The output shaft will move in and out until you assemble everything. Once assembled the only in and out play you should have is from the thrust washer clearance. Did you disassemble the planetary gear set? The trust washers in the planetary gears are a bitch to keep in place. I had to use petroleum jelly to hold them in place while I put it all back together.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebuilding my 32RH transmission (fully successfully)

- Thread starter hear

- Start date

The output shaft will move in and out until you assemble everything. Once assembled the only in and out play you should have is from the thrust washer clearance. Did you disassemble the planetary gear set? The trust washers in the planetary gears are a bitch to keep in place. I had to use petroleum jelly to hold them in place while I put it all back together.

Man, I really thought it had them in right, but the amount I'm off is roughly the length of a tab on the planetary thrust washers. I did not disassemble the planetary sets, but the one that slides out of the driving shell did come out. Both of those had tabbed washers on the backside but I'm pretty confident I had them seated. And yes, they're fun when they fall off when you tip them down.

Ok, I resolve that issue. Turns out the tabbed thrust washer on the planetary set that goes inside the low/reverse drum had not been seated correctly. That tab width was just about the amount I was off by, and sure enough when I seated it correctly everything sat down nicely.

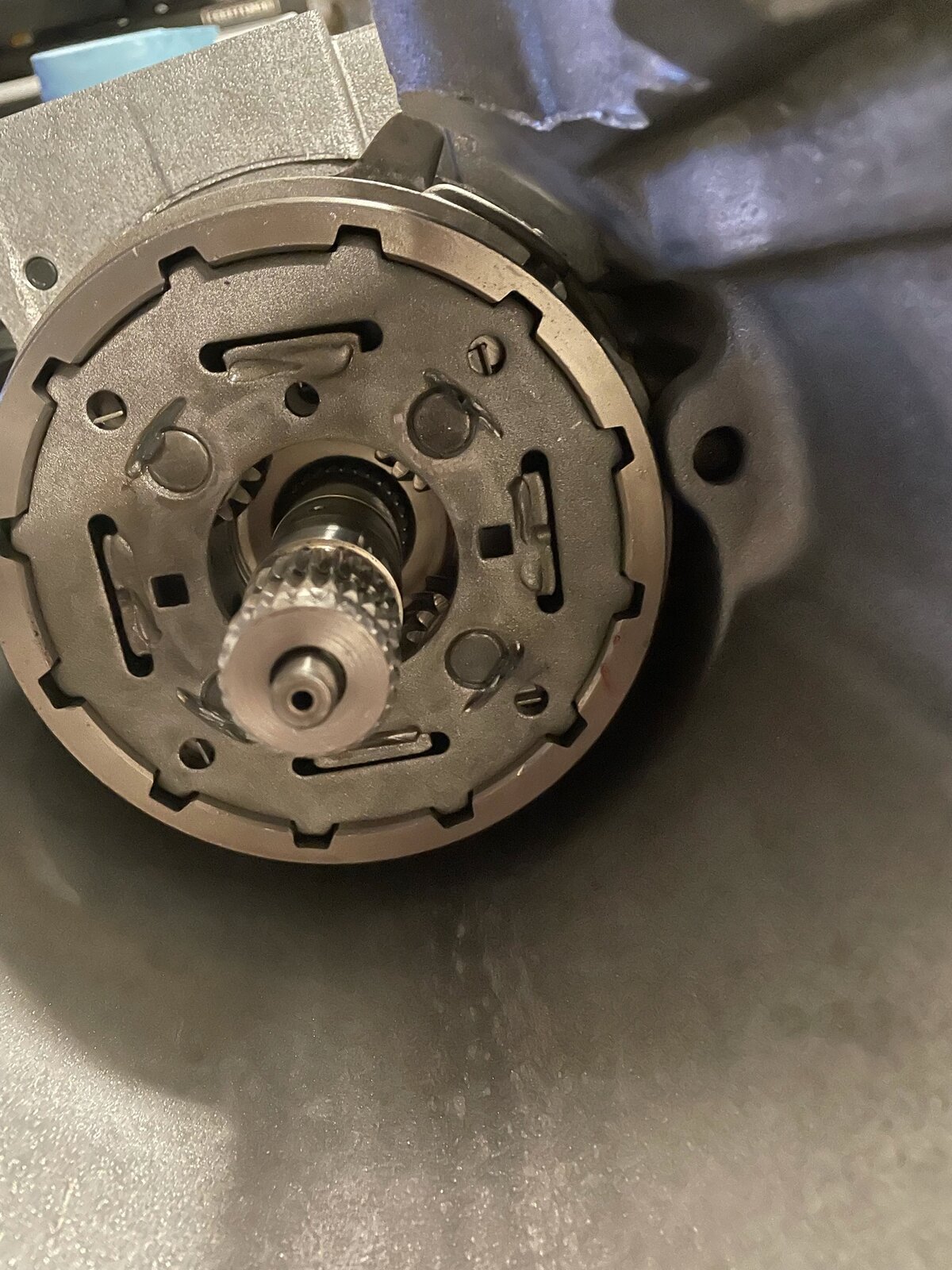

More explicitly, each planetary set has a tabbed thrust washer, this is the "outermost" one which drives the sun gear attached to the driving shell. I have it upside down and offset for your viewing pleasure. It has to go into those notches on the back of the planetary. If you assemble it upright, those like to fall off. You can use grease to hold it in place, but I actually found that assembling everything up to the first clutch drum to be easier if I did it at about a 20 degree angle above horizontal. It helped keep stuff in place as you slide things on.

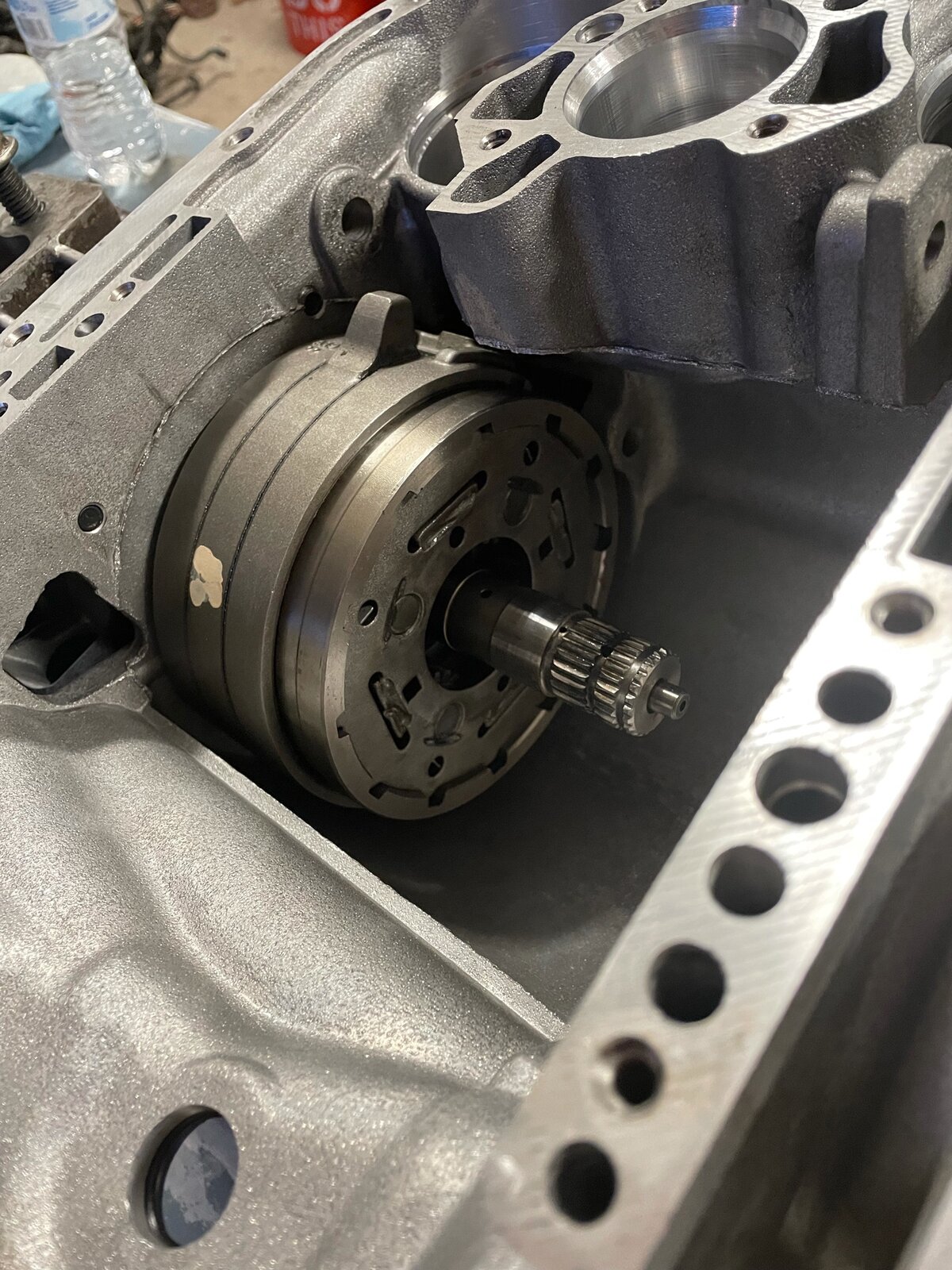

Here is the sun gear on the back of the driving shell which fits into another planetary set which itself splines into the low/reverse drum. Note the tabbed washer is "stuck" to the sun gear, but it needs to be on the planetary below it.

Here is the rearmost planetary, the one that goes into the low/reverse drum. This planetary ALSO has a tabbed washer on the other side. I don't have a picture of it pulled out, so you'll have to trust me. It was there, and it was misaligned. You can see here it is recessed slightly into that drum; while the washer was misaligned that planetary was pretty much flush with the drum (not pictured). I took all these piece apart several times trying to identify the gap, but I never went all the way to the bottom because it looked it fit ok. Lesson learned I guess.

With everything fit together nicely, the groove for the c-clip was visible and easy to install.

More explicitly, each planetary set has a tabbed thrust washer, this is the "outermost" one which drives the sun gear attached to the driving shell. I have it upside down and offset for your viewing pleasure. It has to go into those notches on the back of the planetary. If you assemble it upright, those like to fall off. You can use grease to hold it in place, but I actually found that assembling everything up to the first clutch drum to be easier if I did it at about a 20 degree angle above horizontal. It helped keep stuff in place as you slide things on.

Here is the sun gear on the back of the driving shell which fits into another planetary set which itself splines into the low/reverse drum. Note the tabbed washer is "stuck" to the sun gear, but it needs to be on the planetary below it.

Here is the rearmost planetary, the one that goes into the low/reverse drum. This planetary ALSO has a tabbed washer on the other side. I don't have a picture of it pulled out, so you'll have to trust me. It was there, and it was misaligned. You can see here it is recessed slightly into that drum; while the washer was misaligned that planetary was pretty much flush with the drum (not pictured). I took all these piece apart several times trying to identify the gap, but I never went all the way to the bottom because it looked it fit ok. Lesson learned I guess.

With everything fit together nicely, the groove for the c-clip was visible and easy to install.

I'll get to the rest of the install pics from tonight in a bit, but for now let's talk about the play in the input shaft. I've got the (new!) kickdown band tight to hold the front drum in place, but I don't love how the rear clutch drum is free to wobble. I'm pretty sure all the clutches are engaged, and I I'm also pretty sure the thrust washers stayed in place (I had the same "keyed 3 tab" washer as you, @U8MYDZT ). Now the clutches are free to slide laterally in the drum, so the only thing really keeping that drum in place is the little nub that the thrust washers center over, and the whole thing rides on the end surface of the output shaft, near as I can tell...which means this sort of play at this stage is ok? It feels weird, given how positively everything else fits together up to this point.

Thoughts?

Thoughts?

I'll get to the rest of the install pics from tonight in a bit, but for now let's talk about the play in the input shaft. I've got the (new!) kickdown band tight to hold the front drum in place, but I don't love how the rear clutch drum is free to wobble. I'm pretty sure all the clutches are engaged, and I I'm also pretty sure the thrust washers stayed in place (I had the same "keyed 3 tab" washer as you, @U8MYDZT ). Now the clutches are free to slide laterally in the drum, so the only thing really keeping that drum in place is the little nub that the thrust washers center over, and the whole thing rides on the end surface of the output shaft, near as I can tell...which means this sort of play at this stage is ok? It feels weird, given how positively everything else fits together up to this point.

Thoughts?

View attachment 339159

Pretty sure you're fine. As long as you have all the clips and thrust washers installed it will all tighten up as you put everything together

Pretty sure you're fine. As long as you have all the clips and thrust washers installed it will all tighten up as you put everything together

I’m sure you’re right. I wish there was a way to see that particular alignment, but it is what it is.

