You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jeep 4.0 rear main seal thoughts

- Thread starter Jms76

- Start date

Right about now would be the perfect time to try that cutting the ears off/offsetting the seal ends.

And if that does not work out, when will be the perfect time for you to swing by and redo the entire job?

I’ve taken pictures along the way. The last pic has the white sealant shown. If anyone has removed or experienced this, would appreciate the insight on how to remove. I don’t think it is a big problem based on the little step on the outside diameter of the seal.

Lastly, after reading all methods for installing. My plan is to use the Mopar RMS, use the guide shoe from my felpro kit. Lube the inner seal with oil. Then apply baby shampoo to the back of the seal as I guide and follow all the way in.

looks like gray rtv, but what is it doing up there?

You can also make guide out of a straw, starbucks has large straws that are easy to cut. Overall

HandOverFist

TJ Enthusiast

And if that does not work out, when will be the perfect time for you to swing by and redo the entire job?

Already a known leaker doing it their way...what's to lose. I'll just say if it were mine I would not hesitate to try it just from my experience with other engine two piece seals. Feel free to keep doing the same thing over and over again.

Worked for us 60 years ago dealing with this issue and still works today...

You won't see oil dripping off the bottom of this one.

Last edited:

OP

What is your suggested method of install that results in no leaks?

What is your method that results in no leaks? Don’t want to redo, but would like you to elaborate.

Already a known leaker doing it their way...what's to lose. I'll just say if it were mine I would not hesitate to try it just from my experience with other engine two piece seals. Feel free to keep doing the same thing over and over again.

Worked for us 60 years ago dealing with this issue and still works today...

View attachment 364273

You won't see oil dripping off the bottom of this one.

What is your method that results in no leaks? Don’t want to redo, but would like you to elaborate.

OP

Just a quick update. ATK must apply this rtv (gray) to the back of the upper seal, split line, and lower cap (need to pull seal and verify) maybe in attempts to stop any leakage.

Started working on removing majority of RTV, probably won’t get all of it perfect, but majority.

It is in the corners pretty good. Tried a variety of little objects being mindful not to use anything abrasive or steel.

Found the best things that do a nice job are my WD-40 and PB blaster straws cut to an angled point at the end. They are rigid enough to keep good pressure around the bore while being flexible enough not to crack or snap. They are long enough to got all around, but only do 1/2 side with them.

Definitely makes your hand cramp after a while. Going to head to over to the local hobby store which has lots of small plastic piping, tubing, and pretty much anything else you every could think of and see if I’m able to get some longer sections.

I’ll then triple up some pipe cleaners for some fine removal then used compressed air to clean out.

Also bought a used, like new felpro RMS set from Amazon today for $12. I’ll use it as a sacrificial RMS to get a feel for the job and remove any RTV remnants that can not been seen or removed.

I’ve got the Mopar seal, but figured for $12 I’ll get a little practice and help ensure the groove is good.

The other good this is the the main bearing is separated from the the RMS by the shaft flange making sure no debris being removed makes it to the main bearing.

Here are the pics of the RTV removal tools.

Started working on removing majority of RTV, probably won’t get all of it perfect, but majority.

It is in the corners pretty good. Tried a variety of little objects being mindful not to use anything abrasive or steel.

Found the best things that do a nice job are my WD-40 and PB blaster straws cut to an angled point at the end. They are rigid enough to keep good pressure around the bore while being flexible enough not to crack or snap. They are long enough to got all around, but only do 1/2 side with them.

Definitely makes your hand cramp after a while. Going to head to over to the local hobby store which has lots of small plastic piping, tubing, and pretty much anything else you every could think of and see if I’m able to get some longer sections.

I’ll then triple up some pipe cleaners for some fine removal then used compressed air to clean out.

Also bought a used, like new felpro RMS set from Amazon today for $12. I’ll use it as a sacrificial RMS to get a feel for the job and remove any RTV remnants that can not been seen or removed.

I’ve got the Mopar seal, but figured for $12 I’ll get a little practice and help ensure the groove is good.

The other good this is the the main bearing is separated from the the RMS by the shaft flange making sure no debris being removed makes it to the main bearing.

Here are the pics of the RTV removal tools.

Last edited:

HandOverFist

TJ Enthusiast

What is your suggested method of install that results in no leaks?

What is your method that results in no leaks? Don’t want to redo, but would like you to elaborate.

Just scroll up for an image representation...nothing new, we have done this for many years. You are simply offsetting the parting line of the seals from the parting line of the cap. Also see post #53...he however did not have to deal with the "ears" you have with your cap portion seal. I would likely fill that cavity flush with rtv myself.

Last edited:

OP

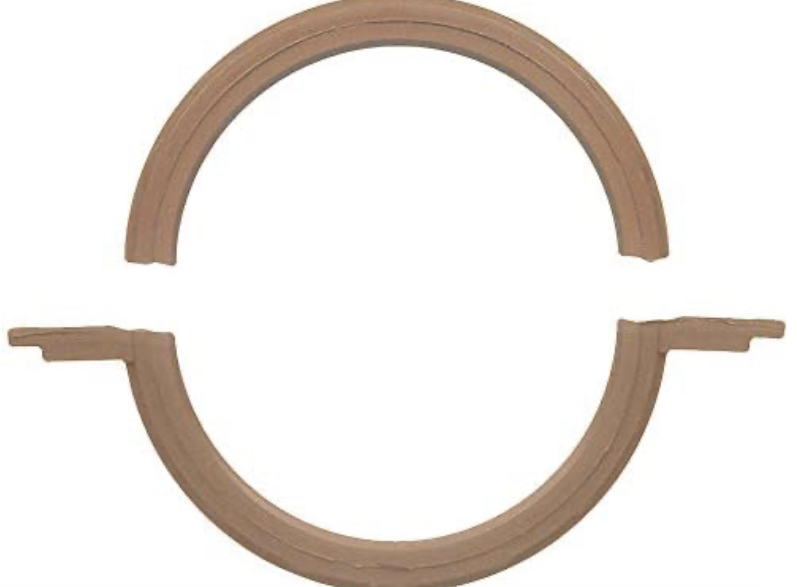

Ok, understand that. However, my seal looks as follows. I’d have to chop the legs off? Is that what you suggest?

HandOverFist

TJ Enthusiast

Yes, that is the only way you would be able to offset them. Entirely your call. Note that design is no longer used...wonder why the change?

Talk it over with as many as you like and make your decision.

Talk it over with as many as you like and make your decision.

Offsetting seems like a great common sense move. My only concern is making sure fitment is good, having the same offset on each half.

HandOverFist

TJ Enthusiast

Offsetting seems like a great common sense move. My only concern is making sure fitment is good, having the same offset on each half.

To be clear, you are NOT cutting the ends of the seals...only those protruding ears. You can eyeball pretty closely for fitment...when the cap goes on it will shift accordingly to mate perfectly. It has no choice and only one direction to go. All the offset it needs is to be away from the caps parting/mating line. Just a touch of atf on the back of each half would insure it could slide easily.

Last edited:

Right. I have an 05 so I don't think mine has the ears. I know the seals have metal in them to maintain rigiditiy so perhaps there is enough play when everything is near reassembly to work itself out?

HandOverFist

TJ Enthusiast

Right. I have an 05 so I don't think mine has the ears. I know the seals have metal in them to maintain rigiditiy so perhaps there is enough play when everything is near reassembly to work itself out?

The only way it could possibly even remotely distort is if someone glued them into the grooves...even that likely couldn't stop them from being forced into position. See post #53...his is a 2004 and he reported good success with offsetting.

Changed RMS on two TJs (97 and 04) in the past two years with ZERO leak. Used Felpro gasket and anaerobic sealant in these areas and torque'ed IAW TJ tech manual.

OP

We’ll been spending about 20 min each night with my plastic angle cut sprayer straws removing the gray RTV, painful but almost done. Included pic of the RTV slivers.

Here is the part bad part at least I think. As I was laying there, looked up at a drip of oil hanging on the dipstick waiting for it to drip on me.

Looking past it for a sec, way caught off guard when I saw metal protruding from sides of cam journal. Upon further inspection, there are two journals that have this issue and are the inner ones near dipstick and oil pump. I’ve not installed cams on on auto engine, but I’m not sure if what I’m seeing is some type of journal sleeve repair gone bad or a bearing. Looks too thin to be a bearing. Took the wind out of my sail needless to say and put my RMS project on hold until i better understand this.

Take a look, let me know what you think this may be.

As FYI, bought this rebuilt ATK engine about 1 year ago, has 6k miles on it now, oil has been changed at least 4 times now.

I’ve had my share of issues with this engine, mainly water leaks due to lack of sealant in 3 locations, joints. Plus a RMS leak.

However, it had been a strong running engine without issue. Changed it last year with dad and brother. Has all new parts and support parts on it.

It has a 3 year warranty, but all the labor is me based on being installed by me.

Also, there was no debris in the pan when I dropped it the other day. None at all nor anything visible by eye in the actual oil.

I’m hoping this is not an engine change, not hard, just very timely.

But, unless this condition is acceptable or OK, think it may need new engine. Don’t think this would be in an end user repair scope. Hopefully ATK feels the same. Maybe it is was a good catch that would have prevented a catastrophic untimely failure.

Just sucks I think.

Here is the part bad part at least I think. As I was laying there, looked up at a drip of oil hanging on the dipstick waiting for it to drip on me.

Looking past it for a sec, way caught off guard when I saw metal protruding from sides of cam journal. Upon further inspection, there are two journals that have this issue and are the inner ones near dipstick and oil pump. I’ve not installed cams on on auto engine, but I’m not sure if what I’m seeing is some type of journal sleeve repair gone bad or a bearing. Looks too thin to be a bearing. Took the wind out of my sail needless to say and put my RMS project on hold until i better understand this.

Take a look, let me know what you think this may be.

As FYI, bought this rebuilt ATK engine about 1 year ago, has 6k miles on it now, oil has been changed at least 4 times now.

I’ve had my share of issues with this engine, mainly water leaks due to lack of sealant in 3 locations, joints. Plus a RMS leak.

However, it had been a strong running engine without issue. Changed it last year with dad and brother. Has all new parts and support parts on it.

It has a 3 year warranty, but all the labor is me based on being installed by me.

Also, there was no debris in the pan when I dropped it the other day. None at all nor anything visible by eye in the actual oil.

I’m hoping this is not an engine change, not hard, just very timely.

But, unless this condition is acceptable or OK, think it may need new engine. Don’t think this would be in an end user repair scope. Hopefully ATK feels the same. Maybe it is was a good catch that would have prevented a catastrophic untimely failure.

Just sucks I think.

HandOverFist

TJ Enthusiast

Whatever that is, it ain't normal. Almost looks like some type of plastic sleeve...try to fish a piece out. Never seen it used, but possibly some plastic sleeves to keep the ham handed at ATK from gouging the bearings during install of the camshaft?

Last edited:

OP

I’ve never seen anything like it either, I reached up and moved it. Think It is aluminum and really reminded me of the top and rim of a pop can. Was thinking it was some site of journal sleeve repair. Rather than an oversized bearing, they use some sort of sleeve. I don’t know, but very concerning. (Any extremely annoying at this point)Whatever that is, it ain't normal. Almost looks like some type of plastic sleeve...try to fish a piece out. Never seen it used, but possibly some plastic sleeves to keep the ham handed at ATK from gouging the bearings during install of the camshaft?

This Jeep is entirely restored and pretty much drive it spring though fall, just very frustrating at this point.

HandOverFist

TJ Enthusiast

Forward those images and get an explanation from them is all I can offer. I have sleeved old harmonic balancers, but this is a new one on me. I've never witnessed any cam bearing journal that had any wear to warrant something like that.

From what I have seen thus far I don't believe I would care for a replacement from that vendor.

From what I have seen thus far I don't believe I would care for a replacement from that vendor.

Last edited:

OP

Spoke to the folks at LKQ who is the parent company to ATK. They are going to review the pics and get back to me shortly.

The gentlemen I spoke with told me they don’t use sleeve repairs, but the do used oversized journals. He thinks the journals got extruded out and rolled. From a mechanical perspective, can definitely see how the two inner journals have the greatest load and deflection potential. It is a long camshaft, supported in 4 of 6 block web locations.

Did a little more investigating, there appears to be 4 journals that support the camshaft, the two inner ones are damaged. The front and rear look fine.

Pulled a piece off tonight, definitely aluminum. Believe it is the bearing compressed and rolled out and over.

Here is a pic of the material.

The gentlemen I spoke with told me they don’t use sleeve repairs, but the do used oversized journals. He thinks the journals got extruded out and rolled. From a mechanical perspective, can definitely see how the two inner journals have the greatest load and deflection potential. It is a long camshaft, supported in 4 of 6 block web locations.

Did a little more investigating, there appears to be 4 journals that support the camshaft, the two inner ones are damaged. The front and rear look fine.

Pulled a piece off tonight, definitely aluminum. Believe it is the bearing compressed and rolled out and over.

Here is a pic of the material.

HandOverFist

TJ Enthusiast

That doesn't look like any bearing material I'm familiar with. Be interested in their reply for sure.