You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motor mount brackets ripped from block

- Thread starter Tigger09

- Start date

It could be fixed if you have good fabrication / welding skills. But it would require removing the engine I would think, and at that point I'd probably just put a new block in there and rebuild it at the same time. I mean, might as well, right?

It could be fixed if you have good fabrication / welding skills. But it would require removing the engine I would think, and at that point I'd probably just put a new block in there and rebuild it at the same time. I mean, might as well, right?

Engine is already pulled but my welding skills aren’t up to this task.

Look at the brown dog motor mounts and see if they will help. Depends on how many good bosses are left.

Brown Dog is a straight replacement, I’d still have nothing to bolt them to.

Brown Dog is a straight replacement, I’d still have nothing to bolt them to.

I thought their mount allows the use of an extra boss already on the block.

I thought their mount allows the use of an extra boss already on the block.

One of their MM options uses more attachments than stock.

I thought their mount allows the use of an extra boss already on the block.

Looks like you’re right but I’m not sure the mount will work with the OEM exhaust manifold.

One of their MM options uses more attachments than stock.

That’s what it was!

http://www.stinkyfab.com/sfr-trail-proof-jeep-00-06-tj-lj-4-0l-engine-mounting-plates-pair/Looks like you’re right but I’m not sure the mount will work with the OEM exhaust manifold.

https://browndogindustries.com/S2883PHW-Wrangler-I6-Engine-Super-Brackets-Header.aspx

RiverDawg24

TJ Enthusiast

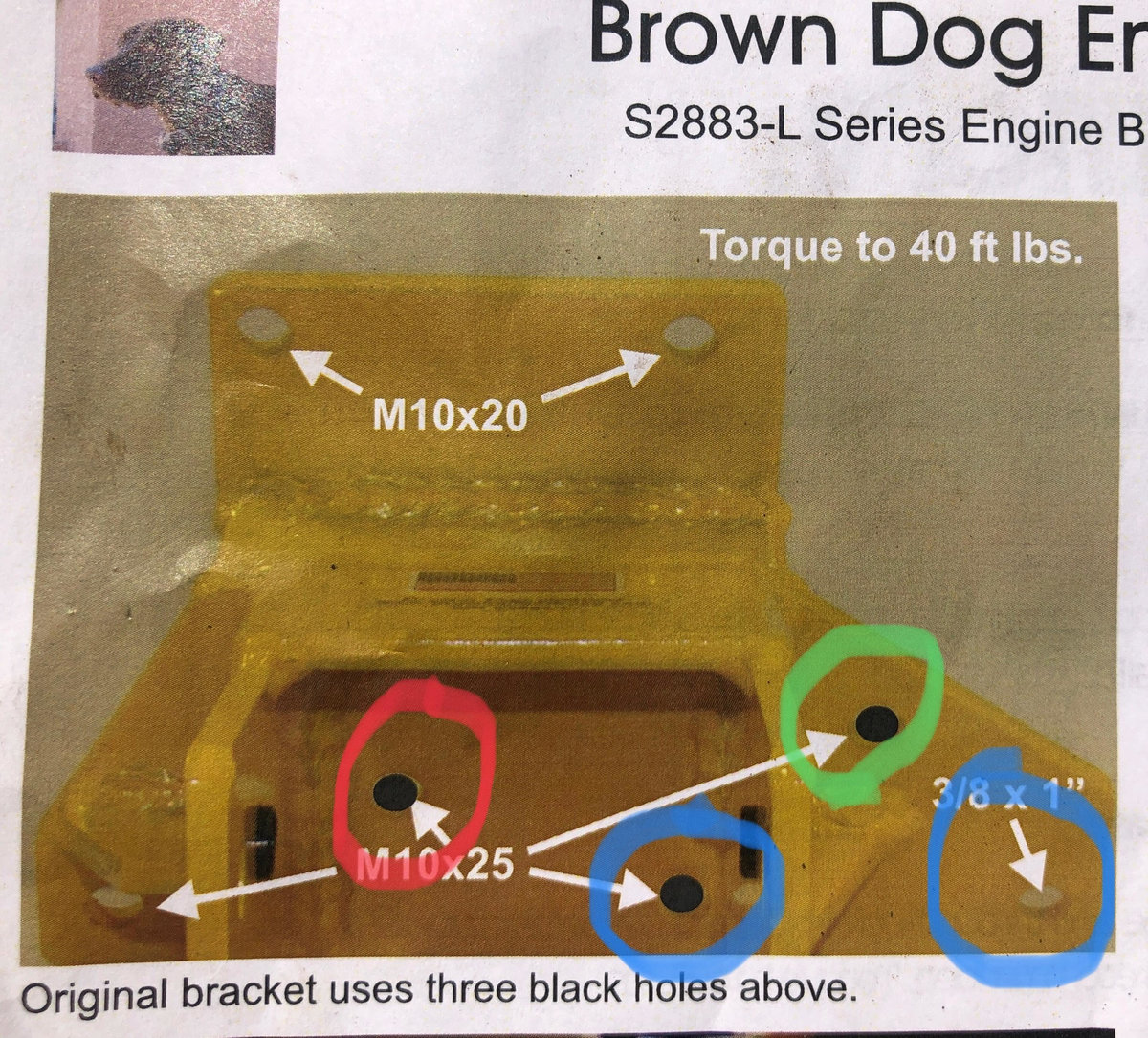

Brown Dog has provisions for as many as 7 mounting points. I was told any 4 points will be enough.

Pic is a passenger side mount I put on my 2002 4.0. I had 2 sheered bolts and a broken emboss

My exhaust is OEM. These work with OEM or aftermarket.

Pic is a passenger side mount I put on my 2002 4.0. I had 2 sheered bolts and a broken emboss

My exhaust is OEM. These work with OEM or aftermarket.

I think I have it figured out. When the time comes I’m going to make a plate that uses the 4 good bosses and has studs for the stock bracket. If that fails Brown Dog it is. Thanks everyone.

Time to do a LS swap!

I’ve got two builds going, my forever Jeep and a bare bones budget build. This is the budget build so no LS.

RiverDawg24

TJ Enthusiast

I think I have it figured out. When the time comes I’m going to make a plate that uses the 4 good bosses and has studs for the stock bracket. If that fails Brown Dog it is. Thanks everyone.

Feel free to copy the design the previous owner of my Jeep used.

I saw your post. How come you’re not mass producing those and selling them?Feel free to copy the design the previous owner of my Jeep used.

View attachment 119549

View attachment 119550

Another option is the Mountain Offroad engine brackets. Put some studs into the block threads that are still there and have them welded in place, and weld a washer on the stud where the original boss face would be. That way you could use some nuts to tighten the brackets up against the washers, and use the additional threaded bosses as extra holding power.

Here's a couple pics of mine during mockup so you can see where the extra bolts would go (keep in mind my motor is upside down on the engine stand).

Driver side:

Passenger side:

Here's a couple pics of mine during mockup so you can see where the extra bolts would go (keep in mind my motor is upside down on the engine stand).

Driver side:

Passenger side: