The factory Dana 35 rear axle found in most TJ Wranglers is a little on the light side, and if you run larger-than-stock tires, you’re likely looking at an eventual failure. If you want to turn really big tires, wheel abusively, or push gobs of power into your rear axle, you’ll probably want to head to 1-ton territory and consider Dana 60 and Corporate 14-bolt axle options. For those looking for an upgrade option to run tires up to about 35 inches or so, the Ford 8.8 is a viable option. It’s been used in Ford cars, trucks, and SUVs for decades and has replaced the Ford 9-inch axle in many instances.

The drum-brake Dana 35 in a TJ Wrangler measures about 60 3/4 inches between wheel mount surfaces. The Ford 8.8 measures about 59 1/2 inches, so just over an inch narrower. The Ford axle uses an 8.8-inch ring gear and has been equipped with 28- and 31-spline axleshafts. The 31-spline versions have ’shafts that are about 1.3 inches in diameter. The tubes are 3-1/4-inch diameter, although they do neck-down a bit near the outer ends. Thickness of the tubes seems to be about 0.250 inches. Although the Ford 8.8 is a semi-floating axle design using C-clip retention, the disc brake rotors can help keep a broken axleshaft from working its way out of the axlehousing.

We pulled our donor axle from the junkyard for just less than $100. It was a D2 code axle from a ’01 Eddie Bauer Explorer so it came with 4.10:1 gearing and the factory Trac-Lok limited-slip differential. The axle code can be found on the sticker in the driver-side door. You can also often find a factory metal tag on the differential cover with the axle gear ratio.

When scouring the junkyards for a Ford 8.8 donor axle, the preference is the 31-spline version from a Ford Explorer. Axles coming from ’94-and-older Explorers came with drum brakes, and the ’95-and-newer models (through ’01) were built with disc brakes. Some ’10-’11 Ranger axles were also equipped from the factory with rear disc brakes. A range of gearing ratios was available, and some axles were equipped with the Trac-Lok limited-slip unit. Aftermarket upgrades for the Ford 8.8 are readily available with gear ratios ranging up to 5.71:1. A number of limited slip and locker options are available as well.

Here are the typical Explorer door codes you’ll find for the various rear axles:

41 - Open Diff - 3.27

42 - Open Diff - 4.10

43 - Open Diff - 3.08

44 - Open Diff - 3.73

45 - Open Diff - 3.55

46 - Open Diff - 3.73

D2 - Limited Slip - 4.10

D4 - Limited Slip - 3.73

L73 - Limited Slip - 3.73

The first order of business after removing the brake components was to cut off the old leaf spring perches and swaybar mounts from the Ford axle. We cut them free, ground the areas smooth, and stripped the paint from most of the axletube sections to prepare for mounting new brackets to the axle.

For our Jeep TJ Wrangler in need of an axle, we’ll most likely run 33-inch tires, so we were interested in finding 4.10 gearing, the lowest ratio offered. If you want deeper gears, you have more flexibility in finding a donor as you’ll be swapping ring-and-pinion anyway. We found a good donor axle at our local junkyard and rebuilt it using Yukon Gear & Axle components. Here is what it took to get the upgraded axle under our TJ chassis.

We marked and then trimmed off the excess webbing on the forward end of the differential housing that was originally used for a stabilizer shock. This housing also had an ABS sensor bolted on top. We may leave it intact or make a simple plate cover to take its place.

Here is our junkyard axle stripped and ready for modification. We set it up on jackstands near our stock Dana 35 so we could easily measure and transfer mount dimensions. We measured the stock pinion angle (with the spring pads level) to be about 11 degrees. For our case, we set our new pinion angle to about 14 degrees to better accommodate a small lift.

