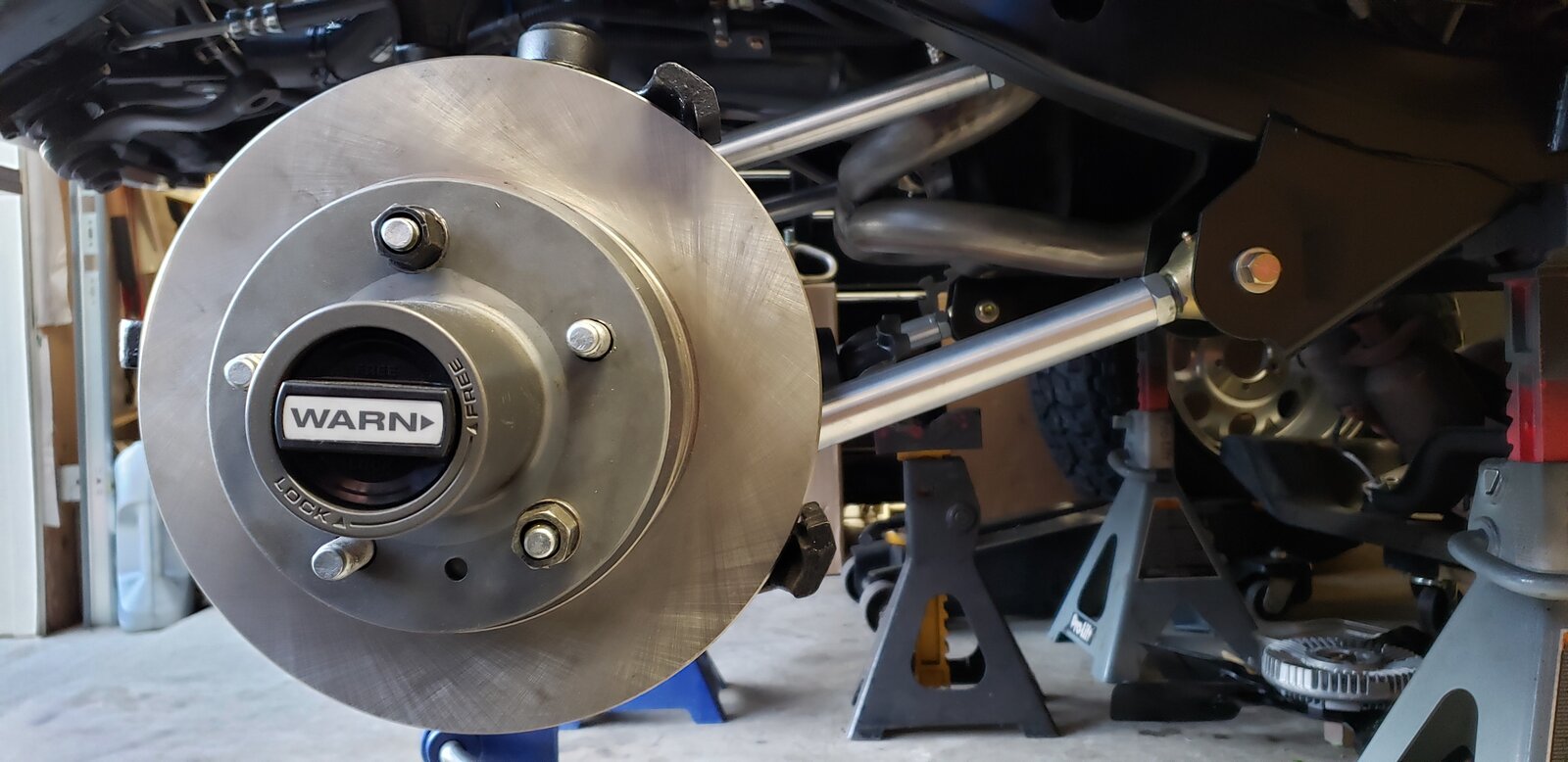

I was able to get all the studs in, but that outer axle shaft dust shield is totally defeating me. I had to stop before I broke something. How did you get them to go on?As expected, @mrblaine was spot on about installing the wheel studs for the lockout conversion with a press. I could get three installed using the standard press arbor plates. After that, no bueno. Had to get creative, found an old hub bearing, removed the wheel studs from it, and it worked perfect. I could use the center of the hub bearing as a way to push the wheel studs down with no issues!

View attachment 226061

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A lesson learned—keep it light and nimble!

- Thread starter Irun

- Start date

If you're talking about the rubber shield, I fought that one too. When I first tried installing it, I greased it and it kept popping off. I pulled it apart, cleaned all the grease off, then installed it dry. It went on easily, and stayed on!I was able to get all the studs in, but that outer axle shaft dust shield is totally defeating me. I had to stop before I broke something. How did you get them to go on?

After multiple configurations, I ended up sandwiching the bracket I made in front of the "V" brace, but behind the cooler. This strengthened up the cooler mount and allowed me to run all the bolts in from the front, while still clearing the condenser and grill. The PSC cooler cleared the grill by literally a couple sheets of paper, so I got lucky and didn't have to notch anything!You may have to notch the fins a bit to have some clearance on the inside of the grill.

I’m talking about the metal shield, the very first thing that goes onto the outer axle shaft.If you're talking about the rubber shield, I fought that one too. When I first tried installing it, I greased it and it kept popping off. I pulled it apart, cleaned all the grease off, then installed it dry. It went on easily, and stayed on!

I also tried greasing it and now I’m thinking that may be counterproductive. It keeps popping off.

Yep, no reason to grease that when installing it. Mine went on, but did take a little coaxing. If yours is a tight fit, meaning the shield is smaller, you could try heating it up before installing it. A MAP gas or similar torch will make quick work of heating it, or, if you don't have a torch, heat it in the oven at 400° for about 15 minutes.I’m talking about the metal shield, the very first thing that goes onto the outer axle shaft.

View attachment 245300

I also tried greasing it and now I’m thinking that may be counterproductive. It keeps popping off.

Your picture of parts has a couple that mine doesn’t have. I added a yellow arrow below and then yellow highlighting in the section with the hub seal.Check your parts and part numbers before proceeding.

In mine that little section with the hub seal only had the seal and the dust shield. It looks like there is another washer. It kind of looks like this one in another picture you posted:

Now the middle section under the yellow arrow has what looks like that snap ring, but it also has another part that I can’t make out. It sort of looks like a brass cylinder about the diameter of a finger. What’s that called and what it for?

The small brass piece was not used. I called Yukon to verify and they had no explanation of what it was, but did confirm it wasn't needed.Your picture of parts has a couple that mine doesn’t have. I added a yellow arrow below and then yellow highlighting in the section with the hub seal.

View attachment 245519

In mine that little section with the hub seal only had the seal and the dust shield. It looks like there is another washer. It kind of looks like this one in another picture you posted:

Now the middle section under the yellow arrow has what looks like that snap ring, but it also has another part that I can’t make out. It sort of looks like a brass cylinder about the diameter of a finger. What’s that called and what it for?

These parts you should have. They are the last two parts to go on, before installing the hublock set (Hub body). There's a grove on the end of the stub shaft that the snap rings goes into. To get it to fit, I used a small pry bar (with light pressure) to push the whole axle assembly in. Once that was done I could see where the snap rings went.

BTW, did you get your dust shield installed?

The shields are on. There was nothing elegant about how I got it done. It involved some heating, sanding, 2” PVC pipe as a driver, various hammers and a big rubber mallet. Oh and also channel lock pliers.

interesting that after heating them up they were slightly different colors.

interesting that after heating them up they were slightly different colors.

Last edited:

I went back to the seller for these. Just curious - do you know if there are other part numbers these are known by, or if replacements for these might be available locally? I tried searching the part numbers shown in the instructions but only found a discussion from an old Ford ranger forum talking about getting them from a junk yard.These parts you should have. They are the last two parts to go on, before installing the hublock set (Hub body).

Local Ford dealer can get equivalent parts for a 97 Ford Ranger (FOTZ-3B458-A and FOTZ-3B457-A) but they are overpriced (~$80 for two sets) and will take 3 days to arrive. Much cheaper options online.I went back to the seller for these. Just curious - do you know if there are other part numbers these are known by, or if replacements for these might be available locally? I tried searching the part numbers shown in the instructions but only found a discussion from an old Ford ranger forum talking about getting them from a junk yard.

But I did speak to the seller, just waiting for Yukon to send the tracking info for the missing parts, should be here in a few days.

Edit - just received tracking info, delivery is tomorrow.

Last edited:

Lots of challenges in my life now, but I did manage to carve out a few hours yesterday and this evening. The new converter and 02 sensors have been installed.

After sitting in the garage for more than 2 months, the Dana 30 is now under the Jeep, attached by the new Savvy arms.

Installing the supplied Currie 7/16 bolts for the front uppers meant drilling out the steel bushings on the axle side. Knowing how hard these are to drill, and that you can melt the bushing, I sharpened a drill bit and alternated drilling on them in small increments. When switching sides I sprayed the hot side down with WD40, letting it cool before starting again.

It ended up taking me a total of 45 minutes just to drill the two, but I was able to complete them both without having to stop and resharpen the drill bit. Having the axle out made the job more tolerable, and I didn't have to resort to using the stock upper bolts. I'm calling this one a small victory!

Installing the supplied Currie 7/16 bolts for the front uppers meant drilling out the steel bushings on the axle side. Knowing how hard these are to drill, and that you can melt the bushing, I sharpened a drill bit and alternated drilling on them in small increments. When switching sides I sprayed the hot side down with WD40, letting it cool before starting again.

It ended up taking me a total of 45 minutes just to drill the two, but I was able to complete them both without having to stop and resharpen the drill bit. Having the axle out made the job more tolerable, and I didn't have to resort to using the stock upper bolts. I'm calling this one a small victory!

Last edited:

Does anyone happen to know the size of the stock power steering feed and return hoses? The PSC cooler I installed has 8 AN fittings and I need to get adapters for the stock lines. FWIW, I bought the 8 AN version knowing I'll upgrade to a PSC pump and box sometime in the future.

The rubber hoses are 3/8” I.D. I have them here on the shelf along with the PSC OEM replacement pump.Does anyone happen to know the size of the stock power steering feed and return hoses? The PSC cooler I installed has 8 AN fittings and I need to get adapters for the stock lines. FWIW, I bought the 8 AN version knowing I'll upgrade to a PSC pump and box sometime in the future.

They forgot the spindle washers again! At least I got that useless brass spacer.Edit - just received tracking info, delivery is tomorrow.

I've had a rash of bad parts luck lately, so I feel your pain. Thankfully, the Jeep is only a toy, so I don't let it get to me.They forgot the spindle washers again! At least I got that useless brass spacer.

If you have a HP 30 disconnect axle with the vacuum shifter, that spacer is not useless. Surprised Yukon does not know that.They forgot the spindle washers again! At least I got that useless brass spacer.

Thanks! Now I see that it is shown on the last page of the instructions under the optional vacuum actuator section.If you have a HP 30 disconnect axle with the vacuum shifter, that spacer is not useless. Surprised Yukon does not know that.

If you have a HP 30 disconnect axle with the vacuum shifter, that spacer is not useless. Surprised Yukon does not know that.

I guess it's like everything else, it depends on who you talk to. When I called Yukon I was told they didn't know what it was, and that it was likely a packaging mistake. Good to know what it's really for. Now it won't be nagging me that I left something out!Thanks! Now I see that it is shown on the last page of the instructions under the optional vacuum actuator section.

So yeah, about that. Stu Olson says about 50 in lbs and the instructions say 50 ft lbs. I think the idea is that when you're done it should rotate about a quarter of a revolution if you give it a spin and let go.Once on, preload the bearing (I'll leave it to you to figure out how much preload to use)