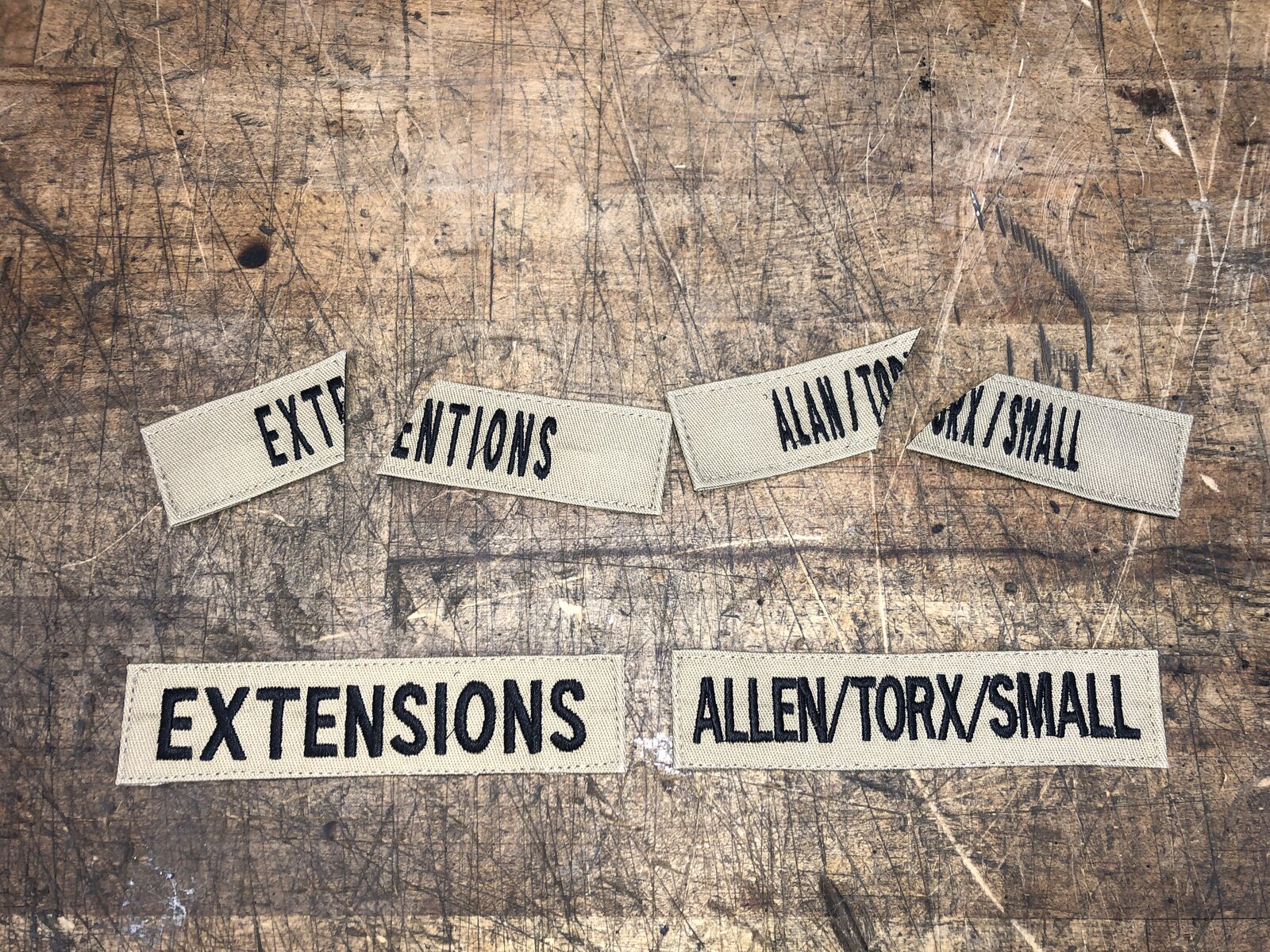

I did receive replacements for my unforunate spelling issues...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nashville TJ's Build - Continued

- Thread starter NashvilleTJ

- Start date

Definitely unforunate

You cut up the wrong ones!!!

I also posted this over on the Two Wheels thread, but wanted to post it here as well.

Today I am heading out to Colorado to run the Colorado Back Country Discovery Route. I’m running it with my usual group of nine adventure buddies. We are planning on ten days on the trail, including running the Alpine Loop.

