You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DrDmoney’s 2000 Jeep Wrangler Sport

- Thread starter DrDmoney

- Start date

Nicely done sir!

Thanks, It helps if you’ve been working with metal most of your life.

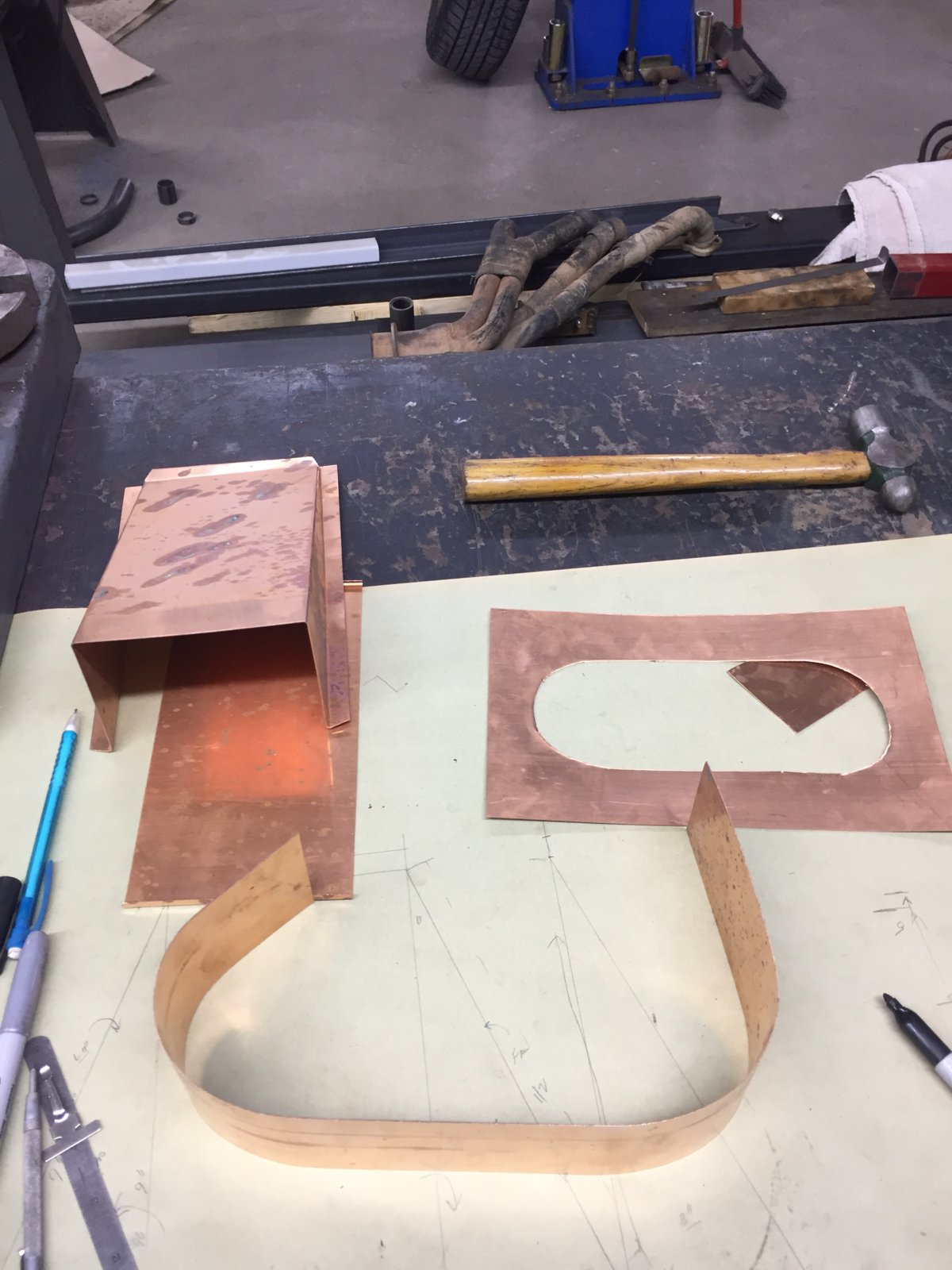

We needed a vent cover for our downdraft that we used oval pipe and I couldn't find one to buy, so I dabble a bit:

We needed a vent cover for our downdraft that we used oval pipe and I couldn't find one to buy, so I dabble a bit:

View attachment 95938

Hmmm a wrapped header in the background, what else do you dabble in?

Spent the day doing honey do list stuff, checked off enough items to get some me time in working on the table.

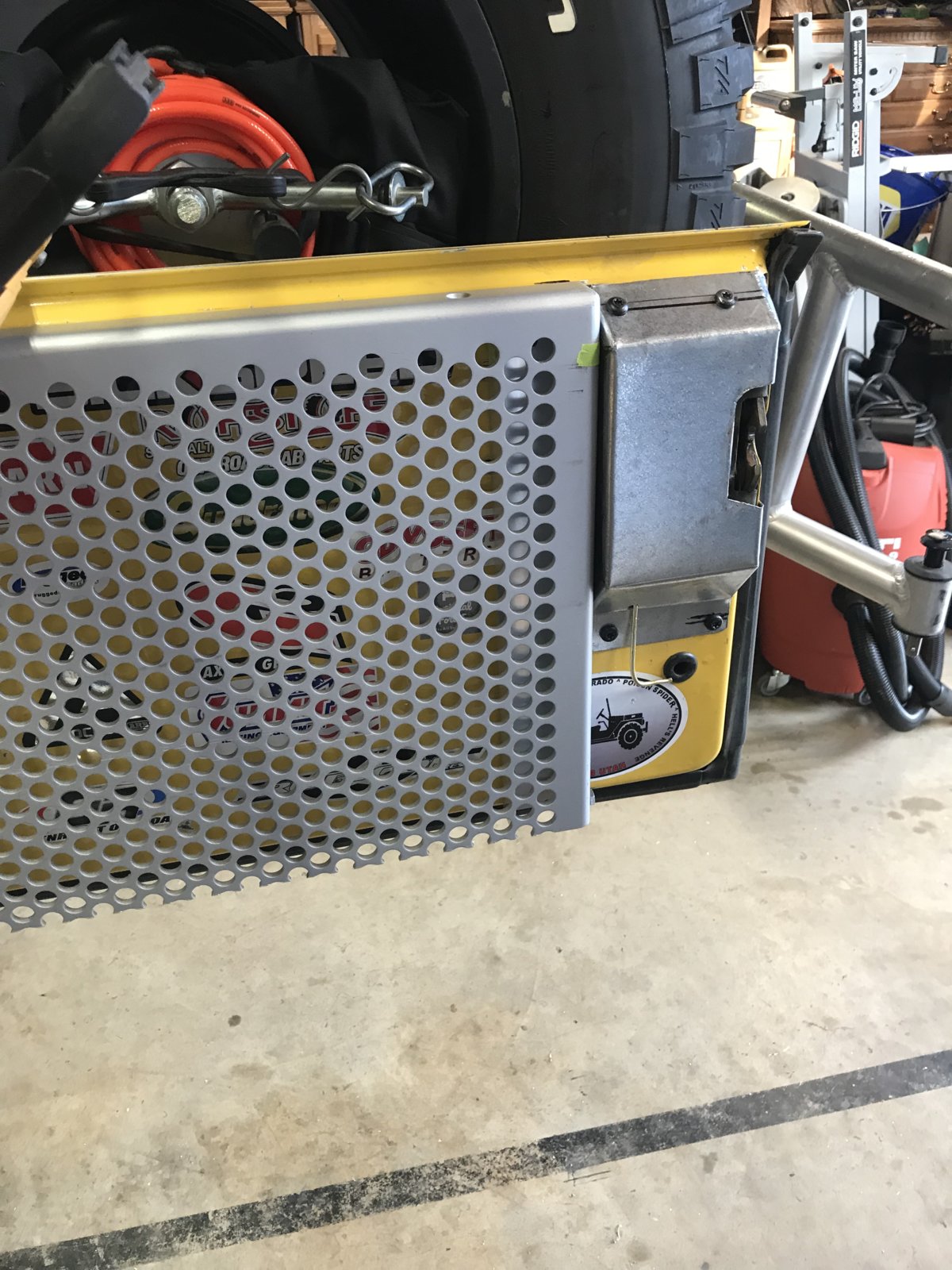

Drilled 3/8” holes in the channels and installed aluminum 1/4-20 Riv-nuts in them for the hinges.

Drilled 1/4” holes in the panel sides at the bottom, this is for the hinge bolt. Filed off the rough stuff around the holes.

Used 1/4-20 stainless hex bolts that I had. Instead of using thread locker, I’m using a longer bolt so I can use a jam nut on the other side of the riv-nut. Since I can lock the bolt with some play in it I’m using “O” rings on the bolt on both sides of the panel. This will hopefully keep it from rattling or vibrating by taking up the free space.

I taped the channels in the closed position and clamped it to the tailgate where I wanted it to be.

I then drilled through the perforated holes at the top, then installed riv-nuts to hold it in position while I drilled the bottom holes. I painted the cover and mounted the table and ran out of time.

I might try something different for the stays, haven’t decided yet, but I have an idea or two.

Drilled 3/8” holes in the channels and installed aluminum 1/4-20 Riv-nuts in them for the hinges.

Drilled 1/4” holes in the panel sides at the bottom, this is for the hinge bolt. Filed off the rough stuff around the holes.

Used 1/4-20 stainless hex bolts that I had. Instead of using thread locker, I’m using a longer bolt so I can use a jam nut on the other side of the riv-nut. Since I can lock the bolt with some play in it I’m using “O” rings on the bolt on both sides of the panel. This will hopefully keep it from rattling or vibrating by taking up the free space.

I taped the channels in the closed position and clamped it to the tailgate where I wanted it to be.

I then drilled through the perforated holes at the top, then installed riv-nuts to hold it in position while I drilled the bottom holes. I painted the cover and mounted the table and ran out of time.

I might try something different for the stays, haven’t decided yet, but I have an idea or two.

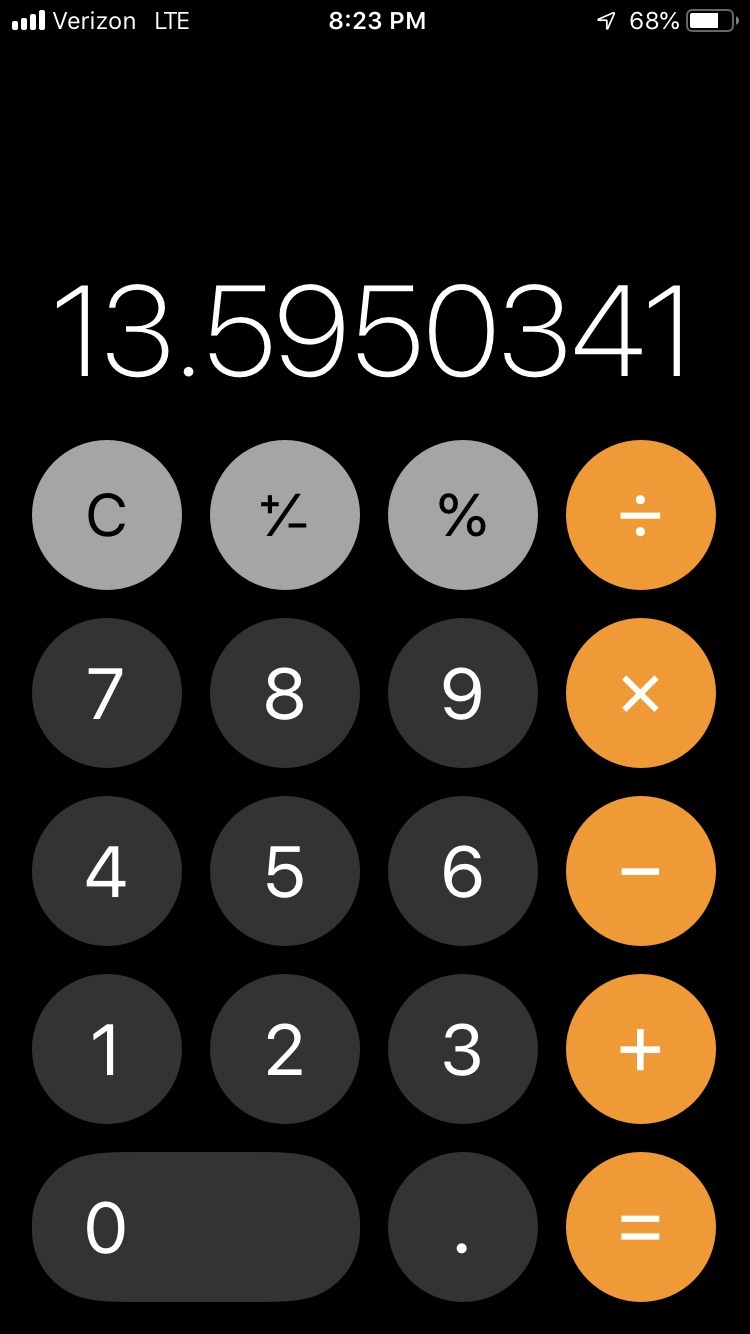

Went to the PowerMart to get some Vino for dinner, while I was there I filled up and checked my fuel mileage. I had “0” highway miles on this tank so I was interested in how bad it would be. 13-1/2 MPG on 35” x 12.50’s with 5.38 gears.

That looks sooooo great and very clean.Spent the day doing honey do list stuff, checked off enough items to get some me time in working on the table.

Drilled 3/8” holes in the channels and installed aluminum 1/4-20 Riv-nuts in them for the hinges.

View attachment 95974View attachment 95975View attachment 95976

Drilled 1/4” holes in the panel sides at the bottom, this is for the hinge bolt. Filed off the rough stuff around the holes.

View attachment 95978View attachment 95979View attachment 95980

Used 1/4-20 stainless hex bolts that I had. Instead of using thread locker, I’m using a longer bolt so I can use a jam nut on the other side of the riv-nut. Since I can lock the bolt with some play in it I’m using “O” rings on the bolt on both sides of the panel. This will hopefully keep it from rattling or vibrating by taking up the free space.

View attachment 95981View attachment 95982

I taped the channels in the closed position and clamped it to the tailgate where I wanted it to be.

View attachment 95983View attachment 95984View attachment 95985

I then drilled through the perforated holes at the top, then installed riv-nuts to hold it in position while I drilled the bottom holes. I painted the cover and mounted the table and ran out of time.

I might try something different for the stays, haven’t decided yet, but I have an idea or two.

View attachment 95986View attachment 95987View attachment 95988

That looks sooooo great and very clean.

Thanks, I got some crazy ideas for the stays that I hope I can pull off.

I'll be watching.Thanks, I got some crazy ideas for the stays that I hope I can pull off.

Kiwi TJ

I don't suffer from insanity I enjoy every minute

Supporting Member

Ride of the Month Winner

That's a cast off from my son's rework on his K-30 off road truck.Hmmm a wrapped header in the background, what else do you dabble in?

Installed a UCF Skid that netted me 1.75 inches extra ground clearance with no MML or BL.

It’s made of 3/8” 6061 aluminum plate.

My tranny mount was cracked but I was replacing it anyway. While I was there I drained the old TC fluid and put some fresh ATF + 4. It had been changed fairly recently but it had a little water in it that I probably picked up last year crossing the East Fork of the Carson River going to the hot springs.

I also got the engine skid as a package, I ordered them on 4/28 and they arrived about 15 days later. The engine skid is formed from 1/4” 6061 and comes with all the hardware.

I swapped a lot of it out for grade 8 and also some stainless that I had.

The install went real smooth, I removed the old plate after supporting the transmission with a stand, pulled the old broken tranny mount off and installed the new one. I drained the old fluid at this point and then refilled it before putting the skid on. I put the skid on my chest and rolled underneath. I lined up the tranny mount bolts and put a nut on to hold it while I bolted the skid to the frame. I snugged it all up and then torqued the bolts. Couple of quick poser pics and then I did a shake down run to Napa to get some RedLine MTL.

Now time for the engine skid. I used some 3/8” Grade 8 bolts that I had to bolt the brackets to the frame. Leave your bolts loose until after the skid is attached to the belly skid. Here they provided some cad plated 3/8” hex bolts, I didn’t like the idea of the bolt heads sticking down to grind on the rocks so I countersunk the 4 holes and used some 3/8” socket flathead stainless fasteners for a smooth look. The front steel brackets were the only thing I had issue with, I had to use the long angle for the short one and make a new longer one so the skid would clear the exhaust. All in all it went great and I’m happy with them.

