We're installing the rock rails and corner armor on a project. The average installer or one time installer will struggle a bunch trying to figure this one out.

The TJ Unlimited already has issues keeping the tub straight since they added length, but did not beef up the frame or add more body mounts. Add some compromised shock lengths, add in some bullshit body mount mounted rock rails and a minor impact to the rear and this is what you wind up with after everything is clamped up as good as it can be.

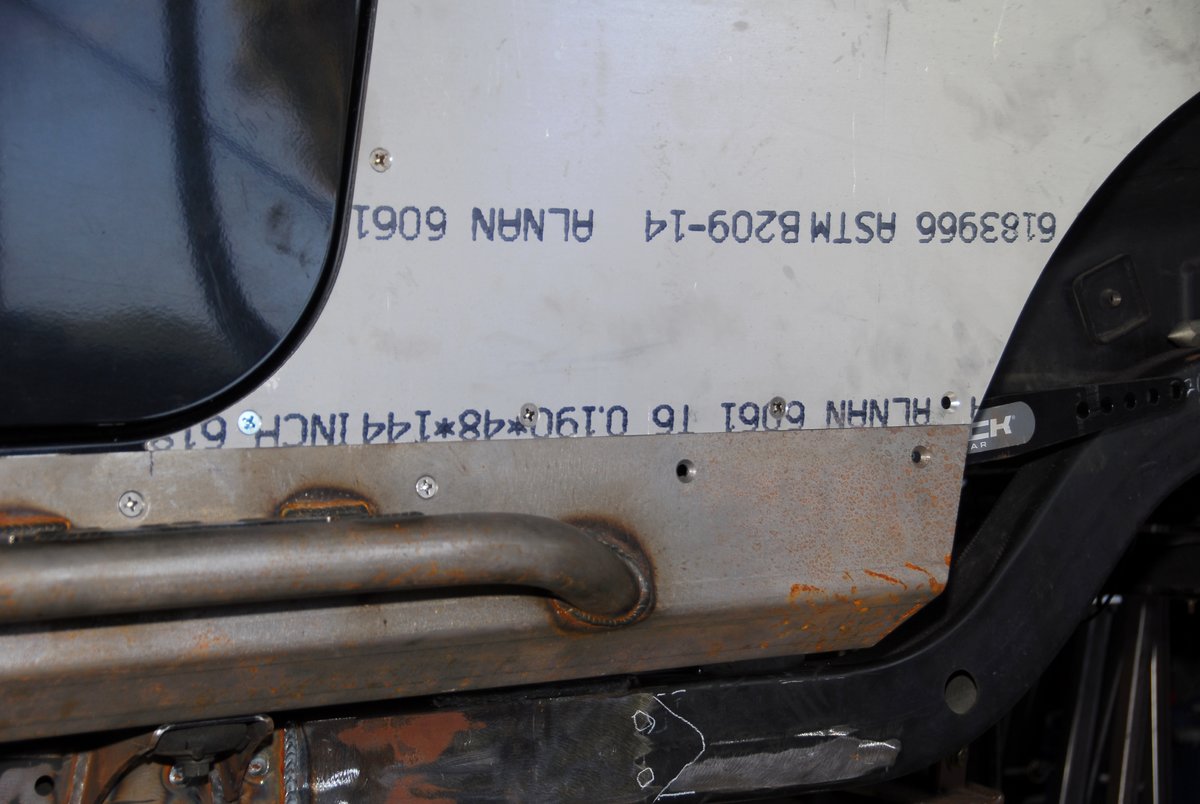

There is a 3/8" difference in 24" that has to be dealt with.

Corner armor is way too high at the door opening.

Rear panel is just as bad. The top side is over too far at the tail gate opening, the lower side is too far away from the opening and that is with it clamped up.

A full day of tweaking, mashing, trimming, smacking, and careful consideration of what needed to move where and we got it to this.

The TJ Unlimited already has issues keeping the tub straight since they added length, but did not beef up the frame or add more body mounts. Add some compromised shock lengths, add in some bullshit body mount mounted rock rails and a minor impact to the rear and this is what you wind up with after everything is clamped up as good as it can be.

There is a 3/8" difference in 24" that has to be dealt with.

Corner armor is way too high at the door opening.

Rear panel is just as bad. The top side is over too far at the tail gate opening, the lower side is too far away from the opening and that is with it clamped up.

A full day of tweaking, mashing, trimming, smacking, and careful consideration of what needed to move where and we got it to this.