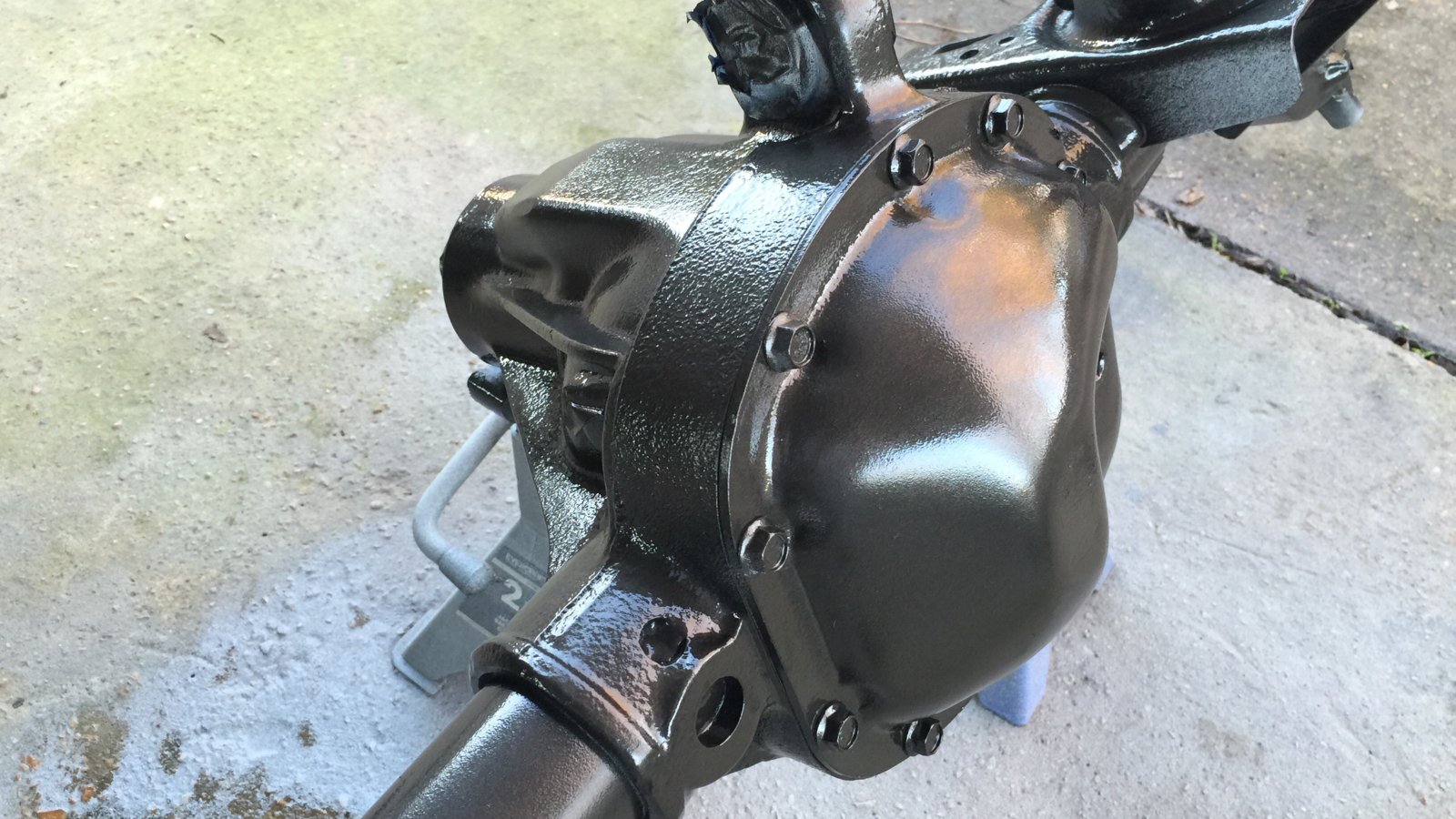

Okay, so after a ton of research and some experiments I finally painted the 1992 Dana 30 high pinion I took out of a trashed MJ.

(Re-gear/locker install will start in about two weeks when my last duck is fully dressed and covered.)

I won't go into all my reasons, but this is what I finally decided on and will now do to my Dana 44. I did it in four or five work days.

First Day

strip down housing of all parts

make repairs as needed to bracketey

Second Day

have housing bead blasted

clean housing interior of most of the media - some *will* get in there for sure

clean exterior with brake cleaner (non-residue formula and lint-free cheese cloth from Kroger)

spray on Rust-Oleum self-etching primer, following all instructions to the letter (4 coats)

allow this to cure for about a week (be patient! there is acid that MUST evaporate)

Third Day

scuff entire axle thoroughly with 320 grit

wash off residue with plain, old soap and water - I used Dawn

allow an hour to dry

apply two or three coats of white Rust-Oleum Clean Metal Primer

allow to fully cure for at least 48 hours

Fourth Day

wipe down with soap and water and allow to fully dry for an hour

apply four coats of Rust-Oleum "Stops Rust" Hammered paint

allow to cure/harden for a week or so

Takes forever but works well and is not costly. Benefits are that the self-leveling Hammered paint hides damage really well, is cheap and is easy to find in stores, pretty much always being in stock. The two primers work well with the bare steel and the Hammered paint.

(Forgot to snap a few pics with the Clean Metal Primer. Imagine this axle snowy white. That is pretty much it.) ;-)

(Re-gear/locker install will start in about two weeks when my last duck is fully dressed and covered.)

I won't go into all my reasons, but this is what I finally decided on and will now do to my Dana 44. I did it in four or five work days.

First Day

strip down housing of all parts

make repairs as needed to bracketey

Second Day

have housing bead blasted

clean housing interior of most of the media - some *will* get in there for sure

clean exterior with brake cleaner (non-residue formula and lint-free cheese cloth from Kroger)

spray on Rust-Oleum self-etching primer, following all instructions to the letter (4 coats)

allow this to cure for about a week (be patient! there is acid that MUST evaporate)

Third Day

scuff entire axle thoroughly with 320 grit

wash off residue with plain, old soap and water - I used Dawn

allow an hour to dry

apply two or three coats of white Rust-Oleum Clean Metal Primer

allow to fully cure for at least 48 hours

Fourth Day

wipe down with soap and water and allow to fully dry for an hour

apply four coats of Rust-Oleum "Stops Rust" Hammered paint

allow to cure/harden for a week or so

Takes forever but works well and is not costly. Benefits are that the self-leveling Hammered paint hides damage really well, is cheap and is easy to find in stores, pretty much always being in stock. The two primers work well with the bare steel and the Hammered paint.

(Forgot to snap a few pics with the Clean Metal Primer. Imagine this axle snowy white. That is pretty much it.) ;-)

Last edited: