summer has been busy with kids sports. I've been driving the heck out of this Jeep and loving it.

I will say I'm hearing chirp from the u-joints at low speeds making turns leaving the neighborhood. Probably needs to jump up the list to replace sooner than later.

Other items on the list for the fall when it cools down:

Other items on the list for the fall when it cools down:

- Front axle u-joints (sooner than later)

- RMS

- Oil pan and gasket

- Clutch replacement

- replace skid nutserts

- oil change

- tire rotation

I've started my shopping list for the axle u-joints.

While I'm in there, my plan is to replace the rusted out brake shields. Pads and rotors look fine and have plenty of life left. I'll save that for another day.

What other items should I be considering? I thought about bearings/hubs and ball joints since I'm sure they are originals and the Jeep is at 135k miles. I'll check the ball joints and hubs for play before ordering.

Would there be any reason to proactively order replacement hub bolts?

The spindle nut kits might be unnecessary, but they are cheap enough to be a "might as well..." item.

As far as tools are concerned:

I'll probably order everything and plan to tackle it sometime next month.

While I'm in there, my plan is to replace the rusted out brake shields. Pads and rotors look fine and have plenty of life left. I'll save that for another day.

What other items should I be considering? I thought about bearings/hubs and ball joints since I'm sure they are originals and the Jeep is at 135k miles. I'll check the ball joints and hubs for play before ordering.

Would there be any reason to proactively order replacement hub bolts?

| part | qty | $ | Amazon |

|---|---|---|---|

| 5-760x ujoint | 2 | $23/ea | https://www.amazon.com/gp/product/B009X1XDZG/?tag=wranglerorg-20 |

| Brake shield L | 1 | $20 | https://www.amazon.com/gp/product/B074MMV85G/?tag=wranglerorg-20 |

| Brake shield R | 1 | $20 | https://www.amazon.com/gp/product/B074MM8HTR/?tag=wranglerorg-20 |

| Spindle nut kit | 2 | $9/ea | https://www.amazon.com/gp/product/B000CO8ZQU/?tag=wranglerorg-20 |

| Timken HA597449 Hub | 2 | $70/ea | https://www.amazon.com/gp/product/B000BZAF36/?tag=wranglerorg-20 |

| Spicer 706944X ball joint kit | 2 | $66/ea | https://www.amazon.com/gp/product/B007N6OHI0/?tag=wranglerorg-20 |

The spindle nut kits might be unnecessary, but they are cheap enough to be a "might as well..." item.

As far as tools are concerned:

- 36mm deep impact socket for the spindle nut

- 13mm 12pt socket for the hub bolts

- Impact wrench

- 50-250ft/lb torque wrench

- ball joint press

I'll probably order everything and plan to tackle it sometime next month.

I completed the u-joint replacement with help from this thread. I have no reason to believe they weren't the factory originals and took quite a bit of encouragement with a 3 lb mini-sledge.

Old joints:

Lots of corrosion on the passenger, long side shaft. Not all that concerned about it. New shafts are on the list, but these will be fine for now and eventually as spares.

Old joints:

Lots of corrosion on the passenger, long side shaft. Not all that concerned about it. New shafts are on the list, but these will be fine for now and eventually as spares.

As part of the axle u-joint project, I replaced the hub assemblies with Timken HA597449. I took @Irun's advice to order new spicer hub bolts as well. I also replaced the brake dust shields and used new spindle nut kits.

Removing the caliper and rotor revealed the hub.

The brake shields were in bad shape. The passenger side more so than the driver.

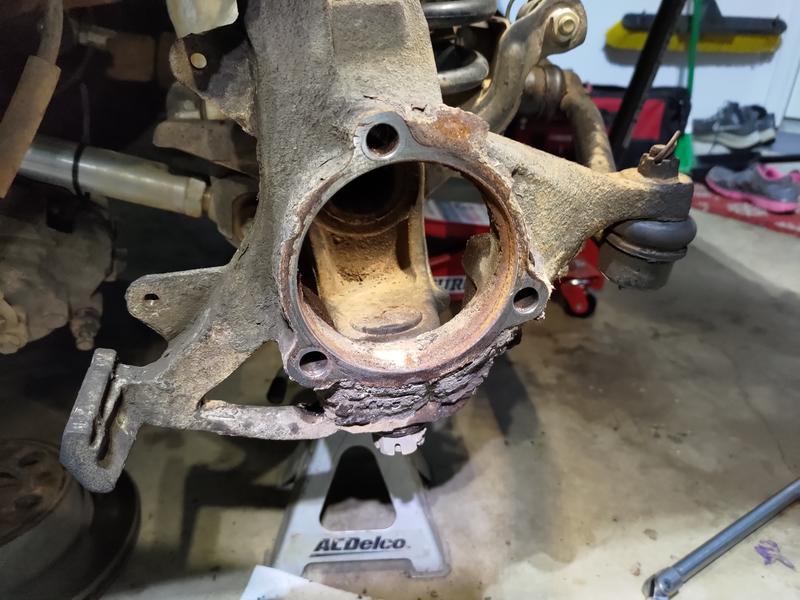

I had soaked the hub bolts for a few days prior and they were removed with out much fuss. The knuckle was gross. Lots of built up gunk and some rust.

I cleaned them up with several different wire brushes and primed/painted the knuckles. They cleaned up ok, not the best job, but good enough. The knuckles themselves are fine, but you can see some areas where rust has pitted them. Eventually they will be replaced, maybe with a big brake kit? The brake pad races were the area that concerned me the most and even those looked fine.

Once painted, the reassembly, including the recently rebuilt shafts, was a breeze with the new hardware.

Nothing fell off during the test drive. The u-joint chirp was gone and there weren't any new noises either. Mark another project off the list.

Removing the caliper and rotor revealed the hub.

The brake shields were in bad shape. The passenger side more so than the driver.

I had soaked the hub bolts for a few days prior and they were removed with out much fuss. The knuckle was gross. Lots of built up gunk and some rust.

I cleaned them up with several different wire brushes and primed/painted the knuckles. They cleaned up ok, not the best job, but good enough. The knuckles themselves are fine, but you can see some areas where rust has pitted them. Eventually they will be replaced, maybe with a big brake kit? The brake pad races were the area that concerned me the most and even those looked fine.

Once painted, the reassembly, including the recently rebuilt shafts, was a breeze with the new hardware.

Nothing fell off during the test drive. The u-joint chirp was gone and there weren't any new noises either. Mark another project off the list.

This site contains affiliate links for which Jeep Wrangler TJ Forum may be compensated.

Nice work, Prindle. Some good lookin' knuckles ya gots there...

Last edited:

Reading the horror stories on the forum about the front CV centering ball seizing up and 'sploding transfer cases, I convinced myself I was hearing "angry birds" chirping. Maybe I imagined them, but better safe than sorry. I ordered Denny's TJ Rubicon Non-Greaseable Rebuild Kit for the CV joint, Spicer 5-793X Non-Greaseable u-joint at the axle yoke and a new

Spicer 2-70-18X Strap and Bolt Set. I didn't order Denny's $30 boot installation tool and (spoiler) I didn't miss it.

Once more proving this forum's worth, I learned that the factory Rubicon driveshaft used a nylon injection to hold the axle end u-joint in place. That was a fun first step. Applying heat to the yoke ear causes the nylon to soften and squirt out.

More heat and a small screw driver were needed to clear the rest of the nylon once the joint cap was removed.

The new joint installs with inner c-clips.

Moving to the CV end, the old centering ball didn't look too bad from a lubrication standpoint, but there was a loose seal in the stud end. The boot was in good shape.

Comparing the new and old centering ball, you can see where the seal should be.

The new boot went on easily with a small screwdriver and a ball peen.

Once that was on, it was a simple job to reinstall the u-joints.

Fairly easy job. Driveshaft reinstall is always fun, especially when you refuse to drop the skid. The test drive was smooth, quiet and uneventful. Nothing went all 'splody.

Spicer 2-70-18X Strap and Bolt Set. I didn't order Denny's $30 boot installation tool and (spoiler) I didn't miss it.

Once more proving this forum's worth, I learned that the factory Rubicon driveshaft used a nylon injection to hold the axle end u-joint in place. That was a fun first step. Applying heat to the yoke ear causes the nylon to soften and squirt out.

More heat and a small screw driver were needed to clear the rest of the nylon once the joint cap was removed.

The new joint installs with inner c-clips.

Moving to the CV end, the old centering ball didn't look too bad from a lubrication standpoint, but there was a loose seal in the stud end. The boot was in good shape.

Comparing the new and old centering ball, you can see where the seal should be.

The new boot went on easily with a small screwdriver and a ball peen.

Once that was on, it was a simple job to reinstall the u-joints.

Fairly easy job. Driveshaft reinstall is always fun, especially when you refuse to drop the skid. The test drive was smooth, quiet and uneventful. Nothing went all 'splody.

I've spent far more time with the front end than the rear at this point. The rear axle has been very slightly off center since I installed the lift but hasn't given me any issues so I ignored it. I have noticed recently that giving it power while making a turn, the back end feels loose or at the very least just not planted like it should. I decided to tear into it to see what i could see. It appears that in my negligence, things have been self-clearancing.

I think I may have found where that squeak was coming from...

Trackbar is also making contact with the exhaust at full droop. I still have not corrected/lowered the exhaust hanger at the transmission mount after the tuck. This would probably allow the trackbar to clear, but might lower the exhaust into contact with the shock.

The shocks have a few new dents. driver side was hitting the (top to bottom) spring, spring perch and brake line(?). The spring just needed to be rotated away from the shock body and the perch was easily trimmed, but the brake line? That's a new one.

Passenger side shock still contacts the perch in two places at full droop.

I think I may have found where that squeak was coming from...

Trackbar is also making contact with the exhaust at full droop. I still have not corrected/lowered the exhaust hanger at the transmission mount after the tuck. This would probably allow the trackbar to clear, but might lower the exhaust into contact with the shock.

The shocks have a few new dents. driver side was hitting the (top to bottom) spring, spring perch and brake line(?). The spring just needed to be rotated away from the shock body and the perch was easily trimmed, but the brake line? That's a new one.

Passenger side shock still contacts the perch in two places at full droop.

I've spent far more time with the front end than the rear at this point. The rear axle has been very slightly off center since I installed the lift but hasn't given me any issues so I ignored it. I have noticed recently that giving it power while making a turn, the back end feels loose or at the very least just not planted like it should. I decided to tear into it to see what i could see. It appears that in my negligence, things have been self-clearancing.

I think I may have found where that squeak was coming from...

View attachment 362417

View attachment 362418

Trackbar is also making contact with the exhaust at full droop. I still have not corrected/lowered the exhaust hanger at the transmission mount after the tuck. This would probably allow the trackbar to clear, but might lower the exhaust into contact with the shock.

View attachment 362419

The shocks have a few new dents. driver side was hitting the (top to bottom) spring, spring perch and brake line(?). The spring just needed to be rotated away from the shock body and the perch was easily trimmed, but the brake line? That's a new one.

View attachment 362420

Passenger side shock still contacts the perch in two places at full droop.

View attachment 362421

View attachment 362422

How much uptravel do you have in the rear versus downtravel? I’d throw some rockjock shock relocation brackets on there and call it good.