With the demise of the OEM cam sensor, TJ owners needing to replace a faulty cam sensor will soon be left with no option other than using an aftermarket sensor. Aftermarket sensors have horrible reputations on this forum, and the intent of this thread is to present some information that may help the forum determine if suitable aftermarket cam sensors exist. In addition, since the crank sensor is the other main engine sensor, and the interaction of the two (more on that later) is monitored by the PCM, at some point, the crank sensors will also become difficult to find, and I suspect that similar problems could crop up.

First, here is what I’ve learned in reading service and parts manuals for all model years, as well as the Powertrain Diagnostic Procedures Manual for my LJ (a 2005 model). There appear (it’s very difficult to find definitive proof of this) to be three main variants of Powertrain Control Modules (PCMs) used across the range of model years for the TJ:

On an unrelated note, another big change implemented with the introduction of the NGC PCM in 2005 is that it integrated the Transmission Control Module (TCM) for the automatic transmission into the PCM (and added a fourth connector to the box.) Incidentally, I think it was Mark at WranglerFix who first pointed out that heat was killing the NGC PCMs due to additional heat generated by the TCM inside the PCM case. Those NGC PCMs simply won’t survive long term in the extremely hot engine compartment of a TJ – the TCM pushed it over the edge of “too hot.”

Soon after I discovered this forum, I read about the “DRB III” computer that Chrysler techs used “back in the day” to diagnose problems with our TJs. I’ve been doing major work on vehicles for decades, and I’ve found that it is essential to have the proper diagnostic computer when working on OBD2-equipped vehicles. I was disappointed at the prices used DRB III computers command, but I decided to invest in one since my LJ is a “bucket list” vehicle – and project – for me.

The DRB III is a fairly sophisticated diagnostic computer (although it may not look it) that works with many Chrysler vehicles, not just Jeeps or TJs. It has adaptive menus, meaning that the menus you see on it depend upon the configuration of the vehicle to which you’ve connected it. The cam and crank sensor signals are used for many purposes in the PCM, and how they relate to each other with respect to crankshaft rotation is important. Because the engine’s crankshaft is rotating at thousands of times per minute and many things happen during a single rotation of the crankshaft, the interaction of the two sensors’ signals is affected by all the production tolerances (mechanical, but also electrical) involved.

The PCM is keeping track of the crankshaft’s position and the camshaft’s position during each revolution and determining when to fire each injector and spark plug based upon those sensor signals (the crank sensor triggers the spark plugs and the cam sensor triggers the injectors). Small variations in the output signal of each individual sensor become problematic to the PCM, as it can cause the PCM to misinterpret those positions, which can cause serious engine problems.

In addition to using the signals to fire injectors and spark plugs, the PCM also monitors them and looks for problems. For instance, the P03XX codes for misfires are triggered when the PCM sees a slight change in the time between two cylinders firing because the crank actually speeds up slightly with each cylinder’s firing, and if a cylinder doesn’t fire, the PCM can detect that from the cam and crank sensor signals because the crank fails to accelerate at that point in the crank’s rotation.

The DRB III has a function for helping the PCM make small adjustments for production variations of individual sensors, but that function is different for the JTEC+ PCM and the NGC PCM.

Cam Sensor Calibration for JTEC+ PCMs with Electronic Ignition (2000-2004 TJs)

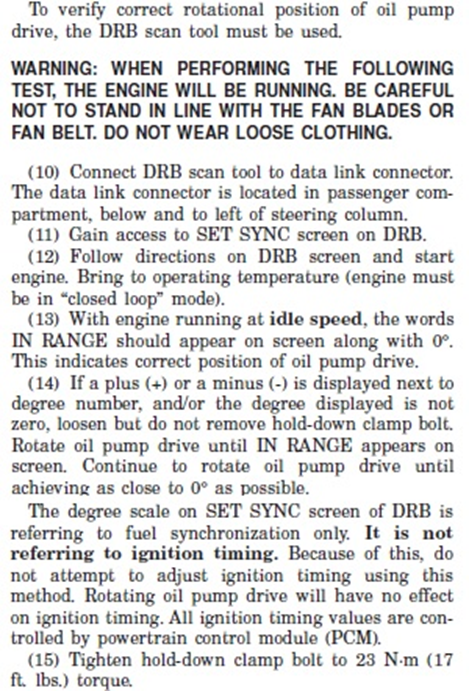

In the JTEC+ PCM, the function is referred to in the service manual as the “SET SYNC” function, and it involves watching the display on the DRB III while adjusting the position of the oil pump drive assembly with the engine running. Here is the description from the service manual:

Unfortunately, I only have access to my 2005 LJ with the NGC PCM, so I can’t show you any screen shots from the DRB III for using this procedure. As soon as I get access to an earlier model TJ, I’ll update this section.

Cam Sensor Calibration for NGC PCMs (2005-2006 TJs)

In the NGC PCM, the function is referred to in the service manual as the “CAM/CRANK RELEARN” function (but, as you’ll soon see, in the DRB III menu system, it’s called “ReLearn Cam Crank”), and it is mentioned at the end of the section on installing the oil pump drive assembly:

Unlike the JTEC+’s “SET SYNC” procedure, this procedure is not done with the engine running, and it is a very uneventful procedure. After you install the new oil pump drive assembly, you execute the function, and nothing noticeable happens with the DRB III. What this function does is tell the PCM to re-learn the relationship between the cam sensor signal and the crank sensor signal because you’ve changed the cam sensor. What happens when the PCM is re-learning is unknown to me for sure, but I suspect that it measures the time between crank and cam signal events and, using the RPM at the time, it determines how many crank degrees there are between the signals, and then sets new event triggers and limits used for diagnostic checks.

This function should be performed when you replace the cam sensor, replace the oil pump drive assembly, or rotate the oil pump drive assembly (see the “If You Rotate Your OPDA” section at the end of this post for more information). Following are screen shots on my DRB III, in progression, showing how you get to that function. Note that not all screens are shown here. There are some intermediate “press a key to continue”-type screens I’ve omitted. For each screen, the highlighted menu item is the selection you need to select to move on to the next screen (you can also press the appropriate number key for option number in the menu).

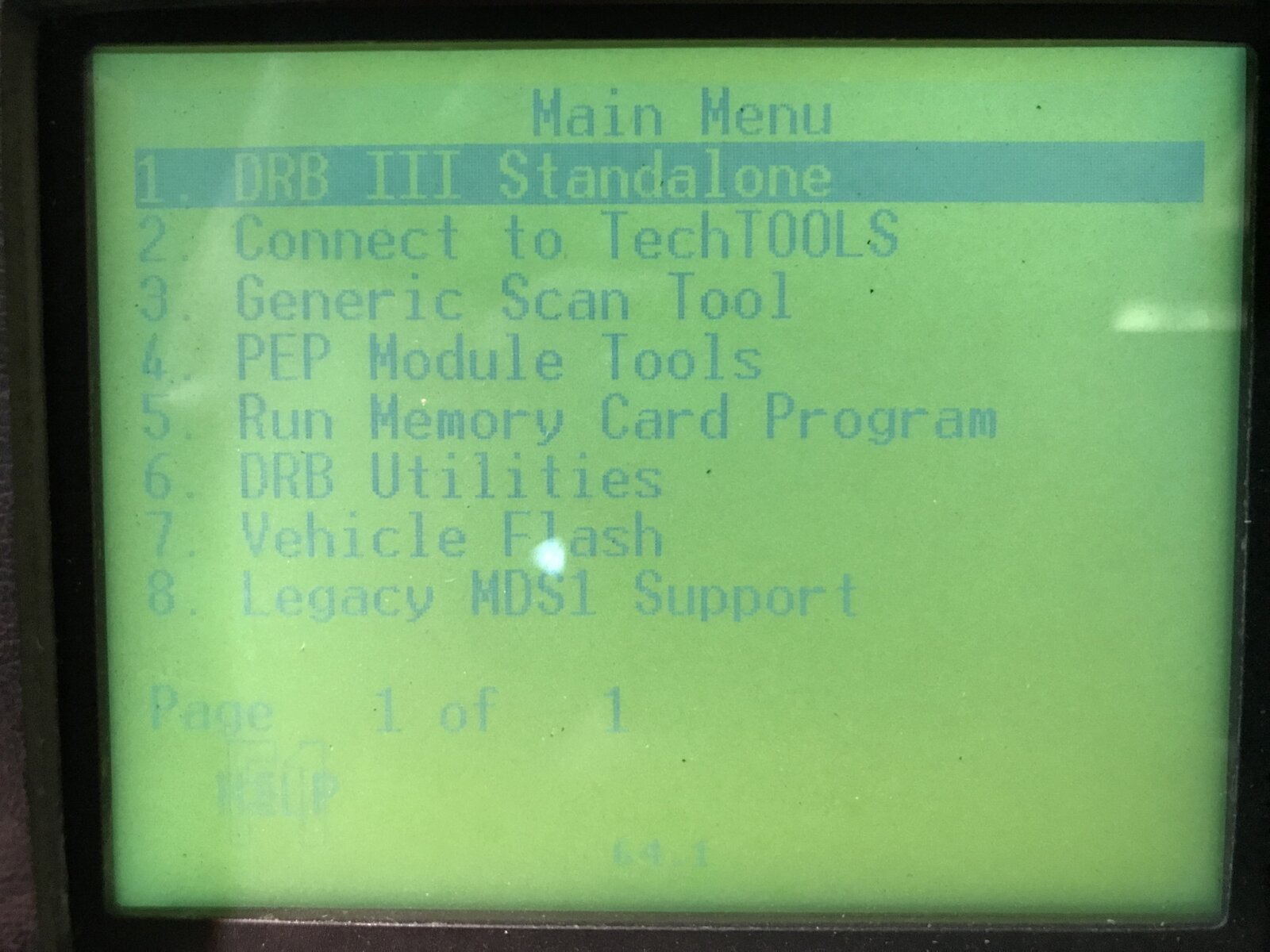

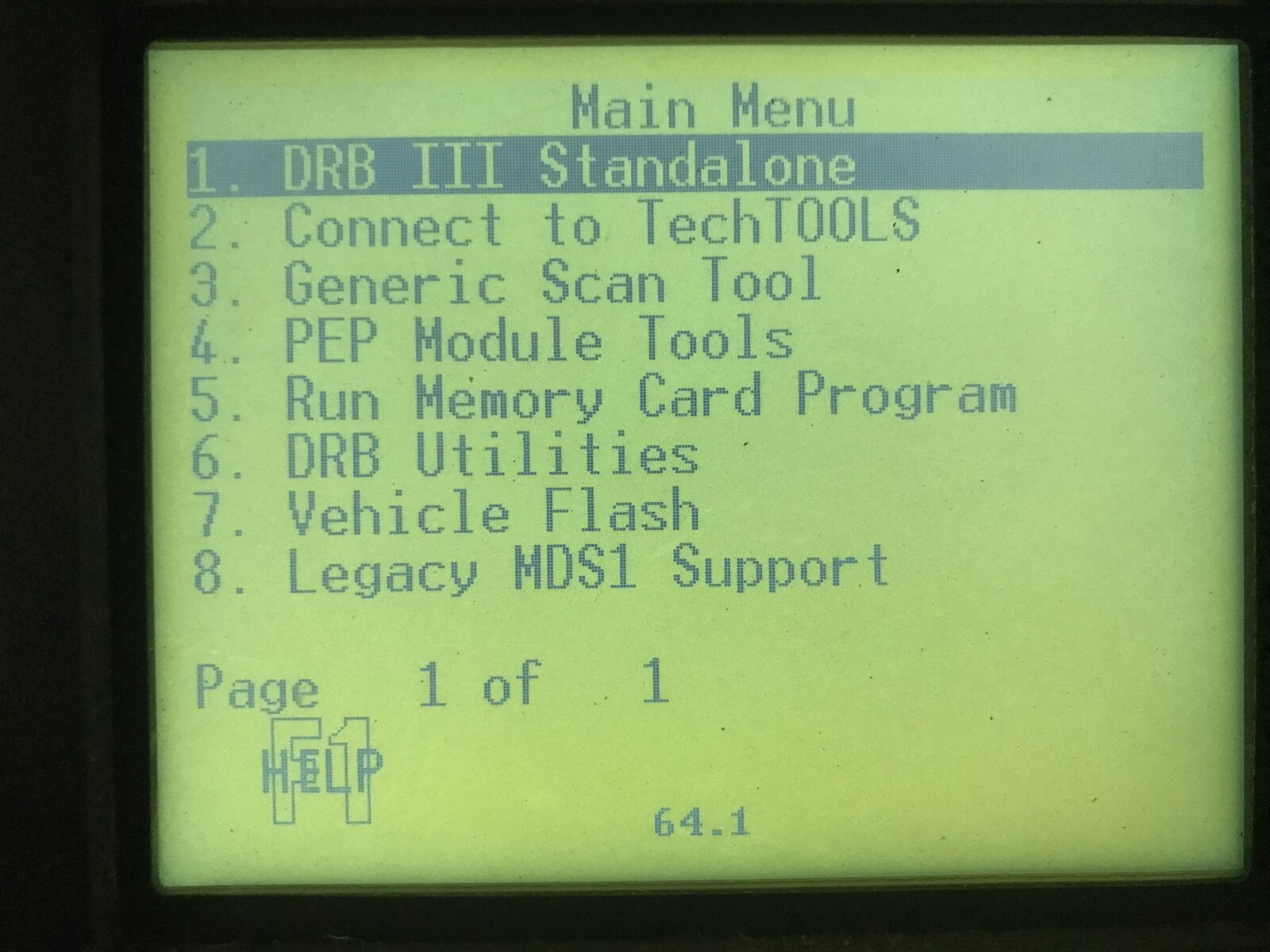

First, select Option 1 – “DRB III Standalone” from the Main Menu:

