What’s the deal with the Jeep Wrangler Rubicon’s four-to-one (4:1) transfer case? What about those 4.10 gears in those beefy Dana 44 axles? Why is it that when people put bigger tires on their vehicles, they have to “re-gear?” Well, the goal of all of this gearing is to help the vehicle transmit more force to the ground. Here’s why it’s so important.

Transmitting Force To The Ground

For any object to accelerate, there must be a net force acting on that object. The same thing applies to a jacked-up Wrangler YJ on 37 inch tires trying to get up a steep rock. To get the vehicle to move over the obstacle, those tires need to be able to transmit force to the rock so that the rock can then produce a reactionary force that pushes the car up and over the obstacle. Maximizing that force has been the goal of off-road enthusiasts since the beginning of time.

Probably the brand that most likes to boast about its off-road cred is Jeep. One of the buzzwords they like to throw around when introducing a “Trail Rated” vehicle is “Crawl Ratio.” They’ll tell you how their new vehicle has a huge 73:1 crawl ratio and that makes it the best off-roader since the Willys MB. But crawl ratio isn’t really what matters off road. What truly matters is how much force your tire tread can apply against the ground surface.

Of course, a bigger crawl ratio helps you get more force to the ground, but there are other factors in play like tire size and engine torque. We’ll talk about all those other factors, but let’s first discuss crawl ratio.

Crawl Ratio

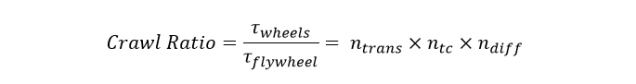

A crawl ratio is simply the ratio of torque at the wheels to torque at your engine’s flywheel. It represents how many times your engine torque is multiplied before it gets to the place where the actual propulsion occurs. There are only three components that determine a vehicle’s crawl ratio: transmission, transfer case, and differential (see image above).

Power from the engine goes through the transmission, then through the transfer case, and finally through the differential (sometimes called the “final drive,” because it is the final gear reduction). Power from the engine is conserved — you can’t gain more power by simply going through a set of gears, but you can gain more torque. And since power is proportional to torque x RPM (horsepower = torque*RPM/5252), if you go through a gear reduction and increase your output torque, you have to decrease your RPM by the same ratio to keep your power constant.

As your engine’s power steps its way through the trans, t-case, and diff, it trades angular velocity (RPM) for torque. In other words, each time engine power is sent through a gear reduction (in the transmission, transfer case, and differential), the output speed is lower than the input speed, but the output torque is higher.

So, how do we figure out how much more torque is at the wheels than at the flywheel? Simple. By multiplying engine torque by the gear ratios in the three gear sets, we can arrive at a crawl ratio. In equation form:

In the equation above, τwheels is the torque at the wheels, τflywheel is the torque leaving the engine and entering the transmission, ntc is the low range gear ratio in the transfer case, ntrans is the first gear ratio in the transmission, and ndiff is the axle ratio.

Example:

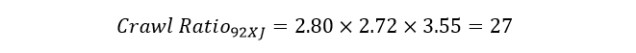

A 1992 Jeep Cherokee has an AW4 4-speed automatic transmission with the following gear ratios (first through fourth): 2.80, 1.53, 1.00 & .75. The Jeep is equipped with an NP231 transfer case with a 2.72-to-one “low range” reduction and 3.55 axle ratios.

To calculate the crawl ratio, simply multiply the shortest transmission gear ratio (the one that multiplies the torque most, i.e. first gear) by the low range gear ratio and the axle ratio.

By comparison, the new Wrangler Rubicon with a manual transmission has a first gear ratio of 4.46, a 4-to-1 transfer case, and 4.10 axle ratios. This equates to an enormous crawl ratio of 73!

Low End Torque

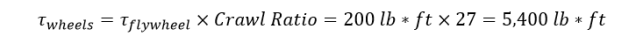

But crawl ratio, by itself, means very little without mentioning engine torque. You need to know what torque you’re actually multiplying by the crawl ratio to really understand how well your vehicle will handle the rough stuff. The crawl ratio of 27 we calculated above for the XJ is perfectly sufficient because the 4.0-liter produces nearly 200 lb-ft of torque at idle. And we know that torque at the wheels is simply the crawl ratio multiplied by engine torque. So, for the XJ, at idle in low range:

That’s a lot of torque at the wheels. That’s good, because not having to rev the engine to produce torque means the Jeep can travel nice and slowly over the rocks. If my XJ had the anemic 2.5-liter inline four, however, the same crawl ratio of 27 would yield much lower torque at the wheels and would make accelerating up rocks a rather pitiful experience. This is why four cylinder XJs came with 4.10 differential gears.

