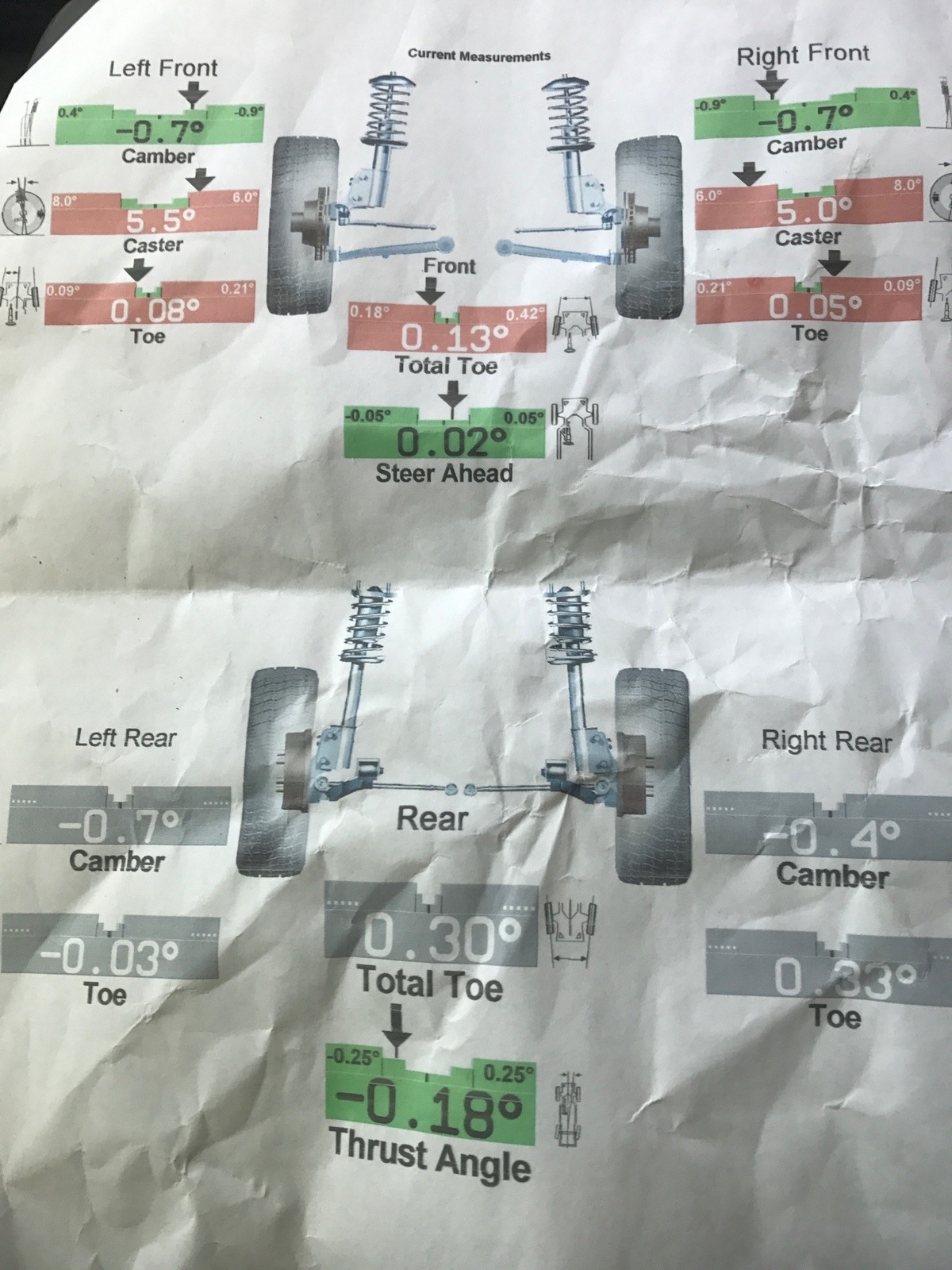

I have finished setting up my control arms and just had new tires put on. Here is my alignment sheet that I had done after I finished. Feel free to tell me what you think!!!

The last thing I want to do is make sure my upper control arms front and rear are not fighting each other and wearing out my joints and bushings.

Can someone give me a quick summary on how to make sure there is no pre load on my upper arms??? I want to make sure they are not working against each other and the load is even between the two.

Thanks

Sent from my iPhone using Tapatalk

The last thing I want to do is make sure my upper control arms front and rear are not fighting each other and wearing out my joints and bushings.

Can someone give me a quick summary on how to make sure there is no pre load on my upper arms??? I want to make sure they are not working against each other and the load is even between the two.

Thanks

Sent from my iPhone using Tapatalk