Right on, that's typically me with the CascadesOh for sure! I’m there like every week exploring and/or camping anyway just wanted to extend the offer is all.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ElectricWizards 2000 TJ Sport Build

- Thread starter ElectricWizard

- Start date

Ran across your how-to on making the aftermarket toggles illuminate at night. Had a bunch of small bulbs but got the connectors on Amazon. Converted the switches today, worked great and can now see the switches at night! Thanks!

deadbeat son

TJ Addict

I've been browsing this forum for the last 4 months or so and just came across your build thread. This is a great build and the detail you've provided makes it an awesome thread, thanks for putting in the effort!Build Summary:

Out of curiosity, how do you like your TeraFlex 3" lift? I'm currently weighing over options for my build, and I'm considering this lift, but likely with other arms. So I guess I'm really interested in your input on the springs and 9550 shocks if you ran those before moving to 5100s (I thought I saw a 9550 in a photo, but perhaps it was just the steering damper). It doesn't seem like a popular option on this forum, but I like the amount of lift it seems to provide.

Thanks for your input!

Ran across your how-to on making the aftermarket toggles illuminate at night. Had a bunch of small bulbs but got the connectors on Amazon. Converted the switches today, worked great and can now see the switches at night! Thanks!

Awesome! I'm glad my write-up was able to help you out. It seemed so simple yet I couldn't really find anything similar online, so I figured others would probably benefit from me detailing the process.

I've been browsing this forum for the last 4 months or so and just came across your build thread. This is a great build and the detail you've provided makes it an awesome thread, thanks for putting in the effort!

Out of curiosity, how do you like your TeraFlex 3" lift? I'm currently weighing over options for my build, and I'm considering this lift, but likely with other arms. So I guess I'm really interested in your input on the springs and 9550 shocks if you ran those before moving to 5100s (I thought I saw a 9550 in a photo, but perhaps it was just the steering damper). It doesn't seem like a popular option on this forum, but I like the amount of lift it seems to provide.

Thanks for your input!

Thank you! I've tried to keep it a pretty mild and stock-ish Jeep, yet still capable of doing anything I need it to. I learned most of my skills from reading forums and browsing online and I enjoy giving some of that knowledge back!

I acquired my TeraFlex lift from a friend who bought it but never got around to installing it before he sold his TJ; the price was very reasonable so it made my decision pretty easy.

I never had the Tera shocks and have always ran my 5100s, but I do have the Tera stabilizer. Contrary to most I like the 5100s, but will be trying the more popular RS500Xs on my XJ, so time will tell which I like more.

The springs have held up good so far without any noticeable sagging, and even the finish on them is holding up great.

I was a dummy and didn't actually measure the stance of my Jeep prior to the lift, but I'm thinking it was a bit over 3" of lift, maybe closer to 4". It does sit a bit higher in the rear like most do; I haven't put any spacers up front yet, but will probably get around to that as a future project.

The arms themselves have also held up good with periodic greasing, I haven't had any start to show any noticeable wear yet. I'll probably still end up replacing them with some johnny joint arms in the future but don't have any complaints, they've done what they need to do.

Last edited:

deadbeat son

TJ Addict

Thanks so much for the input, I really appreciate it. I'm still trying to figure out what route I want to go, lift-wise, for the '02 X I picked up recently. I've always been a fan of OME, since way back in my Land Cruiser days, on through my dark Rover period, and then back to Toyota again. But I'm looking for a bit more lift on the TJ than they offer, and I'm not sure I want to go with a body lift. (Yes, I've read all of the strong arguments in support of a BL, but I haven't gotten over my prejudice yet...)Thank you! I've tried to keep it a pretty mild and stock-ish Jeep, yet still capable of doing anything I need it to. I learned most of my skills from reading forums and browsing online and I enjoy giving some of that knowledge back!

I acquired my TeraFlex lift from a friend who bought it but never got around to installing it before he sold his TJ; the price was very reasonable so it made my decision pretty easy.

I never had the Tera shocks and have always ran my 5100s, but I do have the Tera stabilizer. The springs have held up good so far without any noticeable sagging, and even the finish on them is holding up great.

I was a dummy and didn't actually measure the stance of my Jeep prior to the lift, but I'm thinking it was a bit over 3" of lift, maybe closer to 4". It does sit a bit higher in the rear like most do; I haven't put any spacers up front yet, but will probably get around to that as a future project.

The arms themselves have also held up good with periodic greasing, I haven't had any start to show any noticeable wear yet. I'll probably still end up replacing them with some johnny joint arms in the future but don't have any complaints, they've done what they need to do.

Like you mentioned, your build is pretty simple, but chalk me up as a fan of Simple Green (you can have the name if you want it). It's more go than show, which really strikes a chord with me. Even before I came across your build, I was planning super 35 with e-lockers F&R, stock wheels, and a relatively simple setup. It's good to see someone with a similar design philosophy.

Thanks again for the documentation and inspiration!

Last edited:

I'm sure you'll get it all sorted out, that's what these forums ate amazing for!Thanks so much for the input, I really appreciate it. I'm still trying to figure out what route I want to go, lift-wise, for the '02 X I picked up recently. I've always been a fan of OME, since way back in my Land Cruiser days, on through my dark Rover period, and then back to Toyota again. But I'm looking for a bit more lift on the TJ than they offer, and I'm not sure I want to go with a body lift. (Yes, I've read all of the strong arguments in support of a BL, but I haven't gotten over my prejudice yet...)

Like you mentioned, your build is pretty simple, but chalk me up as a fan of Simple Green (you can have the name if you want it). It's more go than show, which really strikes a chord with me. Even before I came across your build, I was planning super 35 with e-lockers F&R, stock wheels, and a relatively simple setup. It's good to see someone with a similar design philosophy.

Thanks again for the documentation and inspiration!

And I hear ya on the body lift, I was against doing it originally but people here have convinced me otherwise. I may end up doing a small one in the future for squeezing every bit of performance out of the TJ.

I also love that name! Somehow me or my friends haven't come up with anything that clever yet

Clutch Hydraulics Replacement

It has been a little while! This past year has been busy to say the least. Mostly I have been splitting my time between work, other hobbies/projects, and getting out on adventures with the TJ when I can. During that time I have naturally had to do some repairs, which I am going to begin posting about to get all caught back up!

—

After the historic September 2020 wildfires swept through Oregon's northern Cascades I was spending some time helping friends and family with recovery efforts, and while doing that work my TJ's 20 year old clutch hydraulics decided that their time has come to an end. Previously in the fall of 2019, when I replaced the rest of my clutch system, I neglected to replace the hydraulics, and well, that came back to haunt me.

I'm not sure what particular part ended up failing, whether it was the master or slave, as there was no leaking from anywhere; but no matter what the clutch pedal would just not go in. Regardless it didn't really matter as the whole assembly is replaced as one piece. The hydraulics assembly I purchased is a LuK CRS011.

I started the repair off by heading into the cab and up under the dash. First I started with removing the clutch safety switch. There are a couple tabs on the white plastic clip on the top side of the switch, pressing those tabs inwards will let the clip slide free. The rest of the switch can be pulled off of the rod. While in the area I also removed the two bolts above and below the rod which fasten the master cylinder to the firewall. I didn't get pictures of popping the master cylinder rod clip free of the clutch pedal, but it is easily pried off without much effort.

The master cylinder is now free.

Below the Jeep, the slave cylinder is easily located protruding from the driver side of the transmission. It is secured with two nuts on studs. In my case the nuts came off, but if they're stuck to the studs that's fine too.

With both of the cylinders free it all can now easily be removed, right? Well in my case, no!

My problem stems from my ARB compressor, which is installed below the brake booster and clutch master cylinder on the factory ABS tray. The space between the brake booster and my compressor is very tight, barely enough space to fit the hydraulics line through. But the big problem was the master cylinder itself, which couldn't fit through either, nor could it fit through the tangle of brake lines below the brake booster. It wasn't any better trying to pull the slave cylinder through, either.

My solution to this was to simply unbolt the brake master cylinder from the brake booster and carefully pushing it and the hard-lines out of the way. This gave me plenty of room for removing the old hydraulics and sliding the new part in.

With the new part snaked through, and the brake master reassembled, I was pretty much back on track now. The new slave cylinder has a plastic clip keeping it retracted which can be left on and will pop free when the clutch is pressed in the first time. The slave cylinder bolts are torqued to ~16 ft/lbs.

Over on the master cylinder side, the new rod needs to be pushed into the opening on the master cylinder. The new one was made of plastic as most new things tend to be, but it is identical in every other way and worked fine.

After bolting the new master up to the firewall, popping the rod clip back onto the clutch pedal, and reassembling the clutch safety switch, the Jeep was now fixed and ready to roll again!

It has been a little while! This past year has been busy to say the least. Mostly I have been splitting my time between work, other hobbies/projects, and getting out on adventures with the TJ when I can. During that time I have naturally had to do some repairs, which I am going to begin posting about to get all caught back up!

—

After the historic September 2020 wildfires swept through Oregon's northern Cascades I was spending some time helping friends and family with recovery efforts, and while doing that work my TJ's 20 year old clutch hydraulics decided that their time has come to an end. Previously in the fall of 2019, when I replaced the rest of my clutch system, I neglected to replace the hydraulics, and well, that came back to haunt me.

I'm not sure what particular part ended up failing, whether it was the master or slave, as there was no leaking from anywhere; but no matter what the clutch pedal would just not go in. Regardless it didn't really matter as the whole assembly is replaced as one piece. The hydraulics assembly I purchased is a LuK CRS011.

