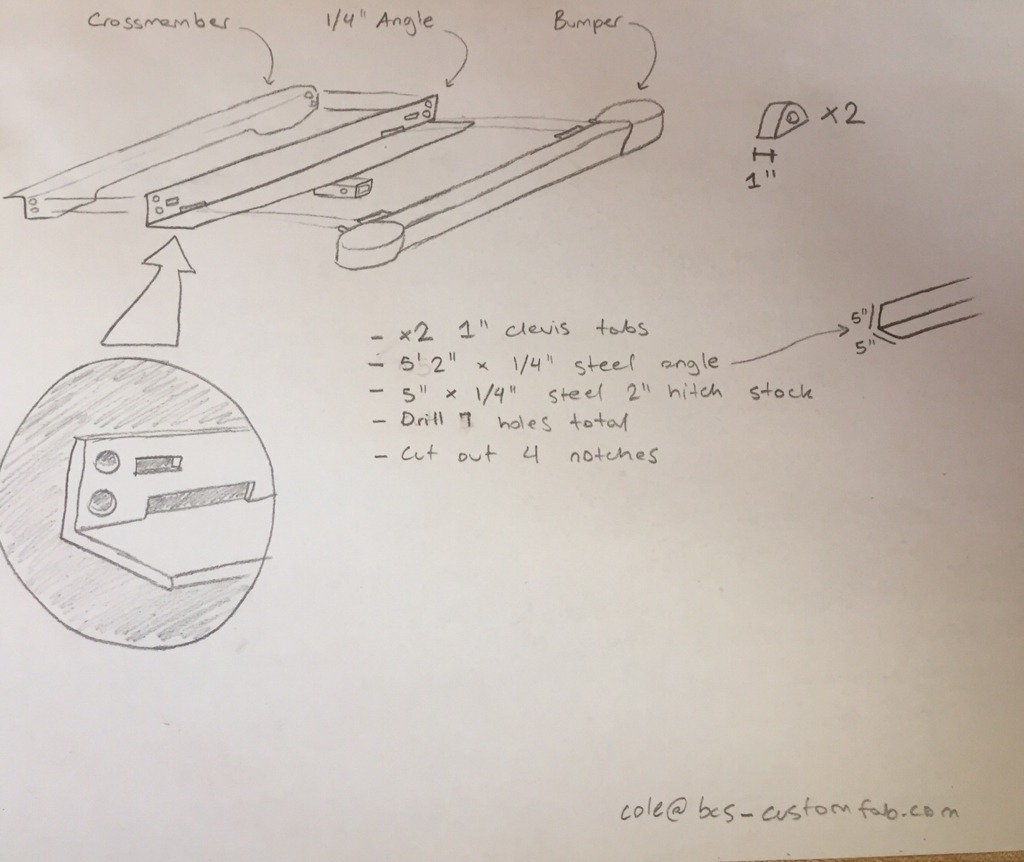

I have been trying to picture in my head and design the most ideal 2" hitch for my Jeep. I used to have one of the generic uHaul hitches - but thought it looked average - so I ended up with this design as a replacement:

The only thing I'm concerned about are those 4 slots cut out of the angle (the factory bumper is designed to slide through those slits and bolt up, so that I do not have to modify it at all), and wether or not they will compromise the integrity of the steel angle? For clarification, my photo shows a 1/4" steel angle. The steel shop I'm using says that they only offer 5/16" steel angle if I want 5x5" dimensions (which is required for correct fit around the factory bumper). So, 5/16" steel with slots cut in it? Is it nothing? I only am concerned because I'm going to use this hitch to tow small trailers and put a d-ring hitch into for recovery. Or actually is it complete overkill and damn heavy?

It's either go with this design, or weld the factory bumper to my piece of angle and then bolt the angle to my Jeep.

Also - those slots are only going to be 1/4" wide x 3" long at the most. They just need to be big enough to fit the wall thickness of the factory bumper. Which is 1/8" or 3/16" thick, I am not sure which one. So, the slots are going to be rather small.

Any opinions from experienced steel workers? Thanks!

The only thing I'm concerned about are those 4 slots cut out of the angle (the factory bumper is designed to slide through those slits and bolt up, so that I do not have to modify it at all), and wether or not they will compromise the integrity of the steel angle? For clarification, my photo shows a 1/4" steel angle. The steel shop I'm using says that they only offer 5/16" steel angle if I want 5x5" dimensions (which is required for correct fit around the factory bumper). So, 5/16" steel with slots cut in it? Is it nothing? I only am concerned because I'm going to use this hitch to tow small trailers and put a d-ring hitch into for recovery. Or actually is it complete overkill and damn heavy?

It's either go with this design, or weld the factory bumper to my piece of angle and then bolt the angle to my Jeep.

Also - those slots are only going to be 1/4" wide x 3" long at the most. They just need to be big enough to fit the wall thickness of the factory bumper. Which is 1/8" or 3/16" thick, I am not sure which one. So, the slots are going to be rather small.

Any opinions from experienced steel workers? Thanks!

Last edited: