Also interested if there is any feedback / concerns with using soft shackles with a shackle anchor that has sharp edges. Makes sense that in a perfect world they would be rounded similar to a hawse fairlead but with TREs 30k break strength if it would be an issue.I was thinking about the soft shackles I got and looking at my bumper anchors. They have sharp edges. Should I break those edges with a die grinder or countersink (if I can find a 3/4" one to borrow) to protect the soft shackle or is it not necessary? This is my first experience with them.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Factor 55 flat link vs standard winch hook

- Thread starter jazngab

- Start date

I was thinking about the soft shackles I got and looking at my bumper anchors. They have sharp edges. Should I break those edges with a die grinder or countersink (if I can find a 3/4" one to borrow) to protect the soft shackle or is it not necessary? This is my first experience with them.

A larger drill bit also works as an effective countersink to round the edges.

but with TREs 30k break strength if it would be an issue.

It is an issue because the winch line (or shackles) is made up of many smaller strands of fiber (like most ropes are). Each of those strands is not rated for the break strength. I've partially cut a few recovering stuck cars when I didn't have anything better to attach with.

A larger drill bit also works as an effective countersink to round the edges.

The only thing I have that large is a couple old spade bits. Will that work?

The only thing I have that large is a couple old spade bits. Will that work?

...

The only thing I have that large is a couple old spade bits. Will that work?

Yes, but only if you run them at the highest speed setting on the drill.

Yes, but only if you run them at the highest speed setting on the drill.

...

It is an issue because the winch line (or shackles) is made up of many smaller strands of fiber (like most ropes are). Each of those strands is not rated for the break strength. I've partially cut a few recovering stuck cars when I didn't have anything better to attach with.

Thanks. I thought so, but wanted to confirm...Now...to find a giant countersink...

Since we all assumed it would not be good to run them on a sharp edge, I figured I would ask TRE. Their response is below.

Hi Joe, you are correct. You need to radius the hole edges and remove the common laser/plasma seam from inside the hole.

I use a large counter-sink bit on the holes, and a pencil file or similar to remove the seam. Then clean up the edges with a 120grit flap disc, It is not perfect but will relieve some of the stress on the soft shackle. We are working on a solution for this very issue! Any more questions, please ask. Thanks, Ricky

Hi Joe, you are correct. You need to radius the hole edges and remove the common laser/plasma seam from inside the hole.

I use a large counter-sink bit on the holes, and a pencil file or similar to remove the seam. Then clean up the edges with a 120grit flap disc, It is not perfect but will relieve some of the stress on the soft shackle. We are working on a solution for this very issue! Any more questions, please ask. Thanks, Ricky

We are working on a solution for this very issue!

Hmm...maybe there's a way to turn the mount into a mini-fairlead, or a cleat...

Last edited:

Giant Countersink (1.5"!)....Check. No Flapdisc, but I do have a mandrel with a slot to receive emory paper. I'll run that through the hole to remove the plasma start/stop point and break the edge from the 45. Its nice having a full toolroom at work

Last edited:

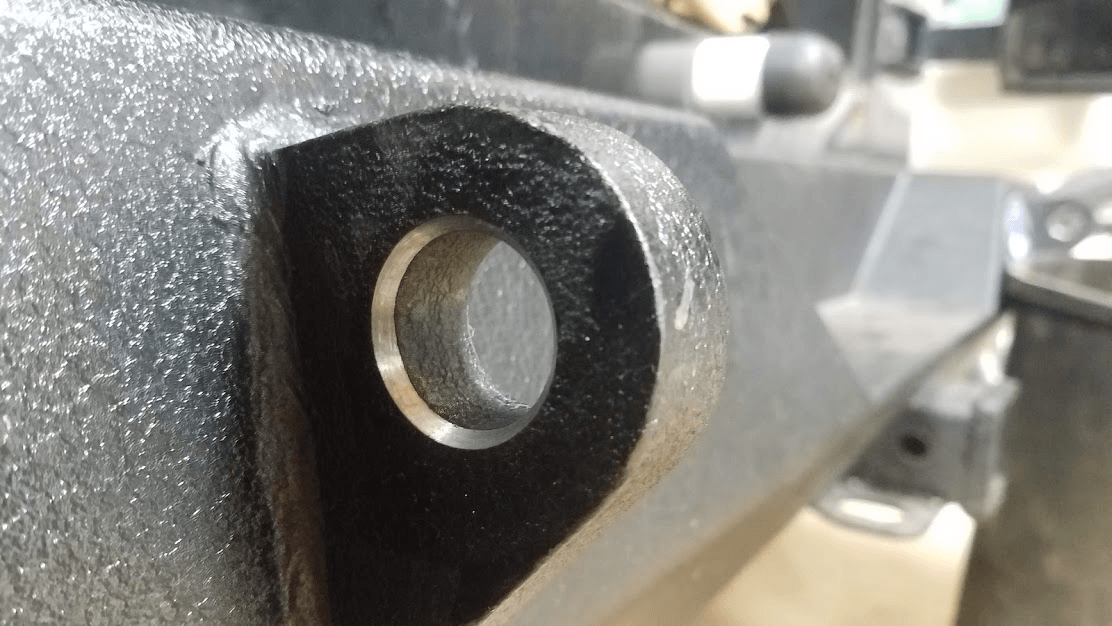

I got my bumpers "softened" up tonight. Put about an 1/8" chamfer on the shackle holes, filed the edges, lumps and bumps, then used my die grinder and strips of emery cloth to polish the new chamfers. Feels nice and soft now.

Looks good, should hit em with some Rustoleum.I got my bumpers "softened" up tonight. Put about an 1/8" chamfer on the shackle holes, filed the edges, lumps and bumps, then used my die grinder and strips of emery cloth to polish the new chamfers. Feels nice and soft now.

View attachment 79660

View attachment 79661

DETOUR

TJ Enthusiast

Jazngab

Get yourself a way more useful soft shackle, instead that fancy F55 paperweight

Jmho

~•lllllll•~

Get yourself a way more useful soft shackle, instead that fancy F55 paperweight

Jmho

~•lllllll•~