I started the repair off by heading into the cab and up under the dash. First I started with removing the clutch safety switch. There are a couple tabs on the white plastic clip on the top side of the switch, pressing those tabs inwards will let the clip slide free. The rest of the switch can be pulled off of the rod. While in the area I also removed the two bolts above and below the rod which fasten the master cylinder to the firewall. I didn't get pictures of popping the master cylinder rod clip free of the clutch pedal, but it is easily pried off without much effort.

The master cylinder is now free.

Below the Jeep, the slave cylinder is easily located protruding from the driver side of the transmission. It is secured with two nuts on studs. In my case the nuts came off, but if they're stuck to the studs that's fine too.

With both of the cylinders free it all can now easily be removed, right? Well in my case, no!

My problem stems from my ARB compressor, which is installed below the brake booster and clutch master cylinder on the factory ABS tray. The space between the brake booster and my compressor is very tight, barely enough space to fit the hydraulics line through. But the big problem was the master cylinder itself, which couldn't fit through either, nor could it fit through the tangle of brake lines below the brake booster. It wasn't any better trying to pull the slave cylinder through, either.

My solution to this was to simply unbolt the brake master cylinder from the brake booster and carefully pushing it and the hard-lines out of the way. This gave me plenty of room for removing the old hydraulics and sliding the new part in.

With the new part snaked through, and the brake master reassembled, I was pretty much back on track now. The new slave cylinder has a plastic clip keeping it retracted which can be left on and will pop free when the clutch is pressed in the first time. The slave cylinder bolts are torqued to ~16 ft/lbs.

Over on the master cylinder side, the new rod needs to be pushed into the opening on the master cylinder. The new one was made of plastic as most new things tend to be, but it is identical in every other way and worked fine.

After bolting the new master up to the firewall, popping the rod clip back onto the clutch pedal, and reassembling the clutch safety switch, the Jeep was now fixed and ready to roll again!

He's alive!! Good to have you posting again @ElectricWizard. Ready for hiking/camping season?

Yes I am alive! Never really intended to step away, but then something gets in the way, I think everybody can relate to that.He's alive!! Good to have you posting again @ElectricWizard. Ready for hiking/camping season?

And of course, I'm always ready for doing stuff outdoors! Lately I've been heading out to Central Oregon a lot more, in part due to the wildfires closing access to the areas of the Cascades I frequented the most, and also due to the remaining areas being generally more crowded now. Also been trying to make my way out to the coast more often, but haven't gone nearly as much as I'd like.

Wheel Hub Replacement

Another issue that popped up earlier in March of this year was that I was hearing a squeaking and chirping sound that would start when I hit about 25mph, and it would persist until I slowed down below 25mph no matter the throttle or brake input. As best as I could tell it seemed to be coming from the passenger side of the Jeep specifically. I suspected that perhaps it could be the wheel hubs, I have never replaced them since I've owned the Jeep, and as far as I know they are still the OEM ones.

I jacked up the front end of the TJ and tried the wiggle test on both front tires, both hubs had no noticeable play. Turning the wheels however there was definitely a noticeable chirping sound on the passenger side.

A few years ago when I pulled apart the front axle to do my re-gear and locker install both hubs were still in good condition and didn't make any noise, it seemed plausible this was the source of the sound that I was chasing. I also already had a set of Timken HA597449 Wheel Hubs my XJ project that I could poach, so figured why not?

