Can you not bolt on an OEM spindle?After explaining what I was seeing, he said he meant to convey that they calpers from the F-350 work with their knuckle, but the hub and the rotor are custom machined to run on their spindle.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nashville TJ's Build - Continued

- Thread starter NashvilleTJ

- Start date

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

I spoke with Dynatrac yesterday and ordered the front hub / rotor assembly that I need for the ProRock. They apparently run a custom spindle, a custom hub, and a milled rotor. Nearly a grand with shipping.

ProRock 60

#partsyoucantgetanywhereelse

Or more likely, off the shelf parts that they just won't tell you what they are.

Anyway, they have the hubs, but need to mill the rotors. Prolly a week or two before I see them. I really wish they were more clear about that when I first spoke to them a month ago and they told me the Ford pieces would work. But, it is what it is...

I can return the rotors, but the hubs I bought from a dude on e-bay for $400, so I'm stuck with them. But, it is still what it is...

So to kill time while I'm waiting, I tackled the brakes. My original master cylinder was a half ton unit with a 1 1/8" bore piston. The total surface area on the 1 ton brakes is much greater than my old setup, and both the 97 F-350 (my font calipers) and the Chevy 2500 HD (my rear calipers) run a 1 5/16" bore MC.

I spoke to Vanco (I run their hydroboost setup) and they suggested I move up to their larger MC which is the 1 5/16".

The unit came with a nice bench bleeding kit - so that was first on the list:

View attachment 224058

I did not want to have to wait until getting the golden Dynatrac hub/rotor assembly to bleed the brakes, so I fiddled a little and got the new calipers and pads installed using the old rotors. This will allow me to bleed the brakes.

The new calipers really dwarf the old rotors.

View attachment 224059

Seeing the shit you have to deal with from dynatrac how everything has to purchased from them definitely has me not considering them for 60s in future. I think currrie uses standard outer stuff so does carbon and ecgs.

I’m not sure it’s not a factory spindle - I just don’t which factory...Can you not bolt on an OEM spindle?

It has 6 bolts, like a GM, but the knuckle takes Ford brakes. The Ford spindle has 5 bolts. I did talk to a guy yesterday and he told me a buddy had swapped his ProRock over to standard spindles, hub and brakes, but by then I’d already pulled the trigger on the Golden Dynatrac parts.

Last edited:

After going at this thing so hard for so long, it's tough to come to a stop while waiting for parts. But I am getting to the point that when the front hub/rotors show up, I'll just have to slap those in and I'll be done. So, a little more house cleaning today.

First up, I pulled out my nitrogen setup and recharged the rear pneumatic bumps since I'd deflated them to do the flex testing. It's another one of those "don't need it often" tools, but when you need it there is not substitute. 275 psi, and I checked that off the list.

First up, I pulled out my nitrogen setup and recharged the rear pneumatic bumps since I'd deflated them to do the flex testing. It's another one of those "don't need it often" tools, but when you need it there is not substitute. 275 psi, and I checked that off the list.

The next task was to get the axle alignment done. This method has always worked well for me. With the rig up on stands, using a two plane laser, a chalk line and a ruler, I first laid out the center line on the floor. Using that line as a basis, I then use some geometry and draw a perpendicular line just in front of the front axle.

Then the same in the rear.

With the layout done, I measure and mark dead center on the front and rear axle. Using the laser, you again fire it down the centerline, and comparing the laser line (which also projects upward to the jeep) with the marks on the axle tells you instantly whether it needs to go driver or passenger. Works every time.

Once you get each axle centered, then you follow a similar procedure to get them straight. Fire the laser down the lines parallel to the axles, and then measure the distance from the projected laser line to each end of the axle, and you adjust the corners until you get it straight.

After that, I double check the centerline again to make sure it has not moved. Finally, I double check my toe and call it good.

Then the same in the rear.

With the layout done, I measure and mark dead center on the front and rear axle. Using the laser, you again fire it down the centerline, and comparing the laser line (which also projects upward to the jeep) with the marks on the axle tells you instantly whether it needs to go driver or passenger. Works every time.

Once you get each axle centered, then you follow a similar procedure to get them straight. Fire the laser down the lines parallel to the axles, and then measure the distance from the projected laser line to each end of the axle, and you adjust the corners until you get it straight.

After that, I double check the centerline again to make sure it has not moved. Finally, I double check my toe and call it good.

Last edited:

Earlier this week I received the Willwood e-brake cable assembly. I'm really happy with it. The cable and case are every bit as heavy as the stock cable. It came with all the hardware to make it work.

After mocking it up, I cut it to length. Since I run this setup as a cutting brake, I needed to install it a bit differently than designed, but the only difference was to put a stop at the end of each individual cable.

Then it was just a matter of running it. Here is my center mount modified to operate each brake independently.

And here is the business end.

Adjusted it and tested it. It feels like it is working, but I'll have to do a final adjustment after I get it back in the road.

After mocking it up, I cut it to length. Since I run this setup as a cutting brake, I needed to install it a bit differently than designed, but the only difference was to put a stop at the end of each individual cable.

Then it was just a matter of running it. Here is my center mount modified to operate each brake independently.

And here is the business end.

Adjusted it and tested it. It feels like it is working, but I'll have to do a final adjustment after I get it back in the road.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Is that a drum in hat E-brake or is the handle actuating the caliper? I'm trying to figure out my own cutting brake setup now.Earlier this week I received the Willwood e-brake cable assembly. I'm really happy with it. The cable and case are every bit as heavy as the stock cable. It came with all the hardware to make it work.

View attachment 225566

After mocking it up, I cut it to length. Since I run this setup as a cutting brake, I needed to install it a bit differently than designed, but the only difference was to put a stop at the end of each individual cable.

View attachment 225567

Then it was just a matter of running it. Here is my center mount modified to operate each brake independently.

View attachment 225568

And here is the business end.

View attachment 225569

Adjusted it and tested it. It feels like it is working, but I'll have to do a final adjustment after I get it back in the road.

View attachment 225570

It's drum in hat setup. If you are interested, I can post up how I did mine.Is that a drum in hat E-brake or is the handle actuating the caliper? I'm trying to figure out my own cutting brake setup now.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Ya please more info is always better and not many tjs have turning brakes. Maybe include how often and hope you use it?It's drum in hat setup. If you are interested, I can post up how I did mine.

Happy Valentines Day, Dudes.

This is what my Valentine got for me...

This is what my Valentine got for me...

The last bit of fab work I had to do for the 14 Bolt project was to modify my tire carrier. The tire carrier swings down and away, and the wheel is held between the swing down assembly and the portion above the rear bumper. Here it is in the up position:

You can see that it mounts such that the front of the wheel faces out, and consequently the wheel mount attaches to the front of the wheel. Here it is in the down position:

And without the tire:

You can see that it mounts such that the front of the wheel faces out, and consequently the wheel mount attaches to the front of the wheel. Here it is in the down position:

And without the tire:

There were two issues which I had to address. First was changing the bolt pattern to fit the 8x6.5 wheel - which was the easy part. The problem was that the carrier was designed specifically to fit the dimensions of the Spyderlocks, and that created two issues with the Racelines. The backspacing is 4.5" vs. the 3.5" on the Spyderlocks, and also the face of the Racelines around the studs is not flat like the Spyderlocks. You can see what I mean here:

So the old mount was not going to work, and it had to go. The plasma cutter was the first step:

Then the death wheel:

And finally a 24 grit flap disk to get it down to the bare tube:

So the old mount was not going to work, and it had to go. The plasma cutter was the first step:

Then the death wheel:

And finally a 24 grit flap disk to get it down to the bare tube:

Last edited:

I was trying to figure out the easiest way to get the bolt pattern layout for the new mounting plate, when it dawned on me that I already had the perfect pattern: The front spacers:

Then it was just a matter of cutting a good circle out of some 3/8" plate. I've used this jig in the past to cut a circle with the plasma.

It works very well.

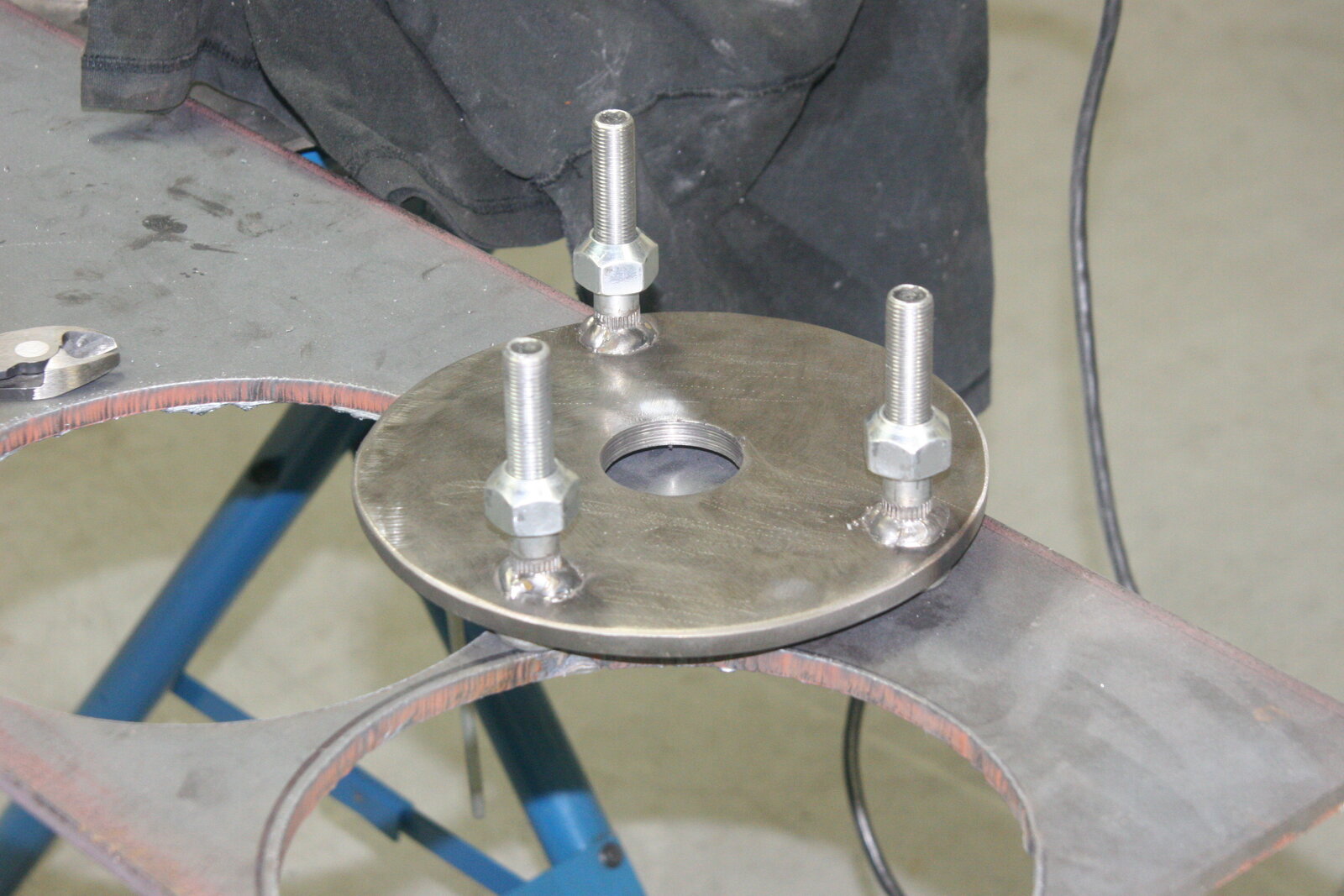

And then to the drill press for three holes to accept the 9/16" studs, a 1 3/4" center bore using a hole saw, a little clean up with the grinder, and here is the new mounting plate:

Then it was just a matter of cutting a good circle out of some 3/8" plate. I've used this jig in the past to cut a circle with the plasma.

It works very well.

And then to the drill press for three holes to accept the 9/16" studs, a 1 3/4" center bore using a hole saw, a little clean up with the grinder, and here is the new mounting plate:

To deal with the issue of the face of the wheel not being flat, I simply used a few lug nuts to create a standoff to the wheel.

This is how the new mounting plate drops onto the front of the wheel:

This is how the new mounting plate drops onto the front of the wheel:

Since the outer potion of the carrier is designed to fit flush with the tire, to position the plate is was a simple matter of laying the carrier on one of the wheels, and tacking it in place:

And then a weld bead on both sides of the plate...

...a quick test fit:

...and some paint:

...and it's all set to go back on the rig - which I can't do right now because the rig is on jack stands and too close to the shop door. I'll have to wait until I get the hubs/rotors from Dynatrac (which still have not shipped) to get it back on four wheels.

And now I'm just waiting for those hubs/rotors. Everything else is done. But when they do finally come it should be a quick wrap-up for the project.

I'm bummed because it looks like we will get some real snow tomorrow, and the Jeep is undrivable...

F-in Dynatrac.

...a quick test fit:

...and some paint:

...and it's all set to go back on the rig - which I can't do right now because the rig is on jack stands and too close to the shop door. I'll have to wait until I get the hubs/rotors from Dynatrac (which still have not shipped) to get it back on four wheels.

And now I'm just waiting for those hubs/rotors. Everything else is done. But when they do finally come it should be a quick wrap-up for the project.

I'm bummed because it looks like we will get some real snow tomorrow, and the Jeep is undrivable...

F-in Dynatrac.

B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

Nice quick mod on the tire carrier.And then a weld bead on both sides of the plate...

View attachment 226433

...a quick test fit:

View attachment 226434

...and some paint:

View attachment 226435

...and it's all set to go back on the rig - which I can't do right now because the rig is on jack stands and too close to the shop door. I'll have to wait until I get the hubs/rotors from Dynatrac (which still have not shipped) to get it back on four wheels.

And now I'm just waiting for those hubs/rotors. Everything else is done. But when they do finally come it should be a quick wrap-up for the project.

I'm bummed because it looks like we will get some real snow tomorrow, and the Jeep is undrivable...

F-in Dynatrac.

I'm in same boat just got real (rare) lowland snow and I have nos driveshafts!!

I've taken thousands of pictures of the rig over the years, and this by far is the saddest one...

Could be worse, could be out in that weather. At least it has a garage to rest in.I've taken thousands of pictures of the rig over the years, and this by far is the saddest one...

View attachment 226712

Ok, so admittedly I am struggling for things to do while waiting for the new hubs, but I knocked out a small detail on the rig today. The original setup on the front hub of the '60 included this custom caliper bracket from Dynatrac.

With the 1 ton brake setup I don't need the bracket anymore. But when I removed it, I was left with five long studs and one long bolt which was bottoming out. Also, the clearance to the inner ring on the spindle only allowed me to use a very thin wall, 3/8" drive socket to loosen or torque down the spindle.

Not a huge deal, and not likely to cause any problems - but, a little irritating. To ease my irritation, I thought I'd turn the bracket into a spacer and solve my bolt dilemma.

So I pulled out a sharpie and the plasma cutter.

Instant spindle spacer.

With the 1 ton brake setup I don't need the bracket anymore. But when I removed it, I was left with five long studs and one long bolt which was bottoming out. Also, the clearance to the inner ring on the spindle only allowed me to use a very thin wall, 3/8" drive socket to loosen or torque down the spindle.

Not a huge deal, and not likely to cause any problems - but, a little irritating. To ease my irritation, I thought I'd turn the bracket into a spacer and solve my bolt dilemma.

So I pulled out a sharpie and the plasma cutter.

Instant spindle spacer.