First big trip on my new T7 - here it is all kitted up for the trip.

If anyone is interested, I always post to instagram about these trips. My handle over there is jeff_doster if you would like to follow along.

Today is all about the drive from Nashville to Denver, so we are doing a lot of staring at the back of the trailer holding our bikes.

Today I am heading out to Colorado to run the Colorado Back Country Discovery Route. I’m running it with my usual group of nine adventure buddies. We are planning on ten days on the trail, including running the Alpine Loop.

First big trip on my new T7 - here it is all kitted up for the trip.

If anyone is interested, I always post to instagram about these trips. My handle over there is jeff_doster if you would like to follow along.

Today is all about the drive from Nashville to Denver, so we are doing a lot of staring at the back of the trailer holding our bikes.

I also posted this over on the Two Wheels thread, but wanted to post it here as well.

Today I am heading out to Colorado to run the Colorado Back Country Discovery Route. I’m running it with my usual group of nine adventure buddies. We are planning on ten days on the trail, including running the Alpine Loop.

First big trip on my new T7 - here it is all kitted up for the trip.

View attachment 344542

If anyone is interested, I always post to instagram about these trips. My handle over there is jeff_doster if you would like to follow along.

Today is all about the drive from Nashville to Denver, so we are doing a lot of staring at the back of the trailer holding our bikes.

View attachment 344546

When I grow up and semi-retire, I wanna be like you!

I also posted this over on the Two Wheels thread, but wanted to post it here as well.

Today I am heading out to Colorado to run the Colorado Back Country Discovery Route. I’m running it with my usual group of nine adventure buddies. We are planning on ten days on the trail, including running the Alpine Loop.

First big trip on my new T7 - here it is all kitted up for the trip.

View attachment 344542

If anyone is interested, I always post to instagram about these trips. My handle over there is jeff_doster if you would like to follow along.

Today is all about the drive from Nashville to Denver, so we are doing a lot of staring at the back of the trailer holding our bikes.

View attachment 344546

Very cool, I saw a pack of 20 (is that the right term?) of adventure bikers out on the remote Denali Hwy last weekend.

Props to them, they were camping and riding in 50 degree rain on a 130 mile unmaintained road. I was warm and toasty staying at a roadside lodge and driving my truck.

Since getting back from Moab in the Spring the rig has had a bit of play in the steering. There has been a dead spot of a little over an inch at the center, when it is normally tight. Turns out my PSC saginaw style steering gear was the source of the play - everything else is tight.

I installed this steering gear, along with the rest of the hydro assist, about a dozen years ago. Back in 2017 I was having a similar problem with play in the gear, and at that time had PSC rebuild it for me and it has been fine until now.

I spoke to PSC about the issue. My current gear is not their big bore offerring (when I originally bought it I'm not even sure that was available), and they told me they've made a bunch of improvements in strength, durability and performance since my original purchase.

So after a lengthly discussion and much consideration, I ordered the current big bore saginaw. We will see if there have been 1100 bucks worth of improvements...

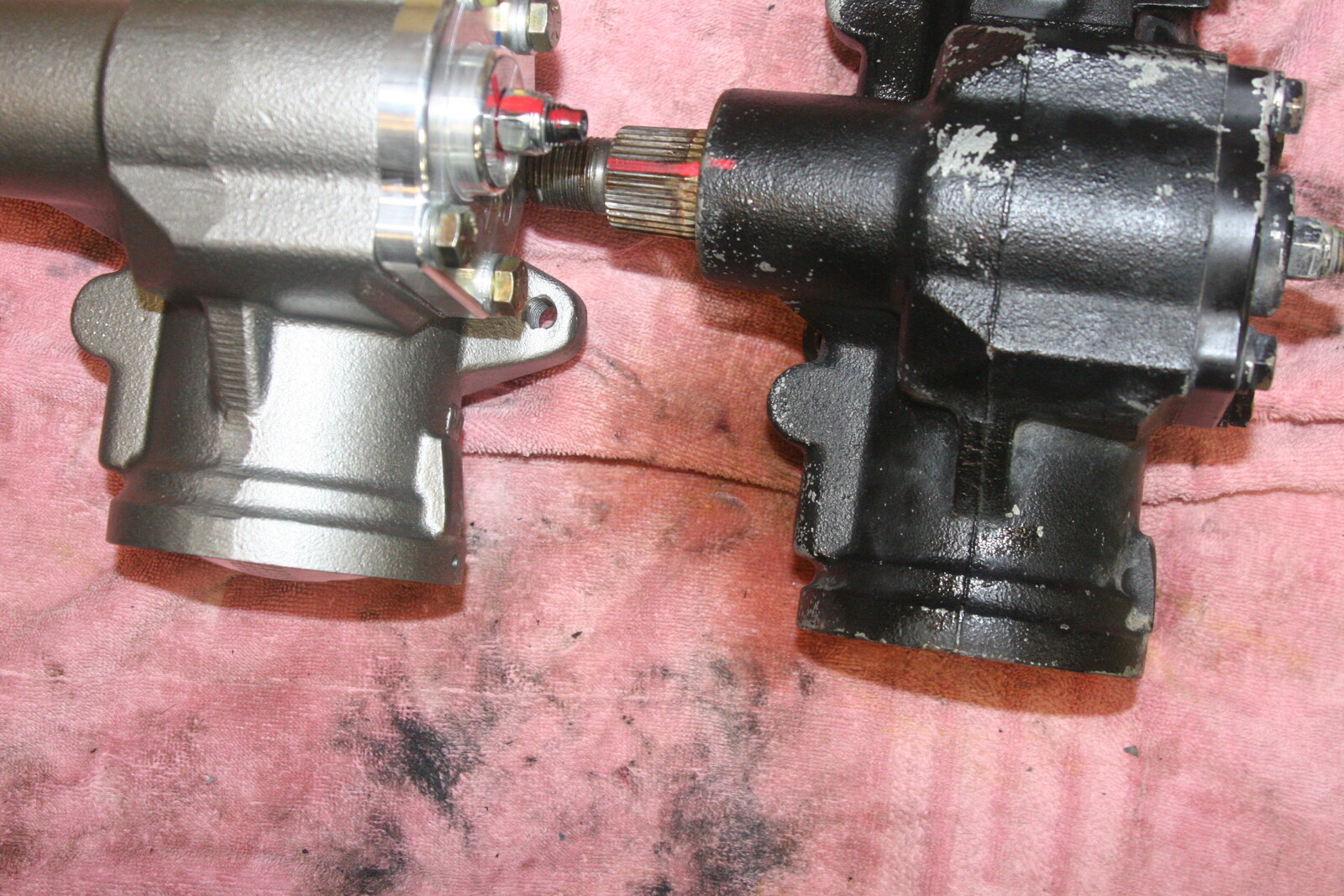

Here it is:

A dozen years ago, PSC sold a modified saginaw gear to fit the '03 to '06 TJ, which as you all know runs the Mercedes box and has a slighly different bolt pattern than the saginaw. PSC actually welded an additional mounting tab to allow for proper fitment. My original saginaw actually had four mounting tabs.

Now over the years I've had a few differrent steering configurations as I pushed the front axle out further and further. At one point I had the gear tucked tightly up under the front cross member, and as such the top front tab would not clear. So I cut that one off and used the remaining top tab for the mount.

Here is a comparison:

It worked fine, and I used that bolt pattern as well on my last front stretch when I replaced the cross member and mounted the gear flat - parallel to the frame.

I had forgotten all of that until the moment the new gear showed up....

These days, PSC manufactures a gear case specifically for this application with no need to weld on an extra mounting tab - and the fourth upper rear tab is no longer there as it is not needed on the '03 - '06 setup.

Well, no big deal as with my current setup I can easily add an additional bolt location to match the new setup. It will certainly be a more complicated installed than I had planned, but not too bad at all

So, first up - off with the front bumper and winch to get to the malfunctioning steering gear:

You can see in this picture how the gear is currently mounted.

I installed this steering gear, along with the rest of the hydro assist, about a dozen years ago. Back in 2017 I was having a similar problem with play in the gear, and at that time had PSC rebuild it for me and it has been fine until now.

I spoke to PSC about the issue. My current gear is not their big bore offerring (when I originally bought it I'm not even sure that was available), and they told me they've made a bunch of improvements in strength, durability and performance since my original purchase.

So after a lengthly discussion and much consideration, I ordered the current big bore saginaw. We will see if there have been 1100 bucks worth of improvements...

Here it is:

A dozen years ago, PSC sold a modified saginaw gear to fit the '03 to '06 TJ, which as you all know runs the Mercedes box and has a slighly different bolt pattern than the saginaw. PSC actually welded an additional mounting tab to allow for proper fitment. My original saginaw actually had four mounting tabs.

Now over the years I've had a few differrent steering configurations as I pushed the front axle out further and further. At one point I had the gear tucked tightly up under the front cross member, and as such the top front tab would not clear. So I cut that one off and used the remaining top tab for the mount.

Here is a comparison:

It worked fine, and I used that bolt pattern as well on my last front stretch when I replaced the cross member and mounted the gear flat - parallel to the frame.

I had forgotten all of that until the moment the new gear showed up....

These days, PSC manufactures a gear case specifically for this application with no need to weld on an extra mounting tab - and the fourth upper rear tab is no longer there as it is not needed on the '03 - '06 setup.

Well, no big deal as with my current setup I can easily add an additional bolt location to match the new setup. It will certainly be a more complicated installed than I had planned, but not too bad at all

So, first up - off with the front bumper and winch to get to the malfunctioning steering gear:

You can see in this picture how the gear is currently mounted.

Well so far, sunshine and rainbows.

I expected to be able to set the box in place, fabricate an additional mount, and be done. But the new box had other plans.

Clouds are rollin' in.

The big-bore gear is identical in exterior dimensions - except for one. On the original box, the end cap is flat and flush with the body of the gear, but on the big bore box the end cap is curved and extends 1/8" past the end.

That does not seem like much, but in my current setup the box tucks in tight against the cross member,

and that 1/8" creates enough interference to keep the mounting bolts from lining up.

%&(*^##!!

I expected to be able to set the box in place, fabricate an additional mount, and be done. But the new box had other plans.

Clouds are rollin' in.

The big-bore gear is identical in exterior dimensions - except for one. On the original box, the end cap is flat and flush with the body of the gear, but on the big bore box the end cap is curved and extends 1/8" past the end.

That does not seem like much, but in my current setup the box tucks in tight against the cross member,

and that 1/8" creates enough interference to keep the mounting bolts from lining up.

%&(*^##!!

heat n donk.

maybe have to give that brake line some room not to rub. looks like it'll be tight once your tucked in.

maybe have to give that brake line some room not to rub. looks like it'll be tight once your tucked in.

Well so far, sunshine and rainbows.

I expected to be able to set the box in place, fabricate an additional mount, and be done. But the new box had other plans.

Clouds are rollin' in.

The big-bore gear is identical in exterior dimensions - except for one. On the original box, the end cap is flat and flush with the body of the gear, but on the big bore box the end cap is curved and extends 1/8" past the end.

View attachment 354809

That does not seem like much, but in my current setup the box tucks in tight against the cross member,

View attachment 354810

and that 1/8" creates enough interference to keep the mounting bolts from lining up.

View attachment 354811

%&(*^##!!

That sucks. You think you'll be able to put a dent in the crossmember deep enough, or will you need to cut and weld a piece in?

Well, easy solution I think to myself. Why the %^(%% did PSC change that end cap just to make it look cleaner? I'll just swap the caps and be done with it! Clouds are parting, sun is pokin' through.

And with apologies to PSC, turns out there is a reason. Everything inside the big bore box is bigger. The increased stroke of the piston and the larger center bolt require the extra cleanence the domed cover and its internal machining provides. So that idea was out the window. I did measure the thickness of the new cover at the center, and although about a 1/4" thick I don't think that's enough to grind the extra 1/8" off without compromising the strength of the cover (idea #2 shot down in flames).

And with apologies to PSC, turns out there is a reason. Everything inside the big bore box is bigger. The increased stroke of the piston and the larger center bolt require the extra cleanence the domed cover and its internal machining provides. So that idea was out the window. I did measure the thickness of the new cover at the center, and although about a 1/4" thick I don't think that's enough to grind the extra 1/8" off without compromising the strength of the cover (idea #2 shot down in flames).

That sucks. You think you'll be able to put a dent in the crossmember deep enough, or will you need to cut and weld a piece in?

heat n donk.

...

Man, you guys are too quick....

So on to idea #3: Ahhhh....heat n donk it.

I run the SwayLoc inside of a 2" OD x .120 wall DOM cross member. The diameter of the outer torsion bar is 1.5" - that means I have just over 1/16" (5 thou over, to be exact) clearence between the wall of the tube and the bar. So not enough room to donk an 1/8" without contacting the torsion bar.

But, I do have a 1/6th available there, and I think I can safely take a 16th off the cap, and between the two I should be able to get it in.

