I have a 97' Tj with a 2.5l that is now shot (broke the #1 piston and put a 1/8" deep gouge in the block, picture attached), and I'm looking to replace the engine, but would like to up to a 6cyl or 8 cylinder, but want the least amount of problems and least amount of Fabrication. Please help with all y'alls collective knowledge.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Whats the easiest engine swap to replace a 2.5?

- Thread starter ProudDad81

- Start date

Unfortunately there isn't any easy engine swap.

First off you have to consider that unlike a 4.0 where you could re-use the AX-15 or other manual transmission with a V8 swap, the transmission in your 4 cylinder can't stand the power of a bigger V8, and it can't even handle the power (or bolt-up) to a 4.0 swap.

Some will say a 4.0 swap, but that's a waste of time, effort, and money. The amount of work required to swap in a 4.0 would probably be about the same amount of time required to swap in a Magnum V8 or similar. Yes, the V8 swap would cost more, but it's going to yield better results.

That being said, as far as the easiest swap, I would think a Magnum V8 would be one of the easier swaps due to the fact that it's already a Mopar engine and it's very well documented, and all the conversion parts already exist.

Maybe someone like @Wildman, @RangerRick, or another person who has done the swap will chime in.

First off you have to consider that unlike a 4.0 where you could re-use the AX-15 or other manual transmission with a V8 swap, the transmission in your 4 cylinder can't stand the power of a bigger V8, and it can't even handle the power (or bolt-up) to a 4.0 swap.

Some will say a 4.0 swap, but that's a waste of time, effort, and money. The amount of work required to swap in a 4.0 would probably be about the same amount of time required to swap in a Magnum V8 or similar. Yes, the V8 swap would cost more, but it's going to yield better results.

That being said, as far as the easiest swap, I would think a Magnum V8 would be one of the easier swaps due to the fact that it's already a Mopar engine and it's very well documented, and all the conversion parts already exist.

Maybe someone like @Wildman, @RangerRick, or another person who has done the swap will chime in.

Novak website is full of information. I ha e the 2.5 also and one day I will swap it for either a vortex 5.3 or the Hemi in my old dodge truck

Personally... I think a ls v8... Dime a dozen to find a wrecked truck if you can do the Fab work yourself. If not, your paying someone to do Fab work either way for whatever engine swap you do... So... It's 6 in one, half dozen in the other. See who has the cheapest/ best mounts pre made etc... But I'm kinda biased to the ls i guess, you can get a full stand alone self learning computer now for 700 i think, and iirc still use the factory tj fuel tank and pump... But haven't done the swap myself yet on a tj.

I have a 97 TJ SE also and when I started looking at engine swaps there weren't a lot of choices at the time. LS engines were still VERY expensive plus I am like to be different. So after looking around I found out about using a Dodge magnum V-8. It is a roller cam engine that fits into a TJ very easy. The V-8 computer mounts in the same spot as the stock PCM. The wiring isn't a HUGE issue and if wiring isn't your thing there are places to get a harness made. Since you have a 97 the first thing you need to do is look and see what the build date of your TJ is. Look on the drives door jam.

As you can see mine was built 01-96 so it is a early build TJ which makes the wiring a little harder as the early build TJ's had some differences. But it isn't anything that can't be figured out.

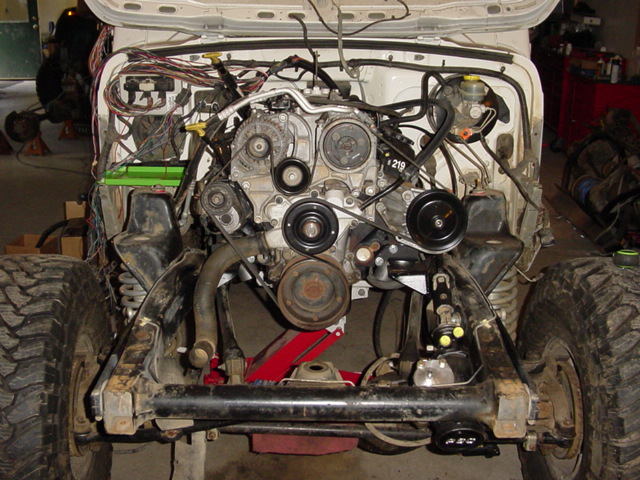

This is what a V-8 swap can look like. This isn't mine but just trying to give you an idea what they can look like.

The shop that did this swap is closed but it gives you an idea. You will have to replace your transmission as your AX-5 is barely strong enough for the 4 cyl. When doing the V-8 swap you either have to go with a AX-15 or NV3550 for a manual or use the automatic behind the V-8 which is a 44RE or 46RE and they are both 4 speed automatics. You will also need to replace the input gear in your transfer case since it has a 21 spline and your need a 23 spline.

Advanced Adapters sells motor mounts for the V-8 swap.

This is my TJ getting the V-8 swapped into it.

You can use a stock TJ auto shifter for the automatic if you choose.

As you can see mine was built 01-96 so it is a early build TJ which makes the wiring a little harder as the early build TJ's had some differences. But it isn't anything that can't be figured out.

This is what a V-8 swap can look like. This isn't mine but just trying to give you an idea what they can look like.

The shop that did this swap is closed but it gives you an idea. You will have to replace your transmission as your AX-5 is barely strong enough for the 4 cyl. When doing the V-8 swap you either have to go with a AX-15 or NV3550 for a manual or use the automatic behind the V-8 which is a 44RE or 46RE and they are both 4 speed automatics. You will also need to replace the input gear in your transfer case since it has a 21 spline and your need a 23 spline.

Advanced Adapters sells motor mounts for the V-8 swap.

This is my TJ getting the V-8 swapped into it.

You can use a stock TJ auto shifter for the automatic if you choose.

This is a really good thread on the JeepForum about doing the Magnum V-8 swap.

https://tinyurl.com/ybcekogv

https://tinyurl.com/ybcekogv

If you want to keep a manual transmission as I said you will have to get a AX-15 or a NVG3550 transmission. You will also need a bell housing from a 92-99 Dodge Dakota 3.9. You can find them on Car-Part.com for around $100.

The Ax-15 or NVG3550 will both work fine behind a stock or slightly warmed up 5.2 V-8.

Gear ratios for the AX15 are: 3.83, 2.33, 1.44, 1.00, 0.79, for first through fifth

Gear Ratios NP3550:

Mfg. Torque Rating: 300 ft. lbs.

The 3550 has a fairly generous torque transmitting capacity (for a transmission of its size) as claimed by its manufacturer. Experience would suggest that it is about the same strength as the AX15.

The AX15 is one of the good successes for Jeep transmissions. They are generally regarded as the best five-speed transmission ever installed into a Jeep.

You could also keep the NV3500 that came in some Dodge pickups. Here are the ratio's for it also.

Motor Mount kit from AA:

https://www.advanceadapters.com/products/713094--dodge-v8-engine-mount-kit/

The Ax-15 or NVG3550 will both work fine behind a stock or slightly warmed up 5.2 V-8.

Gear ratios for the AX15 are: 3.83, 2.33, 1.44, 1.00, 0.79, for first through fifth

Gear Ratios NP3550:

| 4.01 | 2.33 | 1.39 | 1.00 | .78 | R3.57 |

Mfg. Torque Rating: 300 ft. lbs.

The 3550 has a fairly generous torque transmitting capacity (for a transmission of its size) as claimed by its manufacturer. Experience would suggest that it is about the same strength as the AX15.

The AX15 is one of the good successes for Jeep transmissions. They are generally regarded as the best five-speed transmission ever installed into a Jeep.

You could also keep the NV3500 that came in some Dodge pickups. Here are the ratio's for it also.

| Wide ratioUsed in 1500 | Narrow RatioUsed in 2500LD | ||||||||||||||||||||||||||||||

|

|

Motor Mount kit from AA:

https://www.advanceadapters.com/products/713094--dodge-v8-engine-mount-kit/

Last edited:

Now if you want to use a LS engine for the swap AA sells a kit for that also allowing you to retain a manual transmission. But again you'll need a AX-15 or NVG3550 as your AX-5 won't work.

https://www.advanceadapters.com/pro...evy-ls-gen-iiiiv-engines-conversion-package-/

https://www.advanceadapters.com/pro...evy-ls-gen-iiiiv-engines-conversion-package-/

OP, don't want to be a downer discourage you or a pessimist BUT read on if you dare.

This is going to be long, be patient, read if you want the least headaches and a full understanding what you're getting yourself into. Don't take an engine swap lightly. Many, many give up and abandon the job part way through because they become overwhelmed or misjudged what was involved space wise, financially or physically.

1st a couple of questions to the OP:

If you are good at working on things yourself and can fabricate, A Magnum V8 swap is the easiest and closest relative to the native 2.5L 4-cylinder engine that came in early TJ's, easier than a 4.0L possibly PERIOD!

2nd, Your transmission won't work, don't even think of keeping or re-using it as it will just fail in short order as a light duty 125 horsepower rated weak link, it's not worth saving at all.

3rd. If you can't fab and are going to pay someone to do the work for you, Just swap a rebuilt 4-cylinder in your Jeep and sell/trade it off for a 4.0L 6-cylinder. Too much complication and too much expense to pay someone else to build your Jeep unless you have VERY DEEP POCKETS and don't mind budget OVERRUNS!

Just sayin' so save you lots of $$$ and headaches.

You'll thank me later in this.............

If I didn't scare you off yet then read on my dear boy:

Since your jeep is effectively down now with a blown engine, you should start by reading and researching EVERY POST on every forum you can about the swap. Research is key to doing this successfully and asking questions to those of us who have done it and are willing to share our experiences.

Next, outline what you have for a budget, what you want out of your Jeep and what you hope this swap will gain you. Ask those who have done it if you will truly see these benefits such as power, driveability, reliability and mileage you think you are going to get. BECAUSE TALK IS CHEAP!

After research, questions and talking to those of us who have done swaps, next is to start gathering parts for the swap before you even put the Jeep under the knife.

Importance and success is in the details:

Things to keep in mind when researching and asking questions include: Does your Jeep need to pass SMOG or inspections in your state, county and city or township? Is an engine swap legal where you garage and use your Jeep? Do you need SMOG legal equipment on your engine to pass and will it have to pass a computer scan to be registered? Will you ever sell it in the future and don't want trouble with the buyer when they can't transfer title and register it in their name because of illegal engine swap not passing inspection?

Understand your Countries Laws first before proceeding and know this in the U.S. of A. :

The engine you install in any registered motor vehicle that is post 1975 year must be NEWER or EQUAL to the year of the vehicle for which it is going into if it is to be operated on public roads PERIOD! This is a FEDERAL LAW preempting any state and local laws. I'm not saying you can't get away with it if your state and localities don't check but be forewarned you better not sell it after the fact to someone living where there are inspections to check for this or it will bring trouble.

If your state has inspection like California's enhanced area inspections then you must have ALL emissions controls from the engine that is being swapped into the vehicle and at minimum, what the original vehicle had on it cannot be removed or altered unless installing NEWER MORE ADVANCED emissions technology in the Jeep.

Having been through the process several times in the Los Angeles area, I can assure you they will check EVERY PART NUMBER against what the donor vehicle is supposed to have on EVERYTHING RELATED TO THE SWAP and you can't con your way out of it at all.

The engine must be out of the same class of vehicle. Therefore, you cannot put a truck engine that is over 6000 Lbs GVWR and expect it to pass in a 1/4 ton Jeep. Not going to happen so choose your donor well. Look at the MOPAR swap grid on HOTWIRE AUTO website to see if your engine is using the same communications bus as your Jeep does native. This saves lots of headache on MOPAR family engine swaps and makes things much easier when your gauges all work and talk to the ECU properly. On GM swaps, you'll have to start over or get an interface box to work the factory gauges.

Pick an engine from a 1/2 ton truck that is light duty or SUV light duty or car to put in your Jeep. Don't buy your neighbor's 1-ton HD and use it for the donor, you'll be foiled by the inspection if you try and they are modeled after California.

I would buy an ENTIRE DONOR VEHICLE to get ALL SMOG AND ECM related parts from the same vehicle saving you lots on "junkyard nickel & dime" parts.

Also a hint: If you are going for a Magnum, the BEST DONOR is another JEEP. Get the 5.2 or 5.9 from a ZJ Grand Cherokee for early TJ. The starter is on the correct side of the engine, the transmission will work and can bolt right up to the Wrangler transfer case and all emissions will be adaptable. A 4.0L fan shroud will work with the 5.2L mechanical fan and look like it came from the factory that way. The power steering will connect right up and have room, look and work just like stock Jeep TJ stuff, Alternator is 100% connected the same with ECM control and uses the battery temp sensor just like your TJ. The connectors and pinouts on the ECM are the same for the same bus ECM's regardless of application on MOPAR products. The same pins are hooked to the same sensors making it a lot easier to build or troubleshoot a wiring harness. You can blend the existing body harness and dash gauges to the donor harness or add wires to the 4-cyl harness. You can integrate the existing fuse blocks and PDC under the hood into the MOPAR swap, something not as easily done on a GM or other swap.

On a GM Vortec swap, you'll need a stand-alone harness that runs the engine and emissions controls with possibly the transmission and fuel pump/sender. It will have to have a MIL lamp (check Engine) light on it and it's easier to have a separate fuse block for all that. There are lots of people who build harnesses and one I highly recommend is over on Pirate plus is a vendor for all things Gen III/IV/V related, talk to Wayne Heartwig I believe his company is called 150tunes.com . I have used his services on a few GM Gen III/IV swaps and he has built me harnesses that passed the strict California Referee inspections first try. Everything plug-&-Play worked like a champ and my scan-tool worked perfectly. He also supports tuning for performance or economy, I can't say enough good things about his work.

There is a lot more I myself and others such as @Wildman can share in more posts.

I just wanted to start the conversation you need to have and be realistic about what you are getting yourself into here in plain talk, no B.S. or spin.

I loved doing the swaps and I loved the outcome in MOST of the swaps but not everyone can fab or wrench like I can so be prepared, information is your friend here.

Parts:

Engine with all drive accessories DONOR

ECM and engine bay harness DONOR

Emissions controls and evap. controls DONOR

Transmission DONOR or ELSEWHERE if your donor didn't have what you wanted.

Motor Mounts AFTERMARKET (Advanced Adapters, M.O.R.E. or Novak)

Transfer case adapter (Aftermarket or not needed if original MOPAR TRANS)

Exhaust catalytic convertors DONOR

Exhaust O2 sensors & bungs DONOR

Exhaust header piper DONOR

Starter DONOR

Fuel pump/sender (DONOR or Original Jeep if MOPAR SAME FAMILY BUS)

Gauges (FACTORY if MOPAR SAME BUS otherwise Aftermarket or from GM donor on Vortec)

Harness piping or loom (Aftermarket or FACTORY RE-USE)

Harness connectors (FACTORY IF MOPAR SAME BUS or Aftermarket)

Transmission shifter (FACTORY IF MOPAR or AFTERMARKET if other)

Throttle cable (DONOR or factory if MOPAR)

Radiator (AFTERMARKET or factory with adapter hoses) or

optional aftermarket radiator but for MOPAR 5.2L I've found the factory Jeep works and for GM 5.3 etc, it has to be aftermarket conversion radiator.

Driveshafts (PROBABLY CUSTOM LENGTH AFTERMARKET, usually if you have a lift you'll want double cardan anyways to keep angularity down)

Axles (Factory Dana 44's will survive unless really built engine) Also Dana 30 front will suffice in the meantime unless very high power and abuse such as burnouts and hard wheeling like rock crawling.

**The Dana 35 will not live long behind any V8 engine swap and should be swapped for Dana 44, 9" or an 8.8 Explorer axle at minimum to prevent future repairs.

More later.....

RR

This is going to be long, be patient, read if you want the least headaches and a full understanding what you're getting yourself into. Don't take an engine swap lightly. Many, many give up and abandon the job part way through because they become overwhelmed or misjudged what was involved space wise, financially or physically.

1st a couple of questions to the OP:

If you are good at working on things yourself and can fabricate, A Magnum V8 swap is the easiest and closest relative to the native 2.5L 4-cylinder engine that came in early TJ's, easier than a 4.0L possibly PERIOD!

2nd, Your transmission won't work, don't even think of keeping or re-using it as it will just fail in short order as a light duty 125 horsepower rated weak link, it's not worth saving at all.

3rd. If you can't fab and are going to pay someone to do the work for you, Just swap a rebuilt 4-cylinder in your Jeep and sell/trade it off for a 4.0L 6-cylinder. Too much complication and too much expense to pay someone else to build your Jeep unless you have VERY DEEP POCKETS and don't mind budget OVERRUNS!

Just sayin' so save you lots of $$$ and headaches.

You'll thank me later in this.............

If I didn't scare you off yet then read on my dear boy:

Since your jeep is effectively down now with a blown engine, you should start by reading and researching EVERY POST on every forum you can about the swap. Research is key to doing this successfully and asking questions to those of us who have done it and are willing to share our experiences.

Next, outline what you have for a budget, what you want out of your Jeep and what you hope this swap will gain you. Ask those who have done it if you will truly see these benefits such as power, driveability, reliability and mileage you think you are going to get. BECAUSE TALK IS CHEAP!

After research, questions and talking to those of us who have done swaps, next is to start gathering parts for the swap before you even put the Jeep under the knife.

Importance and success is in the details:

Things to keep in mind when researching and asking questions include: Does your Jeep need to pass SMOG or inspections in your state, county and city or township? Is an engine swap legal where you garage and use your Jeep? Do you need SMOG legal equipment on your engine to pass and will it have to pass a computer scan to be registered? Will you ever sell it in the future and don't want trouble with the buyer when they can't transfer title and register it in their name because of illegal engine swap not passing inspection?

Understand your Countries Laws first before proceeding and know this in the U.S. of A. :

The engine you install in any registered motor vehicle that is post 1975 year must be NEWER or EQUAL to the year of the vehicle for which it is going into if it is to be operated on public roads PERIOD! This is a FEDERAL LAW preempting any state and local laws. I'm not saying you can't get away with it if your state and localities don't check but be forewarned you better not sell it after the fact to someone living where there are inspections to check for this or it will bring trouble.

If your state has inspection like California's enhanced area inspections then you must have ALL emissions controls from the engine that is being swapped into the vehicle and at minimum, what the original vehicle had on it cannot be removed or altered unless installing NEWER MORE ADVANCED emissions technology in the Jeep.

Having been through the process several times in the Los Angeles area, I can assure you they will check EVERY PART NUMBER against what the donor vehicle is supposed to have on EVERYTHING RELATED TO THE SWAP and you can't con your way out of it at all.

The engine must be out of the same class of vehicle. Therefore, you cannot put a truck engine that is over 6000 Lbs GVWR and expect it to pass in a 1/4 ton Jeep. Not going to happen so choose your donor well. Look at the MOPAR swap grid on HOTWIRE AUTO website to see if your engine is using the same communications bus as your Jeep does native. This saves lots of headache on MOPAR family engine swaps and makes things much easier when your gauges all work and talk to the ECU properly. On GM swaps, you'll have to start over or get an interface box to work the factory gauges.

Pick an engine from a 1/2 ton truck that is light duty or SUV light duty or car to put in your Jeep. Don't buy your neighbor's 1-ton HD and use it for the donor, you'll be foiled by the inspection if you try and they are modeled after California.

I would buy an ENTIRE DONOR VEHICLE to get ALL SMOG AND ECM related parts from the same vehicle saving you lots on "junkyard nickel & dime" parts.

Also a hint: If you are going for a Magnum, the BEST DONOR is another JEEP. Get the 5.2 or 5.9 from a ZJ Grand Cherokee for early TJ. The starter is on the correct side of the engine, the transmission will work and can bolt right up to the Wrangler transfer case and all emissions will be adaptable. A 4.0L fan shroud will work with the 5.2L mechanical fan and look like it came from the factory that way. The power steering will connect right up and have room, look and work just like stock Jeep TJ stuff, Alternator is 100% connected the same with ECM control and uses the battery temp sensor just like your TJ. The connectors and pinouts on the ECM are the same for the same bus ECM's regardless of application on MOPAR products. The same pins are hooked to the same sensors making it a lot easier to build or troubleshoot a wiring harness. You can blend the existing body harness and dash gauges to the donor harness or add wires to the 4-cyl harness. You can integrate the existing fuse blocks and PDC under the hood into the MOPAR swap, something not as easily done on a GM or other swap.

On a GM Vortec swap, you'll need a stand-alone harness that runs the engine and emissions controls with possibly the transmission and fuel pump/sender. It will have to have a MIL lamp (check Engine) light on it and it's easier to have a separate fuse block for all that. There are lots of people who build harnesses and one I highly recommend is over on Pirate plus is a vendor for all things Gen III/IV/V related, talk to Wayne Heartwig I believe his company is called 150tunes.com . I have used his services on a few GM Gen III/IV swaps and he has built me harnesses that passed the strict California Referee inspections first try. Everything plug-&-Play worked like a champ and my scan-tool worked perfectly. He also supports tuning for performance or economy, I can't say enough good things about his work.

There is a lot more I myself and others such as @Wildman can share in more posts.

I just wanted to start the conversation you need to have and be realistic about what you are getting yourself into here in plain talk, no B.S. or spin.

I loved doing the swaps and I loved the outcome in MOST of the swaps but not everyone can fab or wrench like I can so be prepared, information is your friend here.

Parts:

Engine with all drive accessories DONOR

ECM and engine bay harness DONOR

Emissions controls and evap. controls DONOR

Transmission DONOR or ELSEWHERE if your donor didn't have what you wanted.

Motor Mounts AFTERMARKET (Advanced Adapters, M.O.R.E. or Novak)

Transfer case adapter (Aftermarket or not needed if original MOPAR TRANS)

Exhaust catalytic convertors DONOR

Exhaust O2 sensors & bungs DONOR

Exhaust header piper DONOR

Starter DONOR

Fuel pump/sender (DONOR or Original Jeep if MOPAR SAME FAMILY BUS)

Gauges (FACTORY if MOPAR SAME BUS otherwise Aftermarket or from GM donor on Vortec)

Harness piping or loom (Aftermarket or FACTORY RE-USE)

Harness connectors (FACTORY IF MOPAR SAME BUS or Aftermarket)

Transmission shifter (FACTORY IF MOPAR or AFTERMARKET if other)

Throttle cable (DONOR or factory if MOPAR)

Radiator (AFTERMARKET or factory with adapter hoses) or

optional aftermarket radiator but for MOPAR 5.2L I've found the factory Jeep works and for GM 5.3 etc, it has to be aftermarket conversion radiator.

Driveshafts (PROBABLY CUSTOM LENGTH AFTERMARKET, usually if you have a lift you'll want double cardan anyways to keep angularity down)

Axles (Factory Dana 44's will survive unless really built engine) Also Dana 30 front will suffice in the meantime unless very high power and abuse such as burnouts and hard wheeling like rock crawling.

**The Dana 35 will not live long behind any V8 engine swap and should be swapped for Dana 44, 9" or an 8.8 Explorer axle at minimum to prevent future repairs.

More later.....

RR

Thanks @RangerRick your knowledge is very welcome as always. I wish I'd had your help before when I started my swap. Wondering now if I should source a GC engine harness instead of trying to use the Ram harness I have? Only found 1 on Ebay and he wants $300 for it.

Doug C

New Member

Thanks for the info as i am just getting ready to do a swap.OP, don't want to be a downer discourage you or a pessimist BUT read on if you dare.

This is going to be long, be patient, read if you want the least headaches and a full understanding what you're getting yourself into. Don't take an engine swap lightly. Many, many give up and abandon the job part way through because they become overwhelmed or misjudged what was involved space wise, financially or physically.

1st a couple of questions to the OP:

If you are good at working on things yourself and can fabricate, A Magnum V8 swap is the easiest and closest relative to the native 2.5L 4-cylinder engine that came in early TJ's, easier than a 4.0L possibly PERIOD!

2nd, Your transmission won't work, don't even think of keeping or re-using it as it will just fail in short order as a light duty 125 horsepower rated weak link, it's not worth saving at all.

3rd. If you can't fab and are going to pay someone to do the work for you, Just swap a rebuilt 4-cylinder in your Jeep and sell/trade it off for a 4.0L 6-cylinder. Too much complication and too much expense to pay someone else to build your Jeep unless you have VERY DEEP POCKETS and don't mind budget OVERRUNS!

Just sayin' so save you lots of $$$ and headaches.

You'll thank me later in this.............

If I didn't scare you off yet then read on my dear boy:

Since your jeep is effectively down now with a blown engine, you should start by reading and researching EVERY POST on every forum you can about the swap. Research is key to doing this successfully and asking questions to those of us who have done it and are willing to share our experiences.

Next, outline what you have for a budget, what you want out of your Jeep and what you hope this swap will gain you. Ask those who have done it if you will truly see these benefits such as power, driveability, reliability and mileage you think you are going to get. BECAUSE TALK IS CHEAP!

After research, questions and talking to those of us who have done swaps, next is to start gathering parts for the swap before you even put the Jeep under the knife.

Importance and success is in the details:

Things to keep in mind when researching and asking questions include: Does your Jeep need to pass SMOG or inspections in your state, county and city or township? Is an engine swap legal where you garage and use your Jeep? Do you need SMOG legal equipment on your engine to pass and will it have to pass a computer scan to be registered? Will you ever sell it in the future and don't want trouble with the buyer when they can't transfer title and register it in their name because of illegal engine swap not passing inspection?

Understand your Countries Laws first before proceeding and know this in the U.S. of A. :

The engine you install in any registered motor vehicle that is post 1975 year must be NEWER or EQUAL to the year of the vehicle for which it is going into if it is to be operated on public roads PERIOD! This is a FEDERAL LAW preempting any state and local laws. I'm not saying you can't get away with it if your state and localities don't check but be forewarned you better not sell it after the fact to someone living where there are inspections to check for this or it will bring trouble.

If your state has inspection like California's enhanced area inspections then you must have ALL emissions controls from the engine that is being swapped into the vehicle and at minimum, what the original vehicle had on it cannot be removed or altered unless installing NEWER MORE ADVANCED emissions technology in the Jeep.

Having been through the process several times in the Los Angeles area, I can assure you they will check EVERY PART NUMBER against what the donor vehicle is supposed to have on EVERYTHING RELATED TO THE SWAP and you can't con your way out of it at all.

The engine must be out of the same class of vehicle. Therefore, you cannot put a truck engine that is over 6000 Lbs GVWR and expect it to pass in a 1/4 ton Jeep. Not going to happen so choose your donor well. Look at the MOPAR swap grid on HOTWIRE AUTO website to see if your engine is using the same communications bus as your Jeep does native. This saves lots of headache on MOPAR family engine swaps and makes things much easier when your gauges all work and talk to the ECU properly. On GM swaps, you'll have to start over or get an interface box to work the factory gauges.

Pick an engine from a 1/2 ton truck that is light duty or SUV light duty or car to put in your Jeep. Don't buy your neighbor's 1-ton HD and use it for the donor, you'll be foiled by the inspection if you try and they are modeled after California.

I would buy an ENTIRE DONOR VEHICLE to get ALL SMOG AND ECM related parts from the same vehicle saving you lots on "junkyard nickel & dime" parts.

Also a hint: If you are going for a Magnum, the BEST DONOR is another JEEP. Get the 5.2 or 5.9 from a ZJ Grand Cherokee for early TJ. The starter is on the correct side of the engine, the transmission will work and can bolt right up to the Wrangler transfer case and all emissions will be adaptable. A 4.0L fan shroud will work with the 5.2L mechanical fan and look like it came from the factory that way. The power steering will connect right up and have room, look and work just like stock Jeep TJ stuff, Alternator is 100% connected the same with ECM control and uses the battery temp sensor just like your TJ. The connectors and pinouts on the ECM are the same for the same bus ECM's regardless of application on MOPAR products. The same pins are hooked to the same sensors making it a lot easier to build or troubleshoot a wiring harness. You can blend the existing body harness and dash gauges to the donor harness or add wires to the 4-cyl harness. You can integrate the existing fuse blocks and PDC under the hood into the MOPAR swap, something not as easily done on a GM or other swap.

On a GM Vortec swap, you'll need a stand-alone harness that runs the engine and emissions controls with possibly the transmission and fuel pump/sender. It will have to have a MIL lamp (check Engine) light on it and it's easier to have a separate fuse block for all that. There are lots of people who build harnesses and one I highly recommend is over on Pirate plus is a vendor for all things Gen III/IV/V related, talk to Wayne Heartwig I believe his company is called 150tunes.com . I have used his services on a few GM Gen III/IV swaps and he has built me harnesses that passed the strict California Referee inspections first try. Everything plug-&-Play worked like a champ and my scan-tool worked perfectly. He also supports tuning for performance or economy, I can't say enough good things about his work.

There is a lot more I myself and others such as @Wildman can share in more posts.

I just wanted to start the conversation you need to have and be realistic about what you are getting yourself into here in plain talk, no B.S. or spin.

I loved doing the swaps and I loved the outcome in MOST of the swaps but not everyone can fab or wrench like I can so be prepared, information is your friend here.

Parts:

Engine with all drive accessories DONOR

ECM and engine bay harness DONOR

Emissions controls and evap. controls DONOR

Transmission DONOR or ELSEWHERE if your donor didn't have what you wanted.

Motor Mounts AFTERMARKET (Advanced Adapters, M.O.R.E. or Novak)

Transfer case adapter (Aftermarket or not needed if original MOPAR TRANS)

Exhaust catalytic convertors DONOR

Exhaust O2 sensors & bungs DONOR

Exhaust header piper DONOR

Starter DONOR

Fuel pump/sender (DONOR or Original Jeep if MOPAR SAME FAMILY BUS)

Gauges (FACTORY if MOPAR SAME BUS otherwise Aftermarket or from GM donor on Vortec)

Harness piping or loom (Aftermarket or FACTORY RE-USE)

Harness connectors (FACTORY IF MOPAR SAME BUS or Aftermarket)

Transmission shifter (FACTORY IF MOPAR or AFTERMARKET if other)

Throttle cable (DONOR or factory if MOPAR)

Radiator (AFTERMARKET or factory with adapter hoses) or

optional aftermarket radiator but for MOPAR 5.2L I've found the factory Jeep works and for GM 5.3 etc, it has to be aftermarket conversion radiator.

Driveshafts (PROBABLY CUSTOM LENGTH AFTERMARKET, usually if you have a lift you'll want double cardan anyways to keep angularity down)

Axles (Factory Dana 44's will survive unless really built engine) Also Dana 30 front will suffice in the meantime unless very high power and abuse such as burnouts and hard wheeling like rock crawling.

**The Dana 35 will not live long behind any V8 engine swap and should be swapped for Dana 44, 9" or an 8.8 Explorer axle at minimum to prevent future repairs.

More later.....

RR

Thanks @RangerRick your knowledge is very welcome as always. I wish I'd had your help before when I started my swap. Wondering now if I should source a GC engine harness instead of trying to use the Ram harness I have? Only found 1 on Ebay and he wants $300 for it.

If we were neighbors, I'd have probably helped you build your harness Rick.

The RAM harness will work fine it's just where things are and how they connect is the difference.

The simple answer to the reason I would use a GC as the donor is for all the ancillary parts that come with the donor vehicle and for the accessory drive brackets since they are as close as you can get to the TJ style PS pump and tuck in closer than RAM PS pump and brackets do.

The harness is going to have to be blended so it really doesn't make a difference except for if you get the books that I pictured on some of the other swap pages, they will have the EXACT color codes for the wires. This makes it super easy to follow along on re-wiring the ECM plugs.

The RAM has the same connections at the ECM plugs so the pins are all the same on MOPAR truck ECM's and JEEP ECM's.

I highly recommend the electronics wiring & diagnostics books for BOTH THE DONOR & JEEP the engine is going into. They will make life easy to follow the wiring and blend the two harnesses together.

I kept the charging circuit off my TJ and re-used it on the GC alternator that was on the engine.

I stripped all the wiring that was related to the PDC out one-by-one and put the necessary wiring into the PDC fuse box on the passenger fender of the Jeep. Since mine was an automatic and I was keeping an automatic transmission, I even added the TCR (Transmission Control Relay) into the Jeep PDC and labeled it as such. I used an un-used fuse spot and relay spot.

It is easy to take the PDC apart on the donor and the Jeep by removing the yellow plastic piece carefully that holds all the blade connector sockets into their positions in the PDC. If you do it right, it will look factory like Jeep built the harness and installed the V8 from the factory.

Remember to keep all emissions controls functional if you have to pass inspection or your Jeep will fail. California is really tough on that one and some other states are starting to follow suit.

All-in-all, there were only about 20 wires that had to be changed, added or spliced in total to make the GC harness play in the TJ correctly. What takes the time is it seems intimidating at first but if you study the wiring schematic and compare the GC or RAM engine bay harness and ECM wiring, you'll notice the similarities right away and spot where you need to make the changes.

I added the fuel pump and fuel sender sub-harness from the TJ directly to the GC harness because on the TJ it is kind of separate and could be pinned into the ECM plug positions in the RAM ECM. The fuel harness was built into the GC main harness in the vehicle so I chopped it all away and didn't use any of it. It was all different anyways so it had to go. If I recall, there were a couple of grounds that had to tie in, that's it.

I added the two plugs that go into the firewall from the Jeep harness to the GC harness following the pins on the ECM again. These connect to the fuse block and instrument cluster inside the Jeep. On later 1998+ Jeeps, they also contain the A/C signals for the dash controls. 1996-1997.5 the A/C clutch wires come out of the HVAC box next to the air conditioning lines and are totally separate from the rest of the harness. I added the A/C to both 1997's I converted to V8 because both were base model "S" 2.5's. The nice thing is they were also both automatics from the factory so it was easy to keep the GC automatic transmission.

If you are converting to a manual transmission, you have to have the ECM programmed to delete the transmission or you get error codes. If you can find a manual RAM truck in the salvage yard with the 5.2 or 5.9L engine, that would eliminate having to pay a shop to program the automatic out of the ECM when running a manual stick shift.

RR

Also on my 1996 manufactured TJ, the emissions evap canister was vacuum powered only. On all 1998+ MOPAR went to electronic vacuum pump leak testing and solenoid system. I used the emissions controls out of a 1998-1999 TJ to make the system work because the GC used the same kind of electronic leak down pump and solenoid arrangement since 1996 on their emissions management scheme. By switching to the newer system of the two that the 1997 or 1998 GC uses, I kept it all working and in tact so it passed California emissions testing straight away with zero issues.

This is important and also again, remember the 1997 RAM ECM will not run your 1996+ TJ dash gauges, you must use a 1998 or 1999 ECM from a RAM truck to make the gauges work properly.

I had a spare 1997 ECM as a "get me home" backup just in case the 1998 RAM ECM should have ever failed when out wheeling.

Don't forget to look at Hotwire auto's swap grid for ECM BUS compatibility with your year TJ and engine ECM swap donor. Make sure they match or you'll have other headaches too.....

RR

This is important and also again, remember the 1997 RAM ECM will not run your 1996+ TJ dash gauges, you must use a 1998 or 1999 ECM from a RAM truck to make the gauges work properly.

I had a spare 1997 ECM as a "get me home" backup just in case the 1998 RAM ECM should have ever failed when out wheeling.

Don't forget to look at Hotwire auto's swap grid for ECM BUS compatibility with your year TJ and engine ECM swap donor. Make sure they match or you'll have other headaches too.....

RR

I have the factory repair manuals for both my 97 TJ and the 98 Dodge Ram that the truck wiring harness came out of.

I've been spending some nights going thru the two manuals and making notes about what is different between the two harnesses. Been making notes next to each plug showing what circuit each plug goes to and what wires are different.

I don't plan to tackle my wiring harness until I have the engine sitting on the engine bay so I can get all my lengths right. I am keeping the auto transmission which is why I plan to use the Ram harness and meld the TJ circuits I need into it. Plus I'll remove any wires I don't need from the Ram harness.

I have a Premier Power welder so my alt wiring is really different than stock. One hurdle is the speed sensor that is in the STaK's t-case. It is the one used in the super short SYE kits & like the Rubicon sensor I have been told. So I had to get a Superlift TruSpeed calibrator to make my speedo work.

I've been spending some nights going thru the two manuals and making notes about what is different between the two harnesses. Been making notes next to each plug showing what circuit each plug goes to and what wires are different.

I don't plan to tackle my wiring harness until I have the engine sitting on the engine bay so I can get all my lengths right. I am keeping the auto transmission which is why I plan to use the Ram harness and meld the TJ circuits I need into it. Plus I'll remove any wires I don't need from the Ram harness.

I have a Premier Power welder so my alt wiring is really different than stock. One hurdle is the speed sensor that is in the STaK's t-case. It is the one used in the super short SYE kits & like the Rubicon sensor I have been told. So I had to get a Superlift TruSpeed calibrator to make my speedo work.

Last edited:

I'm assuming when you say "make my speedo work" you're referring to correcting the speed with the size of tire and gearing right?

My 1998 I just hooked up the speedo tone ring output from the NV-241OR Rock Track straight up to the TJ speed sensor input. I made a small adapter so there was no cutting or splicing, just a couple of plugs to adapt.

Also on the AA Atlas-II I have.

Are you getting the big picture looking over the wiring and schematics you have? Can you see the relationship and how similar the ECM's are in both the RAM truck and your JEEP? All pins are the same on all ECM's of those years except if they are populated or not and if the feature exists in the ECM itself.

RR

My 1998 I just hooked up the speedo tone ring output from the NV-241OR Rock Track straight up to the TJ speed sensor input. I made a small adapter so there was no cutting or splicing, just a couple of plugs to adapt.

Also on the AA Atlas-II I have.

Are you getting the big picture looking over the wiring and schematics you have? Can you see the relationship and how similar the ECM's are in both the RAM truck and your JEEP? All pins are the same on all ECM's of those years except if they are populated or not and if the feature exists in the ECM itself.

RR

I'm assuming when you say "make my speedo work" you're referring to correcting the speed with the size of tire and gearing right?

My 1998 I just hooked up the speedo tone ring output from the NV-241OR Rock Track straight up to the TJ speed sensor input. I made a small adapter so there was no cutting or splicing, just a couple of plugs to adapt.

Also on the AA Atlas-II I have.

RR

My speedo wouldn't work with the sensor that STaK's is using. I had to get a TruSpeed to make it work. But it's been years since I did this so I don't remember if I drove it first or not to see if it would work. I need to find a new sensor for my t-case as one of the wires are about to break right at the sensor.

@Wildman I've been on this website for awhile researching and I keep running into your name on the comments. I think I have a very good idea based off what you gave me for info. But I am hoping to maybe talk to you over the phone to ask a few questions on swapping my Jeep 2.5 l engine to a 5.2 l engine as you mentioned before. If you see this comment please, please, please, reach out to me at (620)290-4070, texting and calling both work, thank you!!!