Man, all you guys with TT are making me jealous. @Farmergreg @IPerkWVU . How beneficial has it been for you to be tucked?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2006 LJR "UCF skids and tummy tuck"

- Thread starter Farmergreg

- Start date

I did. It allows full voltage to the headlights to make them as bright as possible. Check out Danielsternlighting.com for the details, but the short version is you create a new harness for your headlights, and use the existing harness to trigger two new relays. The new harness is heavier Gage wire, direct to the battery, so you minimize voltage drop.I did not....is it a good idea?

I didn't measure my voltage drop before or after, so I can't tell you what the difference is... But I do know that my headlights are every bit as good as a modern projector beam setup...

Haven’t gotten to get off road since the install, trip got rained out a few weeks ago. There is a particular rock at Badlands that I got hung up on last time out, that is going to be the test next time I’m there.Man, all you guys with TT are making me jealous. @Farmergreg @IPerkWVU . How beneficial has it been for you to be tucked?

I did the middle option, no cutting or welding needed with the 241. Needed a cable shifter, adjustable rear upper CAs, and a new drive shaft. Did have to trim the rear spring perches after rotating the pinion up. Had 2.5 SL, 1.25 BL, and 1" MML installed prior. Needed the BL for sure. Used oem trans mount

Thank you that is very helpful information.

I am tempted to go this way for ease of install and still 2.5” over stockHaven’t gotten to get off road since the install, trip got rained out a few weeks ago. There is a particular rock at Badlands that I got hung up on last time out, that is going to be the test next time I’m there.

Man, all you guys with TT are making me jealous. @Farmergreg@IPerkWVU . How beneficial has it been for you to be tucked?

@JMT @IPerkWVU and I play in the same sandbox. I'd say it's helped tremendously with the break over.

Going back to my first trip in stock LJR form to the Badlands about a year ago just to figure out the shortcomings.... first thing in my mind was the "shovel" had to go.

About every moderate hill, wall, or rock out there would either hang up or scrape at the top.

Can it all be attributed to the TT? not really since I did the 3" JSPEC springs and 33" tires along with the TT before I ventured back to the ORV park.

Very happy with the combination though.

I'm probably trying shit I now that I shouldn't!

I

I did the middle option, no cutting or welding needed with the 241. Needed a cable shifter, adjustable rear upper CAs, and a new drive shaft. Did have to trim the rear spring perches after rotating the pinion up. Had 2.5 SL, 1.25 BL, and 1" MML installed prior. Needed the BL for sure. Used oem trans mount

^Yes @IPerkWVU it's fresher in your mind!

The middle option will work with stock trans mount if you have a BL.

Starrs

TJ Guru

I really like that wheel/tire combo. I would go as far as to say it’s perfect haha.

I really like that wheel/tire combo. I would go as far as to say it’s perfect haha.

If only I had got the spare.......

Starrs

TJ Guru

That was the best one! LolIf only I had got the spare.......

And some nameless S.O.B is out driving around with it!That was the best one! Lol

Keep in mind the only comparison I have is with the stock presumably tired springs. Pretty much echo what others have said, the top coils are tighter or closer but aren't touching each other. They ride good....but my daily is a 3/4 ton!

When I started the lift the end of October the LJR sat about 6" higher than original.

Changes made:

- Worn 10/32" 31" tires replaced with new 33"

- 1.25" Body lift

- 3" JSPEC springs

I just measured and they have settled about 3/8".

So the spring lift height is coming out fairly close to 3" if you take into account the original springs probably had sagged.

Edit to add: JKS is in Michigan so shipping was only 1/2 days.

Finished up my CB install:

Made an overhead mount for the CB (Uniden Pro 520XL per TJ Forum recs!):

SS Bracket rear taillight bracket. Didn't want to have to clean the powder coat off the black one for grounding and it blends in nice:

Made an overhead mount for the CB (Uniden Pro 520XL per TJ Forum recs!):

SS Bracket rear taillight bracket. Didn't want to have to clean the powder coat off the black one for grounding and it blends in nice:

Any more thoughts on those JSPEC springs? I am hoping to order some in the very near future. Just trying to build up finances a little right now after a VERY slow winter.

Maybe I missed it, but which shocks are you running. Also can you provide some pictures of the profile of your jeep with your current setup. Maybe some pictures with how much the springs are compressed? I'm currious about how much sag you had up front with the winch and if your top coils are fully compressed or not. My LJ appears to be setup similar to yours. So I am trying to figure out what to expect from the JSpec 3" coils.

Maybe I missed it, but which shocks are you running. Also can you provide some pictures of the profile of your jeep with your current setup. Maybe some pictures with how much the springs are compressed? I'm currious about how much sag you had up front with the winch and if your top coils are fully compressed or not. My LJ appears to be setup similar to yours. So I am trying to figure out what to expect from the JSpec 3" coils.

There is a gap between the coils as it sits.

My results pretty well mimic what @Steven Preyer wrote up in his thread.

My results pretty well mimic what @Steven Preyer wrote up in his thread.

Last Sunday fooling around at the Badlands ORV park, I pulled an @ac_ and bent my passenger lower control arm bracket toward the drivers side. Maybe the tire slipped off a rock? Flimsy azzed sheet metal crap.

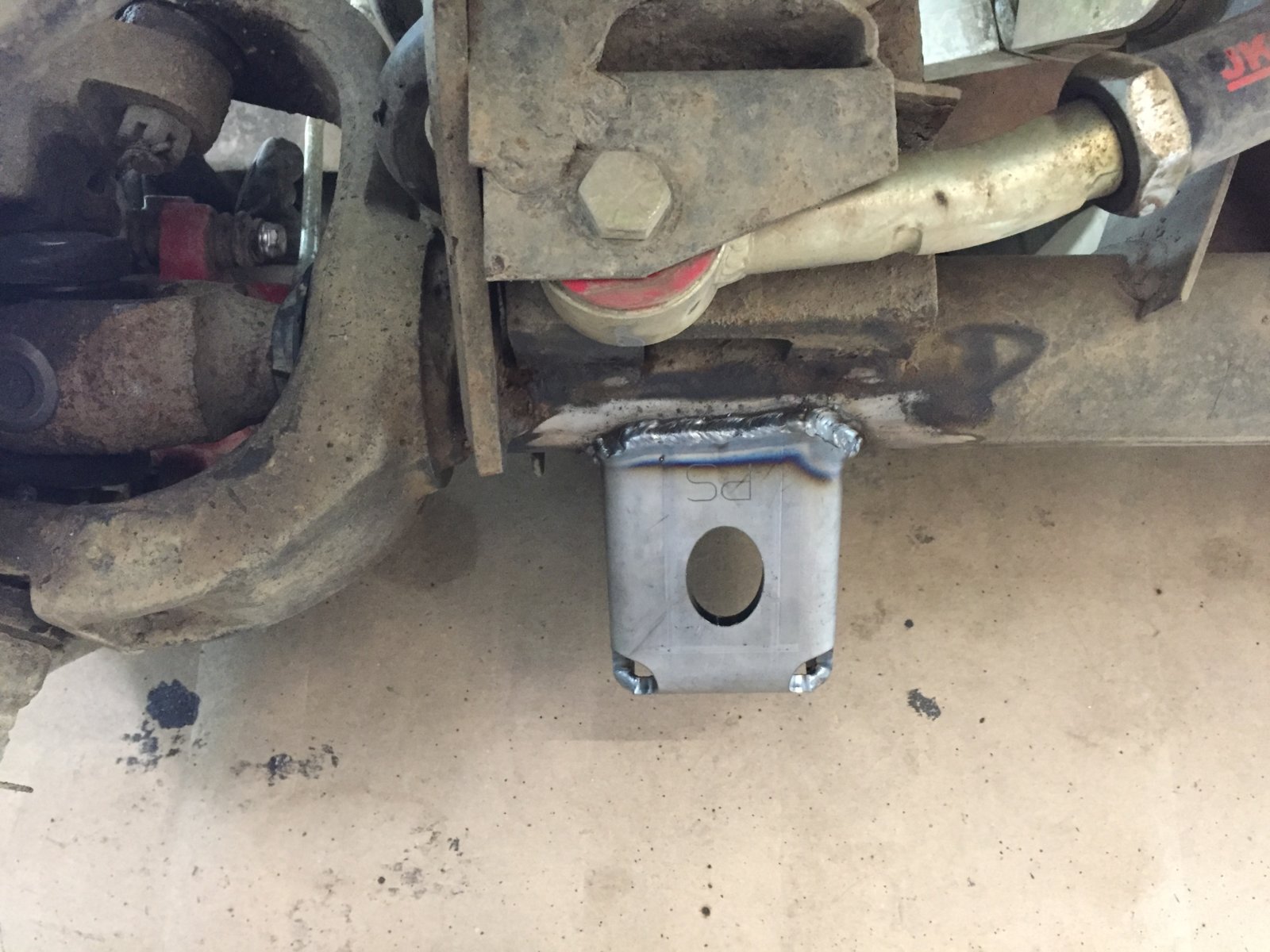

So I ordered some Arctec LCA brackets and installed them.

Bent original bracket with control arm loose hanging from the top:

Beefy Arctec bracket installed:

And painted:

So I ordered some Arctec LCA brackets and installed them.

Bent original bracket with control arm loose hanging from the top:

Beefy Arctec bracket installed:

And painted:

I thought I was seeing double for a minute here. You and @ac_. Whose next?Last Sunday fooling around at the Badlands ORV park, I pulled an @ac_ and bent my passenger lower control arm bracket toward the drivers side. Maybe the tire slipped off a rock? Flimsy azzed sheet metal crap.

So I ordered some Arctec LCA brackets and installed them.

Bent original bracket with control arm loose hanging from the top:

View attachment 91885

Beefy Arctec bracket installed:

View attachment 91887

And painted:

View attachment 91889

On the bright side it seems to be a weakness issue that has several aftermarket solutions. Mini skids before I bent it would have been easier than cutting and grinding off the original bracket.I thought I was seeing double for a minute here. You and @ac_. Whose next?

This was the first time I've had it on the hoist since November when I finished the lift and control arms. Wanted to give it a good looking over and make sure everything was tight, etc..

Found a couple jamb nuts on the control arms that were loose, oil pan skid missing 1 bolt, and the bent bracket.

So check your rigs over!

Smart advice! After the Moab trip I'll be giving a good looking over and changing fluids, checking brake pads, etc....On the bright side it seems to be a weakness issue that has several aftermarket solutions. Mini skids before I bent it would have been easier than cutting and grinding off the original bracket.

This was the first time I've had it on the hoist since November when I finished the lift and control arms. Wanted to give it a good looking over and make sure everything was tight, etc..

Found a couple jamb nuts on the control arms that were loose, oil pan skid missing 1 bolt, and the bent bracket.

So check your rigs over!