This is an installation walkthrough of the ORO York bracket on a 2003 TJ 4.0 with AC (and a 160 amp Durango alternator).

The ORO York bracket is an improved version of the old Kilby York bracket. My understanding is that Kilby eliminates the factory belt tensioner and uses the York itself as the serpentine tensioner via slotted mounting bolt holes. This resulted in reports of squealing and uneven belt wear. ORO relocates the factory tensioner to its mount.

This is the kit.

http://offroadonly.com/shop/on-boar...ompressor-bracket-kit-for-jeep-wrangler-tj-2/

I think I received some of the wrong bolts. More on that later.

The included directions are decent enough and are written in an oddly fun conversational manner.

The bracket with my York compressor and the elusive 6 rib pulley and clutch.

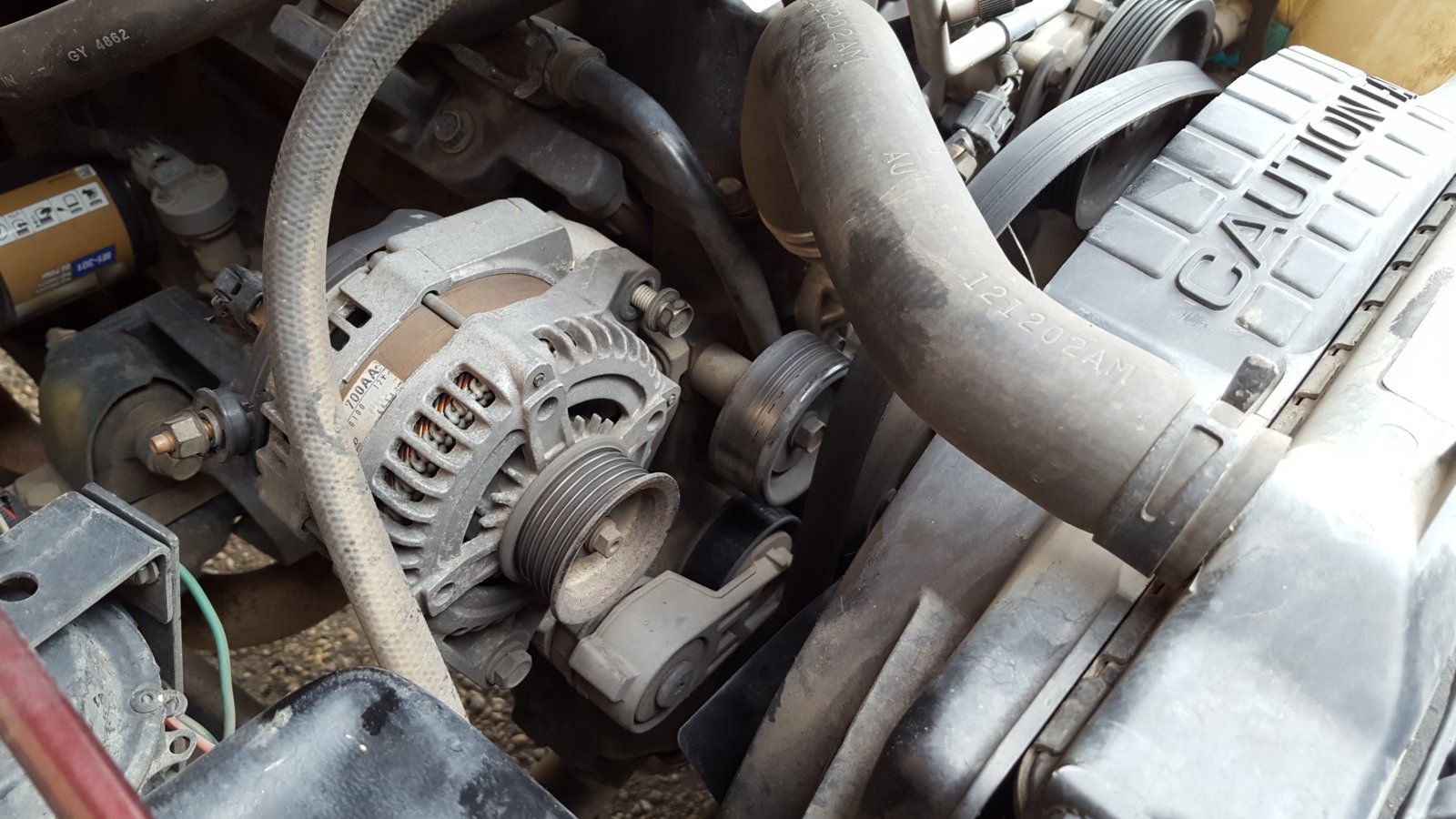

This is the factory 4.0, mostly. Several years ago, I installed a Windstar cowl intake. While you need to remove the factory intake for the install, the ORO bracket is supposed to fit with the factory intake. Remove the serpentine belt. Remove the alternator. Keep the long lower bolt. Then remove the belt tensioner. Keep the torx bolt.

Remove the alternator mounting bracket. this is not used in the final installation.

The empty engine block. The ORO bracket uses the four alternator bolt bosses, as well those two unused bosses further down. Clean those out, if needed.

Attach the factory belt tensioner to the ORO bracket.

Test fit your alternator. There is very little room to work in the final installation, so you need to understand how the alternator fits in place. If the alternator is not factory, you may need to clearance it.

The Durango alternator has an extra mounting arm on the top. This should already be cut off because it blocks the front spark plug. Chances are good that more will need to be filed away to make it fit in the ORO bracket.

After a bit of filing.

Set the alternator on the motor mount. This makes install a little easier later on.

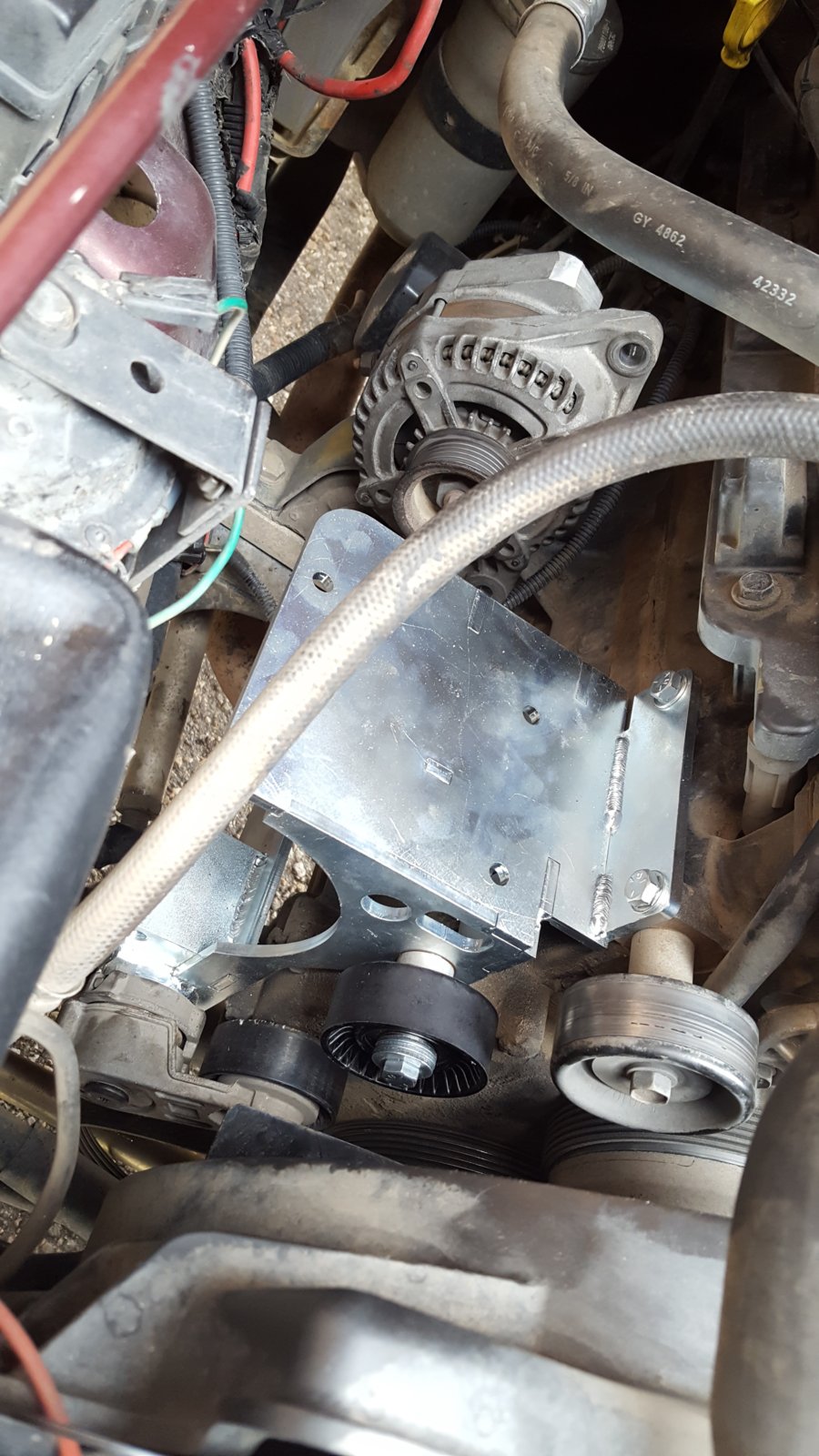

Attach the ORO bracket to the engine block using the old alternator bolt holes and the two bolt holes below. Also attach the added idler pulley.

This is where I hit the only notable problem. ORO supplies a pair of standoffs to fill the gap between the bracket and the lower holes on the block. The lower stand off was a nearly 1/32" too long and the bolt was not long enough.

Lots of work with a file, a trip to the hardware store for a bolt that is slightly too long, a few washers later and the problem was solved.

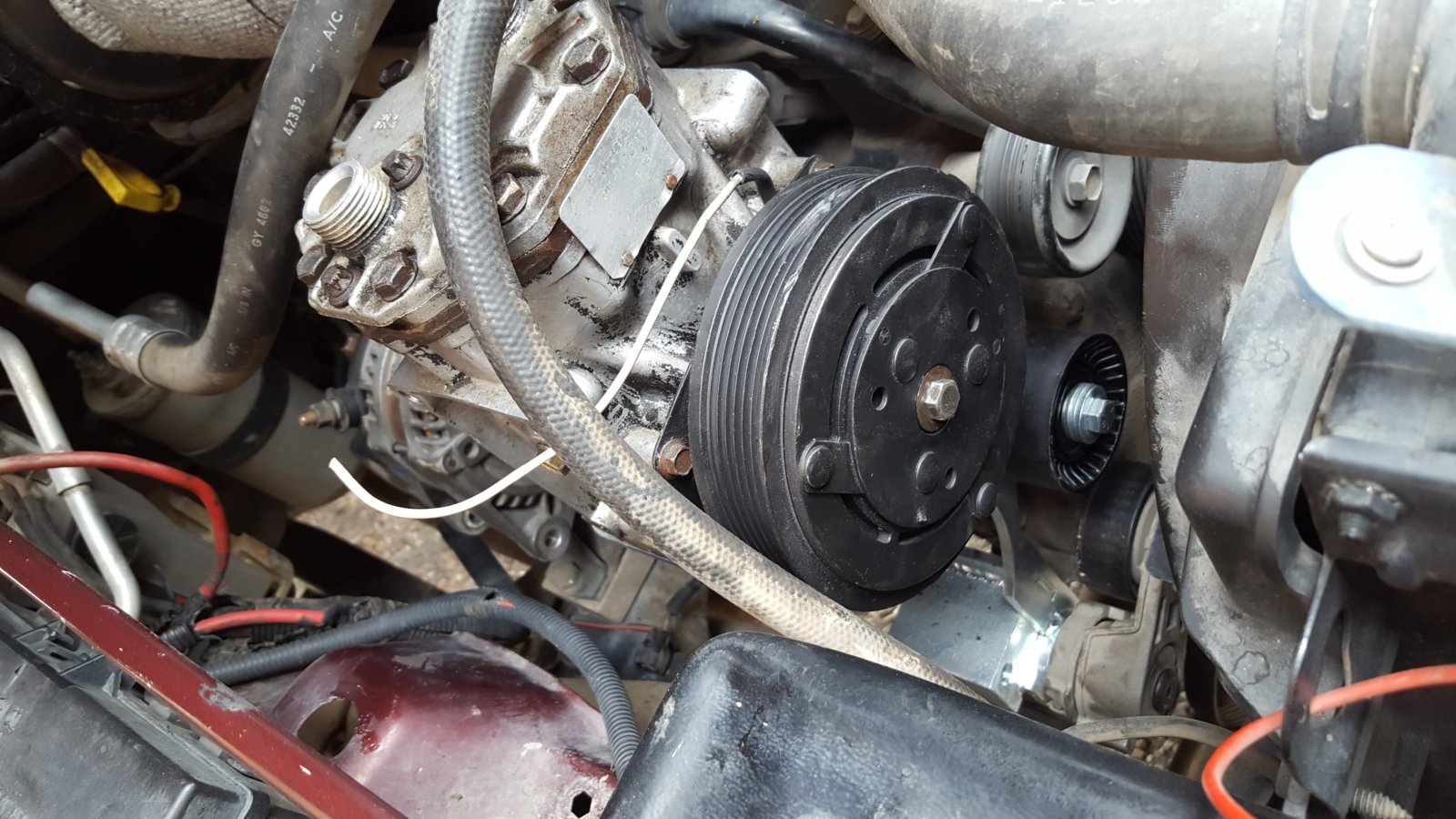

Mount the York to the top of the ORO bracket. I disconnected the AC lines from the bracket in front of the valve cover to help with access. Once the York is installed, you will need to bend the hard AC lines around to clear the York's suction and discharge ports. This isn't as scary as it sounds. Just go slow and make small adjustments all around until it works.

The hardest part is fighting to get the alternator in place. I didn't take pictures, but I found that I had to remove the York pulley in order to get decent access to the top bolt of the alternator. ORO supplies a big hex cap bolt for this. I used a hex socket, rather than a allen wrench. Reuse the factory long lower bolt. Connect the battery cable.

Re-route the new longer serpentine belt according to the supplied diagram. Close your eyes and start the engine.

The bracket install took me about 3-4 hours. It isn't particularly difficult. Just tedious at times. Except for the bolt and standoff issue, the bracket and its design appear to be very good. Driving around town, I can't tell anything new was added to the engine.

Now to figure out the plumbing.

The ORO York bracket is an improved version of the old Kilby York bracket. My understanding is that Kilby eliminates the factory belt tensioner and uses the York itself as the serpentine tensioner via slotted mounting bolt holes. This resulted in reports of squealing and uneven belt wear. ORO relocates the factory tensioner to its mount.

This is the kit.

http://offroadonly.com/shop/on-boar...ompressor-bracket-kit-for-jeep-wrangler-tj-2/

I think I received some of the wrong bolts. More on that later.

The included directions are decent enough and are written in an oddly fun conversational manner.

The bracket with my York compressor and the elusive 6 rib pulley and clutch.

This is the factory 4.0, mostly. Several years ago, I installed a Windstar cowl intake. While you need to remove the factory intake for the install, the ORO bracket is supposed to fit with the factory intake. Remove the serpentine belt. Remove the alternator. Keep the long lower bolt. Then remove the belt tensioner. Keep the torx bolt.

Remove the alternator mounting bracket. this is not used in the final installation.

The empty engine block. The ORO bracket uses the four alternator bolt bosses, as well those two unused bosses further down. Clean those out, if needed.

Attach the factory belt tensioner to the ORO bracket.

Test fit your alternator. There is very little room to work in the final installation, so you need to understand how the alternator fits in place. If the alternator is not factory, you may need to clearance it.

The Durango alternator has an extra mounting arm on the top. This should already be cut off because it blocks the front spark plug. Chances are good that more will need to be filed away to make it fit in the ORO bracket.

After a bit of filing.

Set the alternator on the motor mount. This makes install a little easier later on.

Attach the ORO bracket to the engine block using the old alternator bolt holes and the two bolt holes below. Also attach the added idler pulley.

This is where I hit the only notable problem. ORO supplies a pair of standoffs to fill the gap between the bracket and the lower holes on the block. The lower stand off was a nearly 1/32" too long and the bolt was not long enough.

Lots of work with a file, a trip to the hardware store for a bolt that is slightly too long, a few washers later and the problem was solved.

Mount the York to the top of the ORO bracket. I disconnected the AC lines from the bracket in front of the valve cover to help with access. Once the York is installed, you will need to bend the hard AC lines around to clear the York's suction and discharge ports. This isn't as scary as it sounds. Just go slow and make small adjustments all around until it works.

The hardest part is fighting to get the alternator in place. I didn't take pictures, but I found that I had to remove the York pulley in order to get decent access to the top bolt of the alternator. ORO supplies a big hex cap bolt for this. I used a hex socket, rather than a allen wrench. Reuse the factory long lower bolt. Connect the battery cable.

Re-route the new longer serpentine belt according to the supplied diagram. Close your eyes and start the engine.

The bracket install took me about 3-4 hours. It isn't particularly difficult. Just tedious at times. Except for the bolt and standoff issue, the bracket and its design appear to be very good. Driving around town, I can't tell anything new was added to the engine.

Now to figure out the plumbing.