You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tworley build

For anyone that missed it--I plan on installing a Sanden AC compressor for an on-board air setup. While I do have a C02 tank and it is very easy and cheap to use, it is simply beginning to take up to much space in the rear when I am out wheeling. I chose a sanden compressor for the sake of simplicity. These two are a direct bolt on, unlike the york where I would need to order or fabricate mounting brackets, and new pulley. The plan is to install an oil fogger into the suction port that will come off of the windstar intake (nice cold air...). The discharge port will have an oil separator to collect any oil that gets thru to the hose, then a manifold which will have the pressure switch (wired to dash switch), a pressure gauge, and check valve. I will put the quick air coupler on the front of the grill or fashion a mount somewhere on the bumper. This is going to be used solely for tires (no air tools, no lockers, etc). I already have an ARB compressor for the lockers and have honestly never wheeled with any one that needed an air operated tool on the trail. The downside to the sanden unit is that unlike the york, it does not have an oil sump (hence the oil fogger). It will put out 9cfm at 40 psi (comparable to a york). I have read threads where the OP ran the sanden off an oiler and it lasted 10 years. The other option is to seal off a pressure relief hole within the unit, and grease the entire thing, heavily. This takes away the oiler, but then the unit will only last until it doesn't. I am trying to do this as cheap as I can and will document the build as best I can. A lot of the information I am finding has been way outdated and pictures no longer working.

Last edited:

Can’t wait to see the how to, so far the price and CFM is pretty compelling.

Glad I grabbed a spare. To much force trying to enlarge the discharge hole to a 1/2"

You are working on a positive displacement compressor, porting the discharge port will do almost nothing to the flow rate. As long as the hoses or ports don't physically explode the same volume of air will go through them.Glad I grabbed a spare. To much force trying to enlarge the discharge hole to a 1/2"

Edit: you can increase the flow rate by increasing the RPM or the cylinder volume in the compressor, that's about it

You are working on a positive displacement compressor, porting the discharge port will do almost nothing to the flow rate. As long as the hoses or ports don't physically explode the same volume of air will go through them.

Edit: you can increase the flow rate by increasing the RPM or the cylinder volume in the compressor, that's about it

Maybe I am getting greedy. But I drilled this one out to 3/8". I thought it couldn't hurt.

I think you learned exactly how much it can hurt on the last one.Maybe I am getting greedy. But I drilled this one out to 3/8". I thought it couldn't hurt.

Just giving you crap, I enjoy watching your progress. I'd probably do the same thing. Besides you never know how far you can go until you go too far.

So some state to tap this and put in a grub screw. This will block oil or grease from being pushed thru the pistons. I went a slightly different route and I filled it with gasket maker. 500° and oil resistant which is what I plan to run thru this in the end

More progress on my sanden OBA project. I dont know what I did earlier on mounting this but it doesn't quite fit. Width wise they mount fine but the compressor is just a hair to long. What I did to fix this (and it is not perfect) is drill out the compressor mounting holes carefully with a 1/2" bit

I can get three bolts on it now but the rear corner is still a good 1/4" off. I need to think about how to fix that.

The fittings off the compressor are flare fittings. Which made things a little complicated, luckily I was told about swivels which are gas fittings. These things run about $12 a piece at the ACE hardware

Here is my test fit

Intake side with Speedaire oiler. Lesson learned, buy an oiler with 1/4 inlets. Sizing down from 3/8" took a number of fittings. Not sure how long the intake nipple will last, it's simply a plastic 90 degree that I screwed into place (I know, I need a clamp there still).

Discharge side. I'm not sure how these will hold overtime. My connections are long which is a lot of leverage at the compressor fitting

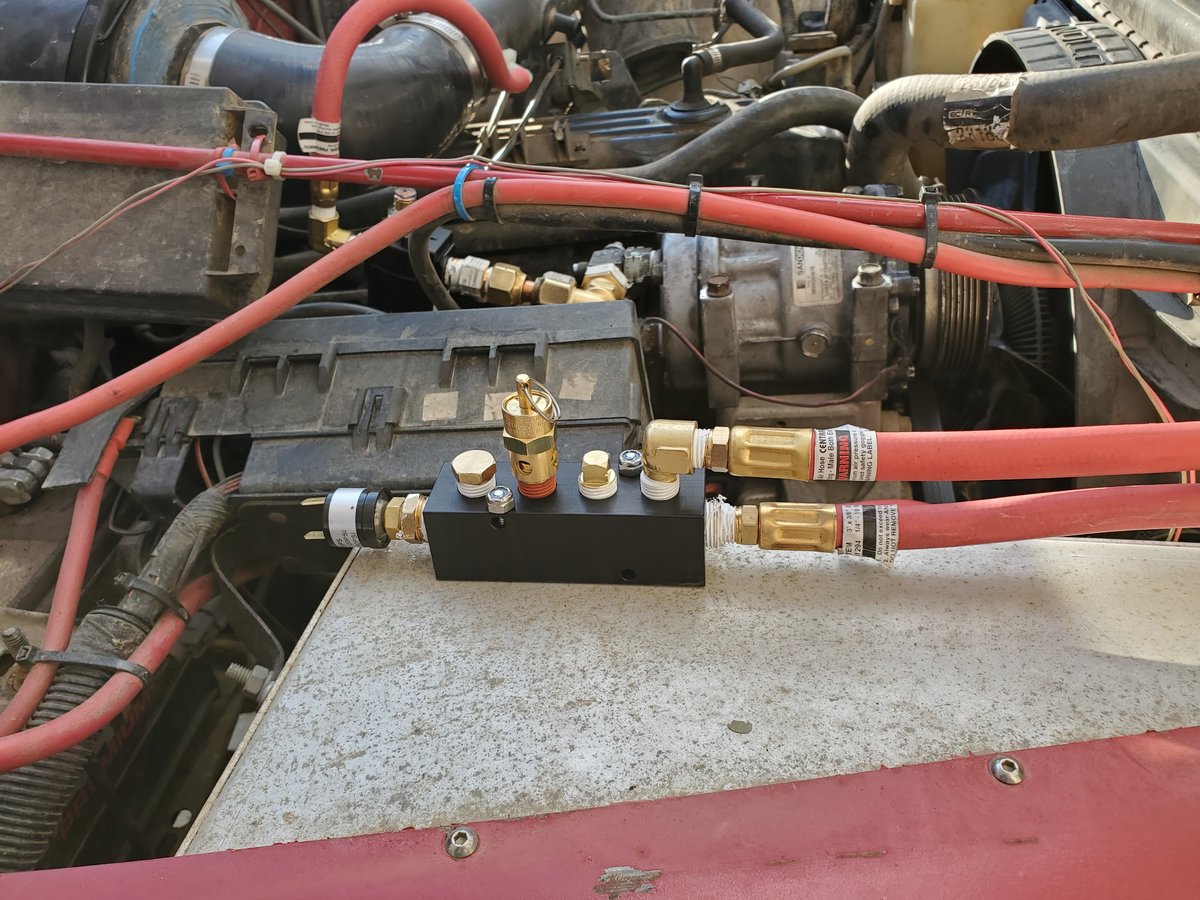

Mounted the manifold on the inner fender. This is pretty self explanatory. Inlet, pressure release (175psi), pressure switch (90/120 psi) and the outlet. I got the 4 hole manifold incase I add a rear outlet.

And the fitting for my air hose will be on the bumper. I plan to either drill thru the winch plate and mount it vertical, or weld a piece on and mount to that. Still need to button it up.

Not quite finished, but its plumbed and ready to hopefully finish tomorrow.

I can get three bolts on it now but the rear corner is still a good 1/4" off. I need to think about how to fix that.

The fittings off the compressor are flare fittings. Which made things a little complicated, luckily I was told about swivels which are gas fittings. These things run about $12 a piece at the ACE hardware

Here is my test fit

Intake side with Speedaire oiler. Lesson learned, buy an oiler with 1/4 inlets. Sizing down from 3/8" took a number of fittings. Not sure how long the intake nipple will last, it's simply a plastic 90 degree that I screwed into place (I know, I need a clamp there still).

Discharge side. I'm not sure how these will hold overtime. My connections are long which is a lot of leverage at the compressor fitting

Mounted the manifold on the inner fender. This is pretty self explanatory. Inlet, pressure release (175psi), pressure switch (90/120 psi) and the outlet. I got the 4 hole manifold incase I add a rear outlet.

And the fitting for my air hose will be on the bumper. I plan to either drill thru the winch plate and mount it vertical, or weld a piece on and mount to that. Still need to button it up.

Not quite finished, but its plumbed and ready to hopefully finish tomorrow.

Last edited:

I don't know where you are with wiring but advice after years of using my air system. I don't like cab controls. I pop my hood and pull the wire from the pressure switch to turn the system off and on near my air chuck. I'd put the switch at the air chuck where you need it. The cab control is just an inconvenience. You are outside your Jeep airing tires, you want the switch outside too. Obviously just my opinion.

Edit: and it looks great, it really is coming together

Edit: and it looks great, it really is coming together

I don't know where you are with wiring but advice after years of using my air system. I don't like cab controls. I pop my hood and pull the wire from the pressure switch to turn the system off and on near my air chuck. I'd put the switch at the air chuck where you need it. The cab control is just an inconvenience. You are outside your Jeep airing tires, you want the switch outside too. Obviously just my opinion.

Edit: and it looks great, it really is coming together

I was going to put my switch inside the engine bay, however my long term plan is to have the adapters on my bumpers and would prefer to not have to pop my hood. It looks like Tyler’s plan is the same.

I have a gauge on my manifold and air all four tires at the same time. Also, I don't mind popping my hood at the end of a run just to let it air out and make sure my damn power steering didn't boil over again but to each his own. I did put cab controls in initially but my system is kinda built around lockers too (lockers I still don't have).I was going to put my switch inside the engine bay, however my long term plan is to have the adapters on my bumpers and would prefer to not have to pop my hood. It looks like Tyler’s plan is the same.

I have a gauge on my manifold and air all four tires at the same time. Also, I don't mind popping my hood at the end of a run just to let it air out and make sure my damn power steering didn't boil over again but to each his own. I did put cab controls in initially but my system is kinda built around lockers too (lockers I still don't have).

Doing all 4 at once would be pretty awesome, and I tend to once over after a run too - including the engine bay in that is probably a good idea.

I don't know where you are with wiring but advice after years of using my air system. I don't like cab controls. I pop my hood and pull the wire from the pressure switch to turn the system off and on near my air chuck. I'd put the switch at the air chuck where you need it. The cab control is just an inconvenience. You are outside your Jeep airing tires, you want the switch outside too. Obviously just my opinion.

Edit: and it looks great, it really is coming together

Interesting, I'll have to play around with it and see what's best. I was initially going to do a dash switch matching my ARB switches. I can also see an outside switch being useful in the event of a failure or overheating compressor.

I recently picked up a set of motobilt rear fenders. I needed something to keep the water/snow down this winter. These are their 4" wide flares.

I started an earlier thread about painting these. I rattle canned the front highline fenders with duplicolor colormatch paint and they began peeling almost immediately after installation and I didn't want that to happen to my new rear fenders. So following that thread I made sure my prep work was correct. Just prepping the two I have maybe 3 hours into them. Packing oil and welding residue are all over, especially in the tight corners and the oil along the welds. I can tell the difference between these and the fronts.

After drying for two days.

I got up early this morning and began prepping the pass. side. Should have it finished this afternoon and will install them next weekend.

I started an earlier thread about painting these. I rattle canned the front highline fenders with duplicolor colormatch paint and they began peeling almost immediately after installation and I didn't want that to happen to my new rear fenders. So following that thread I made sure my prep work was correct. Just prepping the two I have maybe 3 hours into them. Packing oil and welding residue are all over, especially in the tight corners and the oil along the welds. I can tell the difference between these and the fronts.

After drying for two days.

I got up early this morning and began prepping the pass. side. Should have it finished this afternoon and will install them next weekend.

Minor updates. Dual switch panel mod complete and compressor wired up minus to the dash light. I'll finish that single wire hook up and new belt tomorrow, just got to cold to work on it.

Fenders are done. In person the driver rear looks a bit darker or maybe a more cherry red vs flame red. In the prepping thread I was told I was spraying to fast and/or to far away, the difference may be a result of that.

Fenders are done. In person the driver rear looks a bit darker or maybe a more cherry red vs flame red. In the prepping thread I was told I was spraying to fast and/or to far away, the difference may be a result of that.

Those look great. I think primer absorbs water, if those are exposed spots on the inside I'd be sure to shoot it or they'll go quick.

Those look great. I think primer absorbs water, if those are exposed spots on the inside I'd be sure to shoot it or they'll go quick.

Thanks! So far (minus the slight shade difference) I'm pleased with how these turned out. They're covered well with primer, 3 coats of red and another 2 coats of clear. You may be seeing the mounting holes or just glare from the overhead LED lights