The teardown of Homer started in early 2021 in the garage. At the time, my wife and I were in the middle of an IVF journey trying to have children.

We were blessed with good results during the journey in 2021 and prepared for a transfer attempt in early in 2022.

IVF Transfer went as well as we could hope —-> We had a Baby on the way!!

.

.

.

.

A couple ultrasounds later, that baby went through a seismic change…

We now had TWO buns in the oven!

Pregnancy went well up until 29 weeks when my wife was hospitalized with high blood pressure. A few days later, the doctors diagnosed preeclampsia and the babies were set to be delivered within hours…

Talk about a terrifying time. Luckily the boys and my wife were all healthy following the delivery.

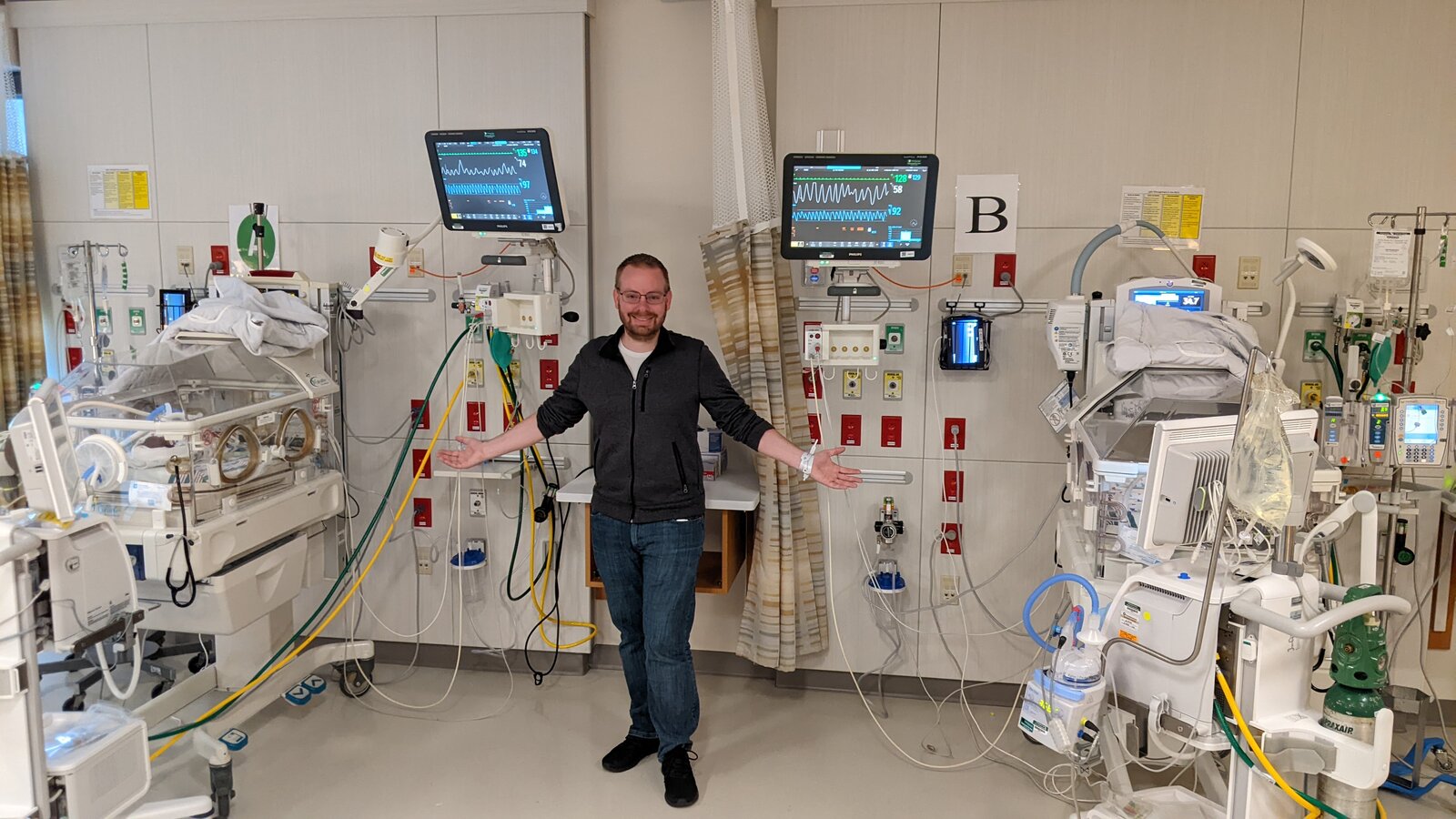

Very happy new father:

My wife left the hospital after a few more days due to further complications. The boys spent 3 months in the NICU. They finally came home in October and have been growing like crazy. Time truly does fly. They are our miracles!

As you can imagine, progress on Homer stalled pretty much to a stop.

We were blessed with good results during the journey in 2021 and prepared for a transfer attempt in early in 2022.

IVF Transfer went as well as we could hope —-> We had a Baby on the way!!

.

.

.

.

A couple ultrasounds later, that baby went through a seismic change…

We now had TWO buns in the oven!

Pregnancy went well up until 29 weeks when my wife was hospitalized with high blood pressure. A few days later, the doctors diagnosed preeclampsia and the babies were set to be delivered within hours…

Talk about a terrifying time. Luckily the boys and my wife were all healthy following the delivery.

Very happy new father:

My wife left the hospital after a few more days due to further complications. The boys spent 3 months in the NICU. They finally came home in October and have been growing like crazy. Time truly does fly. They are our miracles!

As you can imagine, progress on Homer stalled pretty much to a stop.