figured id do a rough walk through on how to replace your starter brushes on the Mitsubishi starter motor used in the 2003-2006 manual trans wrangler.

skip to the end if your just interested in the brushes... otherwise your gonna be looking at the full starter disassembly/reassembly. a whole breakdown isnt necessary for brush replacement but is something goes wrong it may help if need be.

I used maniac electric motors as my parts supplier online as these are not available at the local auto parts shop. maniac motors has a brush set for $13 & brush & solenoid kit for about $33.

Mitsubishi still sells oem brushes and I am uncertain of the part number at the moment but remember they are about $60.

Tools Required

12MM socket *or wrench*

#3 Phillips screwdriver

#2 Phillips screwdriver

Fine Pick *or a few toothpicks*

Scotch brite pad *or very fine grit sandpaper*

Materials highly suggested

CRC QD Electronic Cleaner spray (CRC part number 05103, this is for cleaning everything)

Lithium EP Moly grease (plastic safe required)

Silicone grease (example.. SIL-Glyde which is plastic safe)

Optional Equipment

Q-tips

Small plastic bristled brush *or toothbrush*

Motor oil

Gloves or Hand degreaser

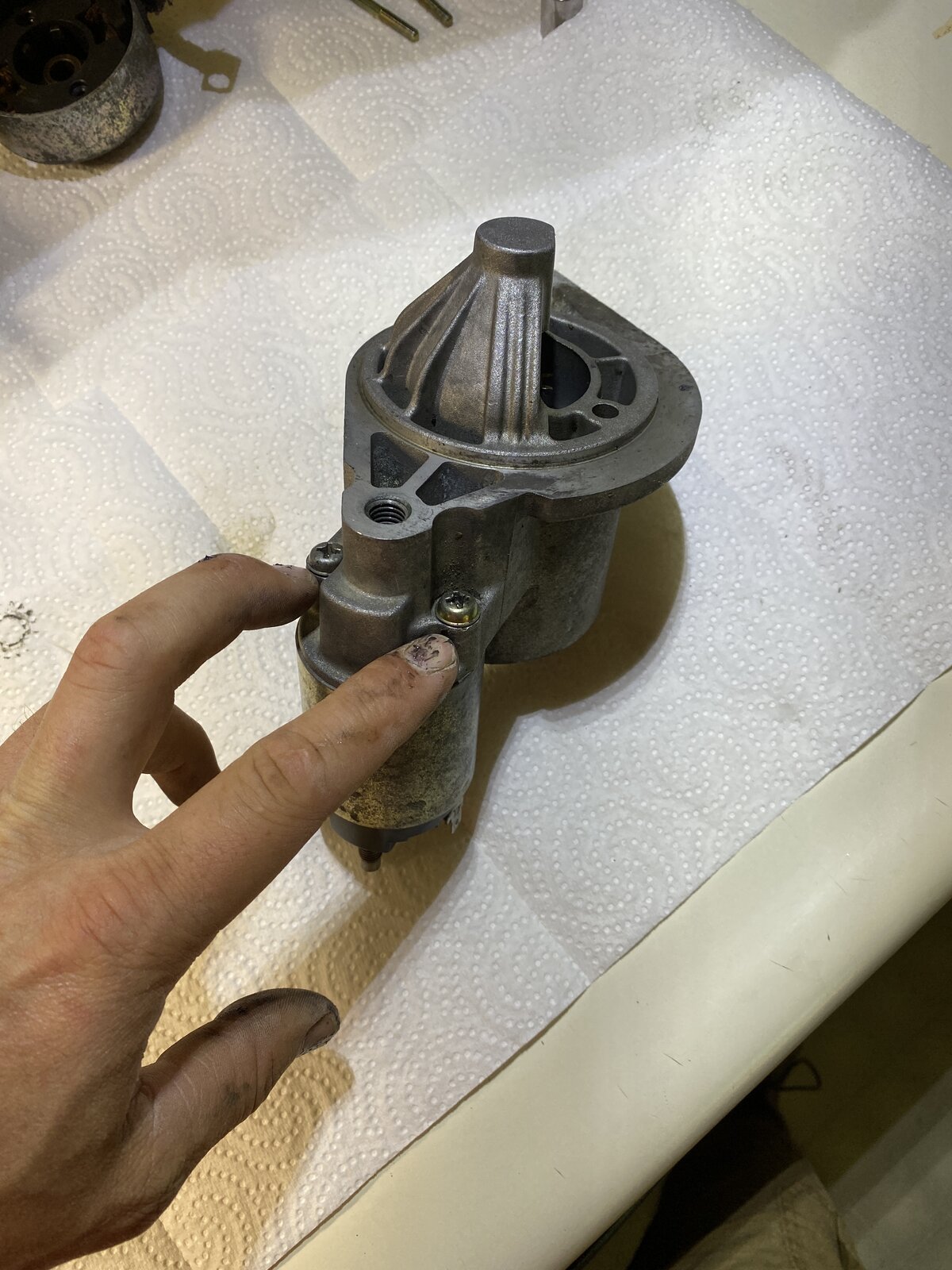

first your gonna start with the starter off of the vehicle

Remove the brushset 12mm nut from the solenoid.

remove the 2x 8mm bolts from the starter being cautious as to not allow the whole starter housing assembly to fall apart as these are what holds the rear, center and front of the starter all together.

you can see what I mean as they are lengthy bolts.

remove the cap containing the brushset

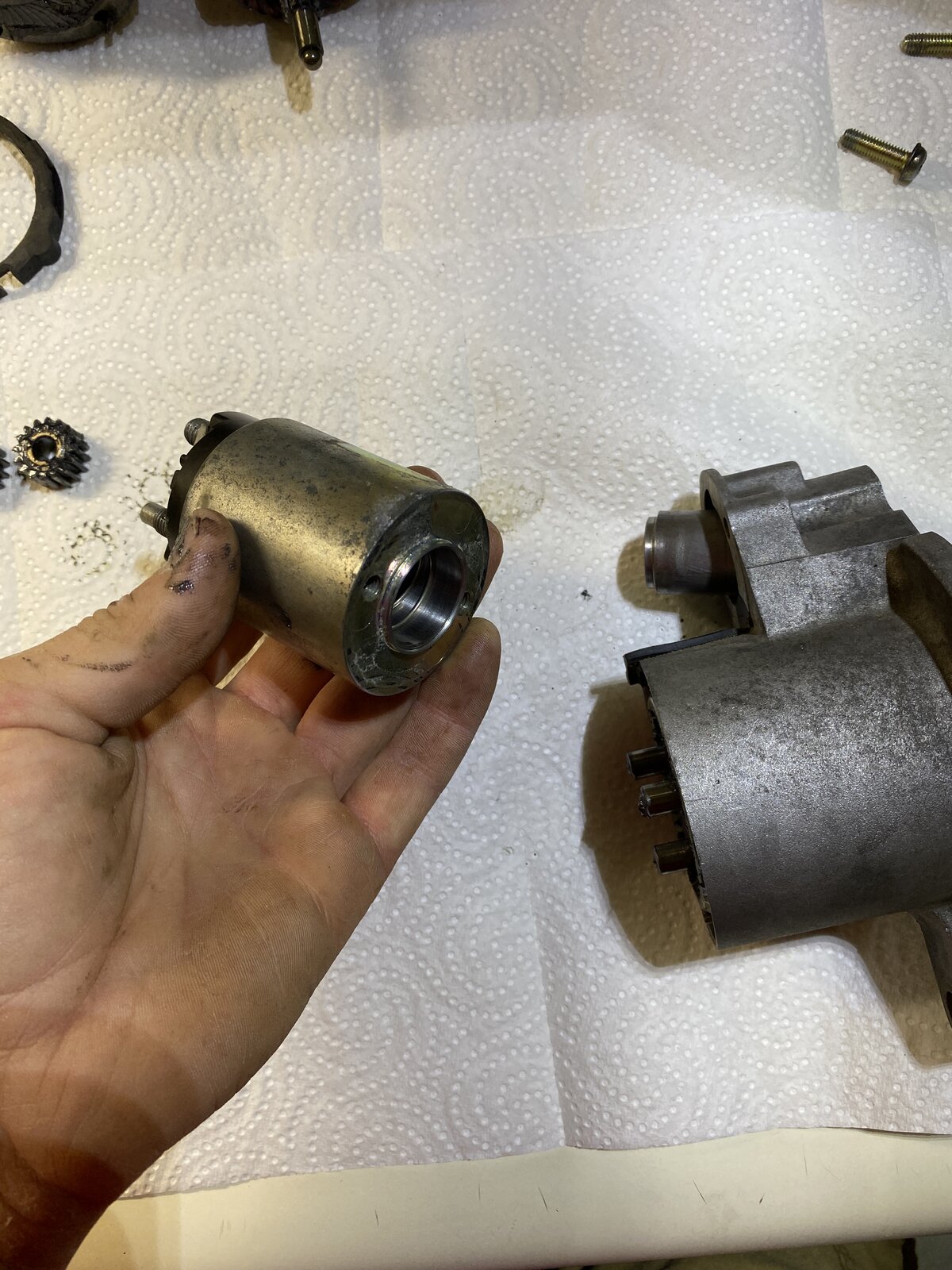

remove the armature (take note of the ball bearing on the bottom of the armature shaft) carefully set this aside and save for reassembly later. it should be accessible once pulling the armature though you may find it in its socket with the gears later during disassembly.

remove the magnet housing (note where the tabs on the bottom came from) the tabs will relocate inline with the solenoid during reassembly.

remove the rubber gear seal

remove the 3 gears

remove the 2 #3 Phillips mounting screws from the solenoid coil

remove the solenoid coil (there is a large spring inside so dont lose it)

unhook the solenoid plunger from the throwout fork and set aside

grab and pull out the rubber seal

pluck out the nickel sized pivot cap, it should just fall out of place.

pivot cap removed

pull out the rest of the gear/clutch assembly. take special note of the orientation of the nylon throw out fork.

again... pay attention to the position the throw out fork is oriented... you dont want to reinstall it upside down!

Now at this point the whole starter should be broken down for the most part other than the brushset and cap. id suggest a heavy dousing with some CRC QD electronic cleaner and get all the grease, dirt and whatever else has caked every component you've disassembled and removed. I attempted using degreaser and also dawn dish soap but both just seemed to smear everything around rather than remove it like the electronic cleaner. ive had good luck with the CRC QD electronic cleaner which is what I would recommend, anything else and your on your own if it damages anything.

skip to the end if your just interested in the brushes... otherwise your gonna be looking at the full starter disassembly/reassembly. a whole breakdown isnt necessary for brush replacement but is something goes wrong it may help if need be.

I used maniac electric motors as my parts supplier online as these are not available at the local auto parts shop. maniac motors has a brush set for $13 & brush & solenoid kit for about $33.

Mitsubishi still sells oem brushes and I am uncertain of the part number at the moment but remember they are about $60.

Tools Required

12MM socket *or wrench*

#3 Phillips screwdriver

#2 Phillips screwdriver

Fine Pick *or a few toothpicks*

Scotch brite pad *or very fine grit sandpaper*

Materials highly suggested

CRC QD Electronic Cleaner spray (CRC part number 05103, this is for cleaning everything)

Lithium EP Moly grease (plastic safe required)

Silicone grease (example.. SIL-Glyde which is plastic safe)

Optional Equipment

Q-tips

Small plastic bristled brush *or toothbrush*

Motor oil

Gloves or Hand degreaser

first your gonna start with the starter off of the vehicle

Remove the brushset 12mm nut from the solenoid.

remove the 2x 8mm bolts from the starter being cautious as to not allow the whole starter housing assembly to fall apart as these are what holds the rear, center and front of the starter all together.

you can see what I mean as they are lengthy bolts.

remove the cap containing the brushset

remove the armature (take note of the ball bearing on the bottom of the armature shaft) carefully set this aside and save for reassembly later. it should be accessible once pulling the armature though you may find it in its socket with the gears later during disassembly.

remove the magnet housing (note where the tabs on the bottom came from) the tabs will relocate inline with the solenoid during reassembly.

remove the rubber gear seal

remove the 3 gears

remove the 2 #3 Phillips mounting screws from the solenoid coil

remove the solenoid coil (there is a large spring inside so dont lose it)

unhook the solenoid plunger from the throwout fork and set aside

grab and pull out the rubber seal

pluck out the nickel sized pivot cap, it should just fall out of place.

pivot cap removed

pull out the rest of the gear/clutch assembly. take special note of the orientation of the nylon throw out fork.

again... pay attention to the position the throw out fork is oriented... you dont want to reinstall it upside down!

Now at this point the whole starter should be broken down for the most part other than the brushset and cap. id suggest a heavy dousing with some CRC QD electronic cleaner and get all the grease, dirt and whatever else has caked every component you've disassembled and removed. I attempted using degreaser and also dawn dish soap but both just seemed to smear everything around rather than remove it like the electronic cleaner. ive had good luck with the CRC QD electronic cleaner which is what I would recommend, anything else and your on your own if it damages anything.

Last edited: