There are a few ways to determine your axle gear ratio:

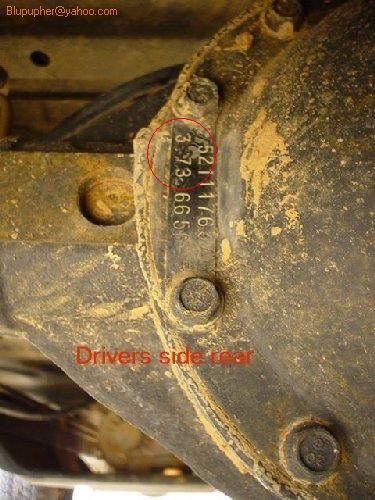

1. Look for a tag under one of the diff cover bolts in the 9 o'clock position. This will tell you what ratio the Jeep originally had and likely should still have. If someone would have regeared it, chances are they would not put the tag back on. Here is an example of an axle tag you would find on a TJ axle:

2. Get your build sheet / equipment listing instantly from Jeep by clicking here or request a build sheet from a Jeep dealer. This will tell you the ratio the Jeep should have left the factory with. Build sheets can be wrong and axles can be regeared or swapped out, so this does not guarantee 100% accuracy.

3. Jack up the rear end. Count driveshaft revolutions while rotating the tire. Turn the tire 2 complete rotations if your other tire remains stationary and does not rotate. Turn the tire 1 complete rotation if the other tire turns in the same direction. The number of times the driveshaft rotates equals the gear ratio. If the driveshaft rotates about 3x, the gear ratio is 3.07. If it rotates 3 3/4 turns, the gear ratio is 3.73. You can mark the driveshaft to help you count. NOTE: see post below if interested why you spin a tire 1 rotation or 2 rotations.

4. Log your RPM at 60 MPH in a 1:1 transmission gear and plug the numbers in the formula below:

5. Open the diff cover and count the number of teeth on the ring and pinion gears. The number of teeth on the ring gear divided by the number of teeth on the pinion gear equals the gear ratio. The tooth counts will also often be stamped in to the side of the ring gear. For example, a 3.73 gear set is pictured below (41 divided by 11).

1. Look for a tag under one of the diff cover bolts in the 9 o'clock position. This will tell you what ratio the Jeep originally had and likely should still have. If someone would have regeared it, chances are they would not put the tag back on. Here is an example of an axle tag you would find on a TJ axle:

2. Get your build sheet / equipment listing instantly from Jeep by clicking here or request a build sheet from a Jeep dealer. This will tell you the ratio the Jeep should have left the factory with. Build sheets can be wrong and axles can be regeared or swapped out, so this does not guarantee 100% accuracy.

3. Jack up the rear end. Count driveshaft revolutions while rotating the tire. Turn the tire 2 complete rotations if your other tire remains stationary and does not rotate. Turn the tire 1 complete rotation if the other tire turns in the same direction. The number of times the driveshaft rotates equals the gear ratio. If the driveshaft rotates about 3x, the gear ratio is 3.07. If it rotates 3 3/4 turns, the gear ratio is 3.73. You can mark the driveshaft to help you count. NOTE: see post below if interested why you spin a tire 1 rotation or 2 rotations.

4. Log your RPM at 60 MPH in a 1:1 transmission gear and plug the numbers in the formula below:

RPM x tire diameter

—————————- = Gear ratio

60 x 336

5. Open the diff cover and count the number of teeth on the ring and pinion gears. The number of teeth on the ring gear divided by the number of teeth on the pinion gear equals the gear ratio. The tooth counts will also often be stamped in to the side of the ring gear. For example, a 3.73 gear set is pictured below (41 divided by 11).