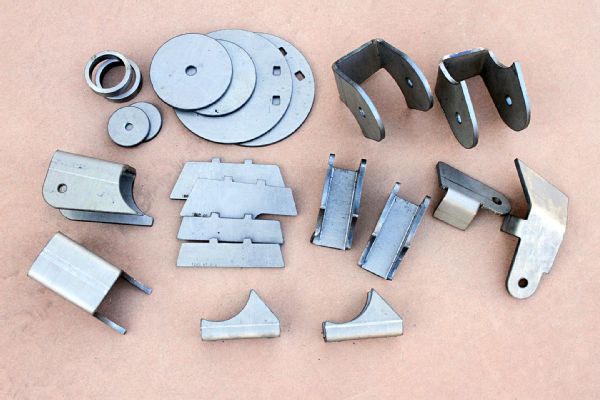

We purchased a Ford 8.8 bracket swap kit from Ballistic Fabrication to make the axle swap onto our TJ suspension easier. All the bracketry is made from 1/4-inch thick steel, a substantial upgrade from the 0.14-inch-thick steel used from the factory.

After setting our pinion angle, we started by tack-welding the spring pads level on the tubes. Note that when transferring measurements, the differential is not centered on the axle. Ballistic includes no instructions with its kit, but they provide CAD-generated assembly images on their website for reference. The company’s lower link mounts do index nicely with the spring pad plates. Once we got the link mounts tacked onto the tubes, we rolled the axle back under our Jeep frame to check fitment.

With our Ford 8.8 axle centered under the frame, we were able to determine the best mounting location for the track bar bracket, which we mounted against the left side upper link mount and later welded the two brackets to each other. This also served to raise the track bar mount upward about 2 inches over stock height. We welded the Ford vent hole closed on the axle tube and tapped a new 7/16-20 hole in the tube in the same location as on the Dana 35.

Next, we determined the best mounting location and angle for each shock mount. You’ll need to make a few measurements with your lift in mind to determine what angle to place the mounts for proper shock travel.

Once all the mounts were tacked into place and all measurements and angles double-checked, we fully welded everything in place. Here’s the Ford 8.8 as it sat in comparison to our old Dana 35.

We tore down the differential and all looked pretty good inside. We visually confirmed that we had 4.10 gearing as expected. One area of weakness we should note is that of the factory differential carrier which has been known to crack when used fairly hard. A second weakness of this axle assembly is where the axletubes enter the differential housing. Ford secured each tube to the housing with three steel rivets that pin the tubes in place. Under harder use, it's possible to spin these tubes in the housing. The common solution is to run a circumferential weld at this joint.

We were able to get all the parts needed to refurbish our axle (except for brake components) in one stop from Yukon Gear & Axle, including a new limited-slip unit and the fluid needed for the differential. We reused the factory ring-and-pinion but rebuilt the differential with new bearings and seals.

We briefly considered rebuilding the factory Ford clutch-type limited-slip unit but knew it would still be a bit weak for the action we wanted. We opted to upgrade to a Yukon Dura Grip that will provide a stronger differential case. We’ve used this unit before and found it provides an aggressive limited-slip action without the harsher characteristics of a mechanical locking differential.

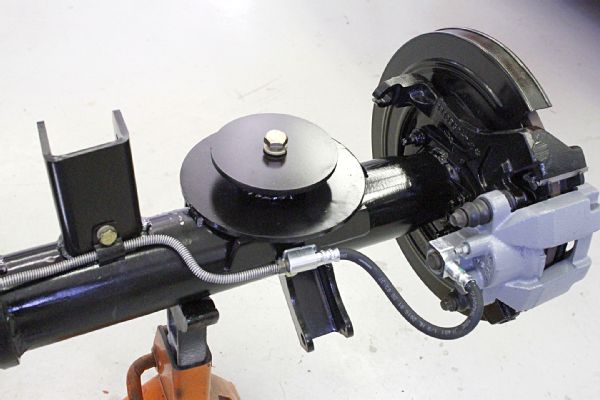

We installed fresh axle bearings and seals from Yukon as well. We inspected the factory axleshafts and they looked fine. Upgraded chromoly ’shafts are available and are an option to us if we find we need more strength later. Here you can also see the drum parking brake assembly that sits under the disc-rotor hat on these axles.

The brake rotors on our junkyard axle looked nearly new. While we had it apart we decided to go ahead and do a quick caliper rebuild and install fresh pads. Both rebuild kits and replacement calipers are reasonably priced for these axles.

When addressing the brake lines, there are several ways to plumb the Ford calipers to the Jeep chassis hard line. We decided to use two right-side Explorer soft lines (flipping the steel mount plate on one) to plumb the calipers to the hardlines we took off the Dana 35. The lines had to be reshaped a bit and new ends flared on. We added bolt-on line retention clips where needed.

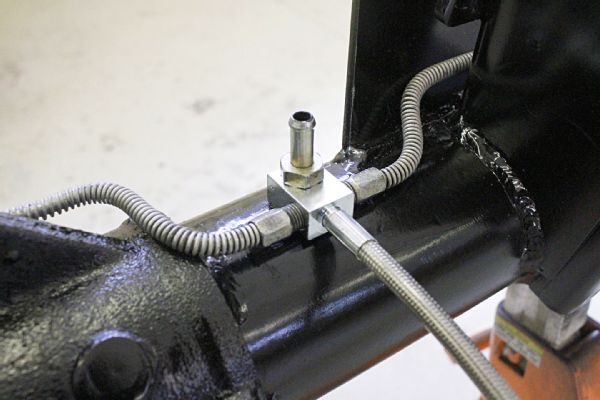

As mentioned, we created an axle vent tube hole in the same location as that on the Dana 35. The vent tube secures the rear brake line tee. We purchased an extended stainless braided brake line and mounted it using the original Jeep vent tube fitting.

The Ford 8.8 we are interested in comes with a pinion flange instead of the more common U-joint yoke found on domestic axles. You can swap on an aftermarket yoke or leave the flanged piece in place. A mating piece can be taken from the salvaged Explorer driveshaft and will accept a 1330-series U-joint, or you can do what we did and purchase a Dana Spicer 2-2-1379 conversion flange that will mate to a standard 1310-series U-joint found on Jeep Wranglers. Aftermarket yokes are also available to bump the joint size up to the heavy-duty 1350 series, if desired. Be sure to grab the mounting bolts for the yoke when you get your junkyard axle.

We brought home the parking brake cables with the Ford axle. We’re not currently using them for our application but there are several options available, including use of Grand Cherokee parking brake cables, aftermarket cable solutions, or modification for reuse of the Ford cables.

This article was originally written for and posted on Fourwheeler.com. I am only sharing it here so that fellow TJ owners might stumble upon it.

The drum-brake Dana 35 in a TJ Wrangler measures about 60 3/4 inches between wheel mount surfaces. The Ford 8.8 measures about 59 1/2 inches, so just over an inch narrower. The Ford axle uses an 8.8-inch ring gear and has been equipped with 28- and 31-spline axleshafts. The 31-spline versions have ’shafts that are about 1.3 inches in diameter. The tubes are 3-1/4-inch diameter, although they do neck-down a bit near the outer ends. Thickness of the tubes seems to be about 0.250 inches. Although the Ford 8.8 is a semi-floating axle design using C-clip retention, the disc brake rotors can help keep a broken axleshaft from working its way out of the axlehousing.

We pulled our donor axle from the junkyard for just less than $100. It was a D2 code axle from a ’01 Eddie Bauer Explorer so it came with 4.10:1 gearing and the factory Trac-Lok limited-slip differential. The axle code can be found on the sticker in the driver-side door. You can also often find a factory metal tag on the differential cover with the axle gear ratio.

When scouring the junkyards for a Ford 8.8 donor axle, the preference is the 31-spline version from a Ford Explorer. Axles coming from ’94-and-older Explorers came with drum brakes, and the ’95-and-newer models (through ’01) were built with disc brakes. Some ’10-’11 Ranger axles were also equipped from the factory with rear disc brakes. A range of gearing ratios was available, and some axles were equipped with the Trac-Lok limited-slip unit. Aftermarket upgrades for the Ford 8.8 are readily available with gear ratios ranging up to 5.71:1. A number of limited slip and locker options are available as well.

Here are the typical Explorer door codes you’ll find for the various rear axles:

41 - Open Diff - 3.27

42 - Open Diff - 4.10

43 - Open Diff - 3.08

44 - Open Diff - 3.73

45 - Open Diff - 3.55

46 - Open Diff - 3.73

D2 - Limited Slip - 4.10

D4 - Limited Slip - 3.73

L73 - Limited Slip - 3.73

The first order of business after removing the brake components was to cut off the old leaf spring perches and swaybar mounts from the Ford axle. We cut them free, ground the areas smooth, and stripped the paint from most of the axletube sections to prepare for mounting new brackets to the axle.

For our Jeep TJ Wrangler in need of an axle, we’ll most likely run 33-inch tires, so we were interested in finding 4.10 gearing, the lowest ratio offered. If you want deeper gears, you have more flexibility in finding a donor as you’ll be swapping ring-and-pinion anyway. We found a good donor axle at our local junkyard and rebuilt it using Yukon Gear & Axle components. Here is what it took to get the upgraded axle under our TJ chassis.

We marked and then trimmed off the excess webbing on the forward end of the differential housing that was originally used for a stabilizer shock. This housing also had an ABS sensor bolted on top. We may leave it intact or make a simple plate cover to take its place.

Here is our junkyard axle stripped and ready for modification. We set it up on jackstands near our stock Dana 35 so we could easily measure and transfer mount dimensions. We measured the stock pinion angle (with the spring pads level) to be about 11 degrees. For our case, we set our new pinion angle to about 14 degrees to better accommodate a small lift.

We purchased a Ford 8.8 bracket swap kit from Ballistic Fabrication to make the axle swap onto our TJ suspension easier. All the bracketry is made from 1/4-inch thick steel, a substantial upgrade from the 0.14-inch-thick steel used from the factory.

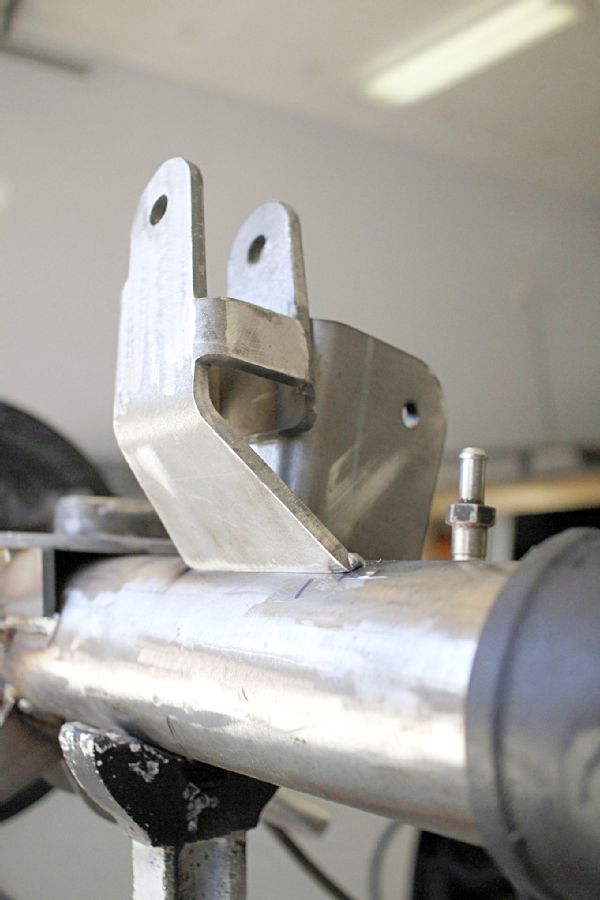

After setting our pinion angle, we started by tack-welding the spring pads level on the tubes. Note that when transferring measurements, the differential is not centered on the axle. Ballistic includes no instructions with its kit, but they provide CAD-generated assembly images on their website for reference. The company’s lower link mounts do index nicely with the spring pad plates. Once we got the link mounts tacked onto the tubes, we rolled the axle back under our Jeep frame to check fitment.