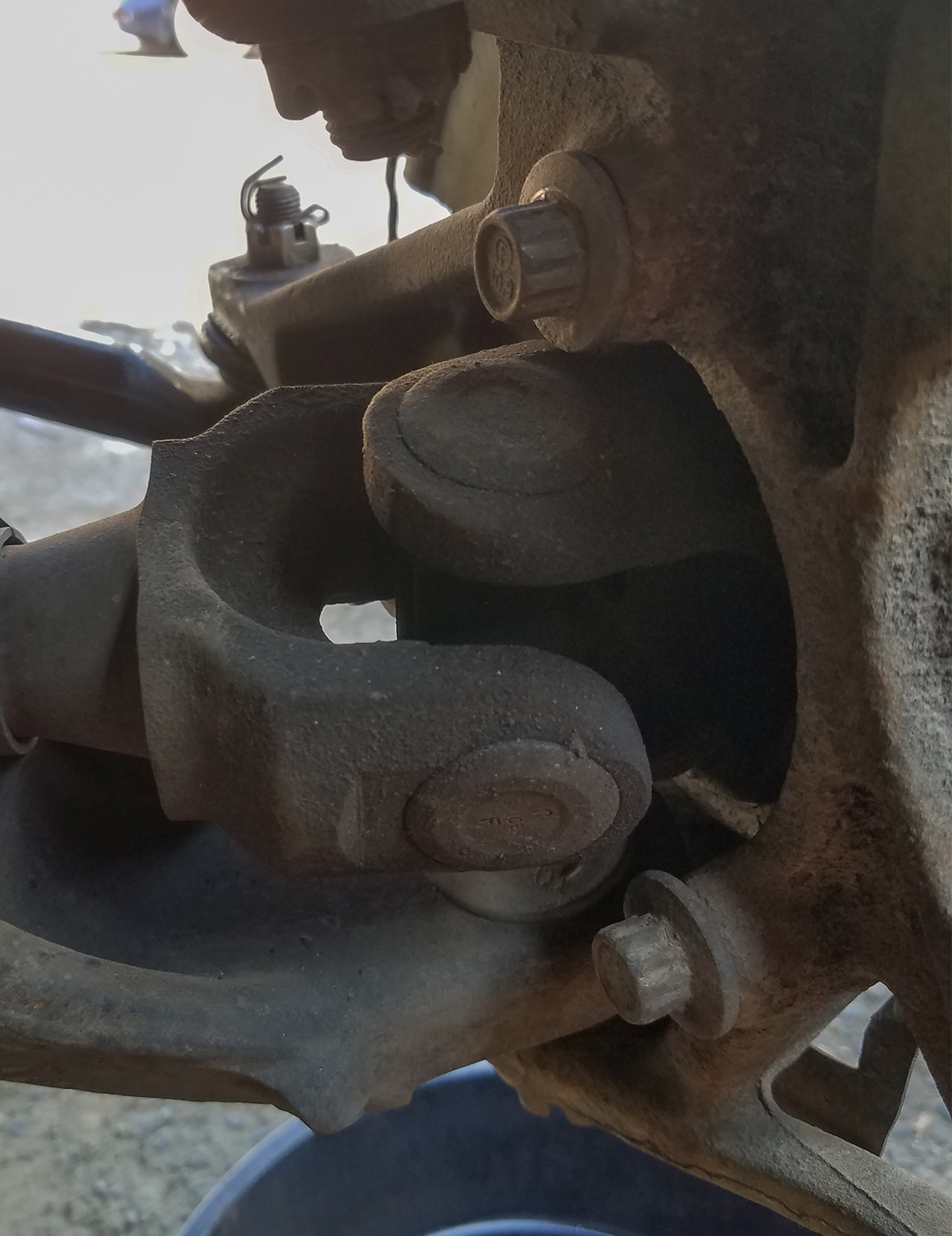

I quickly pulled off the brake caliper and rotor and exposed the hub. I unbent and pulled off the cotter pin and retainer cap and removed the axle nut with an impact.

On the back side of the knuckle I removed the three 12-point bolts that fasten the hub to the knuckle. They were easy to remove using an impact with a universal joint and also turning the steering wheel for better access.

Once the last bolt is removed from the hub it was pretty easy to wiggle it free from the knuckle. Using anti-seize and living in an area without salt sure helps! The dust shield sits behind the hub and will come off with it.

I ran into my parts warehouse and located my hubs, slathered some anti-seize onto the mating surfaces, and got it and the dust shield put back in place on the knuckle. I put the hub bolts back in from the back, torquing them to 75 ft/lbs. I put the washer and nut back onto the axle-shaft and torqued that down to 175 ft/lbs. The retaining cap was put over the nut, ensuring the hole for the cotter pin wasn't obstructed, and put in a new cotter pin.

Final step was to put the brake rotor back on the hub, and reinstall the brake caliper on it's bracket; torquing the bolts to 11 ft/lbs with some blue Loctite. Lastly I put back on the wheel and torqued down the lug nuts, rinse and repeat on the driver side, and I was done!

After a test drive I confirmed that replacing the passenger hub definitely eliminated the chirping noise I was hearing. I have read reports that these newer Chinese made Timken hubs don't last as long and start making noise, so I suppose I will be paying attention to how these perform in the long term.

Another issue that popped up earlier in March of this year was that I was hearing a squeaking and chirping sound that would start when I hit about 25mph, and it would persist until I slowed down below 25mph no matter the throttle or brake input. As best as I could tell it seemed to be coming from the passenger side of the Jeep specifically. I suspected that perhaps it could be the wheel hubs, I have never replaced them since I've owned the Jeep, and as far as I know they are still the OEM ones.

I jacked up the front end of the TJ and tried the wiggle test on both front tires, both hubs had no noticeable play. Turning the wheels however there was definitely a noticeable chirping sound on the passenger side.

A few years ago when I pulled apart the front axle to do my re-gear and locker install both hubs were still in good condition and didn't make any noise, it seemed plausible this was the source of the sound that I was chasing. I also already had a set of Timken HA597449 Wheel Hubs my XJ project that I could poach, so figured why not?

I quickly pulled off the brake caliper and rotor and exposed the hub. I unbent and pulled off the cotter pin and retainer cap and removed the axle nut with an impact.

On the back side of the knuckle I removed the three 12-point bolts that fasten the hub to the knuckle. They were easy to remove using an impact with a universal joint and also turning the steering wheel for better access.

Once the last bolt is removed from the hub it was pretty easy to wiggle it free from the knuckle. Using anti-seize and living in an area without salt sure helps! The dust shield sits behind the hub and will come off with it.

I ran into my parts warehouse and located my hubs, slathered some anti-seize onto the mating surfaces, and got it and the dust shield put back in place on the knuckle. I put the hub bolts back in from the back, torquing them to 75 ft/lbs. I put the washer and nut back onto the axle-shaft and torqued that down to 175 ft/lbs. The retaining cap was put over the nut, ensuring the hole for the cotter pin wasn't obstructed, and put in a new cotter pin.

Final step was to put the brake rotor back on the hub, and reinstall the brake caliper on it's bracket; torquing the bolts to 11 ft/lbs with some blue Loctite. Lastly I put back on the wheel and torqued down the lug nuts, rinse and repeat on the driver side, and I was done!

After a test drive I confirmed that replacing the passenger hub definitely eliminated the chirping noise I was hearing. I have read reports that these newer Chinese made Timken hubs don't last as long and start making noise, so I suppose I will be paying attention to how these perform in the long term.

Steering Box Input Seal Replacement

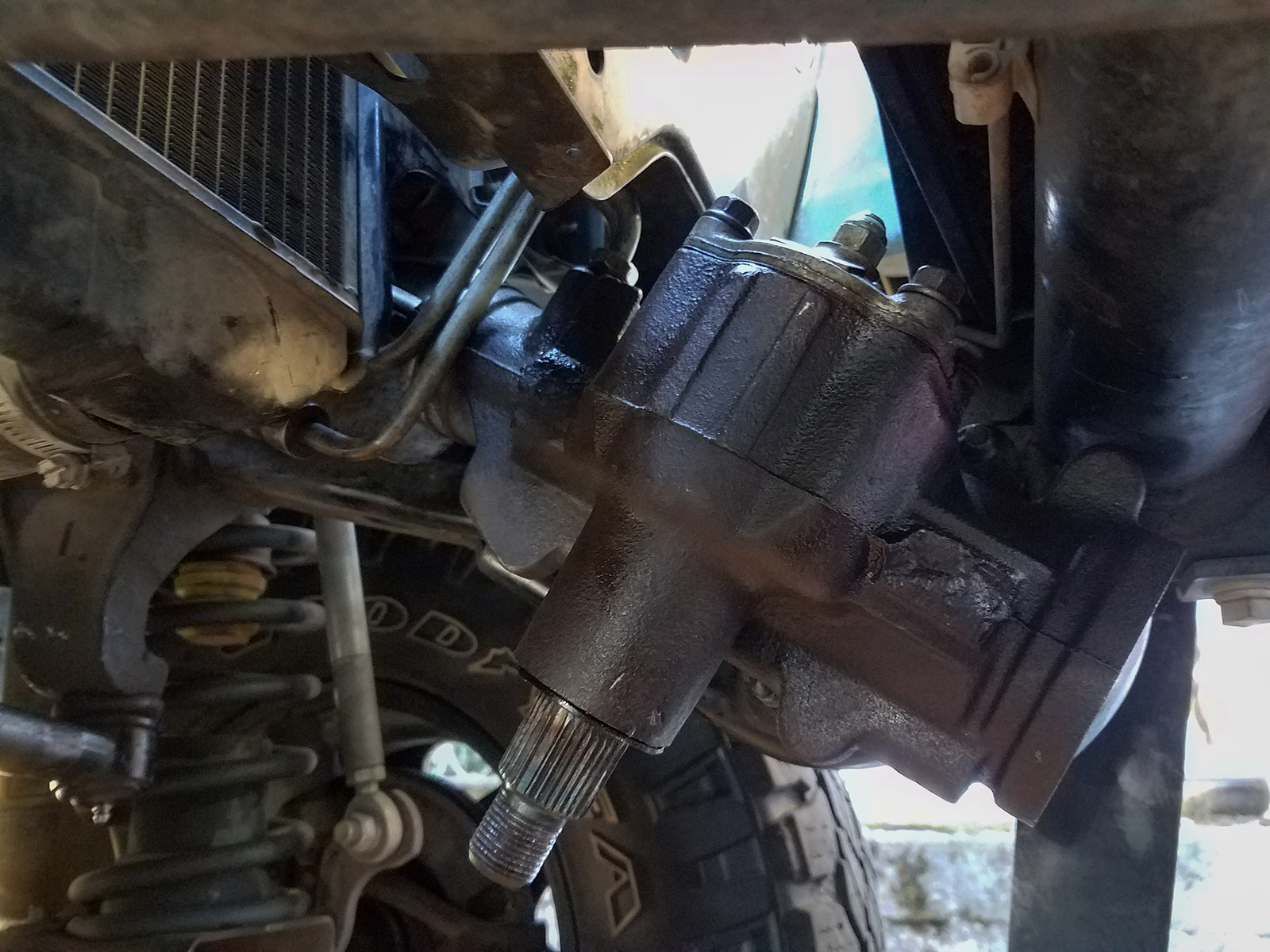

Earlier this year my Jeep started acting rather naughty and began noticeably marking it's territory. A 4.0 leaking oil is nothing out of the ordinary, but in this case, the leak was much farther forward than where the usual engine leaks would show up. For me it was my steering gear box, and it appeared to be leaking pretty good from the input seal at the top of the box.

This was a bit inconvenient as I had a camping trip planned and wanted to get this fixed up prior to that. The rebuilt boxes that you can get from the usual parts stores tend to be sloppy and leak, and new ones were upwards of $500+. My steering box was in good shape other than the leak, with no slop at the pitman shaft, and there were no dead-zones in the steering. I have experience rebuilding the steering box for a friends 87 XJ so I figured this was the route that I'd go. However, due to my time constraints, I chose to just replace the offending seal and not rebuild the entire box at this time. If I need to take it back out later on down the road it isn't a big deal, and not too difficult of a job.

To start out I figured I'd begin with the most dreaded part, removing the pitman arm. I loosened up the pitman arm nut with my impact, but left it screwed on a bit in order to catch the arm when it pops free. My box had a black rubber boot on the pitman arm shaft which had popped out over time; I made sure to push it back up into the box before I used the pitman arm puller.

Now it was time to have some fun! I had a couple Harbor Freight tie-rod/pitman arm pullers laying around that I could torture. I tried being civil with the first one by tightening it with a ratchet and beating on the pitman arm with a BFH. That didn't work at all, and just ended up bending the puller and ovaling out the threaded hole on the puller.

I busted out the second puller, and this time I planned on not being so nice; I put a c-clamp over the open end of the puller to try and prevent it from spreading open. I grabbed my big impact and gave the puller full beans until it started to spread open. I gave the pitman arm a few BHF whacks but still no luck. Using the impact I sent a few more ugga duggas into the puller, and right before the puller was about to spread apart too far, the pitman arm popped free!

I removed the fluid from the reservoir using an OEM tools fluid extractor, afterwards I setup a jack underneath the box to support it as I remove the bolts. I also had to disconnect my SwayLoc links and swing the arms out of the way, the driver-side arm obscures the steering box bolts. With that done I used my impact to remove the steering box bolts, all 3 came out with no issues.

I lowered the jack a bit to give me better access to the power steering lines as well as the steering shaft bolt. I removed the bolt on the collar of the steering shaft and used a pry-bar between it and the box to pop it loose. The lines are easily removed with an 18mm wrench; I didn't have a flare wrench that size but a normal open end worked fine. Once the lines are removed the box was free.

Before starting on the seal replacement I took a rotating preload measurement on the input shaft with my beam-style torque wrench, similar to differential pinions. I neglected to take any pictures but the FSM covers the procedure, called the "over-center adjustment", and it's quite easy to do. In a nut shell you make sure the pitman shaft is centered and then you measure the rotating torque on the input shaft 45* in either direction. In my case the box came in at about 10 in/lbs of rotating torque.

Now the disassembly can begin. The locknut on the outside of the input shaft preload adjuster is the first thing to be removed. I've seen them in different shapes, but they all have notches on the outside edge where you can fit a punch and tap it until it's free.

With the lock ring removed I then scribed a mark aligned with one of the holes on the adjuster nut. This mark, as well as the preload measurement I previously took, will help me ensure everything is put back together correctly in the end.

A special tool is required at this point, it is a large pin spanner used to remove/tighten the adjusting nut. I easily fabricated one using some 3/16" steel stock and grade 8 bolts that fit the pin holes.

The adjuster nut can now be removed with the spanner. The FSM and few guides I found made this step seem easy, and perhaps it is for most situations, but this box wasn't going to give up without a fight. I fought with it for a while on my bench in a vise, but I realized I could mount the box upside-down in the frame to really get good leverage on it. It took a serious amount of force, even bending my tool a couple times, before the nut finally gave up and broke free. Once I spun the nut all the way out it was pretty obvious why it fought so hard: years of crud accumulation had caused lots of rust and corrosion.

The input shaft should now be able to be wiggled free with a little bit of effort. Mine did not want to budge, and I figured it was likely due to the crud and rust. I did lots of cleaning and spraying with penetrating oils and WD40, even using some heat, but the thing just did not budge. Eventually I resorted to putting it back into the frame and tried using the input shaft itself to push the seal/bearing assembly free. It took a lot of force but it finally did break free and move a little. I brought it back to the bench and removed the whole assembly. It is important to not turn the input shaft much past the point where it pushes the assembly free, as that will unleash all of the input-shaft ball screw bearings inside the box.

The input bearing assembly pulls away from the input shaft and valve body

I inspected the input shaft where the seal rides for any grooving and polished it up a bit with some 400 grit and then 600 grit sand paper.

The input shaft seal itself is in the top of the bearing assembly and is easily removed with a seal puller. There is also an o-ring on the outside of the bearing assembly that needs to be removed.

I spent some time cleaning up all of the parts, including sanding and polishing up as much of the rust that I found earlier; this will help decrease the chance of damaging the o-ring upon installation. I dug through my rebuild kit and located the new parts, using my old parts for reference. The kit I ended up using was a Gates 349630 Power Steering Repair Kit

I drove the new seal into the bearing assembly and applied some grease to the seal lip. Then I soaked the o-ring in power steering fluid and put it into it's groove on the outside of the bearing assembly. I poured a bit of power steering fluid into the bearings and then slid the assembly back onto the input shaft. I put some tape over the splines to protect the new seal during install.

The assembly must be aligned with two tangs and a pin that are located inside the box on the worm-screw shaft. I pushed down until the assembly was fully seated.

Due to all the rust discovered during my disassembly I chose to slather all surfaces between the input bearing assembly, adjuster nut, and threads of the box with lots of anti-seize. The adjuster nut was then screwed down until the mark I made previously lined up properly. I tested to make sure that the rotating preload was in spec and everything checked out.

I put a bit more anti-seize onto the outer threads of the adjuster nut and then threaded on the lock-ring. While holding the adjuster nut steady with the spanner I punched the lock-ring in a similar fashion to how it was removed until it was snug.

The box was now finished up, I got it back under the Jeep and reattached the lines and steering shaft. The steering box bolts had blue LocTite applied to them and were torqued to 70 ft/lbs. I applied some anti-size to the pitman arm splines and slipped it on as well as it's nut and lock-washer. The pitman arm nut was torqued to 185 ft/lbs.

I filled the power steering reservoir up with fresh fluid, hopped into the Jeep, and turned the steering wheel lock to lock a few times. I topped the reservoir back up and then fired up the TJ and repeated the process until the level was stable. I took it for a drive around the block, trying to make as many turns as possible to work the system good. Everything felt as good as before the repair, and after getting back and inspecting, there were no leaks! This repair has been a success, and still has no leaks several months later.

Earlier this year my Jeep started acting rather naughty and began noticeably marking it's territory. A 4.0 leaking oil is nothing out of the ordinary, but in this case, the leak was much farther forward than where the usual engine leaks would show up. For me it was my steering gear box, and it appeared to be leaking pretty good from the input seal at the top of the box.

This was a bit inconvenient as I had a camping trip planned and wanted to get this fixed up prior to that. The rebuilt boxes that you can get from the usual parts stores tend to be sloppy and leak, and new ones were upwards of $500+. My steering box was in good shape other than the leak, with no slop at the pitman shaft, and there were no dead-zones in the steering. I have experience rebuilding the steering box for a friends 87 XJ so I figured this was the route that I'd go. However, due to my time constraints, I chose to just replace the offending seal and not rebuild the entire box at this time. If I need to take it back out later on down the road it isn't a big deal, and not too difficult of a job.

To start out I figured I'd begin with the most dreaded part, removing the pitman arm. I loosened up the pitman arm nut with my impact, but left it screwed on a bit in order to catch the arm when it pops free. My box had a black rubber boot on the pitman arm shaft which had popped out over time; I made sure to push it back up into the box before I used the pitman arm puller.

Now it was time to have some fun! I had a couple Harbor Freight tie-rod/pitman arm pullers laying around that I could torture. I tried being civil with the first one by tightening it with a ratchet and beating on the pitman arm with a BFH. That didn't work at all, and just ended up bending the puller and ovaling out the threaded hole on the puller.

I busted out the second puller, and this time I planned on not being so nice; I put a c-clamp over the open end of the puller to try and prevent it from spreading open. I grabbed my big impact and gave the puller full beans until it started to spread open. I gave the pitman arm a few BHF whacks but still no luck. Using the impact I sent a few more ugga duggas into the puller, and right before the puller was about to spread apart too far, the pitman arm popped free!

I removed the fluid from the reservoir using an OEM tools fluid extractor, afterwards I setup a jack underneath the box to support it as I remove the bolts. I also had to disconnect my SwayLoc links and swing the arms out of the way, the driver-side arm obscures the steering box bolts. With that done I used my impact to remove the steering box bolts, all 3 came out with no issues.

I lowered the jack a bit to give me better access to the power steering lines as well as the steering shaft bolt. I removed the bolt on the collar of the steering shaft and used a pry-bar between it and the box to pop it loose. The lines are easily removed with an 18mm wrench; I didn't have a flare wrench that size but a normal open end worked fine. Once the lines are removed the box was free.

Before starting on the seal replacement I took a rotating preload measurement on the input shaft with my beam-style torque wrench, similar to differential pinions. I neglected to take any pictures but the FSM covers the procedure, called the "over-center adjustment", and it's quite easy to do. In a nut shell you make sure the pitman shaft is centered and then you measure the rotating torque on the input shaft 45* in either direction. In my case the box came in at about 10 in/lbs of rotating torque.

Now the disassembly can begin. The locknut on the outside of the input shaft preload adjuster is the first thing to be removed. I've seen them in different shapes, but they all have notches on the outside edge where you can fit a punch and tap it until it's free.

With the lock ring removed I then scribed a mark aligned with one of the holes on the adjuster nut. This mark, as well as the preload measurement I previously took, will help me ensure everything is put back together correctly in the end.

A special tool is required at this point, it is a large pin spanner used to remove/tighten the adjusting nut. I easily fabricated one using some 3/16" steel stock and grade 8 bolts that fit the pin holes.

The adjuster nut can now be removed with the spanner. The FSM and few guides I found made this step seem easy, and perhaps it is for most situations, but this box wasn't going to give up without a fight. I fought with it for a while on my bench in a vise, but I realized I could mount the box upside-down in the frame to really get good leverage on it. It took a serious amount of force, even bending my tool a couple times, before the nut finally gave up and broke free. Once I spun the nut all the way out it was pretty obvious why it fought so hard: years of crud accumulation had caused lots of rust and corrosion.

The input shaft should now be able to be wiggled free with a little bit of effort. Mine did not want to budge, and I figured it was likely due to the crud and rust. I did lots of cleaning and spraying with penetrating oils and WD40, even using some heat, but the thing just did not budge. Eventually I resorted to putting it back into the frame and tried using the input shaft itself to push the seal/bearing assembly free. It took a lot of force but it finally did break free and move a little. I brought it back to the bench and removed the whole assembly. It is important to not turn the input shaft much past the point where it pushes the assembly free, as that will unleash all of the input-shaft ball screw bearings inside the box.

The input bearing assembly pulls away from the input shaft and valve body

I inspected the input shaft where the seal rides for any grooving and polished it up a bit with some 400 grit and then 600 grit sand paper.

The input shaft seal itself is in the top of the bearing assembly and is easily removed with a seal puller. There is also an o-ring on the outside of the bearing assembly that needs to be removed.

I spent some time cleaning up all of the parts, including sanding and polishing up as much of the rust that I found earlier; this will help decrease the chance of damaging the o-ring upon installation. I dug through my rebuild kit and located the new parts, using my old parts for reference. The kit I ended up using was a Gates 349630 Power Steering Repair Kit

I drove the new seal into the bearing assembly and applied some grease to the seal lip. Then I soaked the o-ring in power steering fluid and put it into it's groove on the outside of the bearing assembly. I poured a bit of power steering fluid into the bearings and then slid the assembly back onto the input shaft. I put some tape over the splines to protect the new seal during install.

The assembly must be aligned with two tangs and a pin that are located inside the box on the worm-screw shaft. I pushed down until the assembly was fully seated.

Due to all the rust discovered during my disassembly I chose to slather all surfaces between the input bearing assembly, adjuster nut, and threads of the box with lots of anti-seize. The adjuster nut was then screwed down until the mark I made previously lined up properly. I tested to make sure that the rotating preload was in spec and everything checked out.

I put a bit more anti-seize onto the outer threads of the adjuster nut and then threaded on the lock-ring. While holding the adjuster nut steady with the spanner I punched the lock-ring in a similar fashion to how it was removed until it was snug.

The box was now finished up, I got it back under the Jeep and reattached the lines and steering shaft. The steering box bolts had blue LocTite applied to them and were torqued to 70 ft/lbs. I applied some anti-size to the pitman arm splines and slipped it on as well as it's nut and lock-washer. The pitman arm nut was torqued to 185 ft/lbs.

I filled the power steering reservoir up with fresh fluid, hopped into the Jeep, and turned the steering wheel lock to lock a few times. I topped the reservoir back up and then fired up the TJ and repeated the process until the level was stable. I took it for a drive around the block, trying to make as many turns as possible to work the system good. Everything felt as good as before the repair, and after getting back and inspecting, there were no leaks! This repair has been a success, and still has no leaks several months later.

I just finished up a variant of your eBay Switch Dash Lighting Mod, such a great idea. I used SMT leds but the same basic deal. I always thought those things were painted on. I'm glad @randy328 linked to your build thread from another discussion about these switches.

Edit: Here's what it looks like. The factory light burned out in the O/D switch so I replaced that one too so the colors match.

Edit: Here's what it looks like. The factory light burned out in the O/D switch so I replaced that one too so the colors match.

Last edited:

I just finished up a variant of your eBay Switch Dash Lighting Mod, such a great idea. I used SMT leds but the same basic deal. I always thought those things were painted on. I'm glad @randy328 linked to your build thread from another discussion about these switches.

Edit: Here's what it looks like. The factory light burned out in the O/D switch so I replaced that one too so the colors match.

View attachment 305848

Glad to hear others are benefiting from my write-up!

I came to this thread looking at the light up switch mod. I wound up reading all 15 pages and learned a bunch. Thanks for documenting everything so well!