OP

motomick76

Guest

There are several ways to get fuel to the LS. TJ's have a 5/16" (8AN) fuel, and no return. This generation of LS has a 3/8" (6AN) feed, and 5/16" (8AN) return. Some other LS have a return-less system, so pay attention to which one you have. The TJ fuel pump also cannot handle the LS needs and there are several ways to tackle this too.

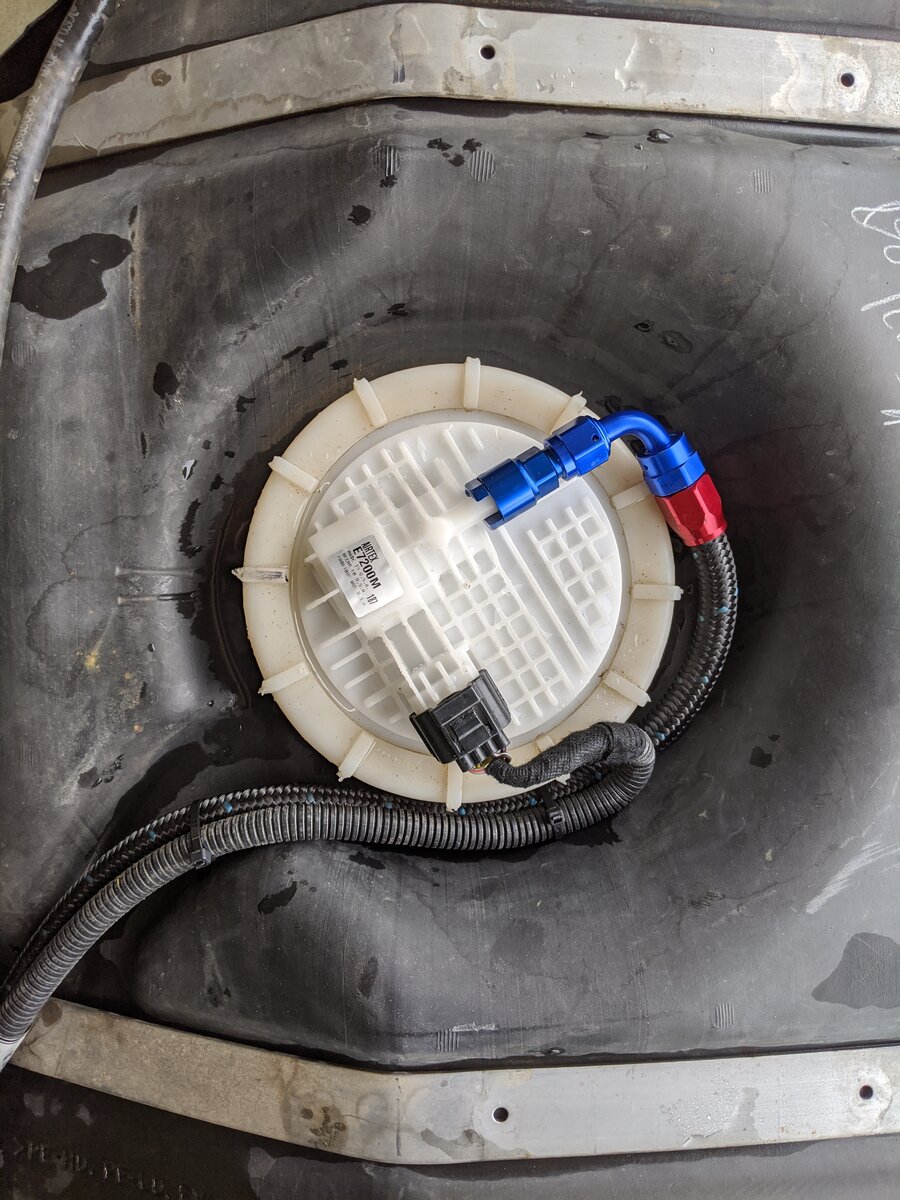

I chose to go with a 05-06 TJ fuel pump, which can deliver the minimum 55psi needed for the LS. Airtex E7200M is almost a drop in replacement. There is a index tab that must be cut off and the 00' harness will not plug directly in the pump. A bit of modification was needed to make it work.

Fuel line I chose to go with Russel 6AN Pro Classic Hose and Russel adapters. I kept the TJ 5/16" for the return line and got adapters from the TJ line to the LS motor. I chose a bulkhead adapter into the fuel tank for the return.

I chose to go with a 05-06 TJ fuel pump, which can deliver the minimum 55psi needed for the LS. Airtex E7200M is almost a drop in replacement. There is a index tab that must be cut off and the 00' harness will not plug directly in the pump. A bit of modification was needed to make it work.

Fuel line I chose to go with Russel 6AN Pro Classic Hose and Russel adapters. I kept the TJ 5/16" for the return line and got adapters from the TJ line to the LS motor. I chose a bulkhead adapter into the fuel tank for the return.