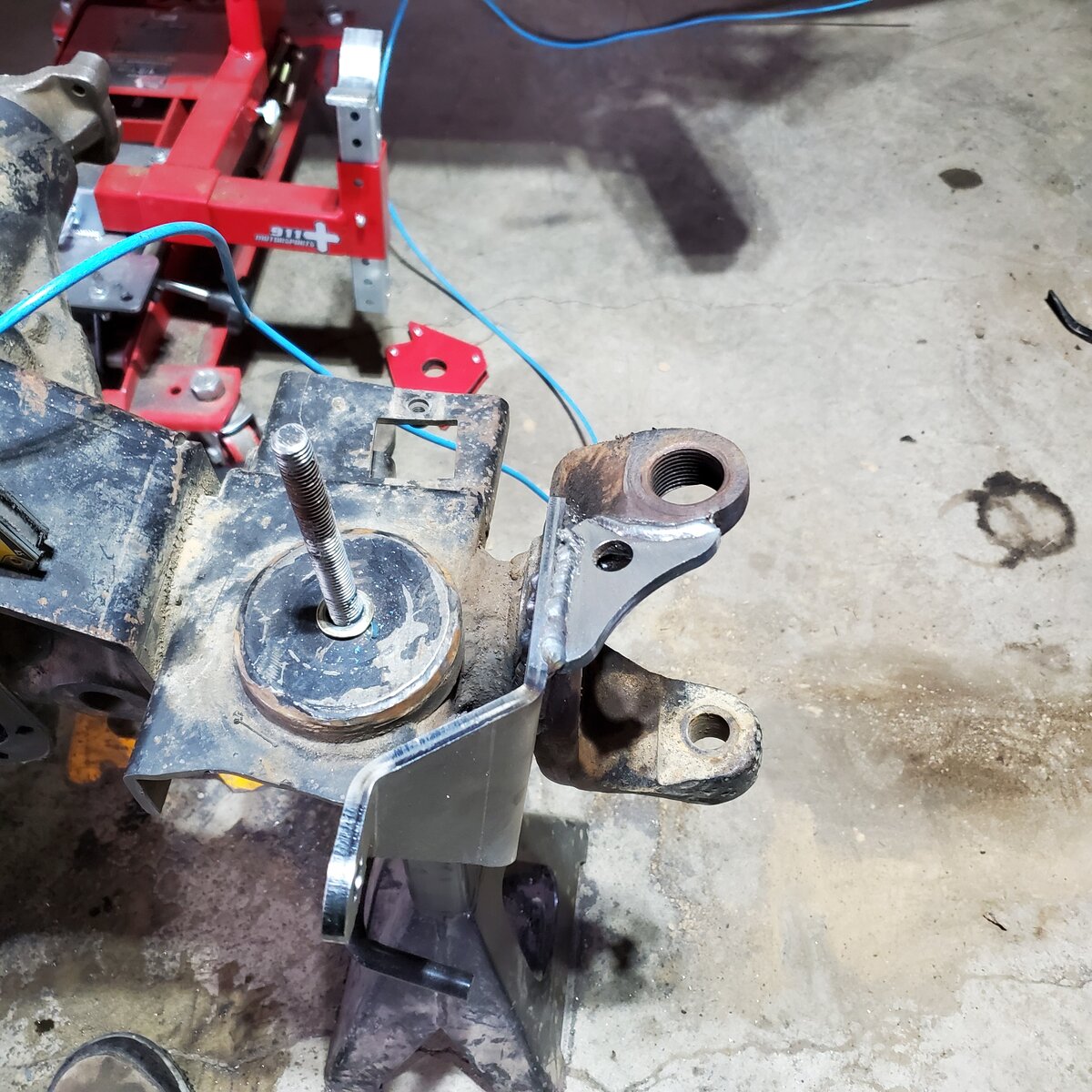

One side done and the other to go. My welds aren't awesome but they'll do.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wildman's TJ is getting a face lift

- Thread starter Wildman

- Start date

Maybe a little more heat in there, mount looks nice!One side done and the other to go. My welds aren't awesome but they'll do.

View attachment 163732

View attachment 163733

View attachment 163734

Just as I'm starting on the other side I start having feed issues. Sounds like a machine gun and you can feel the wire pulsating. And then my daughter called me into the house for dinner. So I'll finish the mount tomorrow.

Make sure your welding lead isn't a knackered mess on the floor. Long smooth bends, don't twist the gun around if that twists the lead too much. Shake the lead and get it to lay naturally without twists. Then check the drive roller and make sure it has enough tension not to slip. Always use a wiper on the wire before it goes into the liner or magnetism from energizing the electrode will carry metal particles into the liner and clog it.Just as I'm starting on the other side I start having feed issues. Sounds like a machine gun and you can feel the wire pulsating. And then my daughter called me into the house for dinner. So I'll finish the mount tomorrow.

Make sure your welding lead isn't a knackered mess on the floor. Long smooth bends, don't twist the gun around if that twists the lead too much. Shake the lead and get it to lay naturally without twists. Then check the drive roller and make sure it has enough tension not to slip. Always use a wiper on the wire before it goes into the liner or magnetism from energizing the electrode will carry metal particles into the liner and clog it.

All I had done was move from the outside of the mount to where I could get to the inside of the mount. I'll try to diagnose the issue in the morning. Just doesn't make any sense.

How’s the tension on your feed?All I had done was move from the outside of the mount to where I could get to the inside of the mount. I'll try to diagnose the issue in the morning. Just doesn't make any sense.

Where's your ground clamp attached?

Also make sure you're not distorting the BJ hole.

Also make sure you're not distorting the BJ hole.

How’s the tension on your feed?

Finger tight. Again I didn't do anything except move from one side of the axle to the other. It's just weird that it would start to act up now.

Where's your ground clamp attached?

Also make sure you're not distorting the BJ hole.

Ground is on a magnetic base. Same spot it was when I was welding on the outer side. I'll mess with it in the morning. Done for the day.

So far so good on the BJ hole. The drivers side is good.

In doing so you twisted the lead. If it was already at the limit, you made it worse.All I had done was move from the outside of the mount to where I could get to the inside of the mount. I'll try to diagnose the issue in the morning. Just doesn't make any sense.

In doing so you twisted the lead. If it was already at the limit, you made it worse.

That was the first thing I checked when it started to act up. Even rolled it one direction and then the other. Made no difference.

And down the rabbit hole we go...I remember learning that trick a few years ago from UTV guys (who probably got it from the Jeep guys).

The less I think in terms of the stock drivetrain the more I realize that the 42RLE is not the answer the further I build.

And down the rabbit hole we go...

I've been in the tunnels so long I've forgotten I'm in them.

i'd turn the wire speed down or the power up......... or a combination of both. if it's got a jerky feed either the liner is KO'd or maybe you got an over-wrap on the spool.

doesn't look like a vert up weld, am i correct ? vertical seams need weaved, back n forth to engage both surfaces.

with modern equip it's not critical to run vert up to establish penetration.

but you have to move slow and weave side to side to ensure penetration into both pieces.

now i'll suffer all the weekend welders and their opinions on vert up. but fact is 90% of um can't do it and will never be able to without being shown and a month of practice.

doesn't look like a vert up weld, am i correct ? vertical seams need weaved, back n forth to engage both surfaces.

with modern equip it's not critical to run vert up to establish penetration.

but you have to move slow and weave side to side to ensure penetration into both pieces.

now i'll suffer all the weekend welders and their opinions on vert up. but fact is 90% of um can't do it and will never be able to without being shown and a month of practice.

i'd turn the wire speed down or the power up......... or a combination of both. if it's got a jerky feed either the liner is KO'd or maybe you got an over-wrap on the spool.

doesn't look like a vert up weld, am i correct ? vertical seams need weaved, back n forth to engage both surfaces.

with modern equip it's not critical to run vert up to establish penetration.

but you have to move slow and weave side to side to ensure penetration into both pieces.

now i'll suffer all the weekend welders and their opinions on vert up. but fact is 90% of um can't do it and will never be able to without being shown and a month of practice.

Okay thanks for the advice. I'll be the first to admit my welding is not the best. I was practicing on scrap and had turned the speed down. When it started to stutter I tried to turn up the speed a little and the heat also. It's a new day so hopefully I can get it working now.

I have issues trying to weld up so I weld down on vertical welds.

I've had dozens of the same comments about "you should weld that vertical up". Yeah you have two choices there buddy, either shut the fuck up you wannabe piece of shit or show me your vertical up Mig weld.now i'll suffer all the weekend welders and their opinions on vert up. but fact is 90% of um can't do it and will never be able to without being shown and a month of practice.

BTW- just so you know, maximum allowable tip movement at the end of the electrode is 2 x the diameter of the wire. Keep the weave down to a minimum and do multiple passes if you need more.

For vertical down, you need the tip pointed upward at a 45 degree angle and you need to stay just at the front edge of the puddle. If the puddle is outrunning your tip speed down, it will do what you see. That and you can hear when you are staying in the puddle too long. The buzz gets erratic and starts popping.Okay thanks for the advice. I'll be the first to admit my welding is not the best. I was practicing on scrap and had turned the speed down. When it started to stutter I tried to turn up the speed a little and the heat also. It's a new day so hopefully I can get it working now.

I have issues trying to weld up so I weld down on vertical welds.

If you move from any other weld to vertical down, you need to change welder settings to speed up the wire speed and just move faster.

Lol, this is how I was taught to weld. Long before MIG welders were popular.doesn't look like a vert up weld, am i correct ? vertical seams need weaved, back n forth to engage both surfaces.

with modern equip it's not critical to run vert up to establish penetration.

but you have to move slow and weave side to side to ensure penetration into both pieces.

now i'll suffer all the weekend welders and their opinions on vert up. but fact is 90% of um can't do it and will never be able to without being shown and a month of practice.

i try not to get into others welding,

(but dammit the weld looks cold to me and i'd hate to see you have 1 fail on you)

i run a huge robotic gantry welder and 2 smaller traversing units.

i will say i'm dictated by how and what my machines can reach, and am responsible for quality welds, regardless of conditions. this is production welding and has to be correct in 1 pass. (there are instances where multi-pass welds are required on large drive bases up to 7000#)

my welds are tested frequently.

each weld in my programs is controlled and each weld condition requires different voltages and wire speeds as well as weave or not. and can have as many as 600 individually programmed movements to complete a sequence.

the machines are capable of a weave amplitude of over an inch, as well as having several weave patterns at a dictated frequency.

i saw a post not long ago about the robots welds from the factory on the newer Jeeps............made my laugh.

you cannot tell/teach a programmer how to weld. and they are running out of welders to teach how to program.

(but dammit the weld looks cold to me and i'd hate to see you have 1 fail on you)

i run a huge robotic gantry welder and 2 smaller traversing units.

i will say i'm dictated by how and what my machines can reach, and am responsible for quality welds, regardless of conditions. this is production welding and has to be correct in 1 pass. (there are instances where multi-pass welds are required on large drive bases up to 7000#)

my welds are tested frequently.

each weld in my programs is controlled and each weld condition requires different voltages and wire speeds as well as weave or not. and can have as many as 600 individually programmed movements to complete a sequence.

the machines are capable of a weave amplitude of over an inch, as well as having several weave patterns at a dictated frequency.

i saw a post not long ago about the robots welds from the factory on the newer Jeeps............made my laugh.

you cannot tell/teach a programmer how to weld. and they are running out of welders to teach how to program.

Last edited:

i try not to get into others welding,

(but dammit the weld looks cold to me and i'd hate to see you have 1 fail on you)

You aren't gunna hurt my feelings. I know I need to improve and the only way I can do that is by having people point out what is wrong with them.

and that's an awesome attitude to have..........these guys have a lot of info to offer. i try to help, but often need my path enlightened too.You aren't gunna hurt my feelings. I know I need to improve and the only way I can do that is by having people point out what is wrong with them.