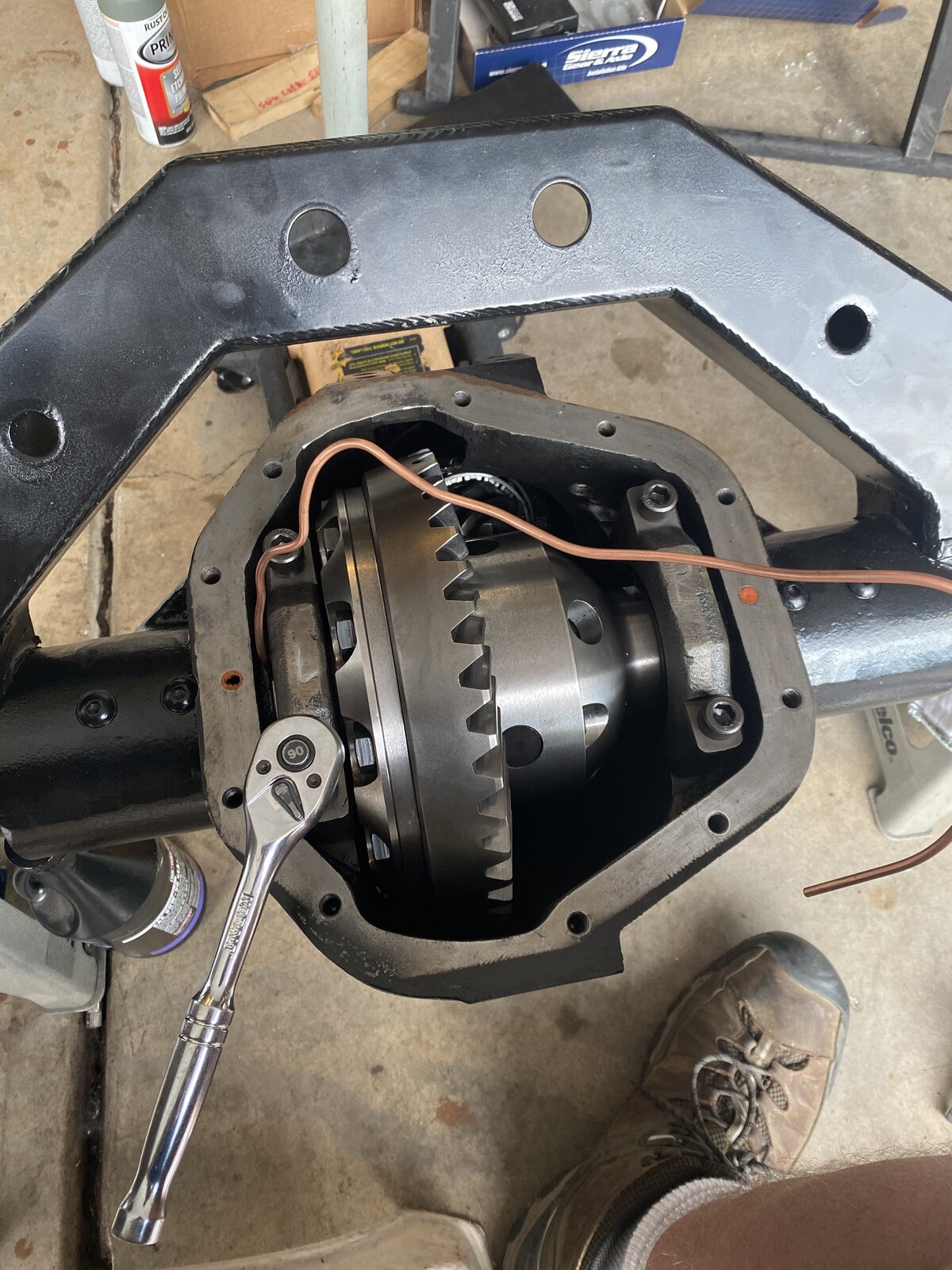

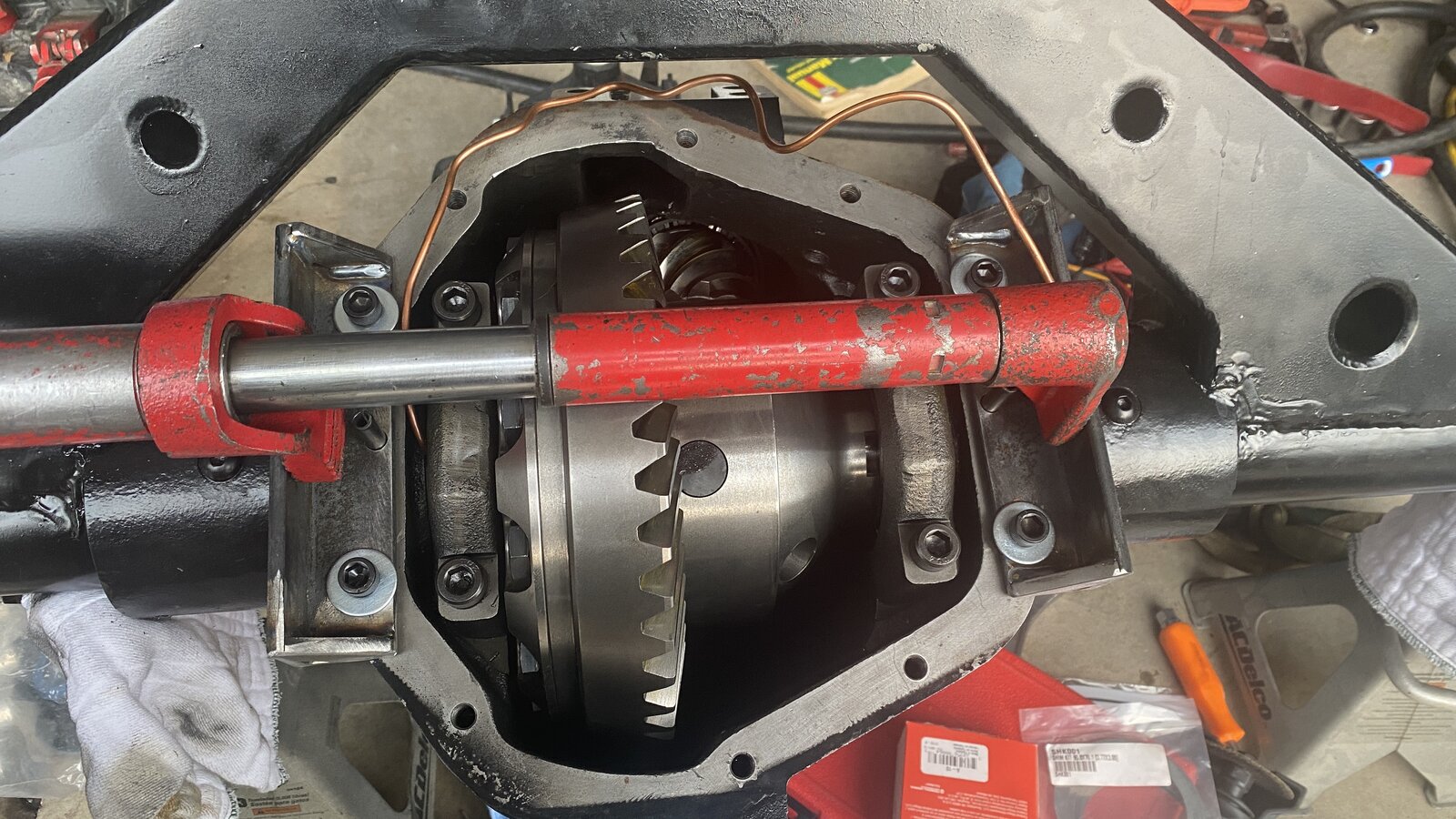

Long story. So I broke my Eaton E-locker. Parts are backordered. So I bought an ARB thinking that would save time. And even though this took awhile the parts for the Eaton still haven’t shipped. But I kept having the shims for the arb crush when trying to set preload on the locker since I couldn’t use a typical case spreader due to the axle truss for the Upper four link mounts. So I decided to build brackets and use a port-a-power jack to use as a case spreader. It worked out great and all is well and backlash is in spec at .009”. I will get the new axle bearing and seals pressed on tomorrow and reverse the brake brackets with the Wizard kit and get this thing all back together tomorrow.

Finally got the new ARB installed in the rear axle. Had to build a case spreader.

- Thread starter Rescue6

- Start date