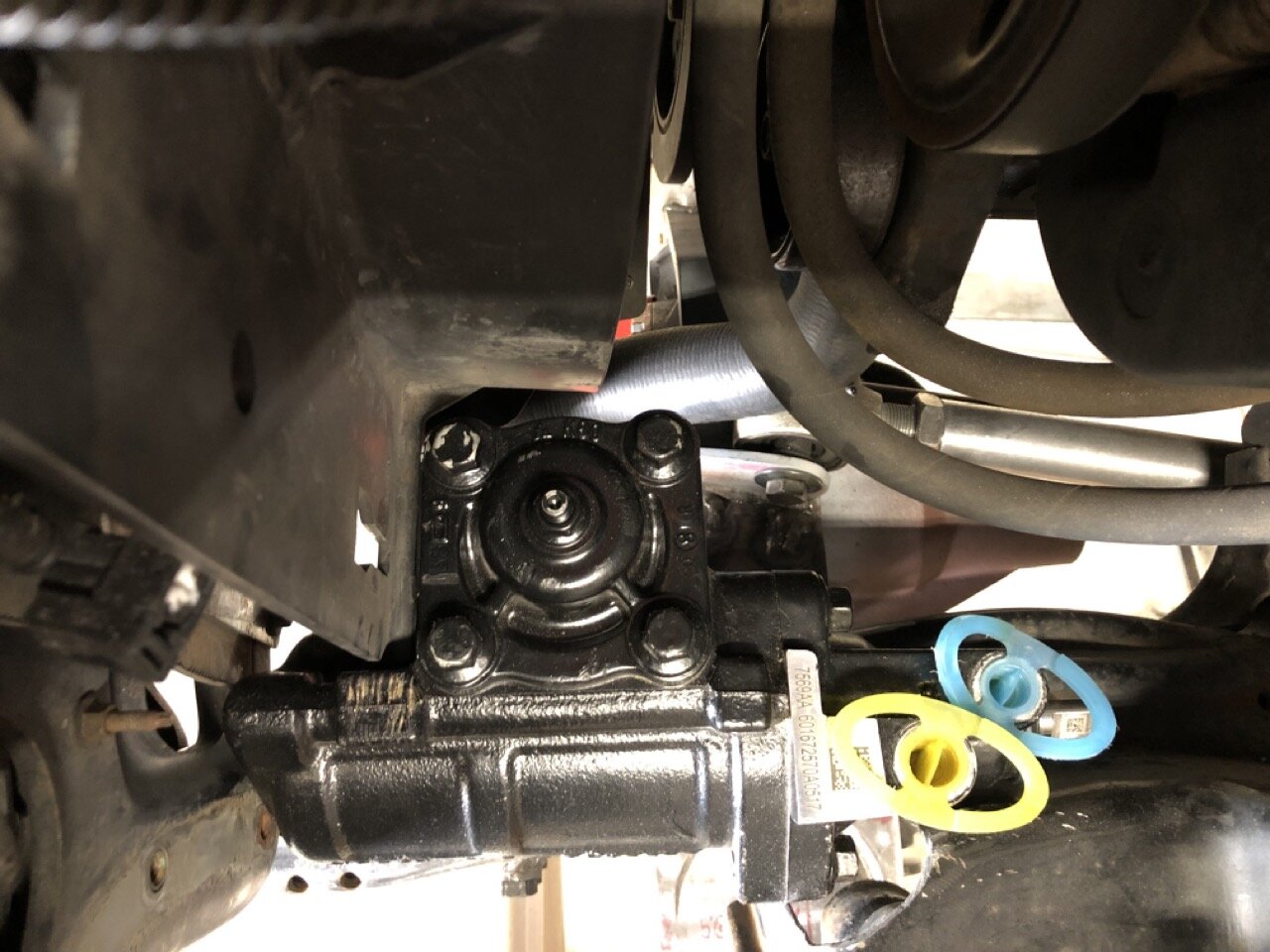

Did some mocking up today just to see where things are at. The steering box almost looks like it is supposed to be there. The coolant overflow tank is definitely going to be an issue though. I'll either need to find a new one or trim 2.75" off it.

As for axle placement, looks like I might be able to cheat in another 1/4-3/8" of stretch . Looks like the thing that will contact first is the ARB fitting against the pitman arm. I don't think the axle can actually get high enough for the diff cover to quite touch it, which works out nice.

. Looks like the thing that will contact first is the ARB fitting against the pitman arm. I don't think the axle can actually get high enough for the diff cover to quite touch it, which works out nice.

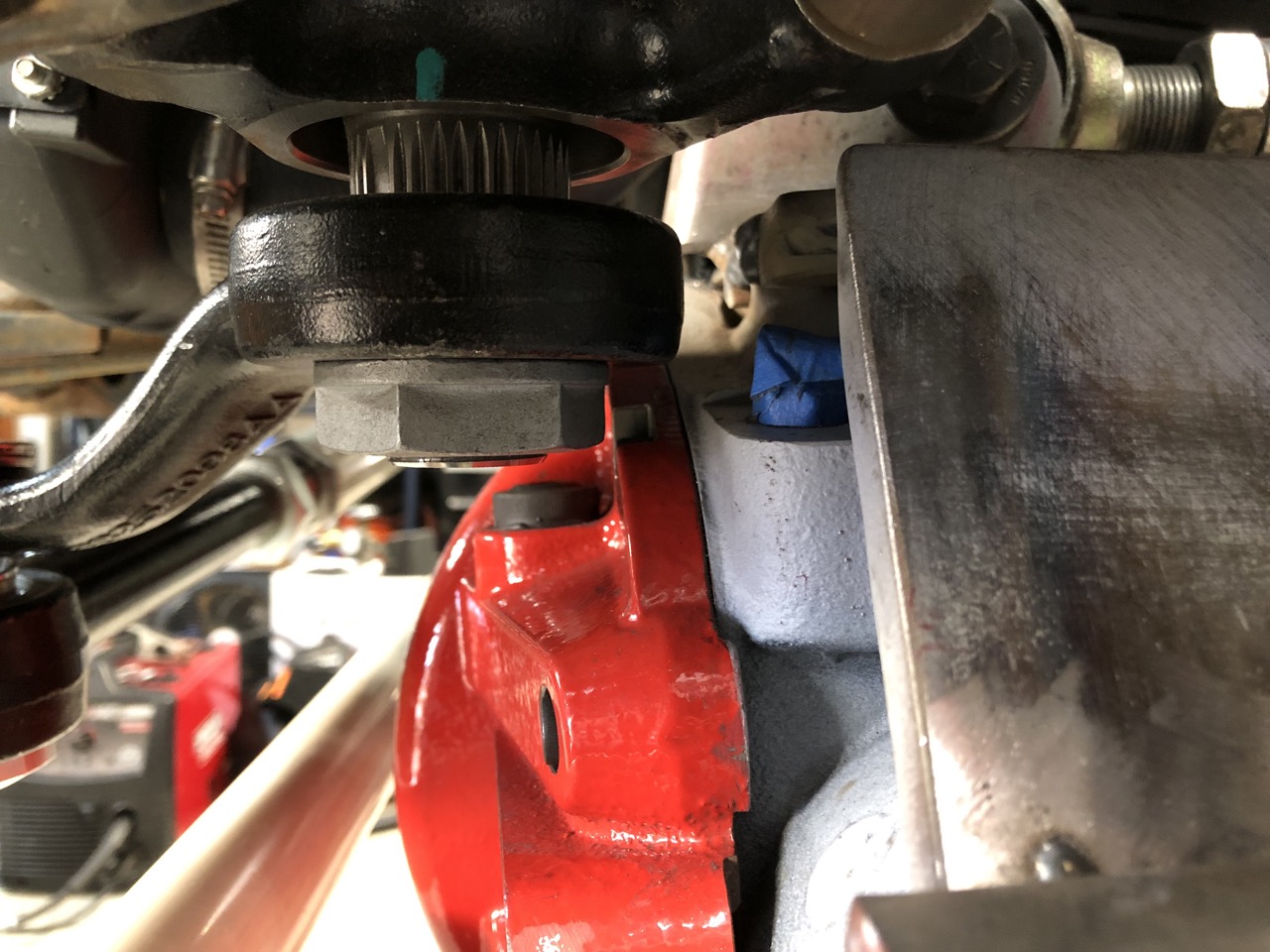

Test fitting in the drag link. Not liking the RareParts ends, and the bent one on the axle side is totally not necessary and just causes more interference with the radiator and frame. I ordered some 1 ton TREs like a normal person. Using 1.5" 7075 links on the smaller 7/8" threads instead of 1.75" bars on the RP ends should help clearances too. Also, the OTK drag link will 100% contact the rim without at least 1" of wheel spacer. Smaller TREs solve a lot of problems.

Ordered a pair of Johnny Joints for the track bar from poly performance along with a second set of shock towers to use on the front, thanks to a recent post from @mrblaine detailing his install process here. After confirming some measurements and considering what I've done so far, I see no reason not to go with 12" travel shocks up front. Not sure if I'll be able to fit a JJ on the axle side for the TB, might have to switch that out for a standard rod end. We'll see what I come up with.

Anyone have any opinions on whether LSC adjusters on FOX resi 2.0s are worth adding on? Maybe just on the rears or something?

As for axle placement, looks like I might be able to cheat in another 1/4-3/8" of stretch

Test fitting in the drag link. Not liking the RareParts ends, and the bent one on the axle side is totally not necessary and just causes more interference with the radiator and frame. I ordered some 1 ton TREs like a normal person. Using 1.5" 7075 links on the smaller 7/8" threads instead of 1.75" bars on the RP ends should help clearances too. Also, the OTK drag link will 100% contact the rim without at least 1" of wheel spacer. Smaller TREs solve a lot of problems.

Ordered a pair of Johnny Joints for the track bar from poly performance along with a second set of shock towers to use on the front, thanks to a recent post from @mrblaine detailing his install process here. After confirming some measurements and considering what I've done so far, I see no reason not to go with 12" travel shocks up front. Not sure if I'll be able to fit a JJ on the axle side for the TB, might have to switch that out for a standard rod end. We'll see what I come up with.

Anyone have any opinions on whether LSC adjusters on FOX resi 2.0s are worth adding on? Maybe just on the rears or something?