You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clean options for connecting winch cables to battery

- Thread starter TJ's-TJ

- Start date

Look up 'military battery terminal' or 'marine battery terminal' on Amazon. You'll be amazed how many options you have.

Or if your battery is old enough consider replacing it with a good quality AGM with connections on the side.

Do you have any recommendations?

I replaced my battery clamps with military style clamps which provide lots of flexibility.

https://www.amazon.ca/dp/B074STQ2C1/?tag=tjforum-20

https://www.amazon.ca/dp/B074STQ2C1/?tag=tjforum-20

Look up 'military battery terminal' or 'marine battery terminal' on Amazon. You'll be amazed how many options you have.

So this would involve cutting off my OEM connectors and crimping on a lug? Then those go on one side and the winch on the other of the military connector bolt?

My first recommendation is to avoid any of Optima's batteries, they no longer hold up since their manufacturing was moved to Mexico and they cheapened how they make the Blue, Red, and Yellow Top batteries. Not to mention Optima's side posts are not up to that 400 amp load I mentioned above.Do you have any recommendations?

Nearly any Group 34 AGM battery with side posts will be fine, get the one with the best warranty. I personally like Odyssey, Bosch, and Northstar but they're spendy. My previous battery was made by Odyssey and it was good for ten years. I recently replaced it with a Northstar.

Yes indeed.So this would involve cutting off my OEM connectors and crimping on a lug? Then those go on one side and the winch on the other of the military connector bolt?

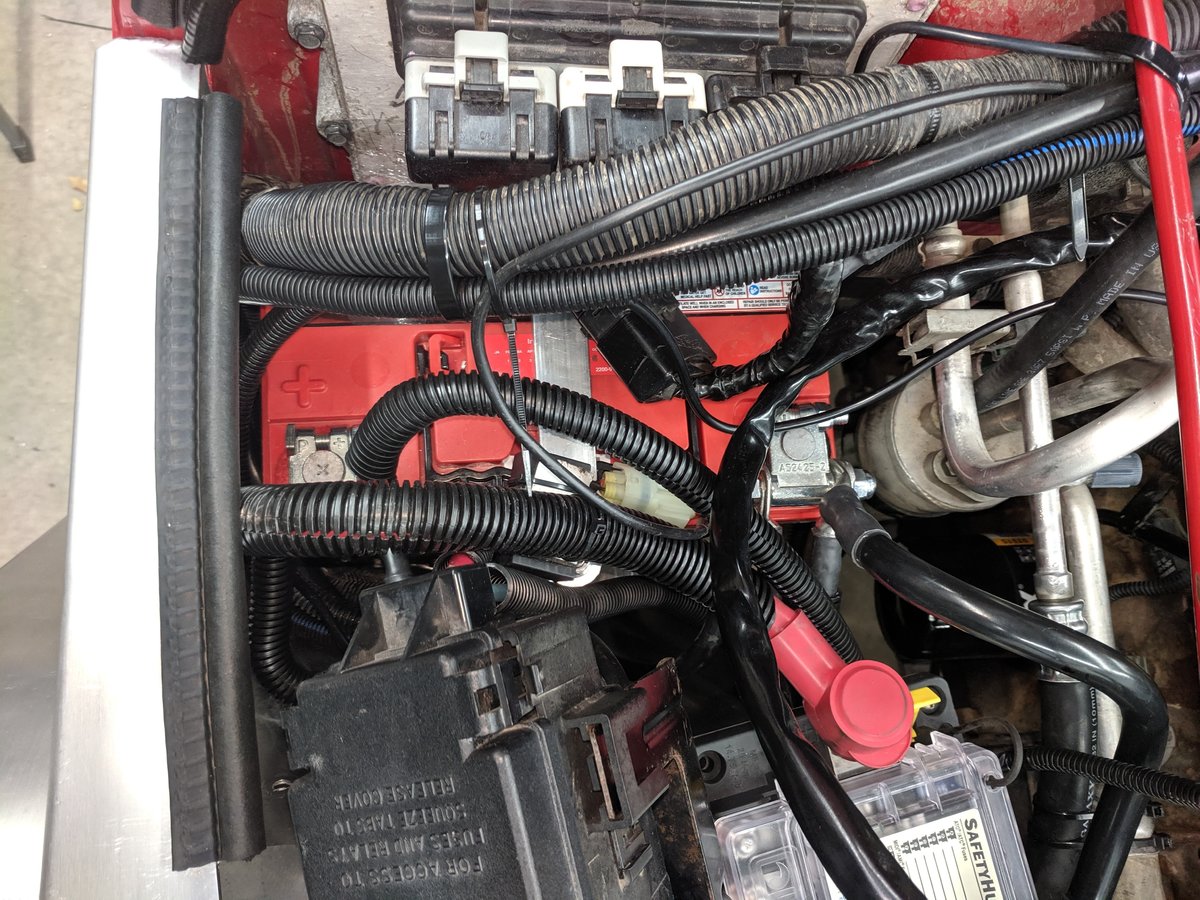

View attachment 134216

My first recommendation is to avoid any of Optima's batteries, they no longer hold up since their manufacturing was moved to Mexico and they cheapened how they make the Blue, Red, and Yellow Top batteries. Not to mention Optima's side posts are not up to that 400 amp load I mentioned above.

Nearly any Group 34 AGM battery with side posts will be fine, get the one with the best warranty. I personally like Odyssey, Bosch, and Northstar but they're spendy. My previous battery was made by Odyssey and it was good for ten years. I recently replaced it with a Northstar.

What do you recommend for minimum CCA?

Look up 'military battery terminal' or 'marine battery terminal' on Amazon. You'll be amazed how many options you have.

This! I've done a couple of these and it's the way to go. I don't crimp though. Instead, I cut the wires, slide them into the terminals and fill them with solder. Also, everything gets heat shrink tubing.

Stop soldering cables. It isn't good for the cable, the connection, or anything else that matters.This! I've done a couple of these and it's the way to go. I don't crimp though. Instead, I cut the wires, slide them into the terminals and fill them with solder. Also, everything gets heat shrink tubing.

View attachment 134218

Another option to solder / crimp is compression lugs. I've used all 3 methods and they work.This! I've done a couple of these and it's the way to go. I don't crimp though. Instead, I cut the wires, slide them into the terminals and fill them with solder. Also, everything gets heat shrink tubing.

View attachment 134218

LOL … I agree with you … but I didn't want to reopen that debate.Stop soldering cables. It isn't good for the cable, the connection, or anything else that matters.

If there's nothing wrong with your current cables, I'd just put the eyelet of the winch cables right on that existing pinch bolt.

Once you start adding a bunch of other stuff a military terminal is convenient. I like the zinc ones from Prime4x4.

Once you start adding a bunch of other stuff a military terminal is convenient. I like the zinc ones from Prime4x4.

Don't solder them, they need to be crimped with a suitable heavy-duty crimping too. Soldering them can create stress risers which can damage the cable. Look around, you won't find any soldered connections in a Jeep except in a few places like on the PCM and radio circuit boards, and a hidden splice of some ground wires.Another option to solder / crimp is compression lugs. I've used all 3 methods and they work.

Stop soldering cables. It isn't good for the cable, the connection, or anything else that matters.

LOL, I knew this wouldn't take long! I've been hearing this debate for decades. The reality is crimping or soldering can work, if done correctly. However, most don't take the time to do it right, so I'll acquiesce and move on.

I've been soldering for over 5 decades, and soldering is NOT the right thing for that type of connector. NASA did studies many years ago and found that soldering is a risky procedure that gives a less reliable connection. That's why the vast majority of connections in automotive, military, and aerospace long-ago went to crimped connections. It was hard for me to give up soldering things like that but I learned and no longer grab my soldering tools for nearly all connections like I used to.LOL, I knew this wouldn't take long! I've been hearing this debate for decades. The reality is crimping or soldering can work, if done correctly. However, most don't take the time to do it right, so I'll acquiesce and move on.

Fact- if you get the solder hot enough to flow and it should flow, it flows into the strands and makes a stress riser at the end of the solder that compromises the ability of the cable to flex as it should in a mobile environment.LOL, I knew this wouldn't take long! I've been hearing this debate for decades. The reality is crimping or soldering can work, if done correctly. However, most don't take the time to do it right, so I'll acquiesce and move on.

Fact- solder has flux that it carries into the wire strands that can easily cause corrosion.

Fact- if you get solder hot enough to flow and you should, that heat level compromises the cable insulation.

You can ignore the facts, but you can't change them.