Hey all, so I went to the scrap yard a couple days ago and saw a 1994 Cherokee with the stock cargo rail setup. I saw it was about 14 torx (the dreaded torx) bolts and it could be mine. 5 minutes and $25 later I was on my way home to install on my hard top. It measured about 60 inches and I had to trim a little and pick up some hardware but below is the process so everyone can do it. FYI. The hard top is NOT meant to handle extreme weights and should not be used to support over 60 lbs.

Started out finding this on the xj.

Got it dismantled at the shop. 4 Philips bolts.

Picked up 20 rubber washers, 10 1 inch long stainless bolts, and according lock nuts.

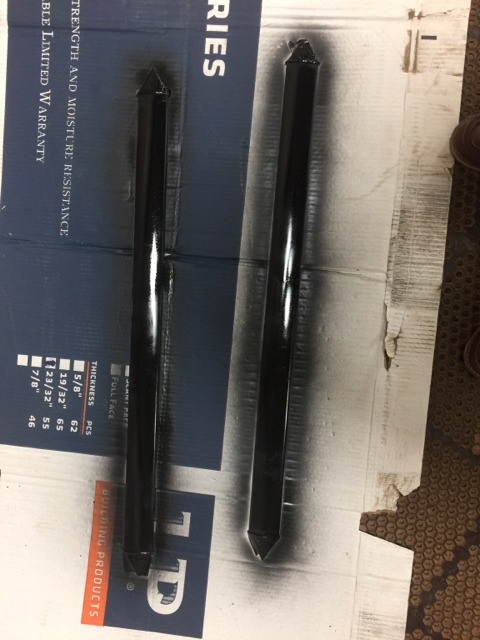

Had to trim the lengths down to 51 inches so I took the end pieces off and used a chop saw and grinder. The end result should mimic the stock factory end you trimmed.

I also picked up a 1/2 inch by 6 ft piece of steel and already had a tube of silicon laying around to seal up the holes drilled in the hard top. The steel is for the inside of the hard top to evenly distribute the load.

I took the two cross members and sanded them with a fine grit sandpaper to make a rough surface and then sprayed them with a couple coats to get rid of the trashy sun damaged look.

Now was the time to put the new bolts in the rails and mark the hard top for drilling. The order of layers should be the following. RAIL, RUBBER WASHER, SILICONE, HARD TOP, ANOTHER RUBBER WASHER, STEEL PLATE, LOCK NUT.

The first 3 bolts (from the windshield) were on the same piece of steel. The sound bar prohibited the same piece be used all the way down the interior so I had to cut the steel. The first piece is 28 inches. The second is 11 inches (for the last two bolts that will be placed In between the sound bar and the rear windshield.)

The result is this beauty. Very very happy and took it through a car wash with no leaks. Very sturdy and strong to carry lightweight gear.

Sent from my iPhone using Tapatalk

Started out finding this on the xj.

Got it dismantled at the shop. 4 Philips bolts.

Picked up 20 rubber washers, 10 1 inch long stainless bolts, and according lock nuts.

Had to trim the lengths down to 51 inches so I took the end pieces off and used a chop saw and grinder. The end result should mimic the stock factory end you trimmed.

I also picked up a 1/2 inch by 6 ft piece of steel and already had a tube of silicon laying around to seal up the holes drilled in the hard top. The steel is for the inside of the hard top to evenly distribute the load.

I took the two cross members and sanded them with a fine grit sandpaper to make a rough surface and then sprayed them with a couple coats to get rid of the trashy sun damaged look.

Now was the time to put the new bolts in the rails and mark the hard top for drilling. The order of layers should be the following. RAIL, RUBBER WASHER, SILICONE, HARD TOP, ANOTHER RUBBER WASHER, STEEL PLATE, LOCK NUT.

The first 3 bolts (from the windshield) were on the same piece of steel. The sound bar prohibited the same piece be used all the way down the interior so I had to cut the steel. The first piece is 28 inches. The second is 11 inches (for the last two bolts that will be placed In between the sound bar and the rear windshield.)

The result is this beauty. Very very happy and took it through a car wash with no leaks. Very sturdy and strong to carry lightweight gear.

Sent from my iPhone using Tapatalk