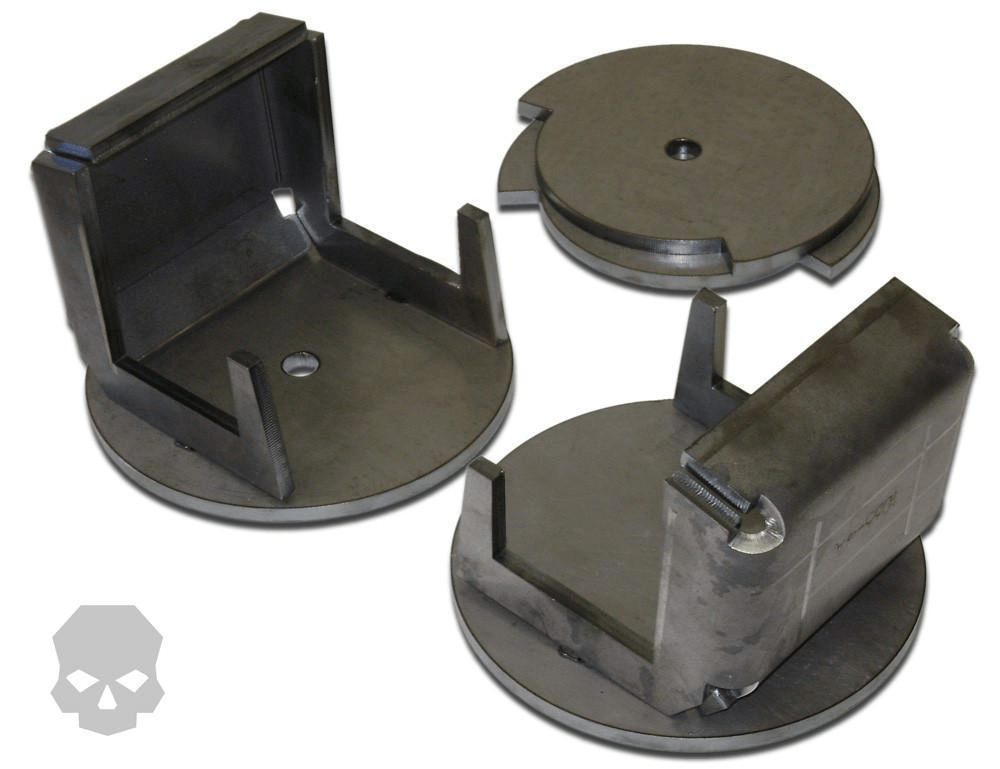

So, yesterday I ordered the new perches from Ballistic Fabrication. They're out of Arizona, if I recall correctly. Inexpensive, but appear to be solidly built.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'98 Sahara build: "Staying the Course"

- Thread starter Squatch

- Start date

xxdabroxx

TJ Addict

I try to justify everything thing that I put on mine as having a needed use. I may stretch my idea of needs just a little sometimesIt's hard to "stay the course", especially being on this forum. You see things and think to yourself, "Yeah, I want that!". Most of the time though, you don't need it, which is important to consider. Don't fall into the same trap I did with my last build, thinking I needed this incredibly built TJ, when in reality I didn't. Unless you're doing the type of wheeling that guys like Jerry and Blaine are doing, you're just wasting your money on parts you don't need. Up here in the PNW, a small lift and some 31" or 32" tires will be more than enough. Pair that with some lockers and a winch, and you've got a TJ that can go just about anywhere.

I'm one of the guys who doesn't exactly like the idea of scraping my nice, clean frame over rocks and other huge obstacles anyways.

Anyways, it's nice to see that other members besides myself are going for the more mild approach these days. Don't get me wrong, a lifted TJ on 35" tires done right looks really awesome, but to do it right, you're going to spend a considerable amount of money. In addition to that, failing driving a TJ on 35" M/T tires isn't going to be the most ideal thing.

Spent some time out in the garage today. Here are the results...

Just a reminder why I did it...

I obviously still have a long way to go, but I'm feeling pretty good about the way it's going. Spent about four hours doing what I enjoy. That always makes for a good day!

Just a reminder why I did it...

I obviously still have a long way to go, but I'm feeling pretty good about the way it's going. Spent about four hours doing what I enjoy. That always makes for a good day!

Last edited:

I figured I'd go ahead and straighten up the coils as a bonus to the main goal, which was simply to replace the rusted perches. It would almost be a waste not to, at this point. With the hidden rust I found between the welded tabs and the frame, I'm really glad I decided to do this.

The frame and TB bracket look good, those coil buckets are like a cavity in a tooth. Hopefully the new ones won’t collect mud and debris like the O.E. ones do.I figured I'd go ahead and straighten up the coils as a bonus to the main goal, which was simply to replace the rusted perches. It would almost be a waste not to, at this point. With the hidden rust I found between the welded tabs and the frame, I'm really glad I decided to do this.

I took a look at those, but couldn't help but wonder if those enormous side plates wouldn't hit on the frame-side track bar mount. They seem to be more style than structure, and the passenger side one would have to be trimmed to clear the TB mount, I suspect. That is, unless you were keeping the perches in basically the stock location. They might be fine, if that's the case. You'll have to let us know how it goes for you when you do yours.

The Artec relocation kit has trac bar provisions.Most of that just needs to be cut off.

The fish plates are beneficial to transmitting the local stress across a wider cross sectional area

Is this a true benefit to the rear relocation kit’s fishplate? I cant answer that. I highly doubt the load and stress there is as much as most people believe.

I understand that the factory coil mounts are mounted where they are for progressiveness.

Last edited:

Jeep didn't think big fish plates were needed there. Shifting them a few inches within the arch isn't going to change that. Artec is simply catering to it's market.

The stock location bending the spring combined with the stock spring creates a progressive spring rate. There are no true aftermarket progressive springs.

However the only real reason to move the spring seats is to make the bump stops line up again after a significant change to the pinion after a taller lift and raised skid. The Rokmen pictures show this very well.

The stock location bending the spring combined with the stock spring creates a progressive spring rate. There are no true aftermarket progressive springs.

However the only real reason to move the spring seats is to make the bump stops line up again after a significant change to the pinion after a taller lift and raised skid. The Rokmen pictures show this very well.

The only reason I purchased a relocation kit.However the only real reason to move the spring seats is to make the bump stops line up again after a significant change to the pinion after a taller lift and raised skid

So, if I'm only running the OME HD springs (2"-2.5" lift), do I run any kind of risk of misalignment of the bump stops as a result of relocating the spring perches?

So, if I'm only running the OME HD springs (2"-2.5" lift), do I run any kind of risk of misalignment of the bump stops as a result of relocating the spring perches?

Is the pinion raised?

Bringing the axle to full bump without coils installed will show you what is going on.

The rear axle hasn't been installed, but I'll be running stock control arms, so no, the pinion hasn't been raised. Now, that isn't to say that one day I wouldn't end up doing a tummy tuck, but that's really up in the air (pun intended).Is the pinion raised?

Bringing the axle to full bump without coils installed will show you what is going on.

That sure would seem to indicate I'd be okay moving it back. Seems like it would only get better with the relocation...I don't know if this is helpful, but this was my rear Dana 44 with pretty much stock arm lengths at full bump. It looks like you could move the upper perch at least an inch forward and still be lined up pretty well.

View attachment 113202

These are what I ordered. The plates are retainer plates, which I'm not sure that I'll need...

Realize this is a year old but am replacing my OEM rubber bushings (mounts) on my 98 sahara and was wondering what you ended up going with ( poly, rubber ,alum ) and brand as well, and how you feel about your choice? I appreciate the input.So, when it comes to the infamous (in some circles) body lift, I'd like to know if there is a noticeable difference in ride quality when going from the OEM rubber bushings (mounts) to either the polyurethane or aluminum ones. I've read reviews that touched on the subject, but I'd rather hear it from folks here. Also, whose kit would you recommend? I've got the OME HD 2" springs, and am considering a 1" body lift. I'd like to limit it to 1", but I see JKS BL's are 1.250". My main concern is that I'll be running 31" tires, and I don't want them to start looking on the smallish side due to the amount of lift. Strictly an issue of aesthetics, I'm embarrassed to admit. And no, @Chris, I am not concerned with the "butt crack" issue. LOL I'm working on a solution to that affliction, and figure I'll try it out on mine and see what others think of it before maybe producing some for the general population. So, what say you all? Poly or aluminum? Brand? Any and all input is appreciated. Regards...Squatch

@taat3, here's what I bought. Cheapest price I could find, and it included the bolts, as well.

https://www.amazon.com/dp/B009XUZ8QY/?tag=wranglerorg-20

https://www.amazon.com/dp/B009XUZ8QY/?tag=wranglerorg-20