I’m also suddenly under extra pressure to nail this because after some 30 years of driving without any transmission issues, I now have two to deal with. This one, and then today my good friends XJ crapped the bed on the trails today. Pretty sure the torque converter has done sort of internal failure based on the horrible noise we heard. But it may be bigger than that, it is absolutely hemorrhaging fluid which we thought was the engine initially because of the color, if that gives you any idea of what we’re in store for. So rebuilding an AW4 is likely in my immediate future.

Great work. Glad you figured out the C-clip issue. It is all about the little details, isn’t it?

Me, I’d have just started hitting it with a big hammer. And yes, that’s why I don’t do transmission work…

Me, I’d have just started hitting it with a big hammer. And yes, that’s why I don’t do transmission work…

Great work. Glad you figured out the C-clip issue. It is all about the little details, isn’t it?

Me, I’d have just started hitting it with a big hammer. And yes, that’s why I don’t do transmission work…

Let me tell you, I was close. I was nearly convinced it was an issue with how well I seated the output shaft & governor assembly, but to inspect it meant I would have to take the extension housing back off. But if it wasn't in far enough then just giving it a little tap tap taparoo with a BFH should seat it the rest of the way right? And then not have to hassle with taking off the housing, right?

Turns out I had to take the housing off anyway because the low/reverse servo has a pivot rod, and the opening that rod goes into is hidden behind the gasket & extension housing.

That recessed black plug looking thing is the exterior end of the servo pivot. It just slides in & has 2 o-rings on it to seal. The extension housing gasket covers it up, and then the extension housing itself lays flat over top of that. I'm usually one of the people who replies on the "help me with my transmission leak" threads, but having gotten neck deep in this thing I'm now realizing just how many places a transmission could leak. Even the extension housing bolts...the holes they thread into on the case are open to the interior of the trans. FSM doesn't say anything about RTV or teflon tape....I never leaked from that spot before but I'm expecting to in a few days. But I digress.

The pivot rod is behind that corner flange on the extension housing. The tip of the screwdriver is on the other end of the opening. Note that the stud bolt is in the wrong location here, it goes on the other side.

Reassembling the servos turned out to not be that big of a deal, although the lock rings are kind of a pain. The biggest trick is compressing the pistons enough to expose the lock ring groove. On the rear servo there is no solid surface to compress onto. Luckily I have a 1-5/16" socket which fits on the lip of the spring retainer, allowing me to compress the spring. If I had this to do again, I would likely use some large fender washers instead of the socket. That socket put the clamp at the very end of it's travel and it didn't want to seat well on the socket face. Washers (as I used on the front servo) are probably a better choice in hindsight.

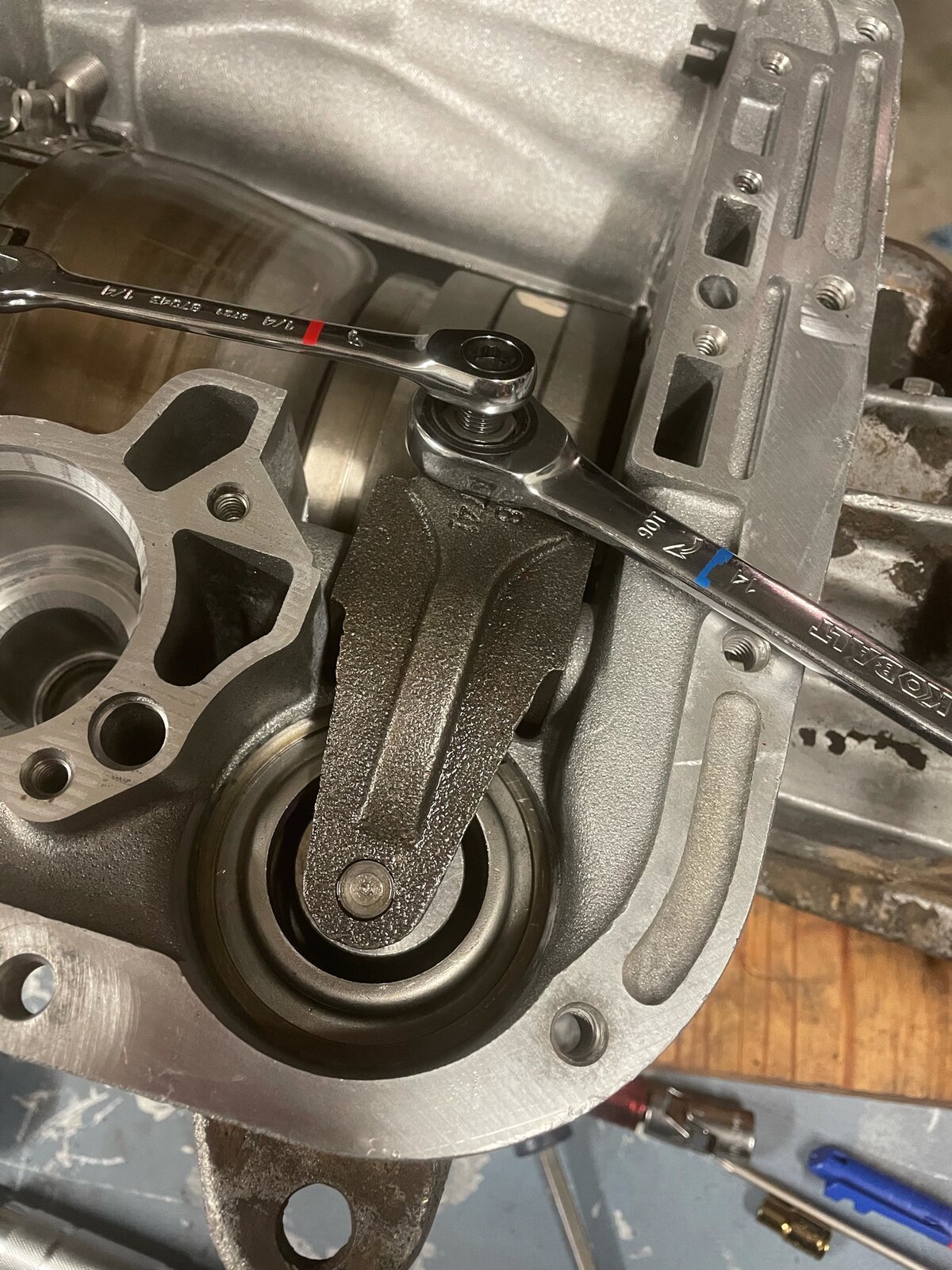

I figured I'd do the low/reverse band adjustment while I was here. The process for the 32RH is to back off the hold down nut and then tighten the screw to 72 inch-lbs, then back off the screw 4 turns, then tighten the hold down nut to 25 ft-lbs. Consult YOUR factory service manual for specifics on your transmission. My FSM also said it was a 5/16" screw but it was actually 1/4". I set the torque on the screw, then put a sharpie mark on one corner of the screw (it has a hex head) and backed it off 4 revolutions. The hold down bolt was 14mm, and I used my ratcheting wrenches to allow me to hold the screw stationary while tightening the hold down, and allowing me to verify the orientation of the adjuster screw during the process. Interestingly, when I did the teardown, the hold down nut was backed way off so the adjuster screw was free to move. I don't know if it did, but it was certainly able to.

The front servo is a different challenge. You have a solid surface to press down against, but there is a piston rod that pokes through from underneath, and you need to compress the upper piston slightly past the point where the rod comes through. Meaning that if you use a c-clamp on the center of the piston it will end up fighting the rod. I put some washers over it to provide enough clearance. Remember to not compress the spring past the lock ring groove; you don't want to scratch up the piston bore putting in the lock ring. (I have the clamp slid off to the side so you can see what I'm talking about).

I figured I'd do the low/reverse band adjustment while I was here. The process for the 32RH is to back off the hold down nut and then tighten the screw to 72 inch-lbs, then back off the screw 4 turns, then tighten the hold down nut to 25 ft-lbs. Consult YOUR factory service manual for specifics on your transmission. My FSM also said it was a 5/16" screw but it was actually 1/4". I set the torque on the screw, then put a sharpie mark on one corner of the screw (it has a hex head) and backed it off 4 revolutions. The hold down bolt was 14mm, and I used my ratcheting wrenches to allow me to hold the screw stationary while tightening the hold down, and allowing me to verify the orientation of the adjuster screw during the process. Interestingly, when I did the teardown, the hold down nut was backed way off so the adjuster screw was free to move. I don't know if it did, but it was certainly able to.

The front servo is a different challenge. You have a solid surface to press down against, but there is a piston rod that pokes through from underneath, and you need to compress the upper piston slightly past the point where the rod comes through. Meaning that if you use a c-clamp on the center of the piston it will end up fighting the rod. I put some washers over it to provide enough clearance. Remember to not compress the spring past the lock ring groove; you don't want to scratch up the piston bore putting in the lock ring. (I have the clamp slid off to the side so you can see what I'm talking about).

Turdworlder

TJ Enthusiast

Sorry for hijacking the thread. But i need a help. I throwed away my 32rh after it died. I already installed the ax15 with all other manual things. Now i need to wire so the engine can start. Also rear lights should work. Here is the nss wires. Which ones should i connect to each other(nss bypass???) And which ones should be connected to rear lights sensor on tranny.

All writeups about tranny swap wiring are made with aw 4 and etc they have different wirings. I am not an electrician so ye can use plain language

All writeups about tranny swap wiring are made with aw 4 and etc they have different wirings. I am not an electrician so ye can use plain language

Let me tell you, I was close. I was nearly convinced it was an issue with how well I seated the output shaft & governor assembly, but to inspect it meant I would have to take the extension housing back off. But if it wasn't in far enough then just giving it a little tap tap taparoo with a BFH should seat it the rest of the way right? And then not have to hassle with taking off the housing, right?

Turns out I had to take the housing off anyway because the low/reverse servo has a pivot rod, and the opening that rod goes into is hidden behind the gasket & extension housing.

View attachment 339191

That recessed black plug looking thing is the exterior end of the servo pivot. It just slides in & has 2 o-rings on it to seal. The extension housing gasket covers it up, and then the extension housing itself lays flat over top of that. I'm usually one of the people who replies on the "help me with my transmission leak" threads, but having gotten neck deep in this thing I'm now realizing just how many places a transmission could leak. Even the extension housing bolts...the holes they thread into on the case are open to the interior of the trans. FSM doesn't say anything about RTV or teflon tape....I never leaked from that spot before but I'm expecting to in a few days. But I digress.

View attachment 339193

The pivot rod is behind that corner flange on the extension housing. The tip of the screwdriver is on the other end of the opening. Note that the stud bolt is in the wrong location here, it goes on the other side.

View attachment 339192

Knew the was a reason I did the tail housing last. Lol Keep it up man you're almost there!

So, how much tear down would I need to fix a slipping second gear?

If you're presuming that I am the expert, then I would guess that minimal rebuild is required to address that symptom. Based on my understanding, 2nd gear is provided via kickdown band holding the front drum & the "rear" clutches. If the band isn't able to hold the drum or the clutches can't drive the outer sun gear, then I believe 2nd gear would slip. This is in fact all that was required on my rebuild. The short list of steps is to pull the pump and then pull out both drums via the input shaft. The drums separate w/o any effort. Replace both sets of clutches (because why only replace one set?). Replace the band, re-install the pump and you're good to go. I'm not sure if pulling out the valve body is required or not. Mine isn't back in yet, and I put the new band in with the valve body out. I'll investigate.

It's possible the overrun clutch is bad as well, but that requires literally pulling everything else out to get to that point. Although "everything else" consists of removing one c-clip, sliding some gears off the output shaft, removing a single lock ring, and sliding out the low/reverse drum to expose the overrun clutch. If that failed I would expect you'd see evidence in the bottom of the pan, but if you're relying on me for your automatic transmission diagnosis you're in deep trouble. The overrun clutch is also used in Drive-1st (not manual 1st) so if you don't have problems there then it's probably not a factor.

I should add that if clutches or bands are failing it is likely that fine debris (or not sot fine debris) has been distributed throughout your transmission which might warrant a more complete overhaul. You can tear these things down much further than I have, what yours requires I certainly can't say. All I know is the more stuff I disassemble, the more stuff I have to correctly re-assemble.

My goal for the day is to get this thing back in the jeep and test it. If that works, then I'll say you should absolutely attempt this if you have the time and the interest.

Narrator: he did not, in fact, get that thing back into the jeep and test it that day.

Last edited:

If you're presuming that I am the expert, then I would guess that minimal rebuild is required to address that symptom. Based on my understanding, 2nd gear is provided via kickdown band holding the front drum & the "rear" clutches. If the band isn't able to hold the drum or the clutches can't drive the outer sun gear, then I believe 2nd gear would slip. This is in fact all that was required on my rebuild. The short list of steps is to pull the pump and then pull out both drums via the input shaft. The drums separate w/o any effort. Replace both sets of clutches (because why only replace one set?). Replace the band, re-install the pump and you're good to go. I'm not sure if pulling out the valve body is required or not. Mine isn't back in yet, and I put the new band in with the valve body out. I'll investigate.

It's possible the overrun clutch is bad as well, but that requires literally pulling everything else out to get to that point. Although "everything else" consists of removing one c-clip, sliding some gears off the output shaft, removing a single lock ring, and sliding out the low/reverse drum to expose the overrun clutch. If that failed I would expect you'd see evidence in the bottom of the pan, but if you're relying on me for your automatic transmission diagnosis you're in deep trouble. The overrun clutch is also used in Drive-1st (not manual 1st) so if you don't have problems there then it's probably not a factor.

I should add that if clutches or bands are failing it is likely that fine debris (or not sot fine debris) has been distributed throughout your transmission which might warrant a more complete overhaul. You can tear these things down much further than I have, what yours requires I certainly can't say. All I know is the more stuff I disassemble, the more stuff I have to correctly re-assemble.

My goal for the day is to get this thing back in the jeep and test it. If that works, then I'll say you should absolutely attempt this if you have the time and the interest.

Nothing in the oil. I replaced the pan recently, and also attempted the band tightening. All other gears work, and second feels like two gears.

Knew the was a reason I did the tail housing last. Lol Keep it up man you're almost there!

I did the tail housing early because I wanted to be able to stand it up on end. If you have a 2WD version with the long tapered tail housing you'd pretty much need the engine stand attachment that lets you swivel the thing. I actually forgot that my XJ friend has an engine stand in his garage. I would have bought that attachment for sure to save my back & give me a ton more table space to clean & assemble things.

Can you explain this better?second feels like two gears.

On mine I had first, but it would continue to build RPMs presumably because it was trying to hold the drum but the band couldn't. So it "thought" it was in 2nd. Then it probably looked at throttle position and RPMs and said "oh you probably need to be in 3rd now" and finished the shift by releasing the band (which did nothing) and applying the front clutches. But I also did some road tests to track speed & rpm and used Grimm Jeeper to definitively figure out what gear I was in.

Sorry for hijacking the thread. But i need a help. I throwed away my 32rh after it died. I already installed the ax15 with all other manual things. Now i need to wire so the engine can start. Also rear lights should work. Here is the nss wires. Which ones should i connect to each other(nss bypass???) And which ones should be connected to rear lights sensor on tranny.

All writeups about tranny swap wiring are made with aw 4 and etc they have different wirings. I am not an electrician so ye can use plain language

View attachment 339227

View attachment 339228

You should definitely start a new thread for this, you'll get more attention than just the handful of people who want to talk about rebuilding an automatic.

When it shifts to second and I keep my foot at the same throttle position the rpms rise and so does the speed, then the rpms fall, but continue to accel.Can you explain this better?

On mine I had first, but it would continue to build RPMs presumably because it was trying to hold the drum but the band couldn't. So it "thought" it was in 2nd. Then it probably looked at throttle position and RPMs and said "oh you probably need to be in 3rd now" and finished the shift by releasing the band (which did nothing) and applying the front clutches. But I also did some road tests to track speed & rpm and used Grimm Jeeper to definitively figure out what gear I was in.

I can also lift slightly when it shifts to second and let the rpms drop to fully engange second gear, and then accelerate again. Either way, second gear is a bit flat as far as acceleration goes.

No slipping in first or third that I can tell.

When it shifts to second and I keep my foot at the same throttle position the rpms rise and so does the speed, then the rpms fall, but continue to accel.

I can also lift slightly when it shifts to second and let the rpms drop to fully engange second gear, and then accelerate again. Either way, second gear is a bit flat as far as acceleration goes.

No slipping in first or third that I can tell.

My money is on band and/or clutches. Those are the only real wear items on the thing, other than stuff like piston seals etc. Now how the valve body affects any of this is anybody's guess. I could be completely wrong and it could be an issue with something in there that causes insufficient pressure to the servo or clutch piston. Obviously aside from the effort to drop the trans out of the jeep, it is not all that difficult to get into the thing and investigate the kickdown band & clutches. But as I've stated, my confidence lies solely in the fact that I can read directions. I have not yet proved I can disassemble & reassemble a transmission and fully restore it to operational condition.