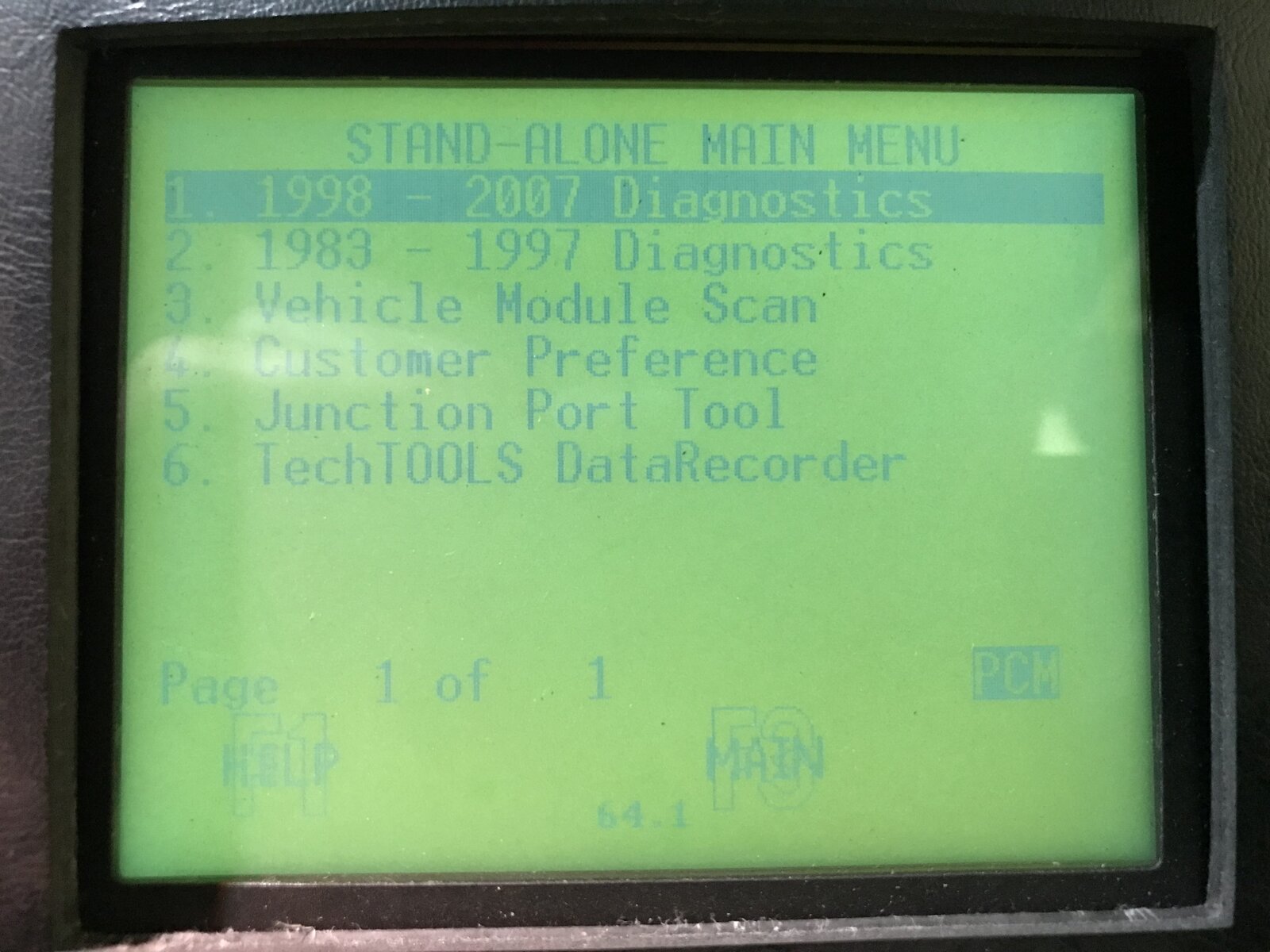

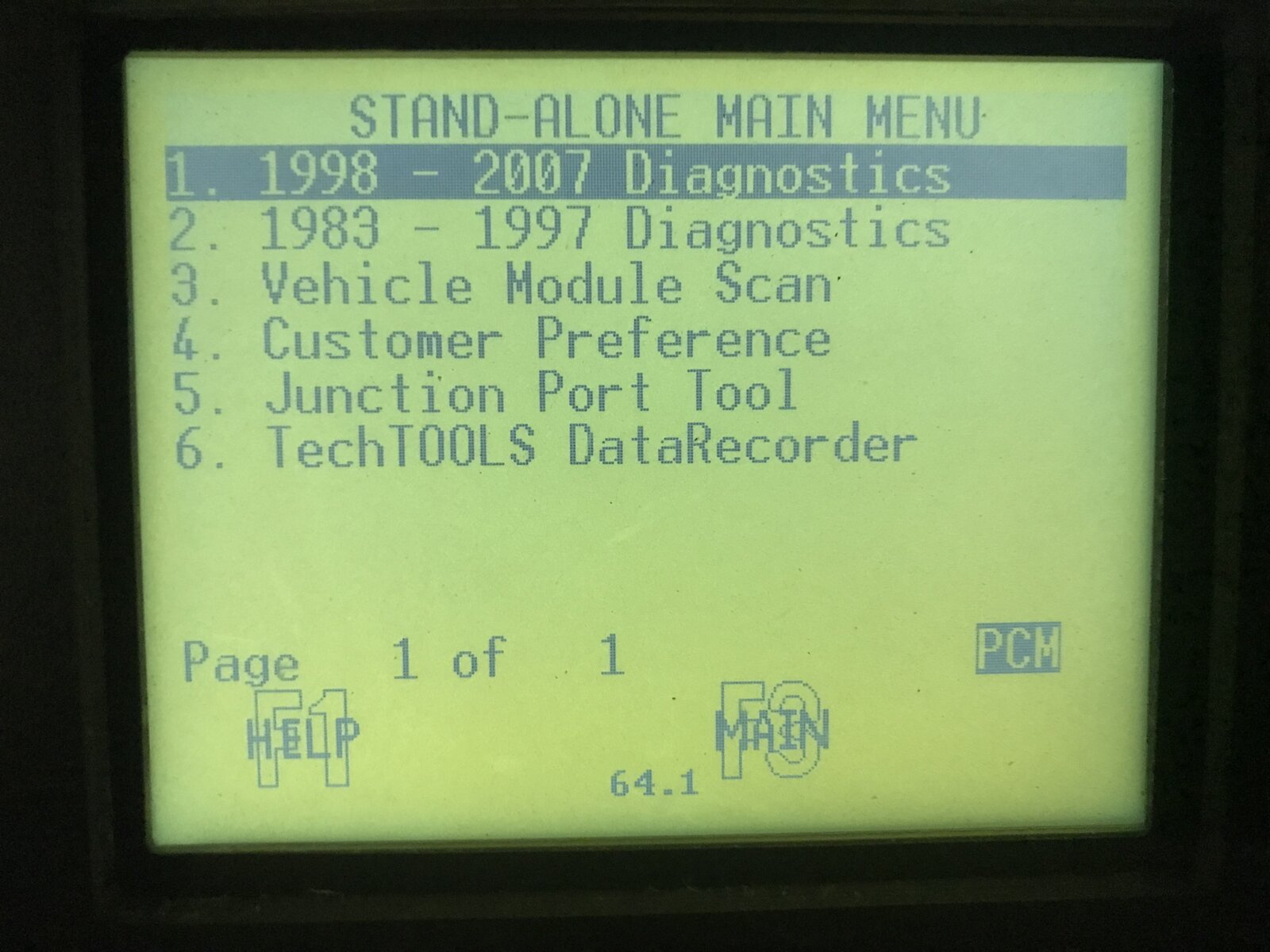

Next, select Option 1 – “1998 – 2007 Diagnostics” from the Stand-Alone Main Menu:

Now, select Option 1 – “All ( Except Below )” from the 1998 – 2007 Diagnostics Menu:

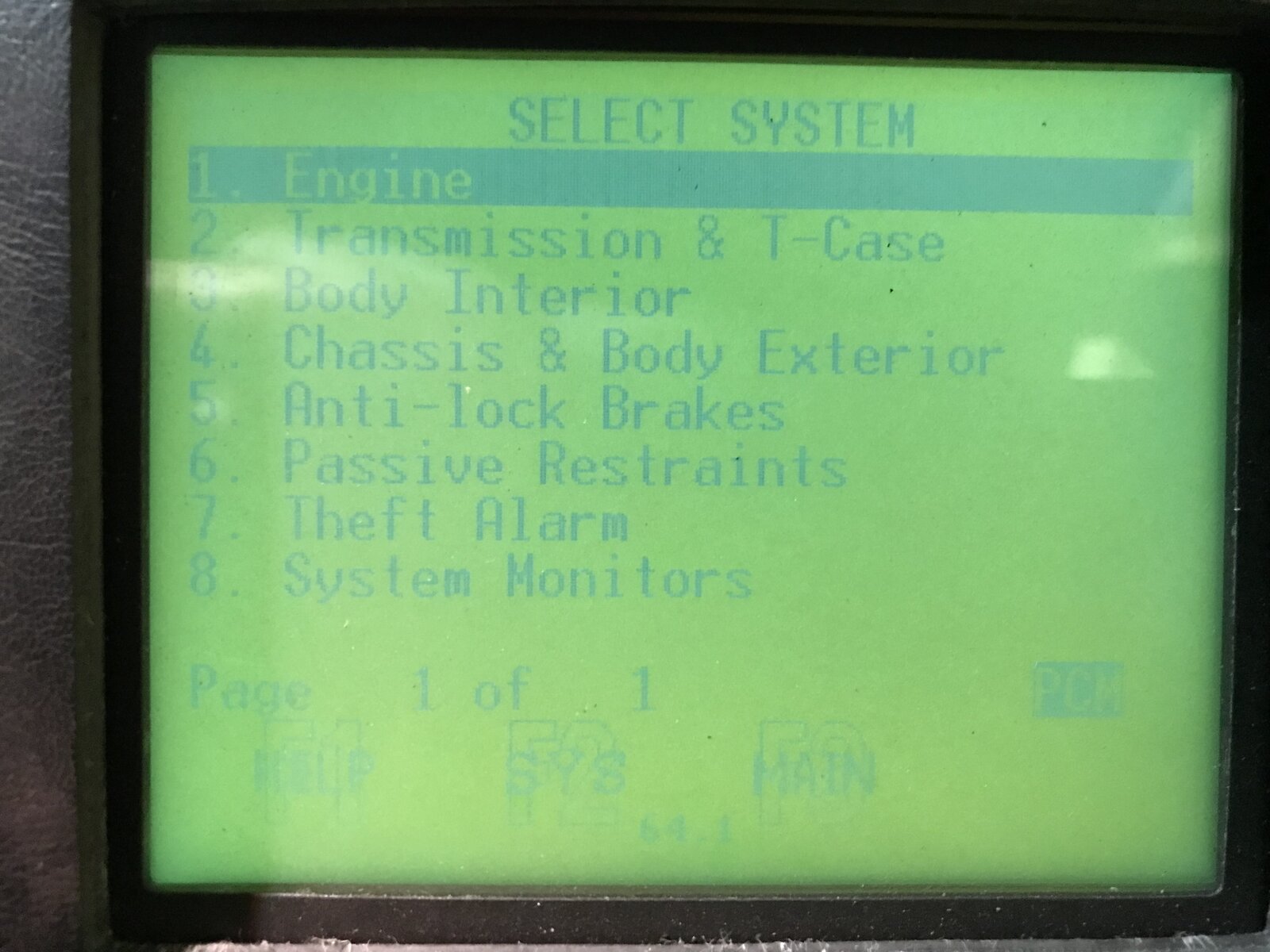

Next, select Option 1 – “Engine” from the Select System Menu:

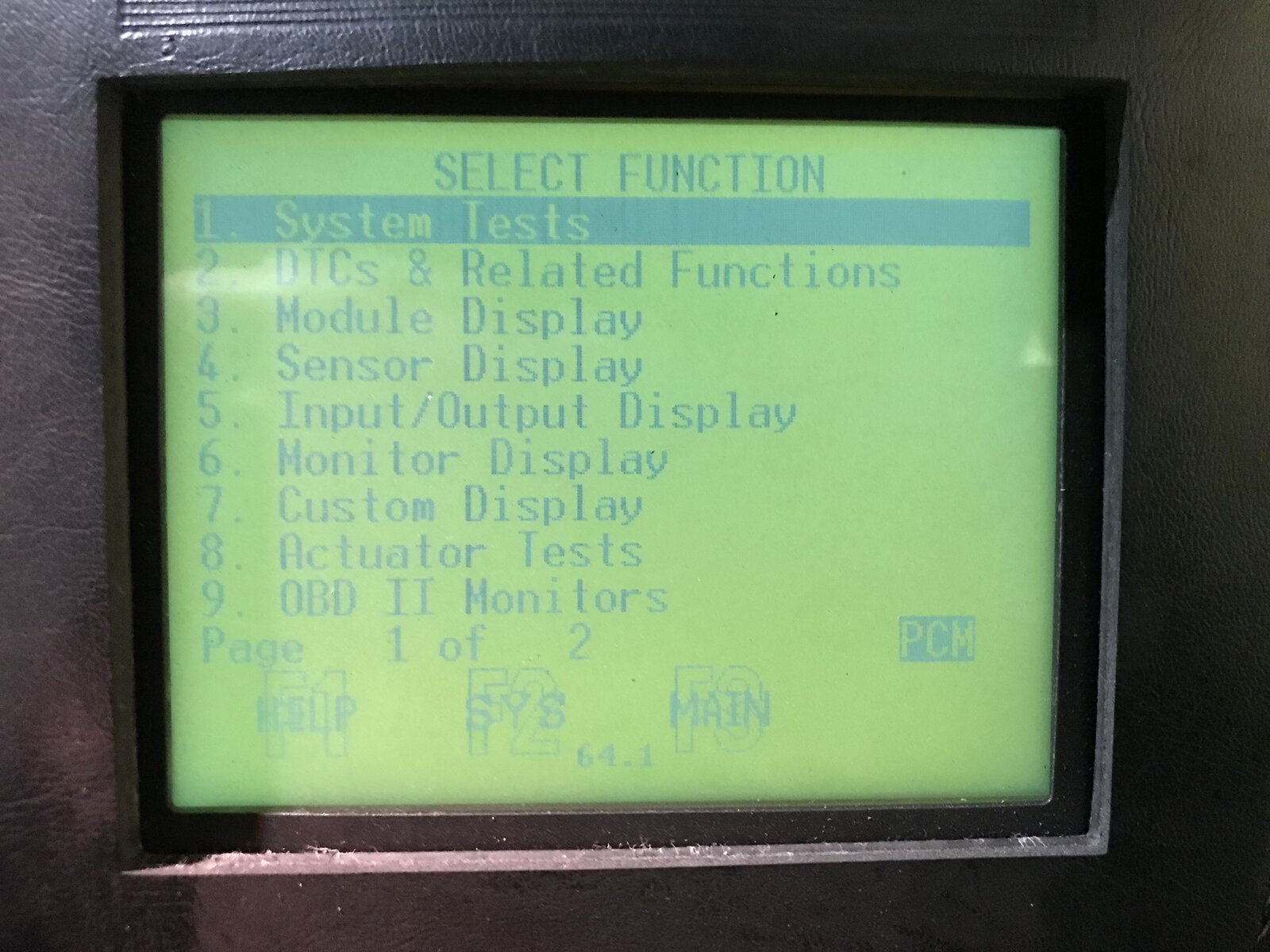

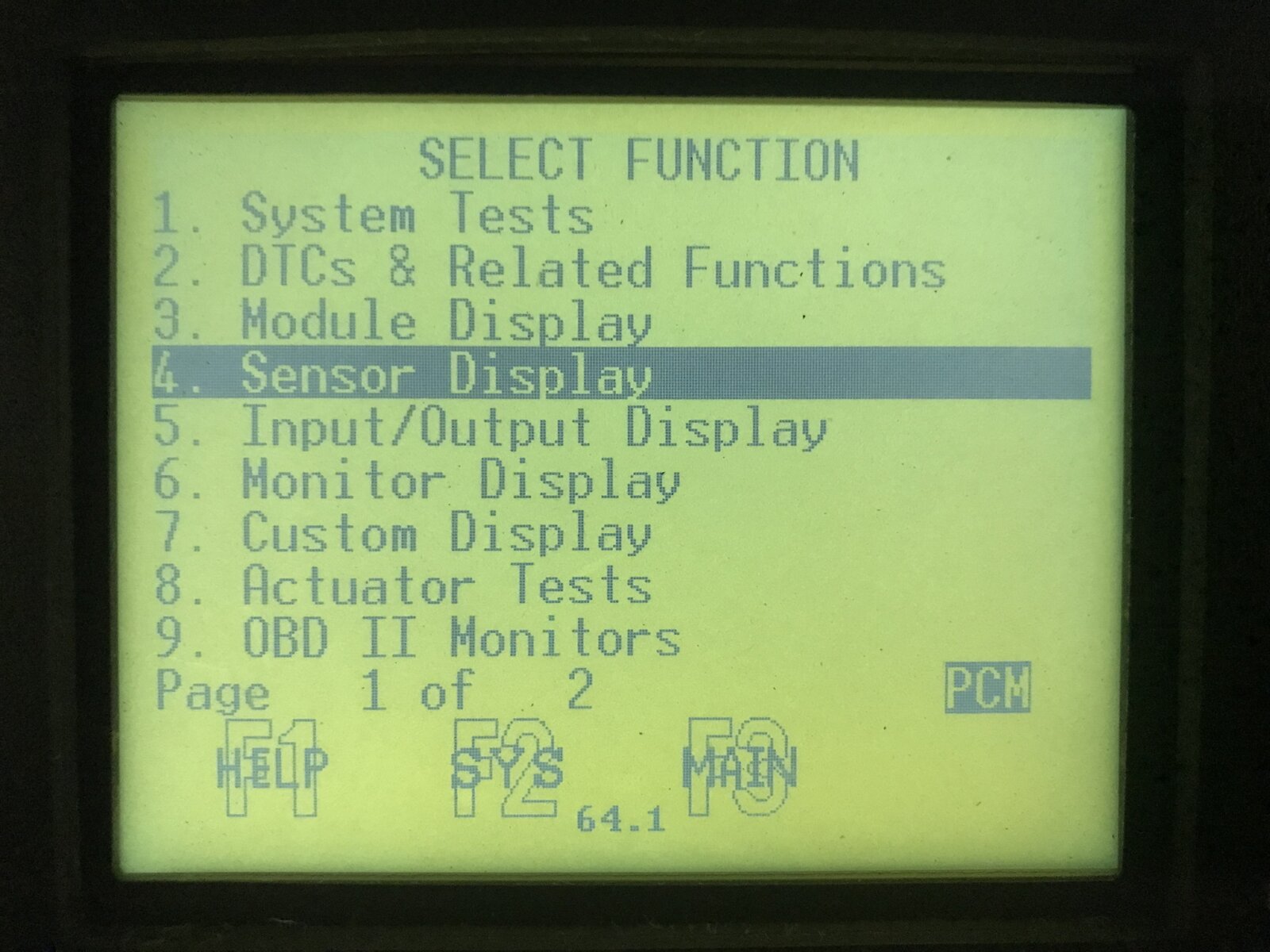

The next menu – Select Function – is actually two pages:

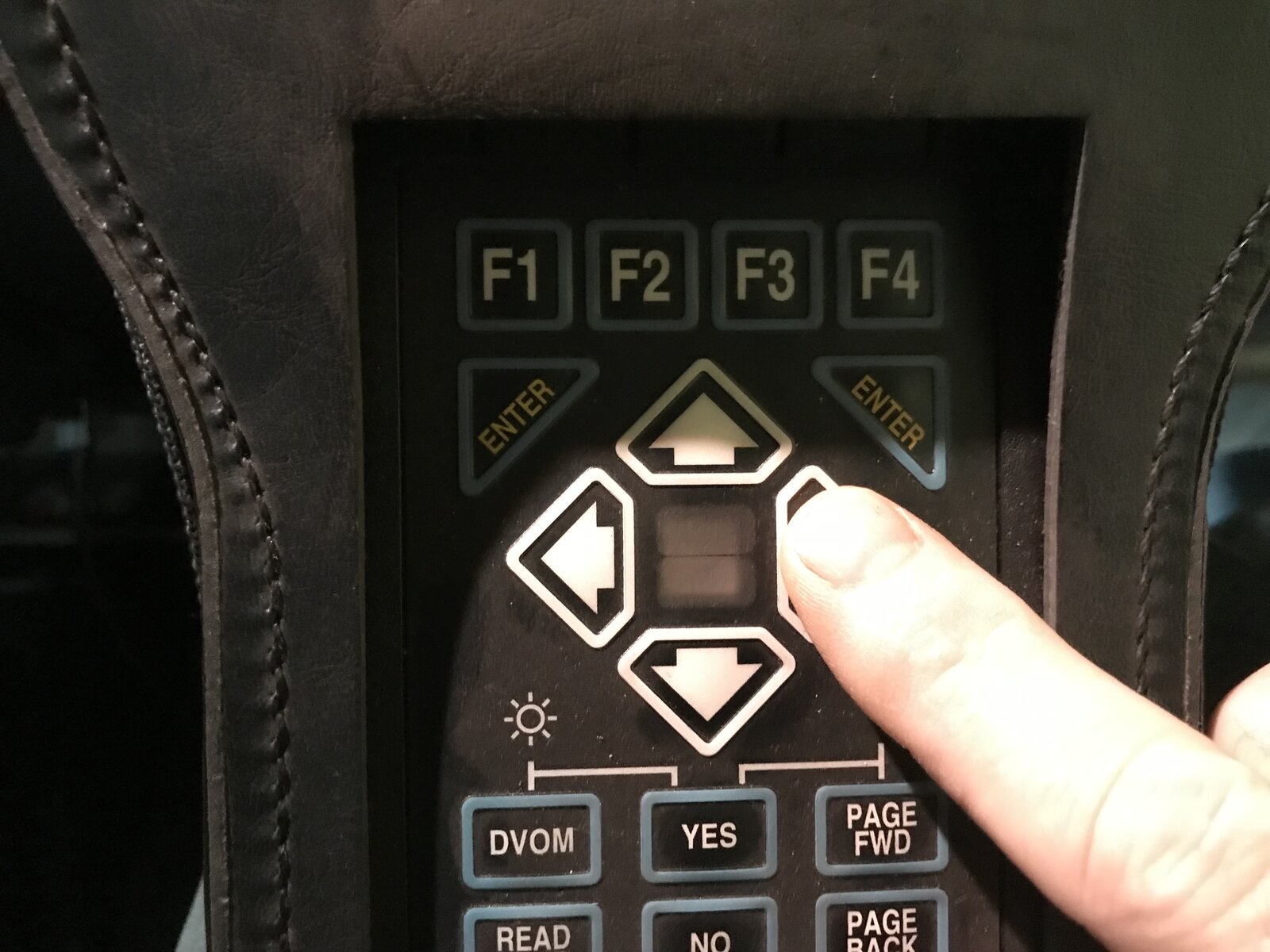

You need to press the right arrow key (shown below) to get to the second page for the next selection:

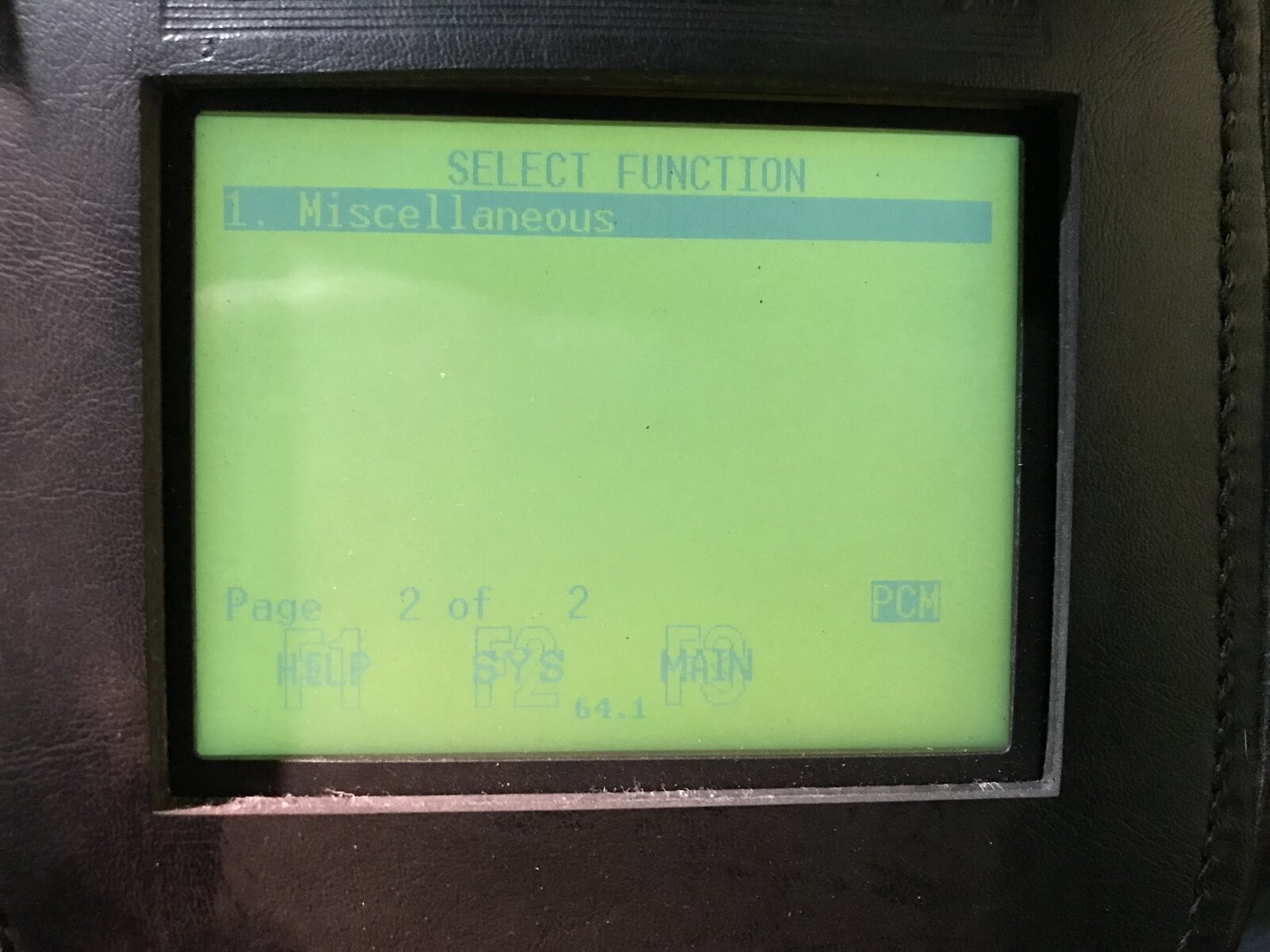

On the second page of the Select Function Menu, select Option 1 – “Miscellaneous”:

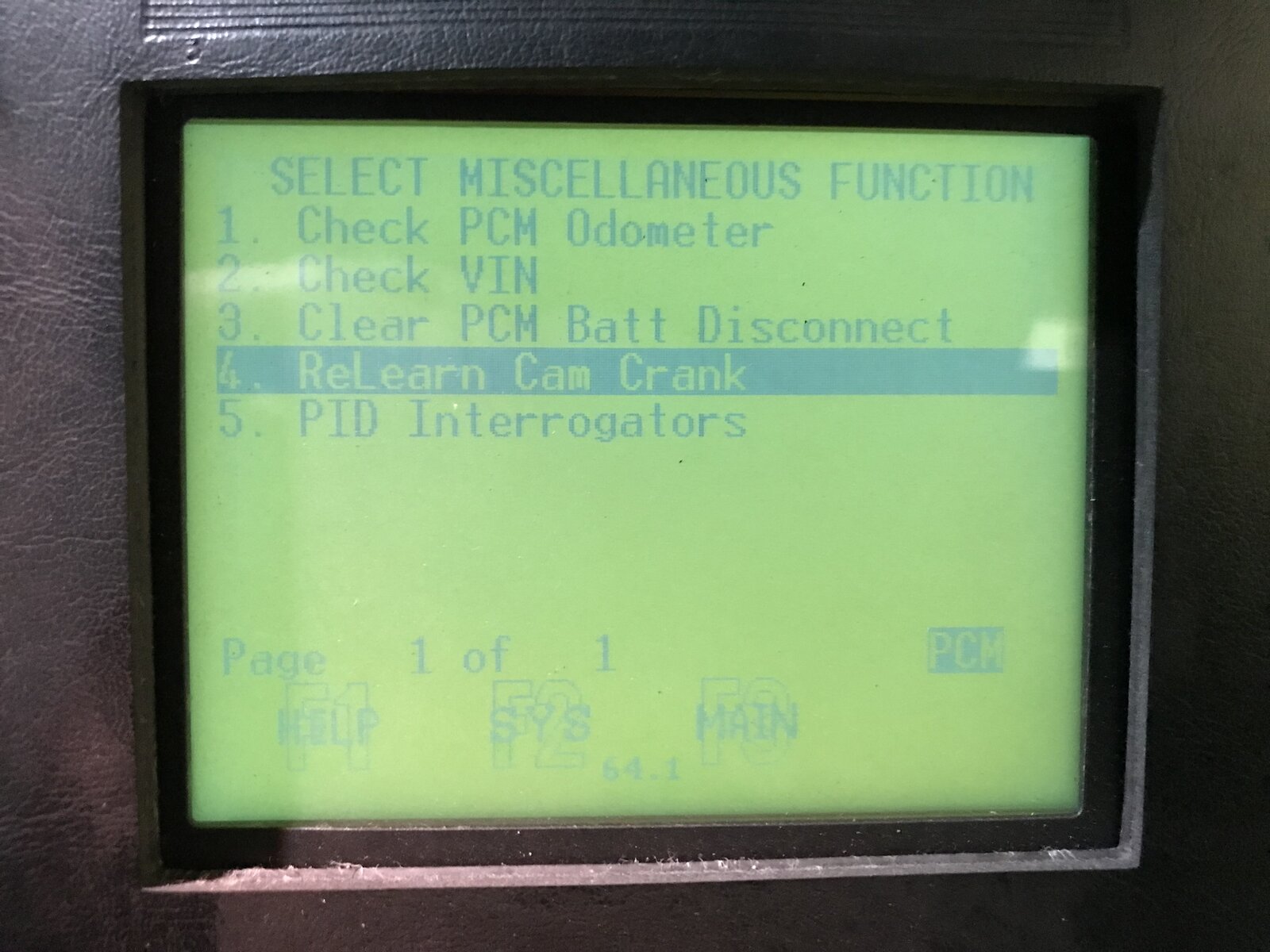

And on the Select Miscellaneous Function Menu, you’ll finally see the “ReLearn Cam Crank” function as Option Number 4. Select it:

After this, you can exit all menus (use the “Page Back” button) and just drive your TJ. The PCM will automatically do its thing.

If You Rotate Your OPDA

Some TJ owners have reported rotating their OPDA to fix cam crank sync issues. Doing so is not a bad idea, but doing so blindly is just relying on luck to get the right position. In fact, for the JTEC+ PCM, it’s actually part of the “SET SYNC” process. See the “Cam Sensor Calibration for JTEC+ PCMs with Electronic Ignition (2000-2004 TJs)” section above for more on that.

However, for the NGC PCM, it’s not covered in the manual, and I suspect that it’s not because no need to do so existed until aftermarket cam sensors become our sole option. Other people have looked at the signals produced by various aftermarket sensors with an oscilloscope, and those sensors were found to output longer pulses than that of the OEM sensors. As a result, the OPDA may need to be rotated to keep the cam and crank sensors in sync.

If your NGC PCM-equipped TJ (2005-2006) throws the P0016 code (or runs poorly) after performing the Cam Crank Relearn function and driving it for a bit, you may want to try rotating your OPDA, especially if you just installed a new aftermarket cam sensor (Note: this is speculation on my part – I have not confirmed that this works.)

Instead of just doing it blindly, there is an output in the diagnostic data stream that may be helpful. It’s called “Cam Crank Difference,” and it’s measured in crankshaft degrees. As with the JTEC+ PCM’s “SET SYNC” procedure, this value should be set to zero (or as close to it as possible). Again, I have not tried this myself, but I suspect that monitoring this value while rotating the OPDA (with the engine running and in closed loop mode), with the goal of getting it to be zero, will get your TJ running properly.

Here are the screen shots showing how to monitor this value, starting at the Main Menu (the highlighted menu item in each screen is the one to select in order to proceed):

If anyone tries this and has anything to add, please respond to this thread so that I can update this accordingly.

Happy syncing!

There's a pdf version of this post attached.

First, here is what I’ve learned in reading service and parts manuals for all model years, as well as the Powertrain Diagnostic Procedures Manual for my LJ (a 2005 model). There appear (it’s very difficult to find definitive proof of this) to be three main variants of Powertrain Control Modules (PCMs) used across the range of model years for the TJ:

- 1997-1998: Jeep/Truck Engine Controller (JTEC)

- 1999-2004: Jeep/Truck Engine Controller Plus (JTEC+)

- 2005-2006: Next Generation Controller (NGC)

On an unrelated note, another big change implemented with the introduction of the NGC PCM in 2005 is that it integrated the Transmission Control Module (TCM) for the automatic transmission into the PCM (and added a fourth connector to the box.) Incidentally, I think it was Mark at WranglerFix who first pointed out that heat was killing the NGC PCMs due to additional heat generated by the TCM inside the PCM case. Those NGC PCMs simply won’t survive long term in the extremely hot engine compartment of a TJ – the TCM pushed it over the edge of “too hot.”

Soon after I discovered this forum, I read about the “DRB III” computer that Chrysler techs used “back in the day” to diagnose problems with our TJs. I’ve been doing major work on vehicles for decades, and I’ve found that it is essential to have the proper diagnostic computer when working on OBD2-equipped vehicles. I was disappointed at the prices used DRB III computers command, but I decided to invest in one since my LJ is a “bucket list” vehicle – and project – for me.

The DRB III is a fairly sophisticated diagnostic computer (although it may not look it) that works with many Chrysler vehicles, not just Jeeps or TJs. It has adaptive menus, meaning that the menus you see on it depend upon the configuration of the vehicle to which you’ve connected it. The cam and crank sensor signals are used for many purposes in the PCM, and how they relate to each other with respect to crankshaft rotation is important. Because the engine’s crankshaft is rotating at thousands of times per minute and many things happen during a single rotation of the crankshaft, the interaction of the two sensors’ signals is affected by all the production tolerances (mechanical, but also electrical) involved.

The PCM is keeping track of the crankshaft’s position and the camshaft’s position during each revolution and determining when to fire each injector and spark plug based upon those sensor signals (the crank sensor triggers the spark plugs and the cam sensor triggers the injectors). Small variations in the output signal of each individual sensor become problematic to the PCM, as it can cause the PCM to misinterpret those positions, which can cause serious engine problems.

In addition to using the signals to fire injectors and spark plugs, the PCM also monitors them and looks for problems. For instance, the P03XX codes for misfires are triggered when the PCM sees a slight change in the time between two cylinders firing because the crank actually speeds up slightly with each cylinder’s firing, and if a cylinder doesn’t fire, the PCM can detect that from the cam and crank sensor signals because the crank fails to accelerate at that point in the crank’s rotation.

The DRB III has a function for helping the PCM make small adjustments for production variations of individual sensors, but that function is different for the JTEC+ PCM and the NGC PCM.

Cam Sensor Calibration for JTEC+ PCMs with Electronic Ignition (2000-2004 TJs)

In the JTEC+ PCM, the function is referred to in the service manual as the “SET SYNC” function, and it involves watching the display on the DRB III while adjusting the position of the oil pump drive assembly with the engine running. Here is the description from the service manual:

Unfortunately, I only have access to my 2005 LJ with the NGC PCM, so I can’t show you any screen shots from the DRB III for using this procedure. As soon as I get access to an earlier model TJ, I’ll update this section.

Cam Sensor Calibration for NGC PCMs (2005-2006 TJs)

In the NGC PCM, the function is referred to in the service manual as the “CAM/CRANK RELEARN” function (but, as you’ll soon see, in the DRB III menu system, it’s called “ReLearn Cam Crank”), and it is mentioned at the end of the section on installing the oil pump drive assembly:

Unlike the JTEC+’s “SET SYNC” procedure, this procedure is not done with the engine running, and it is a very uneventful procedure. After you install the new oil pump drive assembly, you execute the function, and nothing noticeable happens with the DRB III. What this function does is tell the PCM to re-learn the relationship between the cam sensor signal and the crank sensor signal because you’ve changed the cam sensor. What happens when the PCM is re-learning is unknown to me for sure, but I suspect that it measures the time between crank and cam signal events and, using the RPM at the time, it determines how many crank degrees there are between the signals, and then sets new event triggers and limits used for diagnostic checks.

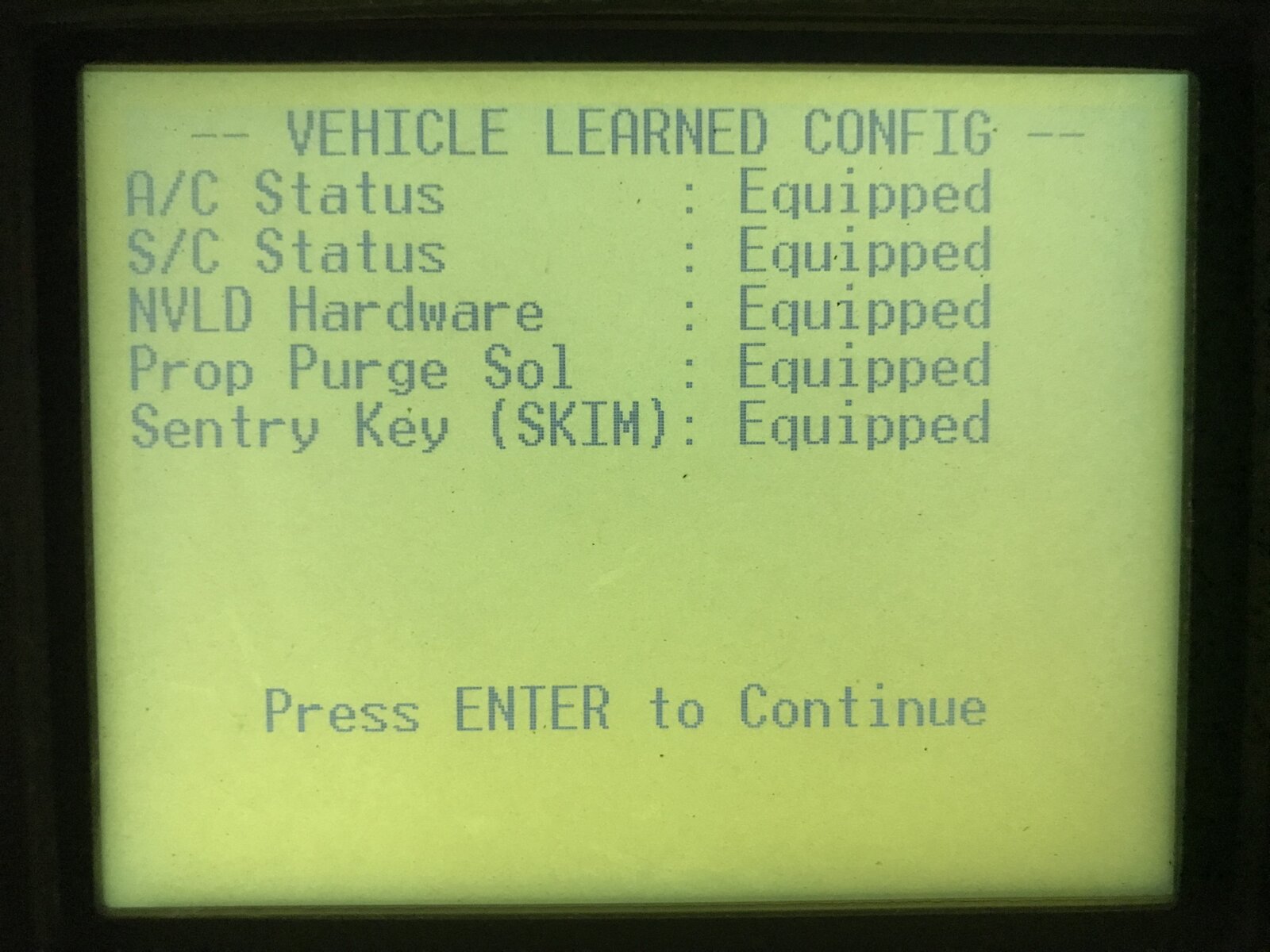

This function should be performed when you replace the cam sensor, replace the oil pump drive assembly, or rotate the oil pump drive assembly (see the “If You Rotate Your OPDA” section at the end of this post for more information). Following are screen shots on my DRB III, in progression, showing how you get to that function. Note that not all screens are shown here. There are some intermediate “press a key to continue”-type screens I’ve omitted. For each screen, the highlighted menu item is the selection you need to select to move on to the next screen (you can also press the appropriate number key for option number in the menu).

First, select Option 1 – “DRB III Standalone” from the Main Menu:

Next, select Option 1 – “1998 – 2007 Diagnostics” from the Stand-Alone Main Menu:

Now, select Option 1 – “All ( Except Below )” from the 1998 – 2007 Diagnostics Menu:

Next, select Option 1 – “Engine” from the Select System Menu:

The next menu – Select Function – is actually two pages:

You need to press the right arrow key (shown below) to get to the second page for the next selection:

On the second page of the Select Function Menu, select Option 1 – “Miscellaneous”:

And on the Select Miscellaneous Function Menu, you’ll finally see the “ReLearn Cam Crank” function as Option Number 4. Select it:

After this, you can exit all menus (use the “Page Back” button) and just drive your TJ. The PCM will automatically do its thing.

If You Rotate Your OPDA

Some TJ owners have reported rotating their OPDA to fix cam crank sync issues. Doing so is not a bad idea, but doing so blindly is just relying on luck to get the right position. In fact, for the JTEC+ PCM, it’s actually part of the “SET SYNC” process. See the “Cam Sensor Calibration for JTEC+ PCMs with Electronic Ignition (2000-2004 TJs)” section above for more on that.

However, for the NGC PCM, it’s not covered in the manual, and I suspect that it’s not because no need to do so existed until aftermarket cam sensors become our sole option. Other people have looked at the signals produced by various aftermarket sensors with an oscilloscope, and those sensors were found to output longer pulses than that of the OEM sensors. As a result, the OPDA may need to be rotated to keep the cam and crank sensors in sync.

If your NGC PCM-equipped TJ (2005-2006) throws the P0016 code (or runs poorly) after performing the Cam Crank Relearn function and driving it for a bit, you may want to try rotating your OPDA, especially if you just installed a new aftermarket cam sensor (Note: this is speculation on my part – I have not confirmed that this works.)

Instead of just doing it blindly, there is an output in the diagnostic data stream that may be helpful. It’s called “Cam Crank Difference,” and it’s measured in crankshaft degrees. As with the JTEC+ PCM’s “SET SYNC” procedure, this value should be set to zero (or as close to it as possible). Again, I have not tried this myself, but I suspect that monitoring this value while rotating the OPDA (with the engine running and in closed loop mode), with the goal of getting it to be zero, will get your TJ running properly.

Here are the screen shots showing how to monitor this value, starting at the Main Menu (the highlighted menu item in each screen is the one to select in order to proceed):

If anyone tries this and has anything to add, please respond to this thread so that I can update this accordingly.

Happy syncing!

There's a pdf version of this post attached.