It’s made of 3/8” 6061 aluminum plate.

My tranny mount was cracked but I was replacing it anyway. While I was there I drained the old TC fluid and put some fresh ATF + 4. It had been changed fairly recently but it had a little water in it that I probably picked up last year crossing the East Fork of the Carson River going to the hot springs.

I also got the engine skid as a package, I ordered them on 4/28 and they arrived about 15 days later. The engine skid is formed from 1/4” 6061 and comes with all the hardware.

I swapped a lot of it out for grade 8 and also some stainless that I had.

The install went real smooth, I removed the old plate after supporting the transmission with a stand, pulled the old broken tranny mount off and installed the new one. I drained the old fluid at this point and then refilled it before putting the skid on. I put the skid on my chest and rolled underneath. I lined up the tranny mount bolts and put a nut on to hold it while I bolted the skid to the frame. I snugged it all up and then torqued the bolts. Couple of quick poser pics and then I did a shake down run to Napa to get some RedLine MTL.

Now time for the engine skid. I used some 3/8” Grade 8 bolts that I had to bolt the brackets to the frame. Leave your bolts loose until after the skid is attached to the belly skid. Here they provided some cad plated 3/8” hex bolts, I didn’t like the idea of the bolt heads sticking down to grind on the rocks so I countersunk the 4 holes and used some 3/8” socket flathead stainless fasteners for a smooth look. The front steel brackets were the only thing I had issue with, I had to use the long angle for the short one and make a new longer one so the skid would clear the exhaust. All in all it went great and I’m happy with them.

Last edited:

Rubicon here you come! Anything else you going to do before the Rubicon in September?Installed a UCF Skid that netted me 1.75 inches extra ground clearance with no MML or BL.

It’s made of 3/8” 6061 aluminum plate.

My tranny mount was cracked but I was replacing it anyway. While I was there I drained the old TC fluid and put some fresh ATF + 4. It had been changed fairly recently but it had a little water in it that I probably picked up last year crossing the East Fork of the Carson River going to the hot springs.

View attachment 97418View attachment 97419View attachment 97420View attachment 97421

I also got the engine skid as a package, I ordered them on 4/28 and they arrived about 15 days later. The engine skid is formed from 1/4” 6061 and comes with all the hardware.

I swapped a lot of it out for grade 8 and also some stainless that I had.

View attachment 97417

The install went real smooth, I removed the old plate after supporting the transmission with a stand, pulled the old broken tranny mount off and installed the new one. I drained the old fluid at this point and then refilled it before putting the skid on. I put the skid on my chest and rolled underneath. I lined up the tranny mount bolts and put a nut on to hold it while I bolted the skid to the frame. I snugged it all up and then torqued the bolts. Couple of quiet poser pics and then I did a shake down run to Napa to get some RedLine MTL.

View attachment 97422View attachment 97423

Now time for the engine skid. I used some 3/8” Grade 8 bolts that I had to bolt the brackets to the frame. Leave your bolts loose until after the skid is attached to the belly skid. Here they provided some cad plated 3/8” hex bolts, I didn’t like the idea of the bolt heads sticking down to grind on the rocks so I countersunk the 4 holes and used some 3/8” socket flathead stainless fasteners for a smooth look. The front steel brackets were the only thing I had issue with, I had to use the long angle for the short one and make a new longer one so the skid would clear the exhaust. All in all it went great and I’m happy with them.

View attachment 97424

Rubicon here you come! Anything else you going to do before the Rubicon in September?

Unfortunately I do need to either rebuild my control arms or get new ones.

I have some RE adjustable front uppers laying around if you want to dismantle them for parts, or use. They have less then 10k miles on them.Unfortunately I do need to either rebuild my control arms or get new ones.

Appreciate the offer but I think I’m going to switch to either the MC’s or Savvy’s. I’ve got an aluminum fetish. LOLI have some RE adjustable front uppers laying around if you want to dismantle them for parts, or use. They have less then 10k miles on them.

None so far and I half expected some as it did raise the TC up about 0.5 inches. Seems like the exhaust is louder but it might be my imagination from expecting something.Nice work! Do you notice any more drive train noise?