No wonder Bugs Bunny could never get there. He was turning left in Albuquerque!!!!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do to your TJ today?

- Thread starter LJRubiconGuy

- Start date

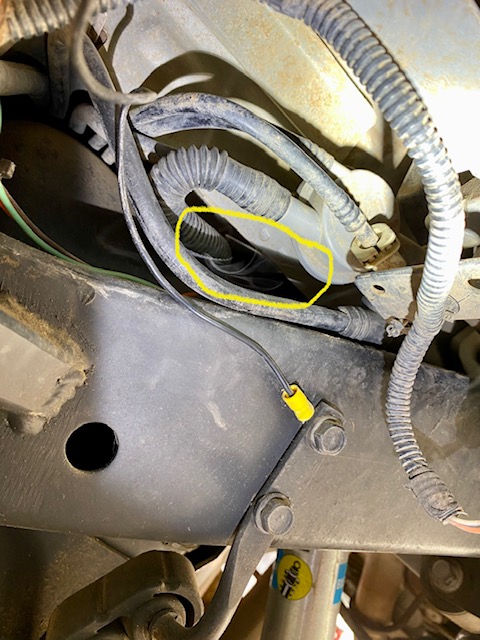

Fixed a minor Evap Leak (P0456). I purchased this Autoline Pro (Made in the USA) smoke machine (I know I probably could have bought a pack of smokes or even a joint from the local pot shop and rigged up some sort of device to blow smoke - I like to support USA made products and thought this smoke machine was worth it. BTW, if anyone is in the SoCal area feel free to reach out to me and you can borrow this thing) and identified the smoke (see photo with the yellow circle area) coming from the Flow Control Valve (I believe that's the assembly name). The challenge was how I was going to replace this assembly since this flow control is an assembly and not what I would call a plug and play (detach the hoses and replace a hose or the little round gray plastic device the smoke was coming from). From my understanding to replace the assembly would require dropping the fuel tank and and since the round gray piece only had a hair line crack or small hole I elected the RTV route. So I took an acid brush and lightly brushed the gray round device with RTV. The following day after the RTV dried I hooked up the smoke machine and zero smoke from this assembly. So, yes I would call this a inexpensive easy fix and a lot less man hours vice purchasing the entire flow control valve ($180-200 range) assembly and dropping the fuel tank and re-assembly. In the end I no longer have a P0456 code.

Last edited:

Looks like your CEL bulb is burned out.

DougyintheBushies

TJ Enthusiast

T

TRE3TOP

Guest

This guy finally came in! So it’s time to get it fitted up and prepped for paint. Hoping it gets warm enough today to paint, otherwise I might have to wait another day or two.

Don’t jinx meLooks like your CEL bulb is burned out.

Replaced the rear Fox reservoir shocks and front Bilstein 5100’s with a set of Rancho 5000x shocks. And replaced the brake pads. Wow, Jeep doesn’t sound like I tossed a box of tools down the stairs any more while on rough roads. Ride is excellent.

drove it down to Temecula and picked up my PRP enduros (+4" tall, seat heaters, lumbar support) that I snagged for 20% off during Black Friday

Head Lice

TJ Addict

Changed out the heater fan control resistor. Now have all fan speeds. Videos from this site were very helpful.

T

TRE3TOP

Guest

How does the lumbar support work? It’s an air bladder or something? Is it manual or do you wire up a switch to it?drove it down to Temecula and picked up my PRP enduros (+4" tall, seat heaters, lumbar support) that I snagged for 20% off during Black Friday

View attachment 302142

tstaut

Member

Tonight, before my eyes, she underwent an amazing, life-changing transformation. Got rid of those euro-clear lamps and went back to the way it was intended. Took a lot of blood, sweat, tears, and minutes wrenching away, but it was all worth it. ;-)

Unfortunately it's the blood pressure cuff bulb air bladder type. Mastercraft Safety seats have the mechanical lumbar support but they don't offer the taller seat back that I need.How does the lumbar support work? It’s an air bladder or something? Is it manual or do you wire up a switch to it?

T

TRE3TOP

Guest

What do you think of it? Do you like it? Are you glad you got it? I’m trying to decide if I want it.Unfortunately it's the blood pressure cuff bulb air bladder type. Mastercraft Safety seats have the mechanical lumbar support but they don't offer the taller seat back that I need.

I just picked them up today and haven't had time to even take a close look before I had to leave for work. It'll be a while until I can figure out a seat base/mounting bracket (I need to have the seat as low as possible/can't use the OEM base) but I'll reply here tomorrow about my opinion after I do a closer inspection in the morning.What do you think of it? Do you like it? Are you glad you got it? I’m trying to decide if I want it.

The brown and gold delivery truck dropped off a present today....

Installed a Tom Woods DC joint rear driveshaft today after installing a G2 SYE last week.

Applied blue loctite to the bolt threads for the flange and clamps; torqued the flange bolts to 20 ft/lbs and the clamp bolts to 14 ft/lbs.

Measured the pinion and driveshaft angles; the difference was 3* with no vehicle occupants.

Asked two neighbors to sit inside the Jeep and the difference went down to approximately 1*.

Test drove the Jeep on the highway for about 15 miles and there were no vibrates felt....

Looks like I do not need the rear upper adjustable control arms to rotate the differential.

The Jeep has a 2" coil spring lift and I had driveline vibrations afterwards, but the DC joint driveshaft and SYE have resolved that...

Installed a Tom Woods DC joint rear driveshaft today after installing a G2 SYE last week.

Applied blue loctite to the bolt threads for the flange and clamps; torqued the flange bolts to 20 ft/lbs and the clamp bolts to 14 ft/lbs.

Measured the pinion and driveshaft angles; the difference was 3* with no vehicle occupants.

Asked two neighbors to sit inside the Jeep and the difference went down to approximately 1*.

Test drove the Jeep on the highway for about 15 miles and there were no vibrates felt....

Looks like I do not need the rear upper adjustable control arms to rotate the differential.

The Jeep has a 2" coil spring lift and I had driveline vibrations afterwards, but the DC joint driveshaft and SYE have resolved that...

Last edited:

T

TRE3TOP

Guest

So I’m sure this has been asked somewhere but how are you guys measuring your Pinion and driveshaft angles and such? Are you measuring relative to the ground being the x axis?

So I’m sure this has been asked somewhere but how are you guys measuring your Pinion and driveshaft angles and such? Are you measuring relative to the ground being the x axis?

Angle gauge on ujoint caps. Old school dial shown below. Or (don't tell @Zorba) you can get a free app and use your phone

It depends upon whether you're running a constant velocity joint at the transfer case or not. With one, you want the driveshaft and pinion shaft coaxial (in line with each other) at rest. Without one, meaning you have a u-joint at each end, the u-joints have to be clocked relative to each other and the transfer case output shaft's axis should be parallel to the pinion shaft at rest, which makes the included angles between the driveshaft axis and the transfer case output shaft and the angle between the driveshaft axis and the pinion shaft axis equal. It's all relative, so referencing a datum axis in not necessary or helpful.

The reason for these requirements is that u-joints accelerate and decelerate during each revolution (at a constant shaft speed). Hence, the "constant velocity" joint distinction. By setting up drivelines as noted above, you synchronize the acceleration and deceleration as much as possible. If they are out of sync, the drive components have to elastically wind up and unwind during each revolution. This winding and unwinding creates vibration and unnecessary torsional stress in the driveline.

Do a Google image search on the words "driveshaft pinion angle" and you'll see examples of the two proper setups.

The reason for these requirements is that u-joints accelerate and decelerate during each revolution (at a constant shaft speed). Hence, the "constant velocity" joint distinction. By setting up drivelines as noted above, you synchronize the acceleration and deceleration as much as possible. If they are out of sync, the drive components have to elastically wind up and unwind during each revolution. This winding and unwinding creates vibration and unnecessary torsional stress in the driveline.

Do a Google image search on the words "driveshaft pinion angle" and you'll see examples of the two proper setups.

The reason for these requirements is that u-joints accelerate and decelerate during each revolution (at a constant shaft speed).

Just realized the above statement is a bit vague. It's a speed differential that changes between the shafts on either side of the u-joint that occurs every revolution. In other words, one shaft speeds up and slows down relative to the other with each revolution. So, if the input coming from the transfer case is a constant speed, the driveshaft speeds up and slows down. By synchronizing the u-joints rotationally and axially, as the energy is transmitted through the u-joint at the pinion, the change in speed occurs at the same time in that u-joint so that the output speed is constant. Hopefully that makes more sense.

With a C.V. joint at the transfer case, you want the u-joint at the pinion to line up the pinion shaft axis with the driveshaft axis because in that configuration, the u-joint keeps the shafts on both sides spinning at near-constant velocities relative to each other during each rotation (u-joints with shafts aligned have insignificant speed changes with each rotation.)

Of course, in both arrangements, as soon as you have vertical suspension movements, things are no longer in sync, but that's temporary until the suspension returns to normal ride height. U-joints are always a compromise because suspensions are in constant motion, but the resting position limits the vibration/stress to a minimum.