Here's how to check and adjust your own toe-in that also includes how to center the steering wheel as well as re-center the axle if necessary. With just a little care on your part with nothing more than a tape measure, a big set of pliers, and a wrench, you can easily set your toe-in with as much accuracy as an alignment shop can. Really.

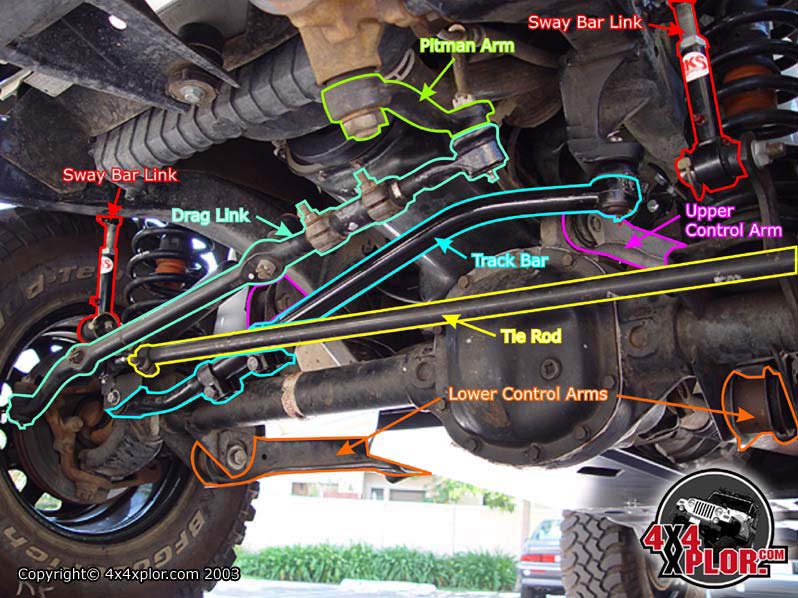

Start after making sure the front axle is properly centered. That may involve adjusting its length if there's an aftermarket adjustable length track bar installed. Or if the original OEM track bar is still installed and you have installed more than about a 2" suspension lift, that means the axle is off-center enough so it needs an adjustable length track bar.

The trackbar's relationship to the frame and axle is like the diagonal line in the letter Z. Raising the frame with a suspension lift causes the diagonally mounted track bar to pull the axle to the side. The taller the suspension lift the more the front axle is pulled toward the driver's side. The rear axle moves opposite toward the passenger side. Adjusting the aftermarket adjustable length track bar to a longer length will re-center the axle.

Using the basic information at http://www.4x4xplor.com/alignment.html, set your toe-in so the fronts of the tires are 1/16" to 1/8" (3/16" for 35's) closer together in front than in the rear. This is done by loosening the clamps that hold the tie rod to the tie rod ends, then rotating the tie rod until you get the desired amount of toe-in. Use a tape measure to measure the distance between the tires at the front and rear.

If the tie rod is too tight to turn using pliers or vise grips, spray the ends with a penetrant like Kroil, Break-Free, or Liquid Wrench. No, WD-40 is not a suitable substitute. Give it some time to work its way into the threads. Then use a pipe wrench on the tie rod to break it loose from where it was seized to the tie rod ends. Better yet, entirely remove the tie rod and dab a little Antiseize on its threads so it will never seize again.

For an easier and more repeatable way of measuring your toe-in than measuring between the tires, use a pair of 1" square aluminum tubes as in the below photos and use them to measure between. Center and hold the square tubes to the rotors with spring steel clamps after marking them at points equal to the diameter of your tires.

Using just a little care, your toe-in setting will be just as accurate as an alignment specialist can produce using an alignment rack. Plus you can be done in 5-15 minutes from start to finish, quicker than you can even drive to the alignment shop. Not to mention you can do this on your own for free vs. the $70-90 an alignment shop charges for something that is far easier to do than most people would ever guess.

This is all that an alignment shop can do to your TJ, this is the sum extent of an alignment where a TJ is concerned. Neither your caster angle nor your camber angle is adjustable without aftermarket parts so without those, only your toe-in is adjustable. There is no real need to waste your money by paying an alignment shop for an alignment since all they're going to do is set your toe-in and center your steering wheel. Both of which are too easy to do for anyone here to pay for.

Re-centering the steering wheel is required whenever the toe-in is adjusted or when the suspension height changes. That is easily done by rotating the short adjustment link on the drag link after loosening its two clamps. Rotating the adjustment link upwards in front will shorten the drag link and rotate the steering wheel CCW and visa-versa.

Make sure the front of your TJ is supported by jack stands placed under the front axle. The front axle must be supporting the weight of the vehicle, the Jeep cannot be supported from the frame during the toe-in check and adjustment.

The above two photos are courtesy of Mrblaine, a true guru of all things Jeep.

Start after making sure the front axle is properly centered. That may involve adjusting its length if there's an aftermarket adjustable length track bar installed. Or if the original OEM track bar is still installed and you have installed more than about a 2" suspension lift, that means the axle is off-center enough so it needs an adjustable length track bar.

The trackbar's relationship to the frame and axle is like the diagonal line in the letter Z. Raising the frame with a suspension lift causes the diagonally mounted track bar to pull the axle to the side. The taller the suspension lift the more the front axle is pulled toward the driver's side. The rear axle moves opposite toward the passenger side. Adjusting the aftermarket adjustable length track bar to a longer length will re-center the axle.

Using the basic information at http://www.4x4xplor.com/alignment.html, set your toe-in so the fronts of the tires are 1/16" to 1/8" (3/16" for 35's) closer together in front than in the rear. This is done by loosening the clamps that hold the tie rod to the tie rod ends, then rotating the tie rod until you get the desired amount of toe-in. Use a tape measure to measure the distance between the tires at the front and rear.

If the tie rod is too tight to turn using pliers or vise grips, spray the ends with a penetrant like Kroil, Break-Free, or Liquid Wrench. No, WD-40 is not a suitable substitute. Give it some time to work its way into the threads. Then use a pipe wrench on the tie rod to break it loose from where it was seized to the tie rod ends. Better yet, entirely remove the tie rod and dab a little Antiseize on its threads so it will never seize again.

For an easier and more repeatable way of measuring your toe-in than measuring between the tires, use a pair of 1" square aluminum tubes as in the below photos and use them to measure between. Center and hold the square tubes to the rotors with spring steel clamps after marking them at points equal to the diameter of your tires.

Using just a little care, your toe-in setting will be just as accurate as an alignment specialist can produce using an alignment rack. Plus you can be done in 5-15 minutes from start to finish, quicker than you can even drive to the alignment shop. Not to mention you can do this on your own for free vs. the $70-90 an alignment shop charges for something that is far easier to do than most people would ever guess.

This is all that an alignment shop can do to your TJ, this is the sum extent of an alignment where a TJ is concerned. Neither your caster angle nor your camber angle is adjustable without aftermarket parts so without those, only your toe-in is adjustable. There is no real need to waste your money by paying an alignment shop for an alignment since all they're going to do is set your toe-in and center your steering wheel. Both of which are too easy to do for anyone here to pay for.

Re-centering the steering wheel is required whenever the toe-in is adjusted or when the suspension height changes. That is easily done by rotating the short adjustment link on the drag link after loosening its two clamps. Rotating the adjustment link upwards in front will shorten the drag link and rotate the steering wheel CCW and visa-versa.

Make sure the front of your TJ is supported by jack stands placed under the front axle. The front axle must be supporting the weight of the vehicle, the Jeep cannot be supported from the frame during the toe-in check and adjustment.

The above two photos are courtesy of Mrblaine, a true guru of all things Jeep.