With our Ford 8.8 axle centered under the frame, we were able to determine the best mounting location for the track bar bracket, which we mounted against the left side upper link mount and later welded the two brackets to each other. This also served to raise the track bar mount upward about 2 inches over stock height. We welded the Ford vent hole closed on the axle tube and tapped a new 7/16-20 hole in the tube in the same location as on the Dana 35.

Next, we determined the best mounting location and angle for each shock mount. You’ll need to make a few measurements with your lift in mind to determine what angle to place the mounts for proper shock travel.

Once all the mounts were tacked into place and all measurements and angles double-checked, we fully welded everything in place. Here’s the Ford 8.8 as it sat in comparison to our old Dana 35.

We tore down the differential and all looked pretty good inside. We visually confirmed that we had 4.10 gearing as expected. One area of weakness we should note is that of the factory differential carrier which has been known to crack when used fairly hard. A second weakness of this axle assembly is where the axletubes enter the differential housing. Ford secured each tube to the housing with three steel rivets that pin the tubes in place. Under harder use, it's possible to spin these tubes in the housing. The common solution is to run a circumferential weld at this joint.

We were able to get all the parts needed to refurbish our axle (except for brake components) in one stop from Yukon Gear & Axle, including a new limited-slip unit and the fluid needed for the differential. We reused the factory ring-and-pinion but rebuilt the differential with new bearings and seals.

We briefly considered rebuilding the factory Ford clutch-type limited-slip unit but knew it would still be a bit weak for the action we wanted. We opted to upgrade to a Yukon Dura Grip that will provide a stronger differential case. We’ve used this unit before and found it provides an aggressive limited-slip action without the harsher characteristics of a mechanical locking differential.

We installed fresh axle bearings and seals from Yukon as well. We inspected the factory axleshafts and they looked fine. Upgraded chromoly ’shafts are available and are an option to us if we find we need more strength later. Here you can also see the drum parking brake assembly that sits under the disc-rotor hat on these axles.

The brake rotors on our junkyard axle looked nearly new. While we had it apart we decided to go ahead and do a quick caliper rebuild and install fresh pads. Both rebuild kits and replacement calipers are reasonably priced for these axles.

When addressing the brake lines, there are several ways to plumb the Ford calipers to the Jeep chassis hard line. We decided to use two right-side Explorer soft lines (flipping the steel mount plate on one) to plumb the calipers to the hardlines we took off the Dana 35. The lines had to be reshaped a bit and new ends flared on. We added bolt-on line retention clips where needed.

As mentioned, we created an axle vent tube hole in the same location as that on the Dana 35. The vent tube secures the rear brake line tee. We purchased an extended stainless braided brake line and mounted it using the original Jeep vent tube fitting.

The Ford 8.8 we are interested in comes with a pinion flange instead of the more common U-joint yoke found on domestic axles. You can swap on an aftermarket yoke or leave the flanged piece in place. A mating piece can be taken from the salvaged Explorer driveshaft and will accept a 1330-series U-joint, or you can do what we did and purchase a Dana Spicer 2-2-1379 conversion flange that will mate to a standard 1310-series U-joint found on Jeep Wranglers. Aftermarket yokes are also available to bump the joint size up to the heavy-duty 1350 series, if desired. Be sure to grab the mounting bolts for the yoke when you get your junkyard axle.

We brought home the parking brake cables with the Ford axle. We’re not currently using them for our application but there are several options available, including use of Grand Cherokee parking brake cables, aftermarket cable solutions, or modification for reuse of the Ford cables.

This article was originally written for and posted on Fourwheeler.com. I am only sharing it here so that fellow TJ owners might stumble upon it.