I've had the doors off since the weather turned nice, but I thought it would be easier to flip a switch to turn on the dome lights, rather than pull and replace fuse #4 every time.

I have roof lights that were installed by the PO, or maybe the PO before him, and I'm not sure if it was done DIY or professionally. I'm leaning toward DIY since they had the power wires running into the cab to the relay they shoved up under the dash.

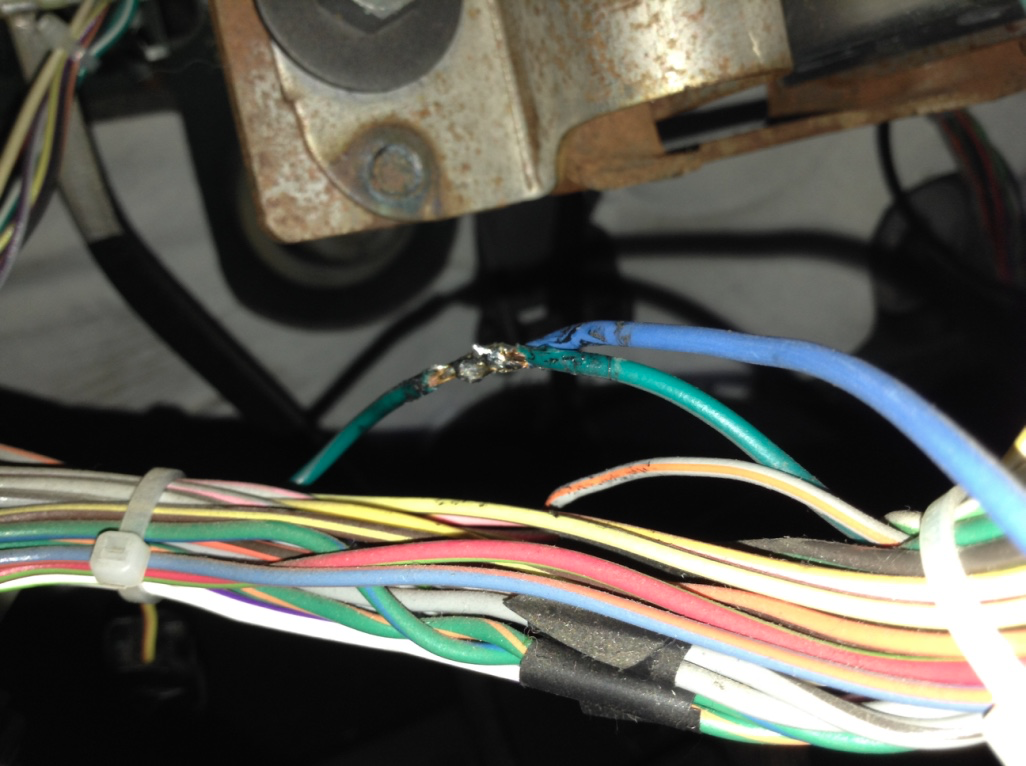

They also spliced into the existing wiring with a solder joint wrapped in hockey tape. While it certainly works, it's not the way I would have done things.

The roof lights were wired to a switch placed to the right of the steering wheel, but I plan on relocating the light switch (and all the other wiring) later on, so I decided to re-purpose it for the dome lights. It's far enough out of the way that it won't accidentally get hit.

Once I pulled the fuse panel there are three wires coming off fuse 4. The yellow/green wires run from the plunger switches on the doors, and the black wire is ground. I figured it would be easier to interrupt the side with one wire.

I ran some 18g wire behind the AC controls and butt-spliced them in, making sure to leave myself plenty of slack to get the panel off and out of the way in the future.

Then I crimped in some quick-disconnects and joined everything together. I put male and female ends on the ground wire ends, so if I ever decide to delete the switch I can just reconnect the grounds to each other.

The switch also now serves as a dome light illuminator (when the doors are off) that's easier to fiddle with than the one on the steering column.

But only after I did all this did I discover the rear-tailgate-dome-light mod, which is something I'd like to do.

I have roof lights that were installed by the PO, or maybe the PO before him, and I'm not sure if it was done DIY or professionally. I'm leaning toward DIY since they had the power wires running into the cab to the relay they shoved up under the dash.

They also spliced into the existing wiring with a solder joint wrapped in hockey tape. While it certainly works, it's not the way I would have done things.

The roof lights were wired to a switch placed to the right of the steering wheel, but I plan on relocating the light switch (and all the other wiring) later on, so I decided to re-purpose it for the dome lights. It's far enough out of the way that it won't accidentally get hit.

Once I pulled the fuse panel there are three wires coming off fuse 4. The yellow/green wires run from the plunger switches on the doors, and the black wire is ground. I figured it would be easier to interrupt the side with one wire.

I ran some 18g wire behind the AC controls and butt-spliced them in, making sure to leave myself plenty of slack to get the panel off and out of the way in the future.

Then I crimped in some quick-disconnects and joined everything together. I put male and female ends on the ground wire ends, so if I ever decide to delete the switch I can just reconnect the grounds to each other.

The switch also now serves as a dome light illuminator (when the doors are off) that's easier to fiddle with than the one on the steering column.

But only after I did all this did I discover the rear-tailgate-dome-light mod, which is something I'd like to do.

Last edited: