There’s your problem, Mike. Your torque converter has a bunch of cuts in it…

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A rebuild of #miRustyJeep...

- Thread starter Mike_H

- Start date

The transmission is out!

View attachment 381406

View attachment 381407

Now, I just need to tear the rest of the Jeep apart and rebuild it with all the auto parts. Easy peasy, lol.

I’ve also finished the rebuild of my tcase. That is sitting on a bench, ready to bolt up to the auto.

While there is no trans bolted up to the motor, that is the time to sneak the cooler lines behind the exhaust. You may have to loosen the manifold bolts and swing the head pipes over to the left a tad, but that beats doing it later and dropping the whole mess.

While there is no trans bolted up to the motor, that is the time to sneak the cooler lines behind the exhaust. You may have to loosen the manifold bolts and swing the head pipes over to the left a tad, but that beats doing it later and dropping the whole mess.

Thanks for the tip! I don’t suppose you have extra of the clamps that are supposed to locate the transmission lines, do you?

Thanks for the tip! I don’t suppose you have extra of the clamps that are supposed to locate the transmission lines, do you?

We move one of the oil pan bolts that is studded to the spot near the front of the oil pan and use an Adel clamp on one line, then zip tie the lower line to that one. We find most of the clips have long since been rendered ineffective due to the snap fit on the stud no longer being tight enough to stay in place.

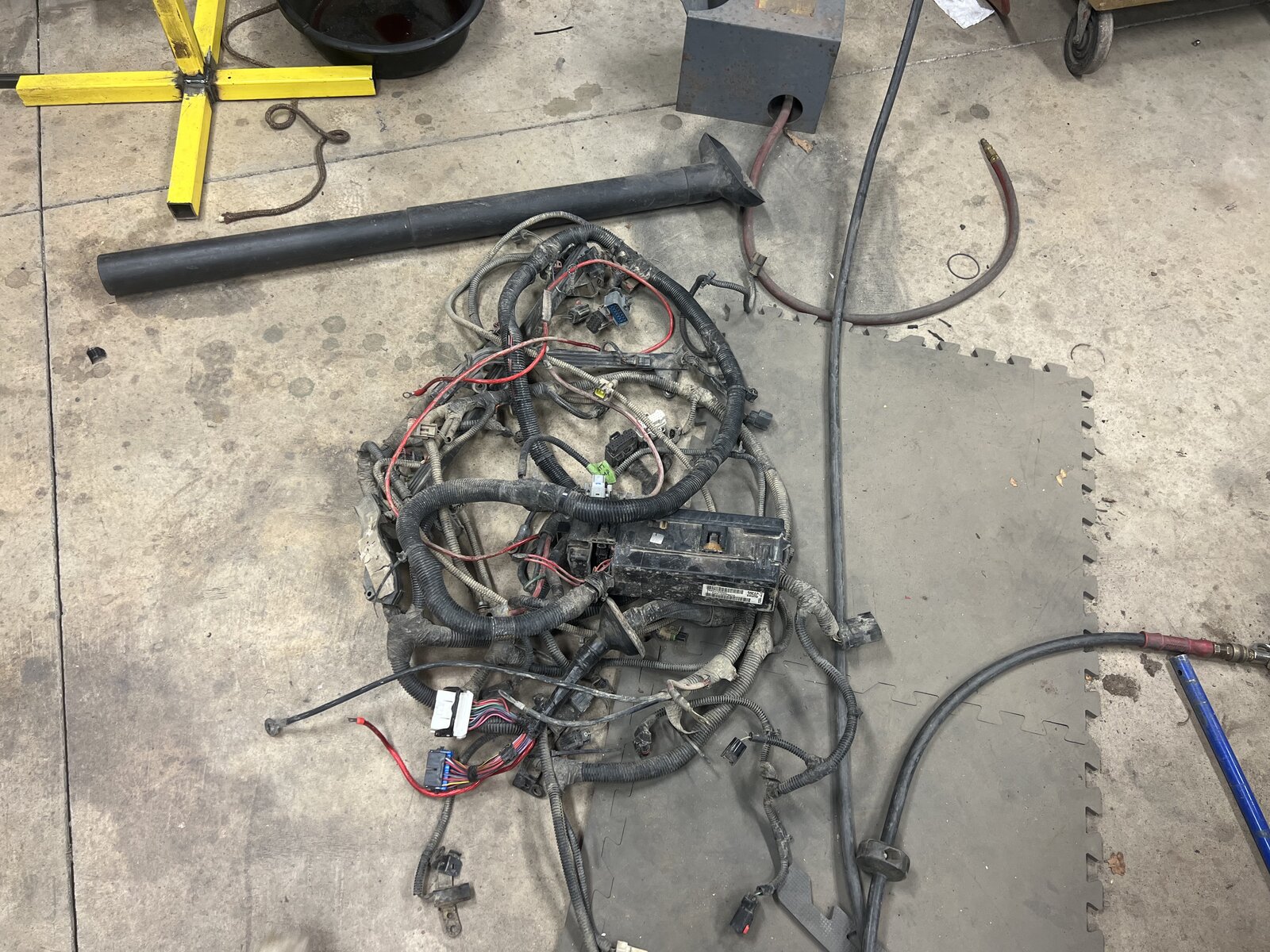

Disassembly continues…

Got the difficult harness out. It took me a while because I worked on it, got frustrated with the stiff, dirty connectors, and had to take a break. So I’d play with the dogs or watch some YouTube, then go back at it. Got everything out with out having a temper tantrum or breaking anything. That’s a win in my book!

Also, more proof that my Jeep has something weird going on in the front end… my upper intermediate steering shaft is off center in the hole through the fire wall.

Got the difficult harness out. It took me a while because I worked on it, got frustrated with the stiff, dirty connectors, and had to take a break. So I’d play with the dogs or watch some YouTube, then go back at it. Got everything out with out having a temper tantrum or breaking anything. That’s a win in my book!

Also, more proof that my Jeep has something weird going on in the front end… my upper intermediate steering shaft is off center in the hole through the fire wall.

Last edited:

Disassembly continues…

View attachment 381475

Got the difficult harness out. It took me a while because I worked on it, got frustrated with the stiff, dirty connectors, and had to take a break. So I’d play with the dogs or watch some YouTube, then go back at it. Got everything out with out having a temper tantrum or breaking anything. That’s a win in my book!

Also, more proof that my Jeep has something weird going on in the front end… my upper intermediate steering shaft is off center in the hole through the fire wall.

View attachment 381477

I need your blank off plug for the firewall connector.

I’m confused. What does the O2 sensor have to do with the block of plug? I can probably pick it out on mouser too, now that I know what the series of connector it is.

I’m confused. What does the O2 sensor have to do with the block of plug? I can probably pick it out on mouser too, now that I know what the series of connector it is.

Nothing, two separate posts. You will pull the block off plug out of the one on the firewall to connect up the auto harness. I need the block off plug for the one I just converted to a manual since I sent mine to someone that needed it.

The O2 sensor thing is me poking fun at Jeep's nonsense for making the 04 a stand alone year for the sensors. We've had to move the connector shells around to do the swaps and it seems very odd to have to do that. If you're lucky, your new harness is an 04 as well. Ours have been an 04 harness for the 03 we were working on and then the 03 harness went into an 04. PITA.

Nothing, two separate posts. You will pull the block off plug out of the one on the firewall to connect up the auto harness. I need the block off plug for the one I just converted to a manual since I sent mine to someone that needed it.

The O2 sensor thing is me poking fun at Jeep's nonsense for making the 04 a stand alone year for the sensors. We've had to move the connector shells around to do the swaps and it seems very odd to have to do that. If you're lucky, your new harness is an 04 as well. Ours have been an 04 harness for the 03 we were working on and then the 03 harness went into an 04. PITA.

Unfortunately, I have an 03 harness, so I’ll have some fucking around to do with that.

Got some more stuff taken apart today. Main firewall harness is out. Talked with Blaine too and apparently I don’t actually need to change this. So, I’m not going to. I know it works and I don’t have to deal with DRL (on my replacement harness) and how it’s going to interact with my HD headlight relay harness. Additionally, the main connectors to the dash on my harness are in good shape, so I’d have to swap them to the replacement harness (which are broken). Finally, the PDC on the replacement harness had some issues. I’ve repaired them as best as I can, but the original is in better shape.

So, I’ll rewrap the harness that came out of my Jeep and give it a quick once over. I’ll do something with the other one I cleaned up. Maybe it’s just spare parts, maybe I’ll build an SPOD type relay box.

I drained coolant and pulled my driver’s fender too. I have the DEI heat protection to install and a new intake/exhaust manifold gasket to install while the Jeep is torn apart.

Tomorrow we have plans, but Tuesday, I should be able to get the grill shell pulled apart. Assembly is the reverse of disassembly.

Mark @Wranglerfix is going to refresh my PCM for an auto, so that should go out next week too.

Oh, and I gotta figure out my switches. I don’t have room in my center bezel for the O/D switch, plus I HATE having a single switch for two lockers. Gotta think on that one. Right now, I’m thinking to make something to hold the factory 4 switches (O/D, rear defrost, rear wiper, and bonus) then I’ll make some spots for Carling switches for lockers and rock lights. I’ll 3D print it out of ABS on my work machine.

So, I’ll rewrap the harness that came out of my Jeep and give it a quick once over. I’ll do something with the other one I cleaned up. Maybe it’s just spare parts, maybe I’ll build an SPOD type relay box.

I drained coolant and pulled my driver’s fender too. I have the DEI heat protection to install and a new intake/exhaust manifold gasket to install while the Jeep is torn apart.

Tomorrow we have plans, but Tuesday, I should be able to get the grill shell pulled apart. Assembly is the reverse of disassembly.

Mark @Wranglerfix is going to refresh my PCM for an auto, so that should go out next week too.

Oh, and I gotta figure out my switches. I don’t have room in my center bezel for the O/D switch, plus I HATE having a single switch for two lockers. Gotta think on that one. Right now, I’m thinking to make something to hold the factory 4 switches (O/D, rear defrost, rear wiper, and bonus) then I’ll make some spots for Carling switches for lockers and rock lights. I’ll 3D print it out of ABS on my work machine.

What did you put in the OD off switch spot?Oh, and I gotta figure out my switches. I don’t have room in my center bezel for the O/D switch, plus I HATE having a single switch for two lockers. Gotta think on that one. Right now, I’m thinking to make something to hold the factory 4 switches (O/D, rear defrost, rear wiper, and bonus) then I’ll make some spots for Carling switches for lockers and rock lights. I’ll 3D print it out of ABS on my work machine.

What did you put in the OD off switch spot?

My switch to enable my lockers in any transfer case position

Got some reportable progress this weekend. Got my old manual radiator out and built the support for the transmission cooler I'm installing. Like every project that I do where I haven't "been there" before, I have some clean up to do from rust. This time, its the mounting screws for the A/C condenser. There is like a little button with threads inside a rubber grommet that holds the condenser to the grill shell. Not sure where I'm going to get those to replace them, so I may "invent" something.

The V-bar was in decent shape. Welded on some 1.5 x 3/16 cold rolled flat stock I had kicking around. By now, this is old hat, but here is my cooler mount

After the parts cooled, the v-bar got a quick run through the sandblaster and a shot of some satin black paint. I also cleaned up the raw steel on my brake pedal assembly and painted that. Finally cleaned up my shop a little bit from all the disassembly. That part of the project is done. Next up is replacing my intake/exhaust gasket and changing my motor mounts. I have the MORE motor mounts that lift the engine 1". I am going back to brand new Mopar Motor mounts with an aluminum lift block. The Cooler should be installed early next week (after a couple parts arrive). The Grill and auto radiator will go in soon too. The "new" radiator needs a good cleaning...its packed full of mud!

The V-bar was in decent shape. Welded on some 1.5 x 3/16 cold rolled flat stock I had kicking around. By now, this is old hat, but here is my cooler mount

After the parts cooled, the v-bar got a quick run through the sandblaster and a shot of some satin black paint. I also cleaned up the raw steel on my brake pedal assembly and painted that. Finally cleaned up my shop a little bit from all the disassembly. That part of the project is done. Next up is replacing my intake/exhaust gasket and changing my motor mounts. I have the MORE motor mounts that lift the engine 1". I am going back to brand new Mopar Motor mounts with an aluminum lift block. The Cooler should be installed early next week (after a couple parts arrive). The Grill and auto radiator will go in soon too. The "new" radiator needs a good cleaning...its packed full of mud!

Got some reportable progress this weekend. Got my old manual radiator out and built the support for the transmission cooler I'm installing. Like every project that I do where I haven't "been there" before, I have some clean up to do from rust. This time, its the mounting screws for the A/C condenser. There is like a little button with threads inside a rubber grommet that holds the condenser to the grill shell. Not sure where I'm going to get those to replace them, so I may "invent" something.

The V-bar was in decent shape. Welded on some 1.5 x 3/16 cold rolled flat stock I had kicking around. By now, this is old hat, but here is my cooler mount

View attachment 383604

View attachment 383605

After the parts cooled, the v-bar got a quick run through the sandblaster and a shot of some satin black paint. I also cleaned up the raw steel on my brake pedal assembly and painted that. Finally cleaned up my shop a little bit from all the disassembly. That part of the project is done. Next up is replacing my intake/exhaust gasket and changing my motor mounts. I have the MORE motor mounts that lift the engine 1". I am going back to brand new Mopar Motor mounts with an aluminum lift block. The Cooler should be installed early next week (after a couple parts arrive). The Grill and auto radiator will go in soon too. The "new" radiator needs a good cleaning...its packed full of mud!

I'm trying to get to mine this week or next, good motivation right here!

Them be wellnuts. I have many, they can go out in the care package tomorrow with new flange head screws if it helps?Got some reportable progress this weekend. Got my old manual radiator out and built the support for the transmission cooler I'm installing. Like every project that I do where I haven't "been there" before, I have some clean up to do from rust. This time, its the mounting screws for the A/C condenser. There is like a little button with threads inside a rubber grommet that holds the condenser to the grill shell. Not sure where I'm going to get those to replace them, so I may "invent" something.

Them be wellnuts. I have many, they can go out in the care package tomorrow with new flange head screws if it helps?

That would be wonderful. I just put a package of 10 of them in my cart, but if you have em, I'll buy em from you.

Last edited:

That would be wonderful. I just put a package of 10 of them in my cart, but if you have em, I'll buy em from you.

On the list to go out tomorrow.