Update #12

Got the rear fenders mostly complete. Still need to fill in the panels. I'm thinking either aluminum or plastic sheeting riveted on but I need to figure out how to make it water tight. Also finished up the headlights & however I only get hyper flash when the fog lights are on at the same time as the turn signals.... weird.

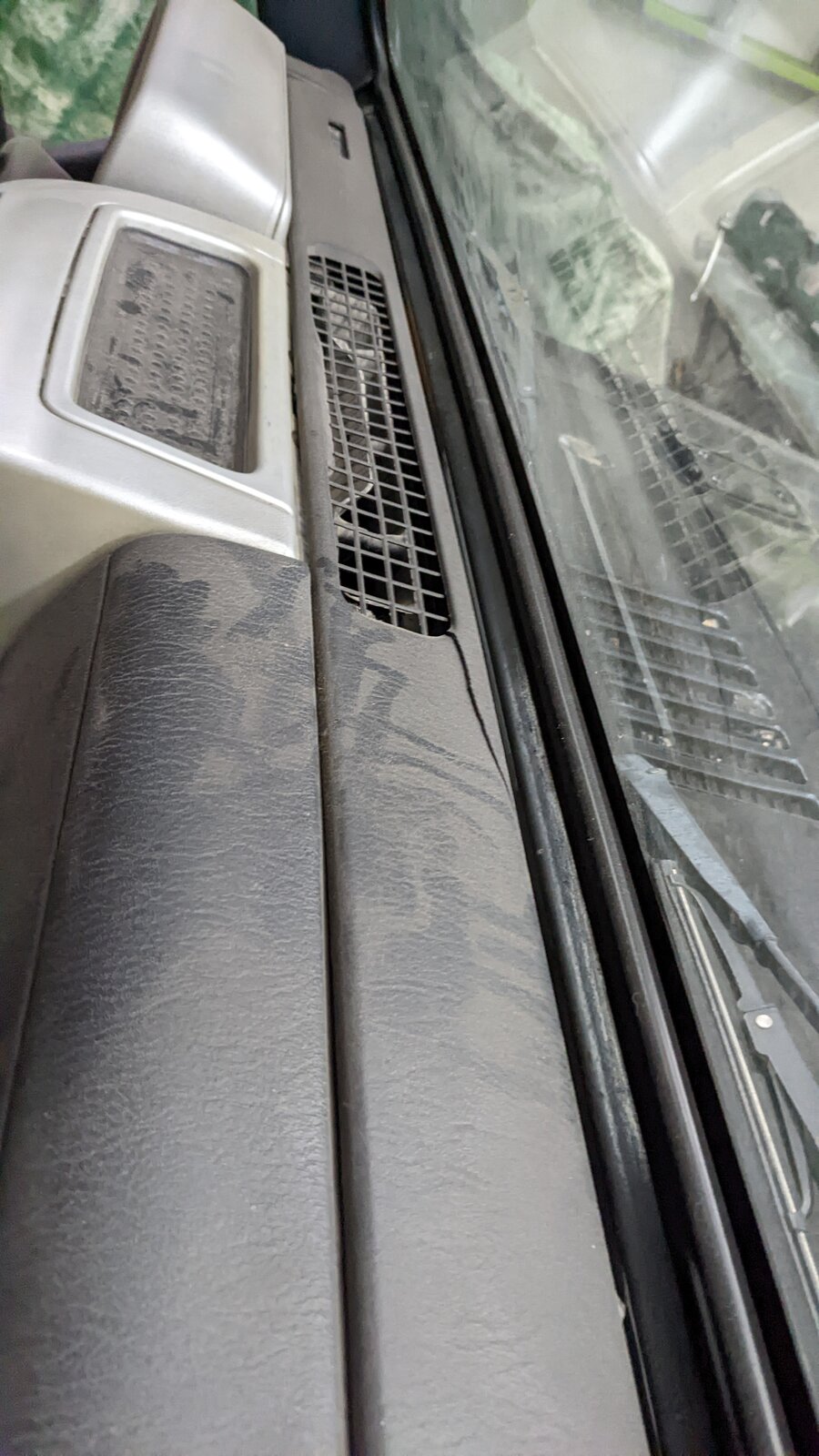

Discovered that the washer fluid pump isn't working or the lines are clogged. The top piece of the dash is cracked & the engine bay light is also busted. I guess I should probably put down the welder an pick up some wrenches for some much needed maintenance.

Started preparing for converting the tailgate to a drop down tailgate. Might tackle that next while I figure out what I want the tire carrier to look like. Eventually I'll get to fabricating the front fenders. I'm torn between taking off the steel fenders completely or partially, might get squirrely and try to make my own high line style fenders.

Thanks for checking out my build

-Daniel

Got the rear fenders mostly complete. Still need to fill in the panels. I'm thinking either aluminum or plastic sheeting riveted on but I need to figure out how to make it water tight. Also finished up the headlights & however I only get hyper flash when the fog lights are on at the same time as the turn signals.... weird.

Discovered that the washer fluid pump isn't working or the lines are clogged. The top piece of the dash is cracked & the engine bay light is also busted. I guess I should probably put down the welder an pick up some wrenches for some much needed maintenance.

Started preparing for converting the tailgate to a drop down tailgate. Might tackle that next while I figure out what I want the tire carrier to look like. Eventually I'll get to fabricating the front fenders. I'm torn between taking off the steel fenders completely or partially, might get squirrely and try to make my own high line style fenders.

Thanks for checking out my build

-Daniel

Last edited: