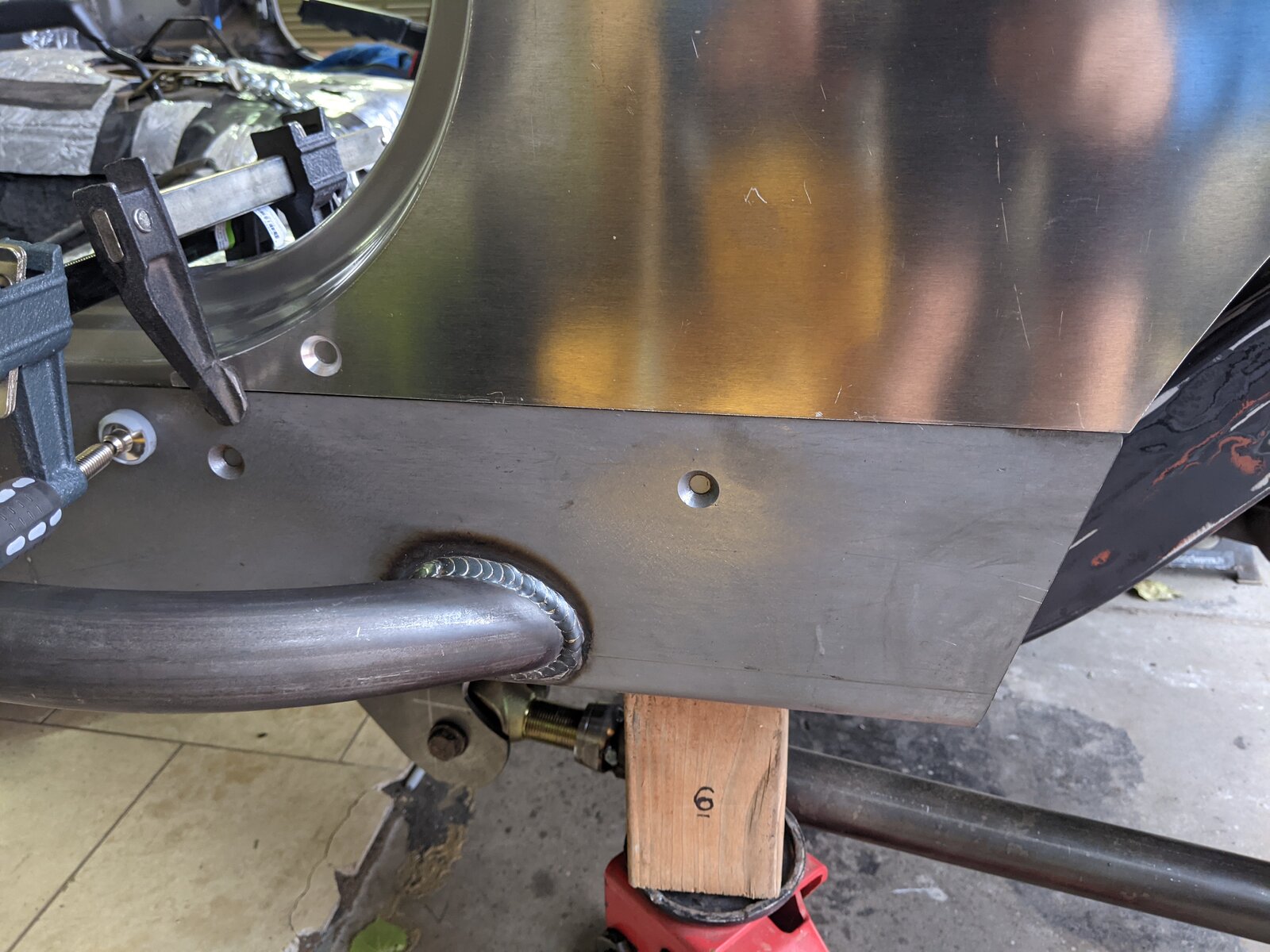

I've started the next step, aligning the corner armor and mini boat side rockers. I've read a lot of the forum posts and how to do this right.

The areas I'm focused on are the sliders being parallel to the body, particularly along the door opening.

And the seam where the rocker meets the corner armor... This one is critical

And the the armor to the tub...

And the tailgate opening reveal

I haven't cut the corner armor yet, but I've got it drawn out. The genright stretch guards move the opening back 4" and are designed for 35's. Since I'm going back 7", I lined up the two guards back to back, and moved one 3", and used it as a template for the other one.

The areas I'm focused on are the sliders being parallel to the body, particularly along the door opening.

And the seam where the rocker meets the corner armor... This one is critical

And the the armor to the tub...

And the tailgate opening reveal

I haven't cut the corner armor yet, but I've got it drawn out. The genright stretch guards move the opening back 4" and are designed for 35's. Since I'm going back 7", I lined up the two guards back to back, and moved one 3", and used it as a template for the other one.

Last edited: