That is the single most optimistic description I've seen on here in awhile. We usually wind up with push, bunch, hold, scooch along, push, bunch, hold, scooch along, milk it to the end.You push it on and it slides over the wires

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I HATE working with plastic split wire loom

- Thread starter MikekiM

- Start date

It’s not fun but I really don’t think it’s that hard. I usually struggle when the wires are taped up loosely or the wires have friction tape on them.That is the single most optimistic description I've seen on here in awhile. We usually wind up with push, bunch, hold, scooch along, push, bunch, hold, scooch along, milk it to the end.

I didn't say it was hard, I was pointing that that "just push it over the wires" is far more optimistic than reality.It’s not fun but I really don’t think it’s that hard. I usually struggle when the wires are taped up loosely or the wires have friction tape on them.

derekmac

TJ Addict

A cheap set of splicing fids can help. Plastic Splicing FidsSorry to be dense, but how do you get wires into a braided loom? Just push them through from one end to the other and hope the wire ends don't catch against the side? Or is there some kind of rounded cap that you put on the end of the wire so that it passes through easily?

I’m all about the wire management,I like the braided betterI didn't say it was hard, I was pointing that that "just push it over the wires" is far more optimistic than reality.

Fish tape one end of the braided loom...stagger the wires...wrap in Super 33 electrical tape...fast, easy done.

The braided stuff melts at a very low temperature...if it's anywhere close to exhaust put a heat sleeve on instead.

Use shrink wrap to finish the ends. Not all of it's the same...you can get different ratios like 4:1 and with epoxy.

-Mac

The braided stuff melts at a very low temperature...if it's anywhere close to exhaust put a heat sleeve on instead.

Use shrink wrap to finish the ends. Not all of it's the same...you can get different ratios like 4:1 and with epoxy.

-Mac

…. That is all.

Jeep content…. Mine is black with black tires.

Hey, I know you started this thread just to rent, but I like how it’s turning into a bit of a resource on pro tips and product suggestions/tool suggestions. What if we updated the original post with a list of some key takeaways?

We use an under hood rated expandable sleeve when we use it.Fish tape one end of the braided loom...stagger the wires...wrap in Super 33 electrical tape...fast, easy done.

The braided stuff melts at a very low temperature...if it's anywhere close to exhaust put a heat sleeve on instead.

Use shrink wrap to finish the ends. Not all of it's the same...you can get different ratios like 4:1 and with epoxy.

-Mac

Damn that looks good.

The braided stuff I’ve used is split, sort of. If you looked at it as a section it’s a spiral.

https://www.cabletiesandmore.com/f6-wrap-around-braided-sleeving

https://www.cabletiesandmore.com/f6-wrap-around-braided-sleeving

Last edited:

Gunnersmate

TJ Enthusiast

I am a huge fan of the flexo fire retardant braided sleeving

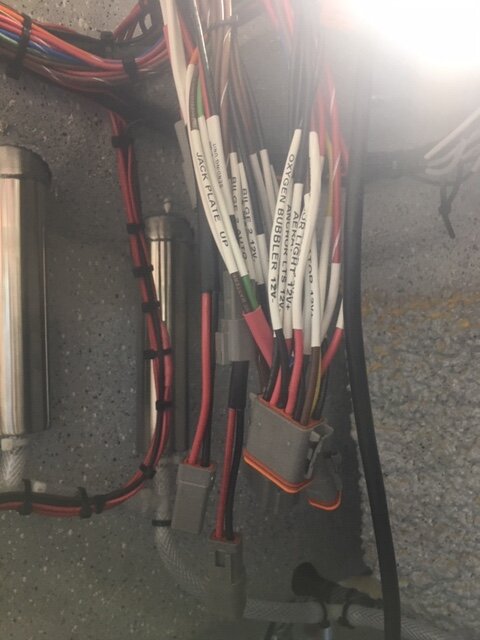

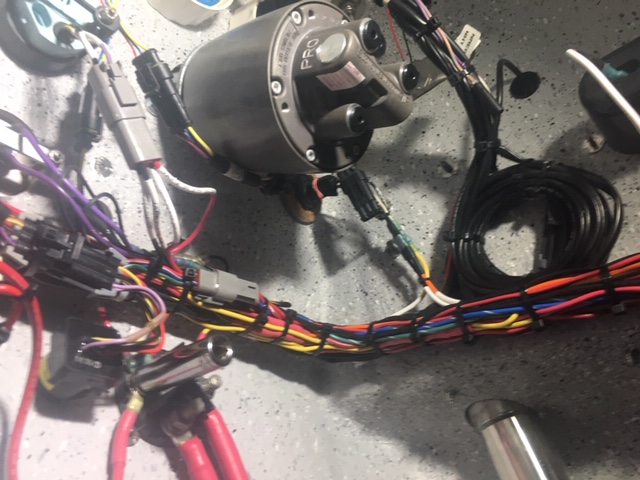

I ran nearly two thousand feet of wire all loomed in this product in my boat you finish the ends with a piece of adhesive heat shrink tube. It looks great and it pulls thru tight places like butter

All the Deutsch connectors you can build your self here are some that I did

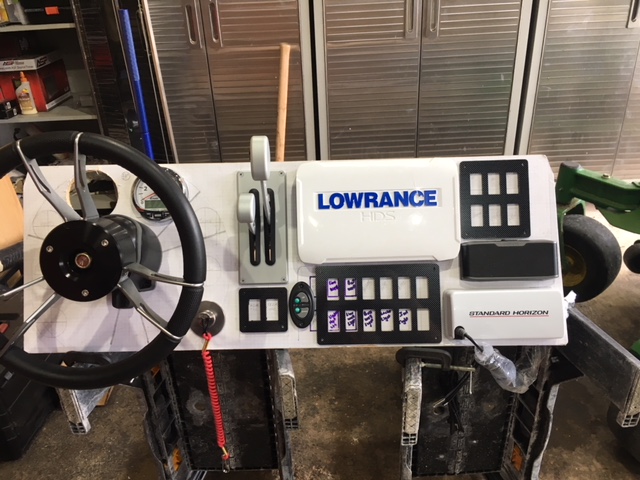

Console Template

Console was brand new and uncut this is after drilling, cutting and mounting everything

Wiring under console

Console after Drilling and Cutting holes

I ran nearly two thousand feet of wire all loomed in this product in my boat you finish the ends with a piece of adhesive heat shrink tube. It looks great and it pulls thru tight places like butter

All the Deutsch connectors you can build your self here are some that I did

Console Template

Console was brand new and uncut this is after drilling, cutting and mounting everything

Wiring under console

Console after Drilling and Cutting holes

Last edited: