B00mb00m

The Church of Cutting Brakes of Atlas-Front Digs

Supporting Member

Ride of the Month Winner

I did hit a bit of a snaggle, which basically means I won't run the metal cloak fenders when I wheel. I do actually like them for sliding against obstacles. Ive been considering switching to savvy corners (aluminum) to save some weight but I think trimming the armor and removing fenders for trails should work. I could help the situation by moving my axle forward but I want my bumps and coils straight lined up and I'm already a bit forward at full bump. I'm making contact on the corner with about 1.25" of shaft showing.

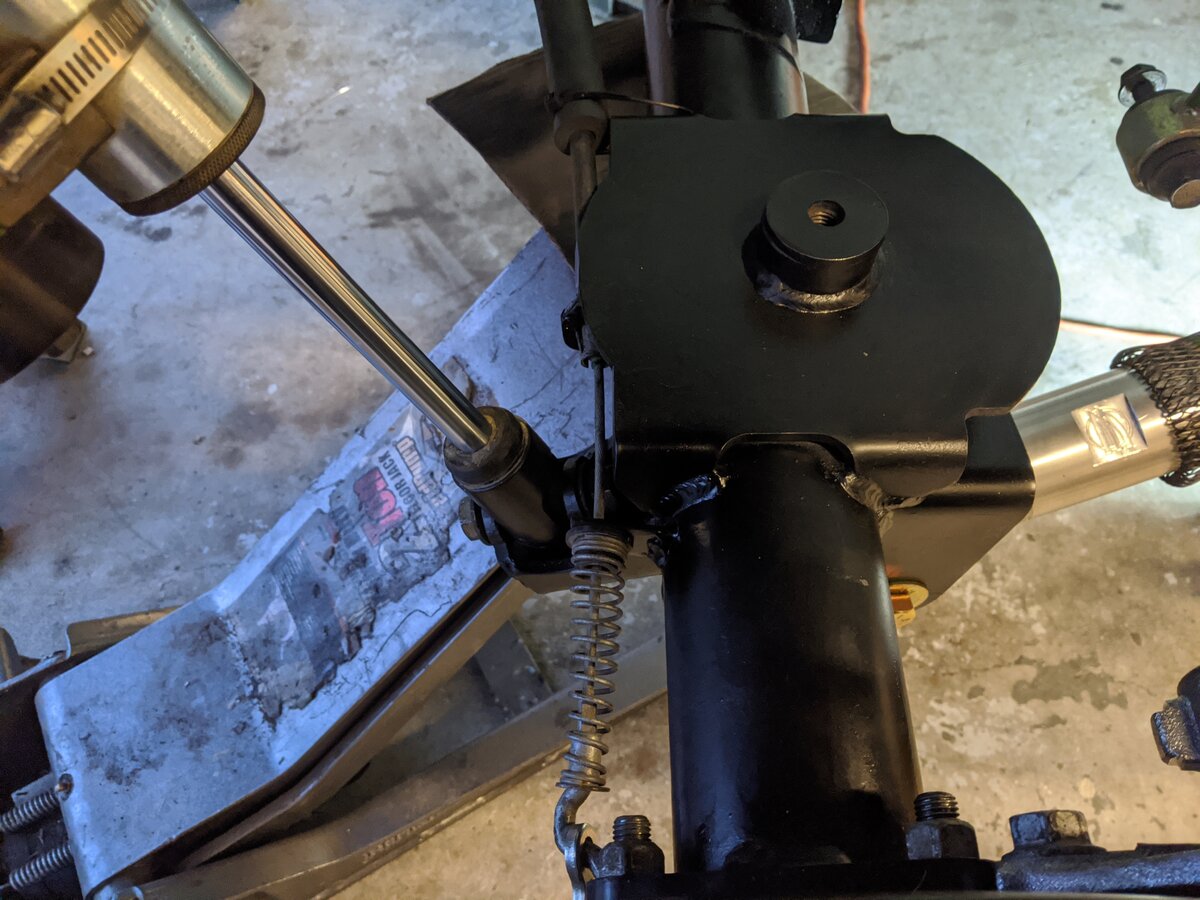

But I did get my ebrake cables ran and connected! One step closer. Summit delivery comes on Saturday so if everything goes well (and it never does) I could be about 90 percent complete with exhaust and the control arm soft line yet to complete next week.

I also got the JL rear caliper mounted up. It does clear 17" trail ready rims so I was happy to see that! I have a full set of Jk brakes that will be for sale...

But I did get my ebrake cables ran and connected! One step closer. Summit delivery comes on Saturday so if everything goes well (and it never does) I could be about 90 percent complete with exhaust and the control arm soft line yet to complete next week.

I also got the JL rear caliper mounted up. It does clear 17" trail ready rims so I was happy to see that! I have a full set of Jk brakes that will be for sale...

Last edited: