It did sit for quite some time with coolant in #2 and #3 cylinders after the head got pulled off. I thought I had gotten it all sucked out when I originally pulled the head. It was almost a year later when I got back to working on it that I pulled the block out of the car and finally got all the coolant out.Looks like it had some moisture sitting in that hole eating at the cylinder wall. Hopefully it’ll clean up at .020 over. And the engine will be even better with a clean up bore and new rings and pistons.

Good call @qslim! If it’s apart that far, might as well do it right!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An Opportunity to Truly Help

- Thread starter Squatch

- Start date

Yeah, I don’t like to build engines that blow oil for 10k miles before falling apartLooks like it had some moisture sitting in that hole eating at the cylinder wall. Hopefully it’ll clean up at .020 over. And the engine will be even better with a clean up bore and new rings and pistons.

Good call @qslim! If it’s apart that far, might as well do it right!

The machine work is almost done on the block. The machinist will do the finish honing once the pistons come in. He wants to insure the bore matches the pistons. They'll also press the new pistons and rods back together. Hoping to have the piston set in hand by Monday.How's the progress coming along?

Sorry I haven't been posting more regular updates, I will do so going forward.How's the progress coming along?

Like reddvl said, machine work is almost done. Thankfully the corrosion that was identified was able to clean up completely with a .040 overbore which was completed late last week. The machinist wanted the pistons in hand to finish up the final hone, so I went ahead and ordered a set of 40 over pistons from Partsology. Those arrived this past Tuesday, but the damn kit was missing a wrist pin & set of circlips. They're sending me out a replacement kit which I should have over the weekend, and the plan is to get them to the machinist first thing monday.

I'll post pics of the engine once I get it back & do my best to make a little build thread with photos going forward

Yes this has turned into a lot longer process than we'd originally HOPED but as qslim has stated it's better to do this RIGHT the first time. Plus why would you want to give a rig to someone to help out if you were worried it might be a POS?

A few extra months of wait to give the man years worth of reliable transportation is a small price me thinks. Hell, played right, he could give it over to his eldest kid when they turn 16 and get their license. Priceless!

This right here. I'm not looking to just get it running. These are great cars, granted there was a batch of engines that had a problem with losing a headbolt thread & overheating, but my buddies who are still in the industry have rebuilt hundreds of them & never had a problem since. If you do the repair right the first time the thing will run until the Government makes gas engines illegal. Might not be the most exciting thing to get around in but the bright red TRD sport paint that I'm going to put on the valve cover should help.A few extra months of wait to give the man years worth of reliable transportation is a small price me thinks. Hell, played right, he could give it over to his eldest kid when they turn 16 and get their license. Priceless!

My father bought a 2009 new. It’s been his daily since then. It has 110k on it, tires, regular maintenance and that’s it. Car is dead nuts reliable.

I4 and auto.

I’ll be taking it over for a work car. I expect 400k out of it.

I4 and auto.

I’ll be taking it over for a work car. I expect 400k out of it.

Progress update - less than I'd hoped!

Like I mentioned before, the first set of pistons I ordered came missing stuff, so I returned them. The new set just got here on Thursday because FedEx can blow me (Sat in North Salt Lake for three days), and I've taken them to the machinist so he can get his final hone on. He said it'd be ready early next week.

Like I mentioned before, the first set of pistons I ordered came missing stuff, so I returned them. The new set just got here on Thursday because FedEx can blow me (Sat in North Salt Lake for three days), and I've taken them to the machinist so he can get his final hone on. He said it'd be ready early next week.

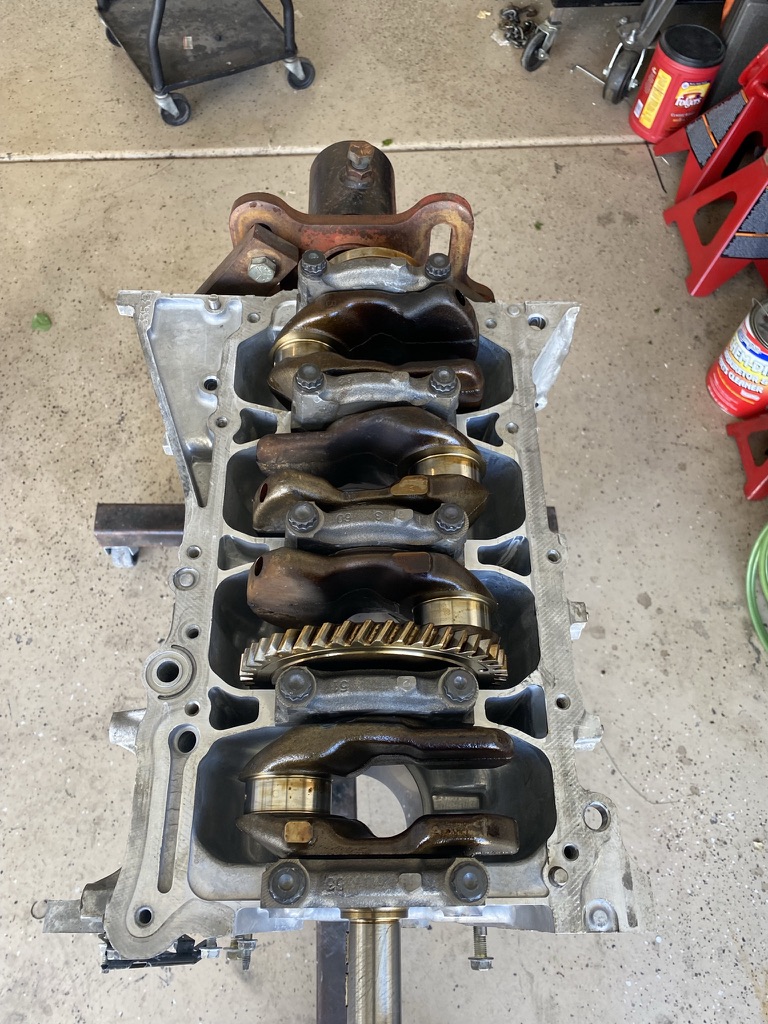

The block is back from the machine shop, nice & shiny.

Pecked away a little at it while the kids were at their friend's house. Swapped the connecting rods over to the new pistons, installed the rings, plopped the crankshaft in the block.

Looking muy bueno!!Pecked away a little at it while the kids were at their friend's house. Swapped the connecting rods over to the new pistons, installed the rings, plopped the crankshaft in the block.

View attachment 261585

View attachment 261587

View attachment 261586

View attachment 261588

I thought the machine shop was going to have to press the wrist pins out the old and back into the new... Bonus I guess, less costly this way...

Nah, I just did it in the garage. Toyota wrist pins float, all you need is a few taps with a socket & mallet to get the old ones out after you remove the circlips. Once everything is cleaned up you can push the new ones in by hand with a little assembly lube & a touch of heat with a small butane torch. . Getting the circlips in really blows when you don't have the right tool. Basically get it smashed in with your thumb as far as it will go & then push the rest in with a flathead. You have to push directly at your thumb, so the odds of stabbing yourself is just north of 100%. I'm glad it's a four cylinder.Looking muy bueno!!

I thought the machine shop was going to have to press the wrist pins out the old and back into the new... Bonus I guess, less costly this way...

Last edited:

Isn't that always the way it is! If there's potential for pain it's going to happen!!Nah, I just did it in the garage. Toyota wrist pins float, all you need is a few taps with a socket & mallet to get the old ones out after you remove the circlips. Once everything is cleaned up you can push the new ones in by hand with a little assembly lube. Getting the circlips in really blows when you don't have the right tool. Basically get it smashed in with your thumb as far as it will go & then push the rest in with a flathead. You have to push directly at your thumb, so the odds of stabbing yourself is just north of 100%. I'm glad it's a four cylinder.

Yeah, like you think real hard "okay, I'm pushing like a motherfucker with this screwdriver directly at my fingernail. It'll be fine though, I know what I'm - FUCK!!!!!".Isn't that always the way it is! If there's potential for pain it's going to happen!!

Edit: for the purpose of record keeping I went 6 for 8 on circlip installation without stabbing myself.

I have MANY scars from jobs that started with those exact same words!!!Yeah, like you think real hard "okay, I'm pushing like a motherfucker with this screwdriver directly at my fingernail. It'll be fine though, I know what I'm - FUCK!!!!!".

Just in case anyone has concerns, I'm following the factory manual to the tee & adhering to every note that the Japanese engineers offered to give:

Did it stick?Just in case anyone has concerns, I'm following the factory manual to the tee & adhering to every note that the Japanese engineers offered to give:

View attachment 261608