Went to clean mine today and found no bottom screw and the top screw was only threaded in about a third of the way. The IAC was flopping around, wasn’t really any idle issues before. In case anyone wants to know, the screws are 10-24.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to clean your IAC (Idle Air Controller) valve

- Thread starter Chris

- Start date

Cleaned mine last week. (That bottom screw was a pain). Results are a smoother idle, nearly eliminated that surge when taking off in first gear, and prob about a 2 mpg increase at the pump.

Kenneth G Zinis

TJ Enthusiast

Mike, mine has 74k, with just a slightest bounce in tach, and little roughness at idle, ~50-100 RPM variation, and a little rough on start off. What were your rough idle symptoms like?This fixed my rough idle with only 56k on it at the time.

The throttle body did not actually look that bad but if definitely smoothed out the idle. It would decrease in RPM and start shaking slightly, then RPMs would go up and smooth out. Sometimes I thought it would die but it never did. It also seemed worse after the engine was nice and hot such as sitting at a stop light after a stretch of highway. Some might say that was heat soak but cleaning the throttle body fixed it all for sure. I did not take the throttle body off or anything. Just shot intake cleaner in while it was idling.

Kenneth G Zinis

TJ Enthusiast

Hey Chris, Stumbled across your instructions today and followed your steps above. My carbon build-up was similar to your pics and parts cleaned up great. Needed to scrub with Q-tips, soaked in cleaner, for the heavy deposits. My symptoms were very mild but now idle is rock steady and silky smooth on start-offs. Thanks for your excellent instructions and pictures. KenIf you're experiencing idle issues on your Jeep Wrangler TJ the most likely culprit (and the first thing you should check) is your IAC (Idle Air Controller). Often times the IAC gets very gunked up causing the Jeep to idle improperly. A simple cleaning is usually all it takes to get it running as good as new.

If you end up needing to replace your IAC valve (they do fail on occasion), you can find the part numbers (and the links to purchase them on Amazon) below:

2005-2006 IAC Valve (Part # 4861552AC)

1997-2004 IAC Valve (Part # 4874373AB)

There is no need at all to remove the throttle body to clean the IAC. This is probably one of the easiest and cheapest things you can do.

Below you'll see a diagram of the top of your throttle body with the IAC sensor labeled.

View attachment 14140

Take your IAC off (it's held on by two small torx screws). Clean it with your throttle body cleaner, this is what it will look like before and after.

View attachment 1798

View attachment 1799

Then take off the IAC housing and both sides (house and throttle body). clean that too. before and after...

View attachment 1800

View attachment 1801

View attachment 1802

Put it all back together and you're good to go. Very, very simple. It doesn't get any easier than this!

Kenneth G Zinis

TJ Enthusiast

Mike,The throttle body did not actually look that bad but if definitely smoothed out the idle. It would decrease in RPM and start shaking slightly, then RPMs would go up and smooth out. Sometimes I thought it would die but it never did. It also seemed worse after the engine was nice and hot such as sitting at a stop light after a stretch of highway. Some might say that was heat soak but cleaning the throttle body fixed it all for sure. I did not take the throttle body off or anything. Just shot intake cleaner in while it was idling.

Just cleaned mine following these steps, idle is rock steady and sounds sweet, thanks.

Ken

Kenneth G Zinis

TJ Enthusiast

Seriously Scotty, improved MPGs too?Cleaned mine last week. (That bottom screw was a pain). Results are a smoother idle, nearly eliminated that surge when taking off in first gear, and prob about a 2 mpg increase at the pump.

Kenneth G Zinis

TJ Enthusiast

What are symptoms of throttle body needing cleaning? What's the process, clean in place? Thanks

Symptoms I was having:

RPMs staying elevated in neutral or with clutch engaged. In gear when I let off the gas pedal the throttle would stay around 2000 RPMs. This was an intermittent problem. No check engine light. Checked throttle body after researching (thanks guys). Above butterfly valve looked good, below was another story.

