I remembered. It was while I was trying to diagnose my issue and looking for info on the pinion bearing. It was EricTheCarGuy’s YouTube channel. He never chased this sound down. It’s probably not worth your time, but this diff was at .014, and that’s not where he set them up.Do you know where you'd read this? I'd like to read the article or thread.

Something else to note is that low pinion and high pinion act differently which is part of what I'm fighting here. A low pinion because you're on the drive side the ring gear isn't being pushed away from the pinion but in the high pinion because you're driving on the coast side of the gear it's being pushed away from the pinion gear. So this is also part of the reason for setting up tighter plus setting the pinion teeth lower in the ring gear. Most times you try to center the pattern towards the center of the ring gear tooth. But from what Carl was telling me he sets up his HP gears with the pattern more towards the root of the ring gear so as it's pushed away it then is in the center of the tooth. I hope I'm explaining this in a way others can understand.

It goes against everything I was taught about setting up gears but he's been doing this for a lot longer so I'm going to take his advice and try to do what he's telling me to do.

Here is his thread on the load bolt when he first released in over on Pirate.

https://tinyurl.com/2p8b53yb

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wildman's TJ is getting a face lift

- Thread starter Wildman

- Start date

That’s a good write up. I love it when people actually do the work to document the effects of a change. Well done. If I’m interpreting it correctly, the deflection on the coast side is about 10x that of the drive side at a given torque AND the load bolt takes the coast side deflection back down to drive side-like numbers. Nice!

Yes that is pretty much what it's trying to do. When driving on the coast side it pushes the gear sway A LOT and the load bolt is suppose to help with this happening.

I remembered. It was while I was trying to diagnose my issue and looking for info on the pinion bearing. It was EricTheCarGuy’s YouTube channel. He never chased this sound down. It’s probably not worth your time, but This diff was at .014, but that’s not where he set them up.

WOW ,014 is LOOSE IMO. But know that once gears are worn in they do get looser than what you set them up at when new.

It's been a few years for me since I've done any gears but I'm hoping it's like riding a bike. I feel like I can do it and I'm just going to take my time. I have tons of it so I don't have to rush and try and get it done in 4 hours.

When I was doing a gear setup like once a week I could get one done in 4-6 hours and once in a while 3 hours if things went great. But as I keep saying I'm sick and tired of pulling that diff cover and finding broken teeth on either the pinion or ring gear.

Also think about this. If you have .014 of backlash when you let off the gas and then stomp down on it that lash is allowing those gears to slam into each other. It ain't gunna take long to break them.

See the cracks in the teeth on the ring gear? This was because of too much backlash. This is my CRD60 rear axle.

And then here are some other pictures of broken teeth on the ring gear.

And this setup was wrong. See how the heel end of the gears are cracked?

Just like you were frustrated with that driveline noise I'm frustrated with replacing R&P sets in this axle. Now I've let someone else do all the other gears so if it's fucked up this time it's on me. I just want to get it fixed and then hopefully NEVER have to replace the gears in this axle again.

my BL range is 006-010.

i think i got a 006 and an 007 as starting points, hoping the break in will stay within the .010 spec. i did consider startin at like 004 and figured it would finish break in to closer to that .006. but was unsure since nobody says to do it that way, i played it safe and stayed in the range.

i think i got a 006 and an 007 as starting points, hoping the break in will stay within the .010 spec. i did consider startin at like 004 and figured it would finish break in to closer to that .006. but was unsure since nobody says to do it that way, i played it safe and stayed in the range.

Last edited:

So, what do you guys think about setting up used gears? I know its not recommended, but I got a really good deal on them, so I'm basically only going to be out time to set them up. I want to do it myself, and what better way to try than with something I didn't really spend any money on?

Anyway, with a used set, that has been broken in once...I'd guess to go tighter than a new set, just because they are used and have already been broken in once.

Anyway, with a used set, that has been broken in once...I'd guess to go tighter than a new set, just because they are used and have already been broken in once.

i'd guess, let the pattern guide you, it's got an established sweet spot that your trying to locate and get back into.So, what do you guys think about setting up used gears? I know its not recommended, but I got a really good deal on them, so I'm basically only going to be out time to set them up. I want to do it myself, and what better way to try than with something I didn't really spend any money on?

Anyway, with a used set, that has been broken in once...I'd guess to go tighter than a new set, just because they are used and have already been broken in once.

So, what do you guys think about setting up used gears? I know its not recommended, but I got a really good deal on them, so I'm basically only going to be out time to set them up. I want to do it myself, and what better way to try than with something I didn't really spend any money on?

Anyway, with a used set, that has been broken in once...I'd guess to go tighter than a new set, just because they are used and have already been broken in once.

You set them up on the coast side since it's really hard to get a reading on the drive side.

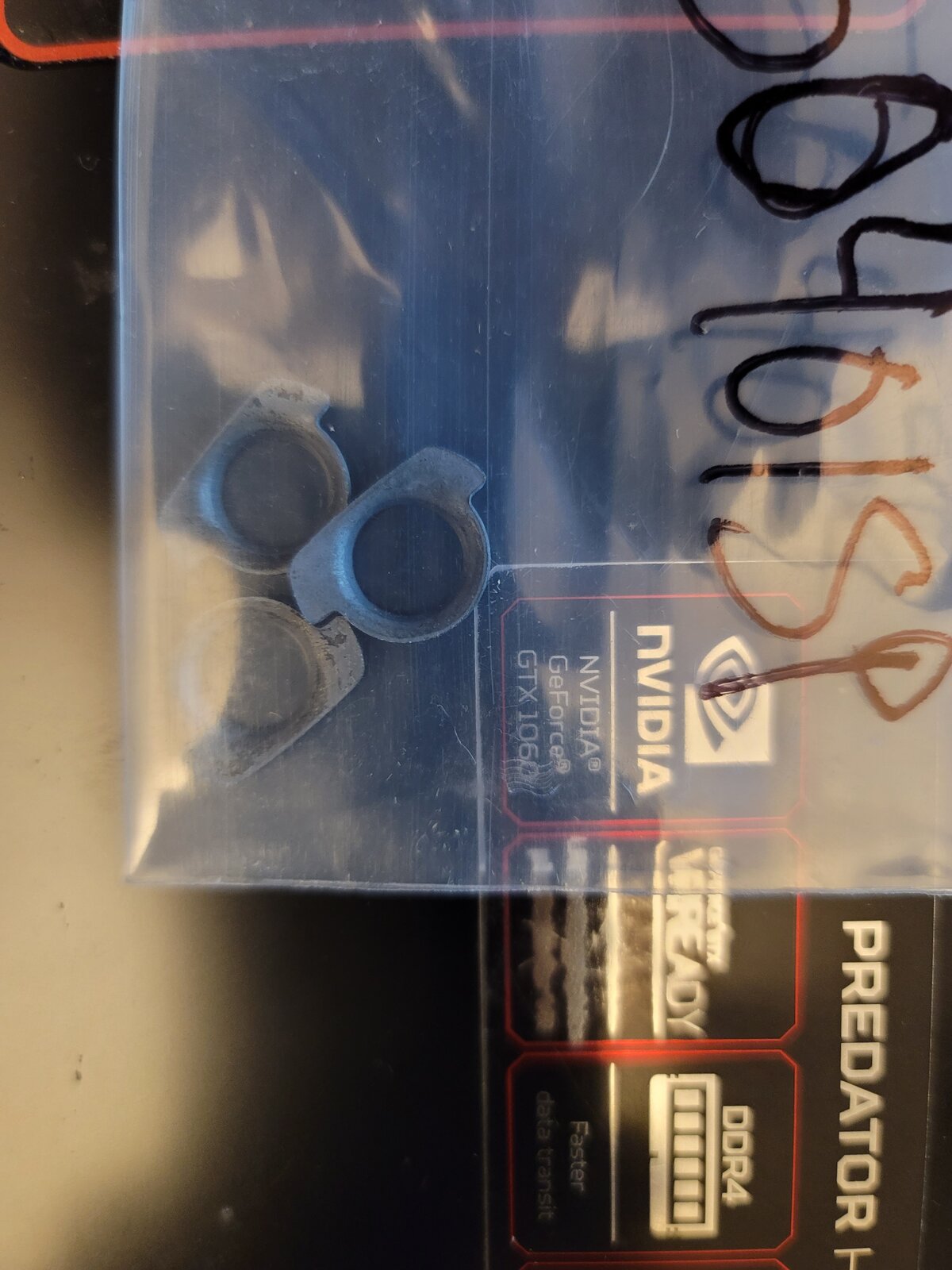

Well DAMN the parts arrived yesterday from Just Differentials only to not be what it's supposed to be.

https://www.justdifferentials.com/ARB150402SP-p/arb150402sp.htm

There is supposed to be 8 locking tabs in a package but instead this is what I got....

So I'd emailed them last night and got this in a email this morning.

So yes it means I end up waiting another day for the parts to get here but they are making it right and IMO that is what matters.

Then I dropped my exhaust off at Performance Coating to get ceramic coated and the guy at the front desk was great. He offered up his advice and then offered me a 15% discount for being a veteran too. So I can't wait to get it back now and it'll be in a silver color to match the headers.

https://www.justdifferentials.com/ARB150402SP-p/arb150402sp.htm

There is supposed to be 8 locking tabs in a package but instead this is what I got....

So I'd emailed them last night and got this in a email this morning.

Rick,

Very strange that those are in a package with sharpie notes on it. I checked our inventory and the ones we have are all in Ziploc bags from ARB with the ARB label on them.

There should in fact be (8) in the pack. I will have one overnight to you today.

Thank you,

New Order - 0451164

So yes it means I end up waiting another day for the parts to get here but they are making it right and IMO that is what matters.

Then I dropped my exhaust off at Performance Coating to get ceramic coated and the guy at the front desk was great. He offered up his advice and then offered me a 15% discount for being a veteran too. So I can't wait to get it back now and it'll be in a silver color to match the headers.

@Blackjack do you know did ARB change from a O-ring to a square type ring on the old lockers? I have a RD36 locker as far as I know. The PDF for it shows this part# 160207SP

https://www.arb.com.au/assets/air-lockers/2-RD36.pdf

And then I don't remember where I found a cross reference to this part#

https://www.justdifferentials.com/ARB-160207SP-p/arb160207sp.htm

The old O-Rings are the round ones and the new ones are the square ones.

And per Carl's instructions I coated the area where I'd welded in the load bolt with a Right Stuff RVT .

Made a HELL of a Mess....

https://www.arb.com.au/assets/air-lockers/2-RD36.pdf

And then I don't remember where I found a cross reference to this part#

https://www.justdifferentials.com/ARB-160207SP-p/arb160207sp.htm

The old O-Rings are the round ones and the new ones are the square ones.

And per Carl's instructions I coated the area where I'd welded in the load bolt with a Right Stuff RVT .

Made a HELL of a Mess....

I can take a look into it tomorrow.@Blackjack do you know did ARB change from a O-ring to a square type ring on the old lockers? I have a RD36 locker as far as I know. The PDF for it shows this part# 160207SP

https://www.arb.com.au/assets/air-lockers/2-RD36.pdf

And then I don't remember where I found a cross reference to this part#

https://www.justdifferentials.com/ARB-160207SP-p/arb160207sp.htm

The old O-Rings are the round ones and the new ones are the square ones.

View attachment 302145

View attachment 302146

And per Carl's instructions I coated the area where I'd welded in the load bolt with a Right Stuff RVT .

View attachment 302147

Made a HELL of a Mess....

View attachment 302148

I can take a look into it tomorrow.

Thank you I truely appreciate it.

I worked on the steering first but didn't take any pictures of it. I installed the new drag link but need to get everything tightened back down.

Then I started to work on the Skid Row skid plate. I took the new angle iron I'd ordered and cut it to match the angle iron in the skid plate. Then I drilled some 1/2" holes in it so I can plug weld them onto the angle iron already on the skid. Then I stripped the old paint off and sprayed the new & old angle iron with weld thru primer.

I'll weld it all up tomorrow morning.

Then I started to work on the Skid Row skid plate. I took the new angle iron I'd ordered and cut it to match the angle iron in the skid plate. Then I drilled some 1/2" holes in it so I can plug weld them onto the angle iron already on the skid. Then I stripped the old paint off and sprayed the new & old angle iron with weld thru primer.

I'll weld it all up tomorrow morning.

Couldn't sleep so I decided to come out and work on the skid plate.

First off I clamped the angle iron down.

Then started welding them down.

I went back and ground down all the plug welds. Honestly don't know if I needed more welds but I welded the sides down also.

Then I smoothed off the ends to help it slide easier.

Skid plate is all done other than the painting. And moving the oil drain hole to fit my V-8.

First off I clamped the angle iron down.

Then started welding them down.

I went back and ground down all the plug welds. Honestly don't know if I needed more welds but I welded the sides down also.

Then I smoothed off the ends to help it slide easier.

Skid plate is all done other than the painting. And moving the oil drain hole to fit my V-8.

Now we'll have to wait until it is driving to see if this strengthen it enough to keep it from bending again.

So according to ARB the square oring is the one used in current production units. He said they will work but because of the machining that was done on the bearing post they have a tendency to roll when installing them. He gave me a number for an industry (probably British) standard oring BS136V75 that you can use. By measurement it is 50.47mm id with a 2.62mm cross section and it is Viton. Not sure if you have a good bearing house close by or something like Motion Industries.Thank you I truely appreciate it.

So according to ARB the square oring is the one used in current production units. He said they will work but because of the machining that was done on the bearing post they have a tendency to roll when installing them. He gave me a number for an industry (probably British) standard oring BS136V75 that you can use. By measurement it is 50.47mm id with a 2.62mm cross section and it is Viton. Not sure if you have a good bearing house close by or something like Motion Industries.

Thanks.

I'll see if I can find those o-rings. The square ones rolled every time I tried to install the air hat.

Just Differentials did overnight those locking tabs for the ARB locker and they arrived about 20 minutes ago. I'd also ordered a ARB skim kit as I've found when setting up the ARB there are times you need the shim pack from ARB.

Find that O-Ring online @ https://www.oringsandmore.com/ and have 4 new ones on their way.

Thanks for all the help @Blackjack I do appreciate it.

Thanks for all the help @Blackjack I do appreciate it.

Not a problem. Glad to see JTs taking care of you. I cannot even get them to return my calls and I am supposedly a Nitro dealer.Find that O-Ring online @ https://www.oringsandmore.com/ and have 4 new ones on their way.

Thanks for all the help @Blackjack I do appreciate it.