MountaineerTom

LJ Enthusiast, Retired USAF Weapons Loader

Supporting Member

Ride of the Month Winner

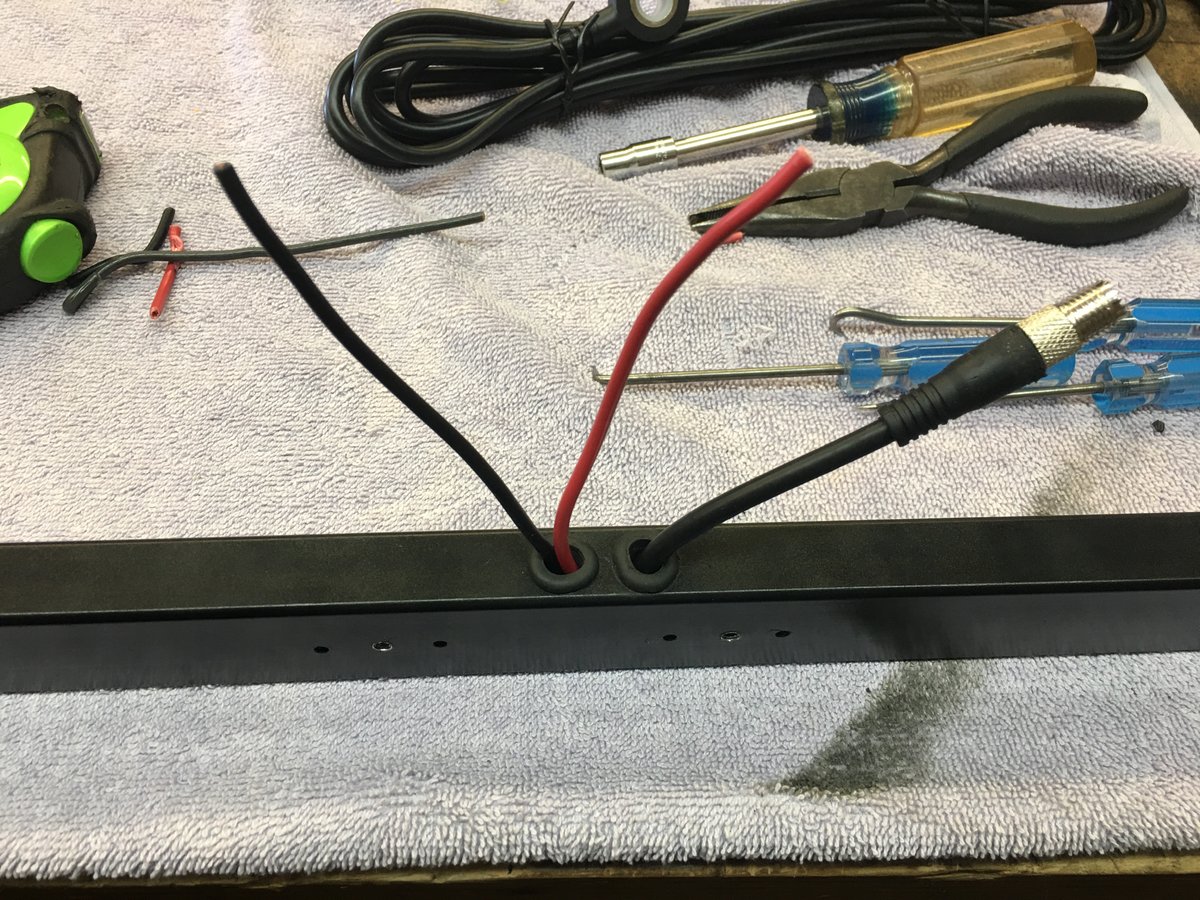

Finished up an install of a Uniden 520XL on an Arizona Rocky Road mount and a 2 foot Firestik II on a Terra Flex drivers side tail light mount with a Firestik Firering FME coax cable. Drilled an extra hole in the ARR mount for the FME coax. Wish I had drilled a slightly bigger hole as it took some work to get the coax end angled through the hole. Ran the coax towards the drivers side under the roll bar padding, down the roll bar, followed the wire harness along the tub, through the grommet at the end of the tub. I coiled up the extra coax and zip tied it in the fender where the tail light wiring is. Cleared paint from the bottom of the Terra Flex mount where the Fire Ring goes and from the area of the mount where the fourth bolt at the top where it goes through the tub and from inside the tub where the washer and nut goes. Hopefully that gets a good ground for it. Ran the power and ground wire down the drivers side A pillar, through the grommet where the clutch pedal piston would be and straight to the battery. 5 amp fuse holder close to the battery. I have little attachments on the terminals that makes adding a ring connector easy. I put bullet connectors on the wiring between the radio and the hole in the ARR mount in case I need to remove the radio. Pulled the bottom cover of the radio off to check for clearance and mounted the mike clip to the bottom cover.

One thing I noticed using the ARR radio mount is the coax on the back of the radio hits the plastic trim above the rearview mirror. It causes the radio to have to be pointed way up or way down to not interfere with it. (in the pic, that coax isn't connected) I've ordered a 90* coax adapter to see if that works without affecting SWR too much. If that doesn't work I'll consider a bracket that lowers the radio, or some type of spacer between the ARR mount and bracket or drilling/tapping new holes in the side of the radio.

I got SWR of 1.5. Was hoping to get under that, but will work on it some more later. I had to stop for the day due to other obligations. The NASCAR race was coming on, that was the obligation. LOL

Thanks @Jerry Bransford for helping and answering questions for me through Private Messages a few weeks ago. I may still use a grounding strap like you mentioned.

One thing I noticed using the ARR radio mount is the coax on the back of the radio hits the plastic trim above the rearview mirror. It causes the radio to have to be pointed way up or way down to not interfere with it. (in the pic, that coax isn't connected) I've ordered a 90* coax adapter to see if that works without affecting SWR too much. If that doesn't work I'll consider a bracket that lowers the radio, or some type of spacer between the ARR mount and bracket or drilling/tapping new holes in the side of the radio.

I got SWR of 1.5. Was hoping to get under that, but will work on it some more later. I had to stop for the day due to other obligations. The NASCAR race was coming on, that was the obligation. LOL

Thanks @Jerry Bransford for helping and answering questions for me through Private Messages a few weeks ago. I may still use a grounding strap like you mentioned.