What fixed it:

I decided to pull entire throttle body off for access...it’s only 4 bolts.

Pulled IACM, TPS, and MAP off for cleaning. Even though it looked like my TB had been cleaned before(160,000 miles) the IACM was filthy so I pulled the IACM housing off and I’m glad I did, it was caked and probably not letting the IAC plunger seat correctly.

1.5 bottles of throttle body cleaner and a little elbow grease and it cleaned up nicely. Reinstalled all the sensors and my idle is definitely smoother and the RPM “sticking” is gone.

What you will need:

Throttle body cleaner (minimum 1 bottle if it is filthy).

A bunch of clean rags

Eye protection...seriously

Gloves...took some skin off my thumbs when I got lazy and didn’t glove up

T20 torx bit (mandatory if removing sensors and IACM housing)

10mm socket and an extension (I think it was 10, can’t remember exactly.)

New Throttle body gasket (it’s cheap just get it)

Gasket stock material (the gasket between the IACM housing and the TB crumbled when I removed it so I had to make a new one) Got some cheap from NAPA and made a new one using a ball pin hammer and razor knife...look up how to do this, it took me the most time by far.

Thoughts:

Some have suggested cleaning without removing throttle body. I believe that would work after you thoroughly clean everything once and then maintain a regular cleaning schedule (like every time you change your air filter). But there is no way I could’ve cleaned mine without taking it off. Save yourself the aggravation and take the throttle body off.

There are 2 gaskets involved (at least on my 2004 4.0). I’ve seen it posted where people didn’t have gaskets or had them but didn’t replace them.

Throttle body gasket

IACM housing gasket

They were on there when I took it off for a reason so I replaced them. (My 2 cents)

I guess you could get away with not removing the IACM housing and save yourself the trouble of replacing that gasket but I went all the way, just my style.

As previous posters have warned be very careful torquing these bolts...it’s aluminum and not under a lot of stress.

I didn’t use thread lock

TB bolts are 100 in lbs or 8.3 ft lbs so finger tighten and snugged with a 1/4 driver and 2 fingers

TPS sensor and IACM 60 in lbs or 5 ft lbs

MAP sensor...I just tightened enough to keep it from moving, it’s T20 bolt. 25 in lbs....so basically finger tight

Total time 2 hours but 45 min was making that damn IACM housing gasket

I know it’s all been covered before but just thought I’d add my experience. Thanks to all previous posters who helped me knock this out.

RPMs staying elevated in neutral or with clutch engaged. In gear when I let off the gas pedal the throttle would stay around 2000 RPMs. This was an intermittent problem. No check engine light. Checked throttle body after researching (thanks guys). Above butterfly valve looked good, below was another story.

What fixed it:

I decided to pull entire throttle body off for access...it’s only 4 bolts.

Pulled IACM, TPS, and MAP off for cleaning. Even though it looked like my TB had been cleaned before(160,000 miles) the IACM was filthy so I pulled the IACM housing off and I’m glad I did, it was caked and probably not letting the IAC plunger seat correctly.

1.5 bottles of throttle body cleaner and a little elbow grease and it cleaned up nicely. Reinstalled all the sensors and my idle is definitely smoother and the RPM “sticking” is gone.

What you will need:

Throttle body cleaner (minimum 1 bottle if it is filthy).

A bunch of clean rags

Eye protection...seriously

Gloves...took some skin off my thumbs when I got lazy and didn’t glove up

T20 torx bit (mandatory if removing sensors and IACM housing)

10mm socket and an extension (I think it was 10, can’t remember exactly.)

New Throttle body gasket (it’s cheap just get it)

Gasket stock material (the gasket between the IACM housing and the TB crumbled when I removed it so I had to make a new one) Got some cheap from NAPA and made a new one using a ball pin hammer and razor knife...look up how to do this, it took me the most time by far.

Thoughts:

Some have suggested cleaning without removing throttle body. I believe that would work after you thoroughly clean everything once and then maintain a regular cleaning schedule (like every time you change your air filter). But there is no way I could’ve cleaned mine without taking it off. Save yourself the aggravation and take the throttle body off.

There are 2 gaskets involved (at least on my 2004 4.0). I’ve seen it posted where people didn’t have gaskets or had them but didn’t replace them.

Throttle body gasket

IACM housing gasket

They were on there when I took it off for a reason so I replaced them. (My 2 cents)

I guess you could get away with not removing the IACM housing and save yourself the trouble of replacing that gasket but I went all the way, just my style.

As previous posters have warned be very careful torquing these bolts...it’s aluminum and not under a lot of stress.

I didn’t use thread lock

TB bolts are 100 in lbs or 8.3 ft lbs so finger tighten and snugged with a 1/4 driver and 2 fingers

TPS sensor and IACM 60 in lbs or 5 ft lbs

MAP sensor...I just tightened enough to keep it from moving, it’s T20 bolt. 25 in lbs....so basically finger tight

Total time 2 hours but 45 min was making that damn IACM housing gasket

I know it’s all been covered before but just thought I’d add my experience. Thanks to all previous posters who helped me knock this out.

MrMark52

TJ Enthusiast

All FWIW - I did this yesterday after not being happy with both the idle, and my perception of less than average gas mileage.

Mine is a 2003 4.0L - I pulled the air duct between the air filter housing and the throttle body (and found a cracked PCV vent hose in the process. I also bought a new filter for it, even though the one that was in there wasn't really that bad).

I could not find throttle body cleaner so bought instead a couple of cans of SeaFoam TBI cleaner (I have become a real fan of SeaFoam). Using the included straw, I followed can directions, starting and insuring a warm engine, then liberally spraying SeaFoam into the IAC port and throttle body while the wife held 2000 RPM's. I all but emptied one can of SeaFoam into the IAC and throttle body.

Since doing this, "Oreo" (my TJ's nick name) seems to have a more steady idle, more pep, and the last 1/4 of tank of gas seemed to go further than before. I filled it up today and took a mileage reading. We're heading on a 2 week trip out West Friday - will report back my findings (assuming I don't do O2 sensors tomorrow before hitting the road. 108k miles on what I expect are the OEM sensors - they may also have an affect on milage and performance, although I am not getting any codes).

Mine is a 2003 4.0L - I pulled the air duct between the air filter housing and the throttle body (and found a cracked PCV vent hose in the process. I also bought a new filter for it, even though the one that was in there wasn't really that bad).

I could not find throttle body cleaner so bought instead a couple of cans of SeaFoam TBI cleaner (I have become a real fan of SeaFoam). Using the included straw, I followed can directions, starting and insuring a warm engine, then liberally spraying SeaFoam into the IAC port and throttle body while the wife held 2000 RPM's. I all but emptied one can of SeaFoam into the IAC and throttle body.

Since doing this, "Oreo" (my TJ's nick name) seems to have a more steady idle, more pep, and the last 1/4 of tank of gas seemed to go further than before. I filled it up today and took a mileage reading. We're heading on a 2 week trip out West Friday - will report back my findings (assuming I don't do O2 sensors tomorrow before hitting the road. 108k miles on what I expect are the OEM sensors - they may also have an affect on milage and performance, although I am not getting any codes).

Yes - Jerry is the one who gave me those instructions. So we know its right!

I took off the intake tube, and gave quick bursts of TB cleaner into the idle air slit that's right above the throttle valve. Then, I sprayed a bunch on top of the throttle valve and revved my engine. I did this until the bottle was empty.

The first few sprays made my engine die, then I couldn't get my engine to die at all. Which I assume means the cleaner worked.

Also, I could literally hear my engine quiet down and smooth out while I was spraying the TB cleaner it. Another sign that I assume it worked!

Hi. I am new here with a 2005 Jeep TJ. My vehicle sometimes dies when coming to a full stop. Also occasionally, on a slight incline while stopped, the RPMs go up and down (300 to 1000). It usually normally idles between 600 to 700 RPMs, I think.

My question on Kyle's post is when the engine would not die at all while spraying the TB cleaner, was he spraying while idle or revving? Because I tried doing the instructions from Jerry (use 1/3 of bottle during idle, and the rest while revving), and not sure if I need to continue spraying it while idle, and until it really stops dying. Thanks... Don

MrMark52

TJ Enthusiast

Have you scanned for codes (on my 03, you can do a key-on, key-off sequence 3 times, the last time leaving the key-on - and any stored codes will show in the odometer; alternatively, take it to AutoZone or O'Reilly's and have them scan.Hi. I am new here with a 2005 Jeep TJ. My vehicle sometimes dies when coming to a full stop. Also occasionally, on a slight incline while stopped, the RPMs go up and down (300 to 1000). It usually normally idles between 600 to 700 RPMs, I think.

My question on Kyle's post is when the engine would not die at all while spraying the TB cleaner, was he spraying while idle or revving? Because I tried doing the instructions from Jerry (use 1/3 of bottle during idle, and the rest while revving), and not sure if I need to continue spraying it while idle, and until it really stops dying. Thanks... Don

Next, I would make certain you have no vacuum leaks anywhere at all in the engine bay.

Finally, and to answer you question - when I did mine, the engine never died. It might have studdered some but never acted as if it was going to die (mine is a 4.0l, and held a fairly solid idle at from 750-850 RPM, except for when my wife was accelerating to 2000 RPM as noted above).

MrMark52

TJ Enthusiast

All FWIW - I did this yesterday after not being happy with both the idle, and my perception of less than average gas mileage.

Mine is a 2003 4.0L - I pulled the air duct between the air filter housing and the throttle body (and found a cracked PCV vent hose in the process. I also bought a new filter for it, even though the one that was in there wasn't really that bad).

I could not find throttle body cleaner so bought instead a couple of cans of SeaFoam TBI cleaner (I have become a real fan of SeaFoam). Using the included straw, I followed can directions, starting and insuring a warm engine, then liberally spraying SeaFoam into the IAC port and throttle body while the wife held 2000 RPM's. I all but emptied one can of SeaFoam into the IAC and throttle body.

Since doing this, "Oreo" (my TJ's nick name) seems to have a more steady idle, more pep, and the last 1/4 of tank of gas seemed to go further than before. I filled it up today and took a mileage reading. We're heading on a 2 week trip out West Friday - will report back my findings (assuming I don't do O2 sensors tomorrow before hitting the road. 108k miles on what I expect are the OEM sensors - they may also have an affect on milage and performance, although I am not getting any codes).

Update on this after our trip to the mountains - I'm not sure what our mileage was before, I think around 16 mpg or so, but since getting back to Dallas we are seeing ~18 mpg - and that is before I replaced the TPS (once I did that, the engine runs much smoother and has more pep. Now if i could just figure out the erratic starting issues).

I’m a little confused about my setup. I don’t have the bolts (screws) it talks about.

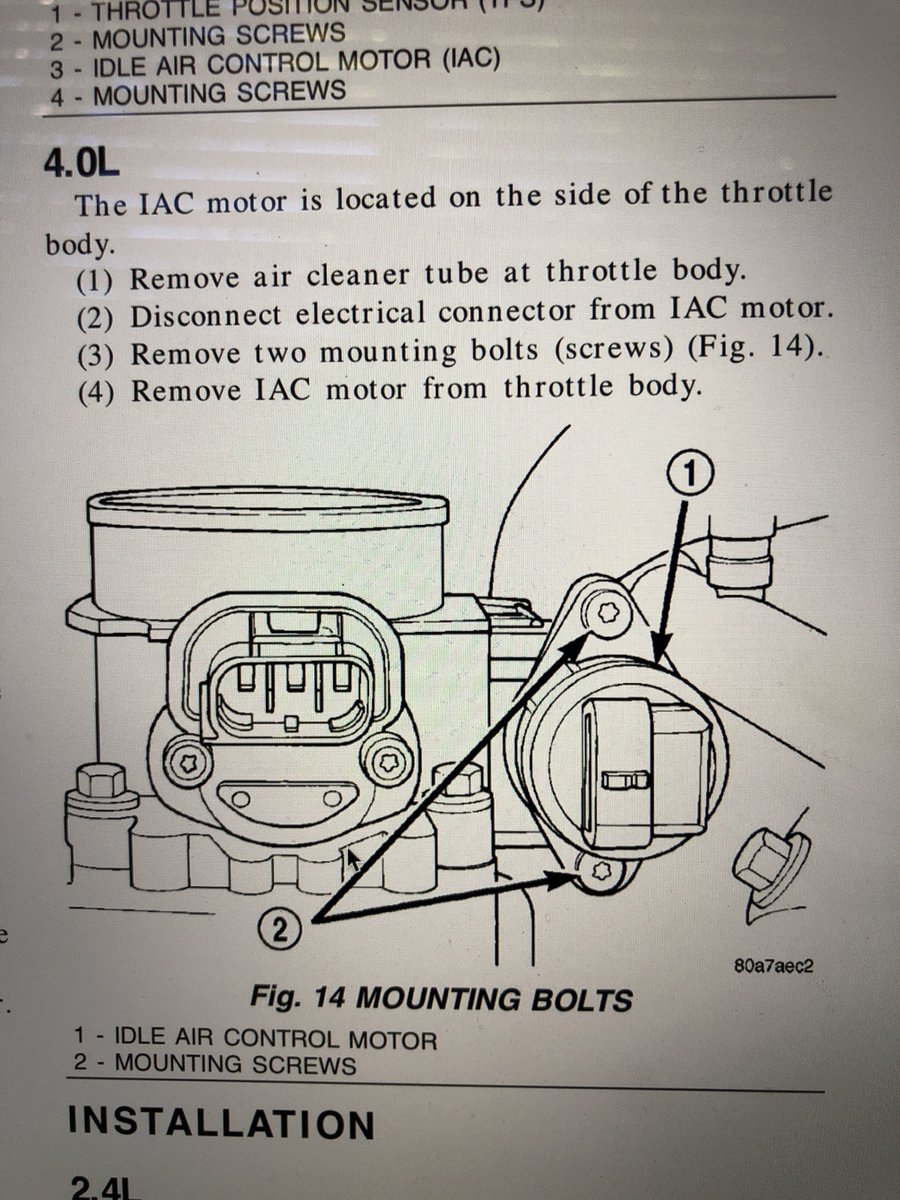

Looking at the FSM:

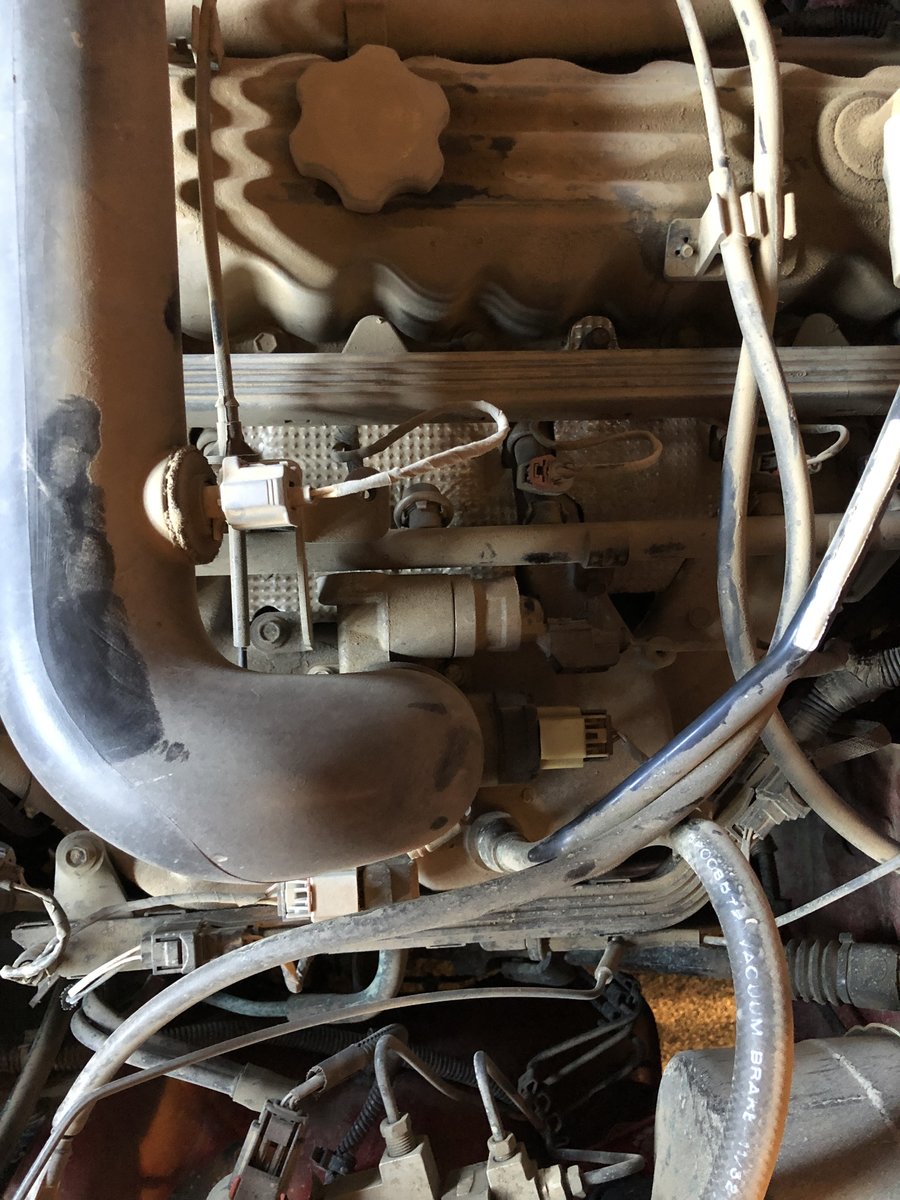

Vs my motor

Anyone know what’s up?

Looking at the FSM:

Vs my motor

Anyone know what’s up?

I’m a little confused about my setup. I don’t have the bolts (screws) it talks about.

Looking at the FSM:

View attachment 113546

Vs my motor

View attachment 113547

Anyone know what’s up?

I think I found the bolt underneath, and it’s just 1. I’m curious why this looks different than the FSM.

Edit: see page 2, and I’ll probably just follow Jerry’s method of spraying it in while idling.

Last edited:

MrMark52

TJ Enthusiast

Maybe a screw is missing on yours? Is there a hole there for a screw?I think I found the bolt underneath, and it’s just 1. I’m curious why this looks different than the FSM.

Edit: see page 2, and I’ll probably just follow Jerry’s method of spraying it in while idling.

I would certainly clean the top of that engine up some before I pulled the air tube. Fine particles of dust can wreck havoc on the engine. Granted it probably takes more than what is seen on your engine, but why take chances?

Maybe a screw is missing on yours? Is there a hole there for a screw?

I would certainly clean the top of that engine up some before I pulled the air tube. Fine particles of dust can wreck havoc on the engine. Granted it probably takes more than what is seen on your engine, but why take chances?

Nope, it looks to be just a different design (edit: image added below). The valve itself looks to be a bit different. At first I thought it was an after market throttle body, but from what I can tell it's a late model TJ thing.

And I agree on the engine cleanup, that dust is from last weekend and since it's stalling out constantly it's been stuck in the garage. Today is the work day on it (blowing it off with my air compressor before I change out O2s and some other cleanup work like the IAC).

Last edited: