ayyye another 33s build, welcome to the clubso I want to build for 33's. I think this would get me right where I want to be without going absolutely insane with the mods and $$$.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2005 Rubicon; A Rubi Brother

- Thread starter Jamison C

- Start date

Dude this thing is going to be sweet. 33s are insanely fun and will get you through all but the hardest rock crawling stuff. Love the pintlers

That is correct. I did need to cut out the inner cross-member to fit the GR universal cross-member. I believe the guy I spoke with at UCF was Matt. He said since I cut out the inner cross-member to try and tuck the GR cross-member as close to the skid as possible without hitting it. The idea was any deflection on the skid would be transferred to the GR cross-member. The only unforeseen issue I ran into was the 3rd cat had to be moved a bit since the GR cross-member needed to share the same place.You’ll likely need to cut out the existing crossmember in the skid when you go to do the weld in crossmember. @Alex01 did a weld in I believe the genright so he can give input on how he likes that one!

You’ll likely need to cut out the existing crossmember in the skid when you go to do the weld in crossmember. @Alex01 did a weld in I believe the genright so he can give input on how he likes that one!

My first thought when looking at the skid crossmember was "oh that's gonna have to go"That is correct. I did need to cut out the inner cross-member to fit the GR universal cross-member. I believe the guy I spoke with at UCF was Matt. He said since I cut out the inner cross-member to try and tuck the GR cross-member as close to the skid as possible without hitting it. The idea was any deflection on the skid would be transferred to the GR cross-member. The only unforeseen issue I ran into was the 3rd cat had to be moved a bit since the GR cross-member needed to share the same place.

View attachment 296403View attachment 296404View attachment 296405

I do a bad job at browsing some of the more experienced build threads because they are literally thousands of posts long and it's hard to sit and sift through the chit chat. So I appreciate you guys throwing your experiences in here for me to learn from.

@Alex01 I'm curious how the bushings handle vibs at idle. Anything noticeable? @starkey480 mentioned the UCF LoPro really gets on your nerves after awhile. I want to be able to enjoy street drivability too. Did the bent tubing help free up space between the tub and atlas?

Are you trying to say you actually have a life and don’t sit on WTJ forum all day??I do a bad job at browsing some of the more experienced build threads because they are literally thousands of posts long and it's hard to sit and sift through the chit chat.

I did not notice any increased vibs. I don't think the bend helped with the atlas but it certainly didn't hurt. For $200, or whatever it was, it was worth it to me not to have to source the parts and cut the piping to fit.@Alex01 I'm curious how the bushings handle vibs at idle. Anything noticeable? @starkey480 mentioned the UCF LoPro really gets on your nerves after awhile. I want to be able to enjoy street drivability too. Did the bent tubing help free up space between the tub and atlas?

I wanna say yes but honestly I check this site more than I check my instagram or Facebook lol.Are you trying to say you actually have a life and don’t sit on WTJ forum all day??

Good to know. How low is the crossmember sitting below the frame rails? UCF ultra clearance is in inch tall at it's lowest point.I did not notice any increased vibs. I don't think the bend helped with the atlas but it certainly didn't hurt. For $200, or whatever it was, it was worth it to me not to have to source the parts and cut the piping to fit.

You could stuff it up that high. In my case it's about 2" down because I have the no bl ucf skid. If I clocked the atlas though I bet I could have fit the ultra high. I just didn't know that at the time but wish I would have went though route.Good to know. How low is the crossmember sitting below the frame rails? UCF ultra clearance is in inch tall at it's lowest point.

Are you trying to say you actually have a life and don’t sit on WTJ forum all day??

I have no life.

For those of you who don't know, I have been toying with the idea of an auto swap. In fact, I've religiously been scouring the interwebz for either a good price on a transmission or an entire donor jeep to do the swap. Last week my wishes came true when an entire drivetrain with an auto transmission, the wiring harness, and ECM from a 2005 Rubi (same as mine) came up for sale. I was quick on the draw and took it all home Friday night for $500. I'm extremely excited for this swap because there's a lot to figure out electrically and I'm up for the challenge.

I believe I could recoup the money I spent just off of the NSG370, with only 59k miles on it. I have no interest in the donor engine so I will be selling that too once I swap the necessary parts off of it and the main harness. The gentleman I bought this from had removed it all for an LS swap. The main harness is in rough shape as he tried to piggyback off of the original ECM to make the factory gauges work with the swap. Luckily the transmission wiring is all intact, with a simple cut between the main harness and the transmission harness. It's about twelve wires or so that need spliced back together.

Here's the transmission wiring sitting in place over the transmission.

My goal is to create a standalone harness for the transmission as my current engine harness is in much better shape than the donor one. I already have the green PCM plug (transmission plug) present on the engine side of the donor harness. The goal is to de-pin what I need from the donor harness and make one harness that will work with my current harness .

Mechanically I have everything I need to swap the transmissions, minus the shifter stuff, brake pedal, transmission lines, and radiator. I'm excited to see where this will take me. I've done a lot of research on wiring which I will explain in a separate post.

I believe I could recoup the money I spent just off of the NSG370, with only 59k miles on it. I have no interest in the donor engine so I will be selling that too once I swap the necessary parts off of it and the main harness. The gentleman I bought this from had removed it all for an LS swap. The main harness is in rough shape as he tried to piggyback off of the original ECM to make the factory gauges work with the swap. Luckily the transmission wiring is all intact, with a simple cut between the main harness and the transmission harness. It's about twelve wires or so that need spliced back together.

Here's the transmission wiring sitting in place over the transmission.

My goal is to create a standalone harness for the transmission as my current engine harness is in much better shape than the donor one. I already have the green PCM plug (transmission plug) present on the engine side of the donor harness. The goal is to de-pin what I need from the donor harness and make one harness that will work with my current harness .

Mechanically I have everything I need to swap the transmissions, minus the shifter stuff, brake pedal, transmission lines, and radiator. I'm excited to see where this will take me. I've done a lot of research on wiring which I will explain in a separate post.

So a quick update. I've being going through the wiring diagrams in the FSM, and while everything is MOSTLY straightforward, there are a few sensors that splice into some sensors on the main harness like cam sensor, IAC sensor etc. So the idea of a standalone harness might not be as simple. I don't mind tying everything in, but I'm missing the C109 plug that goes above the grey and black plugs in the middle of the engine harness above the valve cover. This plug carries the auto transmission wiring from the cab and PDC to to the PCM. I'll have to make a junkyard run to see if I can snag one from a 4.0 Cherokee. I imagine most of the plugs are similar.

I also threw in the auto PCM to see if it worked and if SKIM was active. The good news is that it's a remanufactured Mopar unit which means the original PCM (05-06) crapped out at some point, and this was a factory replacement. I actually thought of this when I was picking up the drivetrain so I'm glad this problem was addressed.

The bad news is when I fired it up, it ran great for about three seconds and then shut off Which means it has SKIM and I'm gonna have to get this thing reprogrammed. I didn't want to have to spend this money, but at the same time I've been wanting to add SKIM, so I could knock out two birds with one stone here and add it and my VIN since it needs programmed anyways.

Which means it has SKIM and I'm gonna have to get this thing reprogrammed. I didn't want to have to spend this money, but at the same time I've been wanting to add SKIM, so I could knock out two birds with one stone here and add it and my VIN since it needs programmed anyways.

I want to get the wiring done first, so I think I'm gonna set up a little workbench in my condo and get that all taken care of before I install the transmission. I'll document the process as I go with as much detail as possible.

I also threw in the auto PCM to see if it worked and if SKIM was active. The good news is that it's a remanufactured Mopar unit which means the original PCM (05-06) crapped out at some point, and this was a factory replacement. I actually thought of this when I was picking up the drivetrain so I'm glad this problem was addressed.

The bad news is when I fired it up, it ran great for about three seconds and then shut off

I want to get the wiring done first, so I think I'm gonna set up a little workbench in my condo and get that all taken care of before I install the transmission. I'll document the process as I go with as much detail as possible.

Might be a long shot But you get contact the guy you got the engine from and see if he doesn't have a spare key and then repent yourepair your lock cylinder to fit the New keySo a quick update. I've being going through the wiring diagrams in the FSM, and while everything is MOSTLY straightforward, there are a few sensors that splice into some sensors on the main harness like cam sensor, IAC sensor etc. So the idea of a standalone harness might not be as simple. I don't mind tying everything in, but I'm missing the C109 plug that goes above the grey and black plugs in the middle of the engine harness above the valve cover. This plug carries the auto transmission wiring from the cab and PDC to to the PCM. I'll have to make a junkyard run to see if I can snag one from a 4.0 Cherokee. I imagine most of the plugs are similar.

I also threw in the auto PCM to see if it worked and if SKIM was active. The good news is that it's a remanufactured Mopar unit which means the original PCM (05-06) crapped out at some point, and this was a factory replacement. I actually thought of this when I was picking up the drivetrain so I'm glad this problem was addressed.

View attachment 304856

The bad news is when I fired it up, it ran great for about three seconds and then shut offWhich means it has SKIM and I'm gonna have to get this thing reprogrammed. I didn't want to have to spend this money, but at the same time I've been wanting to add SKIM, so I could knock out two birds with one stone here and add it and my VIN since it needs programmed anyways.

I want to get the wiring done first, so I think I'm gonna set up a little workbench in my condo and get that all taken care of before I install the transmission. I'll document the process as I go with as much detail as possible.

Unfortunately I would need the SKIM module out of his Jeep as well and I believe he sold it awhile back.Might be a long shot But you get contact the guy you got the engine from and see if he doesn't have a spare key and then repent yourepair your lock cylinder to fit the New key

So it begins!

I want to get the wiring 100% figured out before I even think of swapping everything in. Mechanically this seems like a straightforward swap, so I don’t want to lay the Jeep up and get hung up on the wiring portion.

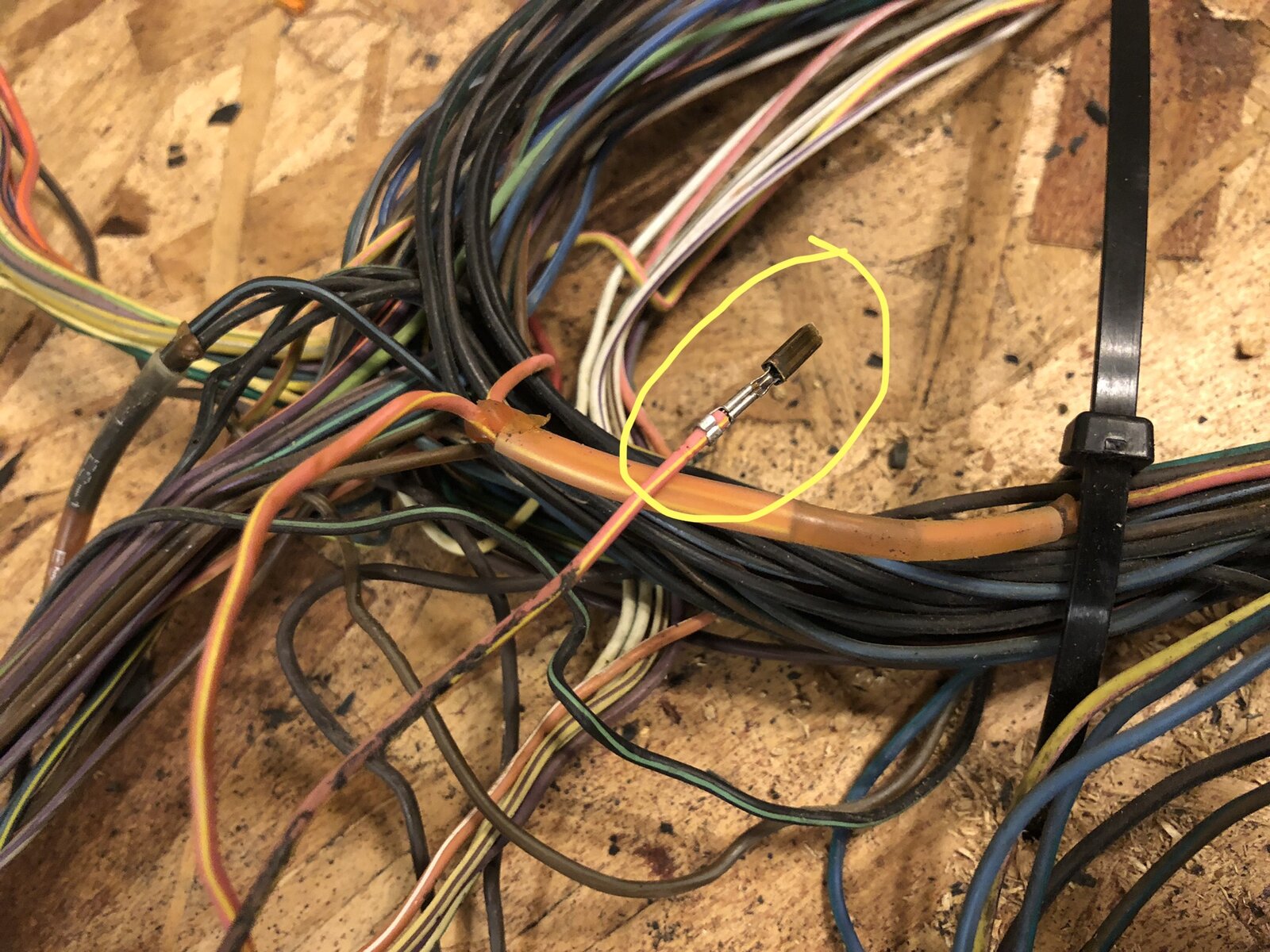

I started tonight by stripping back the wiring loom and tape from the harness. I didn’t bother with the engine sensors as I won’t need any of those, just everything from the PCM plugs down to the transfer case wiring.

To make sure I’m keeping the proper shape and lengths of the harness, I laid it out on some OSB and used zip ties to hold it to the board. Then started the stripping process.

I’ve religiously read about the magnum swaps from my time of my 02 and 00 ownership. I’m going to follow the same wiring harness guidelines that most of these guys use. Basically I’ll start with the PCM plugs, identify what I need in the harness, and de-pin the rest. There’s a few wires that run into the PCM 1 and 2 plugs that I need, but for the most part, most of the wires from those two plugs will be removed, leaving me with the PCM 4 plug.

Sadly the Jeep this harness came from had horrible leaks. Most of this wiring just looks plain black, so it will be challenging trying to trace through the harness and remove what I need. But I only need to add four plugs to my current Jeep so I don’t think it will be too trivial.

I’m starting a new job this week and phasing out of my old one, as well as attending school full time, so my time for this project will be somewhat limited. But if I spend an hour every night or two on this project, I think I could work through it pretty quickly. I’ll try to document as many details as I can about this swap.

Any advice anyone has for me I’ll happily heed!

I want to get the wiring 100% figured out before I even think of swapping everything in. Mechanically this seems like a straightforward swap, so I don’t want to lay the Jeep up and get hung up on the wiring portion.

I started tonight by stripping back the wiring loom and tape from the harness. I didn’t bother with the engine sensors as I won’t need any of those, just everything from the PCM plugs down to the transfer case wiring.

To make sure I’m keeping the proper shape and lengths of the harness, I laid it out on some OSB and used zip ties to hold it to the board. Then started the stripping process.

I’ve religiously read about the magnum swaps from my time of my 02 and 00 ownership. I’m going to follow the same wiring harness guidelines that most of these guys use. Basically I’ll start with the PCM plugs, identify what I need in the harness, and de-pin the rest. There’s a few wires that run into the PCM 1 and 2 plugs that I need, but for the most part, most of the wires from those two plugs will be removed, leaving me with the PCM 4 plug.

Sadly the Jeep this harness came from had horrible leaks. Most of this wiring just looks plain black, so it will be challenging trying to trace through the harness and remove what I need. But I only need to add four plugs to my current Jeep so I don’t think it will be too trivial.

I’m starting a new job this week and phasing out of my old one, as well as attending school full time, so my time for this project will be somewhat limited. But if I spend an hour every night or two on this project, I think I could work through it pretty quickly. I’ll try to document as many details as I can about this swap.

Any advice anyone has for me I’ll happily heed!

Small update:

Today I spent some time labeling all of the connectors and de looming more of the PCM.

To explain further from my previous post, I’m ripping everything out except the transmission stuff. The way I’m going to do this is I’m going to pick a labeled connector, find the corresponding wires in the PCM plug, unpin those wires from the PCM plug, and pull the connector and wires out of the harness. This will keep things neat, and allow me to retain any factory wiring if I need it. I wanted to salvage the harness but it’s too hacked up to be useful to anyone.

On a side note, I don’t think this stuff came out of a Rubicon. It’s the correct year, but I noticed the lack of locker wiring in the TC locations, and the TC switch is wrong. Upon investigating, the brown wire that is supposed to feed the TC switch signal to the instrument cluster is green, for a normal model. This doesn’t affect the transmission side of things, but that means I need an entirely new computer to keep my Jeep a Rubicon electrically. Oh well.

Today I spent some time labeling all of the connectors and de looming more of the PCM.

To explain further from my previous post, I’m ripping everything out except the transmission stuff. The way I’m going to do this is I’m going to pick a labeled connector, find the corresponding wires in the PCM plug, unpin those wires from the PCM plug, and pull the connector and wires out of the harness. This will keep things neat, and allow me to retain any factory wiring if I need it. I wanted to salvage the harness but it’s too hacked up to be useful to anyone.

On a side note, I don’t think this stuff came out of a Rubicon. It’s the correct year, but I noticed the lack of locker wiring in the TC locations, and the TC switch is wrong. Upon investigating, the brown wire that is supposed to feed the TC switch signal to the instrument cluster is green, for a normal model. This doesn’t affect the transmission side of things, but that means I need an entirely new computer to keep my Jeep a Rubicon electrically. Oh well.

Back with more, and I have lots of pictures for you all! Got lots of work done last night and tried to document my process best I could.

Here's what I started with vs. what I ended with last night.

Amazing how much wire is in these harnesses. I also have a ton of extra plugs and wires now if anyone needs any.

As for my process, I'll explain how to read and de-pin wires from the harness in order to remove a plug. The wires go all over the place, so it'll be up to you to find where they go using diagrams. Once you've figured out wiring paths based off of the wiring diagrams, you can begin.

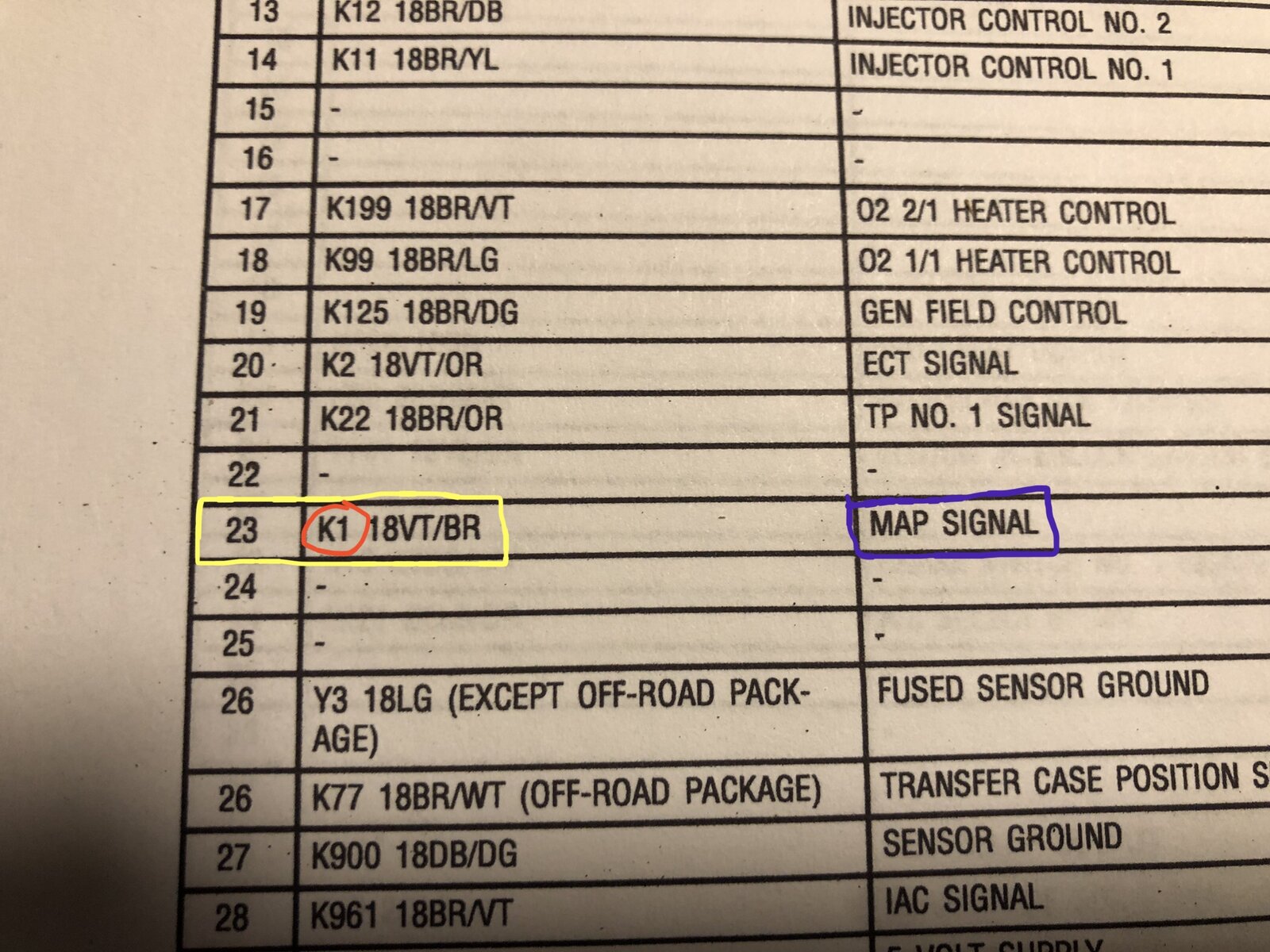

I'll start with the Manifold Absolute Pressure (MAP) sensor. I wanted to remove the wiring from the harness and pull the plug out in one fell swoop. Going through the FSM and picking the pinout connector, I found the shape of the plug and the corresponding wires.

We see three wires with specific colors; VT/BR (Violet with a Brown stripe or "tracer") which is the MAP Signal, DB/DG (Dark Blue with a Dark Green tracer) which is Sensor Ground, and YL/PK (Yellow with a Pink tracer) which is 5 Volt Supply. If we look through our FSM we see that all of these wires end up at the PCM plug. The 5 Volt Supply and Sensor Ground are shared by several sensors through various splices. Focusing on the wire specific to the MAP (VT/BR), I used the PCM pinout to figure out it's location in the 38-cavity plug. There are duplicates of colored wires used throughout the vehicle, so there's a special code given to a wire so a user isn't confused. You'll see "K1" circled in red on each connector description. That's a foolproof way of knowing this is referring to the same feed of wire. We can see the same code here.

The number "23" represents the wiring cavity in the PCM plug. Each PCM plug has 38 total possible cavities for wiring. I need to remove the VT/BR wire from cavity 23 to free up the first wire on my MAP sensor.

To open up the PCM plug, start by removing the back cover from the plug. Insert a little screwdriver into the slots circled in yellow on each side and pop the cap off.

Once off, slide it down the wiring a few inches to give yourself room to work. The white piece is a grommet to keep moisture out, remove this too.

Next focus on the front. Push in on the little tabs on each side circled in yellow and the front cover should pop off, exposing the pins.

Once removed, start locating the wiring you need to remove using your FSM. Cavity 23 finds me with a VT/BR wire which is our MAP Signal, ripe for removal.

Once removed, I pulled it back through the harness to the MAP sensor. First wire is unhooked! Next we'll move to Sensor Ground which is DB/DG. This wire shares several splices with other sensors, so I opted to just cut it coming from the connector at the first splice.

Lastly, I moved to my final wire; the YL/PK wire for 5 Volt Supply. This wires shares the same sensors as the DB/DG wire did, so I did the same thing by cutting the wire at the first splice. You can see the splice tucked under a few wires.

With all three wires free, I was able to remove the plug entirely from the harness and coil it up off to the side.

As another example, I used the same method with the Throttle Position Sensor (TPS). I located the wiring I needed and began the removal process.

I found my PK/YL wire and removed it. This is another 5 Volt Supply with multiple splices, but I opted to remove this wire from the PCM plug first using the pinout chart to find the right cavity.

Wire at the splice. I snipped the wire coming from the TPS connector at the splice.

I did the same with my shared DB/DG Sensor Ground and snipped the wire coming from the connector at the splice.

Then lastly I removed the BW/OR (K22) wire from cavity 21 in the PCM connector.

With all three wires free, I pulled the connector out and coiled up the wiring off to the side like I did with the MAP connector.

As you work, you'll be left with a jumbled mess like this, but don't worry. As you move along, the wires start to disappear and everything makes more sense.

This is the process that I used to remove all of the driver side sensors for the engine. I now have a somewhat neat pile of very much intact wires and sensor plugs that I can use for other things in the future.

There are still a few sensors left on the passenger side of the engine that need to go away, like CKP, CPS, Coil Rail etc. These share the same leg as the transmission wiring, so I decided to wait until tonight to knock them out. Removing everything on the driver side seemed like a good start and helped me make some major headway in reducing the size of this harness.

I'll try to update tomorrow or Saturday with my progress!

Here's what I started with vs. what I ended with last night.

Amazing how much wire is in these harnesses. I also have a ton of extra plugs and wires now if anyone needs any.

As for my process, I'll explain how to read and de-pin wires from the harness in order to remove a plug. The wires go all over the place, so it'll be up to you to find where they go using diagrams. Once you've figured out wiring paths based off of the wiring diagrams, you can begin.

I'll start with the Manifold Absolute Pressure (MAP) sensor. I wanted to remove the wiring from the harness and pull the plug out in one fell swoop. Going through the FSM and picking the pinout connector, I found the shape of the plug and the corresponding wires.

We see three wires with specific colors; VT/BR (Violet with a Brown stripe or "tracer") which is the MAP Signal, DB/DG (Dark Blue with a Dark Green tracer) which is Sensor Ground, and YL/PK (Yellow with a Pink tracer) which is 5 Volt Supply. If we look through our FSM we see that all of these wires end up at the PCM plug. The 5 Volt Supply and Sensor Ground are shared by several sensors through various splices. Focusing on the wire specific to the MAP (VT/BR), I used the PCM pinout to figure out it's location in the 38-cavity plug. There are duplicates of colored wires used throughout the vehicle, so there's a special code given to a wire so a user isn't confused. You'll see "K1" circled in red on each connector description. That's a foolproof way of knowing this is referring to the same feed of wire. We can see the same code here.

The number "23" represents the wiring cavity in the PCM plug. Each PCM plug has 38 total possible cavities for wiring. I need to remove the VT/BR wire from cavity 23 to free up the first wire on my MAP sensor.

To open up the PCM plug, start by removing the back cover from the plug. Insert a little screwdriver into the slots circled in yellow on each side and pop the cap off.

Once off, slide it down the wiring a few inches to give yourself room to work. The white piece is a grommet to keep moisture out, remove this too.

Next focus on the front. Push in on the little tabs on each side circled in yellow and the front cover should pop off, exposing the pins.

Once removed, start locating the wiring you need to remove using your FSM. Cavity 23 finds me with a VT/BR wire which is our MAP Signal, ripe for removal.

Once removed, I pulled it back through the harness to the MAP sensor. First wire is unhooked! Next we'll move to Sensor Ground which is DB/DG. This wire shares several splices with other sensors, so I opted to just cut it coming from the connector at the first splice.

Lastly, I moved to my final wire; the YL/PK wire for 5 Volt Supply. This wires shares the same sensors as the DB/DG wire did, so I did the same thing by cutting the wire at the first splice. You can see the splice tucked under a few wires.

With all three wires free, I was able to remove the plug entirely from the harness and coil it up off to the side.

As another example, I used the same method with the Throttle Position Sensor (TPS). I located the wiring I needed and began the removal process.

I found my PK/YL wire and removed it. This is another 5 Volt Supply with multiple splices, but I opted to remove this wire from the PCM plug first using the pinout chart to find the right cavity.

Wire at the splice. I snipped the wire coming from the TPS connector at the splice.

I did the same with my shared DB/DG Sensor Ground and snipped the wire coming from the connector at the splice.

Then lastly I removed the BW/OR (K22) wire from cavity 21 in the PCM connector.

With all three wires free, I pulled the connector out and coiled up the wiring off to the side like I did with the MAP connector.

As you work, you'll be left with a jumbled mess like this, but don't worry. As you move along, the wires start to disappear and everything makes more sense.

This is the process that I used to remove all of the driver side sensors for the engine. I now have a somewhat neat pile of very much intact wires and sensor plugs that I can use for other things in the future.

There are still a few sensors left on the passenger side of the engine that need to go away, like CKP, CPS, Coil Rail etc. These share the same leg as the transmission wiring, so I decided to wait until tonight to knock them out. Removing everything on the driver side seemed like a good start and helped me make some major headway in reducing the size of this harness.

I'll try to update tomorrow or Saturday with my progress!

Last edited:

Wow. That’s an impressive amount of work. Nice job.