To donk just a 16th out of the cross member, I didn't think I needed to resort to heat. But man, that DOM is tough. I must have donk'd that thing a coupld of hunder times with a 3 pound hammer to get it to move. But, move it did.

I then took a flap disc gently to the end cap, and that did it. Here it is finally bolted in place.

I originally thought that I would have to french the sleeve into the frame as I had to do with the rear top mount, but as it is it sits flush with the top of the frame. I need to give it a bit more thought, but I think I can weld it right where it sits.

it's 1/2 way there, just mount it next to the winch..........Man, you guys are too quick....

So on to idea #3: Ahhhh....heat n donk it.

I run the SwayLoc inside of a 2" OD x .120 wall DOM cross member. The diameter of the outer torsion bar is 1.5" - that means I have just over 1/16" (5 thou over, to be exact) clearence between the wall of the tube and the bar. So not enough room to donk an 1/8" without contacting the torsion bar.

View attachment 354817

But, I do have a 1/6th available there, and I think I can safely take a 16th off the cap, and between the two I should be able to get it in.

To donk just a 16th out of the cross member, I didn't think I needed to resort to heat. But man, that DOM is tough. I must have donk'd that thing a coupld of hunder times with a 3 pound hammer to get it to move. But, move it did.

I then took a flap disc gently to the end cap, and that did it. Here it is finally bolted in place.

View attachment 354818

I originally thought that I would have to french the sleeve into the frame as I had to do with the rear top mount, but as it is it sits flush with the top of the frame. I need to give it a bit more thought, but I think I can weld it right where it sits.

if you can work the linkage to be clean i'd mount it over the frame .......the game is clearance.

it's 1/2 way there, just mount it next to the winch..........

if you can work the linkage to be clean i'd mount it over the frame .......the game is clearance.

Yeah, everything up there is crazy tight. If I moved the mounts for the box back even that 1/8" to clear, the pitman arm would hit the tie rod. So, it was important that the box remained in the same location.

I guess I could have mounted the gear above the frame, but that would have required a super-duper dropped pitman arm. And you know how that would have gone over around here....

ya. i'm that tight between links too. no going backwards. i think it sits nice like you have it....

i might hold that pitman up there and be sure it's not gonna swing into the mount horn or anything. but i;m pretty sure you have.

i might hold that pitman up there and be sure it's not gonna swing into the mount horn or anything. but i;m pretty sure you have.

Unreal. While I love figuring out problems like that, there are some days I just wish things would fit

Then it was just a matter of a little tack...

A little weld...

A little paint...

And a little reconnectin'.

Now all that's left is to clearence the bumper just a bit, reinstall the SwayLoc, and...

...oh yeah, almost forgot. Spend the next 3 days bleedin' the damned thing...

A little weld...

A little paint...

And a little reconnectin'.

Now all that's left is to clearence the bumper just a bit, reinstall the SwayLoc, and...

...oh yeah, almost forgot. Spend the next 3 days bleedin' the damned thing...

After getting the steering all back together and bled, all that remained was to clearance the bumper for the new mount.

I had previously cut a slot to clear the top of the steering gear, and all I had to do today was extend the cut to clear the mount.

That would have been fine, and most of that sits behind the winch anyway so no one would even know it was there....

...but of course, I would. So I spent a little time boxing it in.

And then a little paint.

Man do I know how to turn a small project into a big one...

I had previously cut a slot to clear the top of the steering gear, and all I had to do today was extend the cut to clear the mount.

That would have been fine, and most of that sits behind the winch anyway so no one would even know it was there....

...but of course, I would. So I spent a little time boxing it in.

And then a little paint.

Man do I know how to turn a small project into a big one...

jesseshoots

TJ Enthusiast

After getting the steering all back together and bled, all that remained was to clearance the bumper for the new mount.

View attachment 355360

I had previously cut a slot to clear the top of the steering gear, and all I had to do today was extend the cut to clear the mount.

View attachment 355362

That would have been fine, and most of that sits behind the winch anyway so no one would even know it was there....

...but of course, I would. So I spent a little time boxing it in.

View attachment 355363

And then a little paint.

View attachment 355364

Man do I know how to turn a small project into a big one...

Now you have to do the right side... you know... for symmetry and stuff! Because why not make a small project drag on as long as possible

But on a more serious note, that looks killer. You sure have more guts than I do grinding into the cap of a new steering gear