Is this adhesion paste/glue the correct way to bond two pieces of metal that act as the floor of the tub? Or is welding the proper way to bond two pieces of metal together for a floor pan? Im confused. Is this a new process?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Capt'n 2003 Jeep Wrangler “Freedom Edition”

- Thread starter Capt'n

- Start date

Good question. Adhesive panel bond is not new but is used in the automotive industry to adhere metal to metal in both structural and non structural applications, depending on the specific adhesive used... It typically is accompanied by spot welds or rivets to increase the strength of the joint. But the adhesive panel bond is impressively strong (YouTube it), even without welding and it has a high heat tolerant melting point (not even close to temps that occur on our Jeep floors.... I am not a welder so this was my motivation for using the product. I figure that if it’s good enough to glue tiles on a space shuttle it’ll probably be just fine for gluing on my floor pan. It ain’t going anywhere.... but time will be the true judge. If you can weld, weld it. Probably the best tried and true method as this 3M stuff isn’t cheap but not being a welder, this metal to metal structural adhesive is a solid alternative.

Last edited:

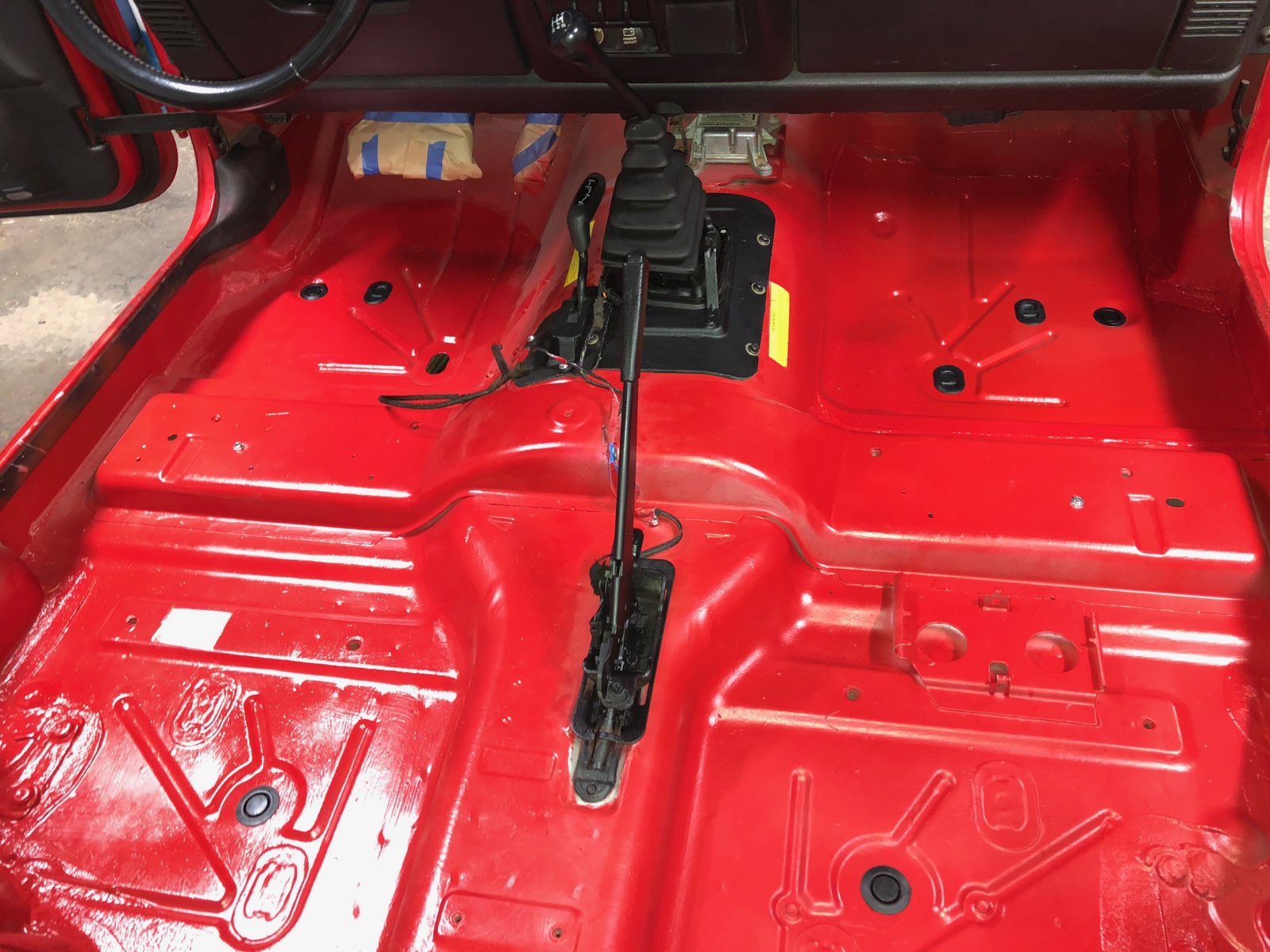

Ready to start prepping for painting! Looking forward to sanding, washing, rust inhibitor painting, priming, and applying top coat and a clear coat.

How does that rubber boot on the shift tower of your NV3550 look? The one on my '01 was fried, fried, fried.

It looks great! But the gear shift shaft has some serious pitting.How does that rubber boot on the shift tower of your NV3550 look? The one on my '01 was fried, fried, fried.

Yep, I'd say that boot was fairly new; lucky you. As for the shaft, it is pretty pitted but, assuming that what you see is pretty well down to good metal, it's not anywhere close to being bad enough to really weaken the shaft. Wire brush, rust inhibitor, paint the crap out of it. Once the paint dries well, a bit of silicone grease (like dielectric grease) around where the boot seals might be a good thing as well.

Dielectric grease? Is this to act like as as a water repellant / rust inhibitor? Anywhere else i should use this type of grease? Thanks for your suggestions!Yep, I'd say that boot was fairly new; lucky you. As for the shaft, it is pretty pitted but, assuming that what you see is pretty well down to good metal, it's not anywhere close to being bad enough to really weaken the shaft. Wire brush, rust inhibitor, paint the crap out of it. Once the paint dries well, a bit of silicone grease (like dielectric grease) around where the boot seals might be a good thing as well.

I suggested dielectric grease for this application because 1) it plays well with rubber where many hydrocarbon greases can deteriorate it, 2) to act as a seal impover since your shaft is no longer perfectly smooth, and 3) because it does inhibit corrosion.

The most common use for dielectric grease is for electrical connections. I always have a tube around (I actually put some in a big syringe to make using it easier) and squirt some in every connection I take apart. It inhibits corrosion and keeps water from being able to penetrate the connection and cause damage and signal issues. FYI, it's called dielectric because it is non-conductive (so it does not cause issues with electrical connections) and is formulated to protect the types of materials used in electrical connections.

EDIT: Here's an example product.

The most common use for dielectric grease is for electrical connections. I always have a tube around (I actually put some in a big syringe to make using it easier) and squirt some in every connection I take apart. It inhibits corrosion and keeps water from being able to penetrate the connection and cause damage and signal issues. FYI, it's called dielectric because it is non-conductive (so it does not cause issues with electrical connections) and is formulated to protect the types of materials used in electrical connections.

EDIT: Here's an example product.

Kiwi TJ

I don't suffer from insanity I enjoy every minute

Supporting Member

Ride of the Month Winner

Im a bit late to the party but that floorpan could be worse....

Thanks. Will pick up some tomorrow.I suggested dielectric grease for this application because 1) it plays well with rubber where many hydrocarbon greases can deteriorate it, 2) to act as a seal impover since your shaft is no longer perfectly smooth, and 3) because it does inhibit corrosion.

The most common use for dielectric grease is for electrical connections. I always have a tube around (I actually put some in a big syringe to make using it easier) and squirt some in every connection I take apart. It inhibits corrosion and keeps water from being able to penetrate the connection and cause damage and signal issues. FYI, it's called dielectric because it is non-conductive (so it does not cause issues with electrical connections) and is formulated to protect the types of materials used in electrical connections.

EDIT: Here's an example product.

Progress! Rust Bullet Rust Inhibitor Paint...

Last edited:

I'm so OCD... Ha! Why do I do what I do? I Save the Heat Warning Stickers but Ripped off the Visor Warning Stickers.Nice!

I see you're protecting the heat warning stickers...man I just painted right over those beeatches

Starting to Wrap up the Interior Up-Grade Project. Fresh Paint, Heat / Sound Pad, New Carpet... And new seat covers! Happy man.

Last edited:

Finished my first ever Stereo Installation. Looking forward to Topless Tunes...

* Kenwood Excelon KDC-X303. 6 channels (4 speakers + room for future add on of a Sub-woofer) (Required in dash cutting of stock radio mounting bracket)

* MB Quart MA1-440.4 400W 4 Channel Amp. (Fits nicely under drivers seat)

* Polk Audio DB 462 Dash Speakers. (Stock fit)

* Polk Audio DB 522 Sound Bar Speakers (Stock fit)

I added sound insulation material (foil backed bubble wrap) to create "pods" in the dash and sound bar + stuffed poly-fill in them prior to mounting the speakers. Not sure if it actually makes any real difference but what the heck... was fun going the extra mile anyway...

With this simple set-up, there's more than enough quality sound and volume for topless driving enjoyment. I'm a Happy Music Man.

BTW... The Jeep loves Country Music....

* Kenwood Excelon KDC-X303. 6 channels (4 speakers + room for future add on of a Sub-woofer) (Required in dash cutting of stock radio mounting bracket)

* MB Quart MA1-440.4 400W 4 Channel Amp. (Fits nicely under drivers seat)

* Polk Audio DB 462 Dash Speakers. (Stock fit)

* Polk Audio DB 522 Sound Bar Speakers (Stock fit)

I added sound insulation material (foil backed bubble wrap) to create "pods" in the dash and sound bar + stuffed poly-fill in them prior to mounting the speakers. Not sure if it actually makes any real difference but what the heck... was fun going the extra mile anyway...

With this simple set-up, there's more than enough quality sound and volume for topless driving enjoyment. I'm a Happy Music Man.

BTW... The Jeep loves Country Music....

New Front Brakes calipers, pads, and lines.... it’s been 40 years since I have done this. Was kinda fun. Ha!

And Today.... I finally got my Canyon Rims and 31” BFG KO2s installed on the Capt’n. (Before / After).

Lovin’ the new look! Now... time to go enjoy the summer...

Lovin’ the new look! Now... time to go enjoy the summer...