So, torque at the wheels is good, but it doesn’t tell the whole story. Tires also play a big role in gearing, too.

Tires

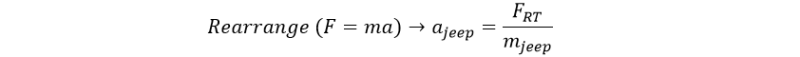

Going from skinny 30 inch tires to knobby 37s is great for ground clearance and traction, but it can do a number on a vehicle’s acceleration. Why? By rearranging Newton’s second law, we know that the acceleration of a car is equal to the net force acting on the car, divided by the mass of the car:

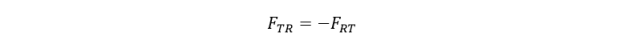

The reason why your car moves forward at all is because the ground is actually “pushing” the car forward by reacting to your wheel’s force against the ground. This is Newton’s Third Law: The force that the tire produces on the road is greeted by an equal and opposite force of the road onto the tire:

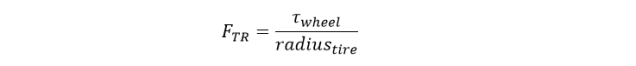

As shown in the image above, your axle produces a torque, τwheel, on your wheel. As we know, this torque is simply the engine torque times the crawl ratio. To determine the force the tire imparts on the road, FTR, we need to recall that torque is equal to a force times a distance. Think of this like your wrench: if you produce a force on a long wrench, it will produce more torque than imparting that same force on a short wrench.

The torque produced at the wheel, then, results in a force at the ground equal to the torque divided by the tire radius. This means bigger tires yield less force. And since mass is remaining unchanged, Newton’s Second Law (see rearranged equation above) says our acceleration will drop. This is why you want to regear when you have bigger tires: you want to increase τwheel to keep the force, Frt high enough to provide decent acceleration.

It should also be noted that the principles mentioned above are highly simplified and don’t account for increased moments of inertia of the larger tires. But larger tires do indeed have higher moments of inertia, meaning they require more torque to rotate. We won’t delve into this, but it provides yet another reason why re-gearing is so crucial.

Having More Control While Going Slowly

Another huge benefit of proper gearing besides simply getting more force to the ground is the ability to traverse obstacles more slowly and in a more controlled manner. Engines tend to produce maximum power high in their rev range (which makes sense, as power = torque x rpm). In order to provide your vehicle with lots of torque to traverse steep grades at low vehicle speeds, you want your engine to be able to spin fast while your wheels spin slowly. This keeps your engine near peak power while your vehicle is at a low, controlled speed.

This is the benefit of a big crawl ratio: it not only multiplies your engine torque, but it allows your engine to actually produce more power by keeping it high in the rev range at low vehicle speeds. This power can then go through many gear reductions to ultimately produce lots of torque at the wheels.

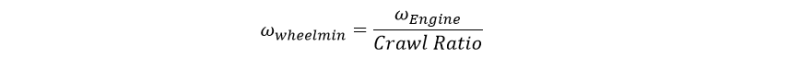

Having enough power to slowly traverse obstacles is one thing, but even if you have enough power at idle, you may be limited in how slowly you can physically drive before stalling the engine. And driving slowly off-road can be the difference between navigating a complex obstacle and shearing an axle shaft. Low speed limits are especially a problem for vehicles with a manual transmissions where your wheels are rigidly coupled with your engine. The engine has a certain minimum idle speed, usually around 600-800 rpm. This idle speed, ωEngine, is directly related to your minimum wheel RPM by the following equation:

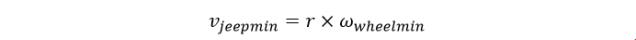

This means that a high crawl ratio yields a low minimum rotational wheel speed. This makes sense: if you have really short gearing, your wheels will spin really slowly compared to your crankshaft. And a low rotational tire speed means a low vehicle speed, because vehicle speed is related to tire RPM by the tire radius, r:

So, if you have enormous tires, your minimum driving speed will be pretty high, that is, unless you regear and bump up that crawl ratio.

Having too high of a crawl speed can cause trouble when you’re in tight, hairy spots. Of course, there are ways to drive more slowly with a manual if you aren’t geared properly, but you’d either have to use the starter motor to move the car, or allow the tires or clutch to slip. Not exactly great options when there’s a 100 foot cliff on either side.

This “minimum crawl speed” isn’t so much of an issue for an automatic, since you can drive as slowly as you want without the engine stalling thanks to some good ol’ torque converter slippage. This will keep the engine idling even if your wheels aren’t spinning at all, though there will quite a bit of oil shearing, so it tends to generate considerable heat in the transmission. A well-sized transmission cooler can handle that, though. In fact, when the torque converter is slipping and shearing fluid, it will actually multiply engine torque by up to a factor of two. And more torque equals more better.

On-Road Driveability

Another thing to consider when gearing a car is how it will affect on-road driving. Shorter gearing will allow for for more torque at the wheels, and thus better acceleration, but it may limit top speed. Having a high crawl ratio (i.e. short gearing) means your tires will spin very slowly while your engine RPM is very high. This can lead to low top speeds, unless you size your tire properly. Recall that vehicle velocity is simply tire radius times tire RPM. So even with a huge crawl ratio, larger tires can bring your engine speeds down and make highway driving work just fine.

Tall gearing tends to allow for better fuel economy, but increases minimum crawl speed and does a number on acceleration. Tall gearing doesn’t necessarily equate to low highway RPMs and good fuel economy, though. Often times, people throw enormous tires onto their Jeeps and don’t bother to regear. The bigger tires reduce the thrust that moves the car forward, and when that forward force cannot overcome drag, the transmission will have to downshift to provide more torque to the wheels. This results in poor fuel economy and loud highway driving.

The sweet spot is a crawl ratio that gives the best of all worlds: short enough to provide good acceleration and low crawl speed, but tall enough to allow the engine to keep its RPMs down on highway speeds. Understanding the balance between gearing and tire size is the key to off-road success!

Transmitting Force To The Ground

For any object to accelerate, there must be a net force acting on that object. The same thing applies to a jacked-up Wrangler YJ on 37 inch tires trying to get up a steep rock. To get the vehicle to move over the obstacle, those tires need to be able to transmit force to the rock so that the rock can then produce a reactionary force that pushes the car up and over the obstacle. Maximizing that force has been the goal of off-road enthusiasts since the beginning of time.

Probably the brand that most likes to boast about its off-road cred is Jeep. One of the buzzwords they like to throw around when introducing a “Trail Rated” vehicle is “Crawl Ratio.” They’ll tell you how their new vehicle has a huge 73:1 crawl ratio and that makes it the best off-roader since the Willys MB. But crawl ratio isn’t really what matters off road. What truly matters is how much force your tire tread can apply against the ground surface.

Of course, a bigger crawl ratio helps you get more force to the ground, but there are other factors in play like tire size and engine torque. We’ll talk about all those other factors, but let’s first discuss crawl ratio.

Crawl Ratio

A crawl ratio is simply the ratio of torque at the wheels to torque at your engine’s flywheel. It represents how many times your engine torque is multiplied before it gets to the place where the actual propulsion occurs. There are only three components that determine a vehicle’s crawl ratio: transmission, transfer case, and differential (see image above).

Power from the engine goes through the transmission, then through the transfer case, and finally through the differential (sometimes called the “final drive,” because it is the final gear reduction). Power from the engine is conserved — you can’t gain more power by simply going through a set of gears, but you can gain more torque. And since power is proportional to torque x RPM (horsepower = torque*RPM/5252), if you go through a gear reduction and increase your output torque, you have to decrease your RPM by the same ratio to keep your power constant.

As your engine’s power steps its way through the trans, t-case, and diff, it trades angular velocity (RPM) for torque. In other words, each time engine power is sent through a gear reduction (in the transmission, transfer case, and differential), the output speed is lower than the input speed, but the output torque is higher.

So, how do we figure out how much more torque is at the wheels than at the flywheel? Simple. By multiplying engine torque by the gear ratios in the three gear sets, we can arrive at a crawl ratio. In equation form:

In the equation above, τwheels is the torque at the wheels, τflywheel is the torque leaving the engine and entering the transmission, ntc is the low range gear ratio in the transfer case, ntrans is the first gear ratio in the transmission, and ndiff is the axle ratio.

Example:

A 1992 Jeep Cherokee has an AW4 4-speed automatic transmission with the following gear ratios (first through fourth): 2.80, 1.53, 1.00 & .75. The Jeep is equipped with an NP231 transfer case with a 2.72-to-one “low range” reduction and 3.55 axle ratios.

To calculate the crawl ratio, simply multiply the shortest transmission gear ratio (the one that multiplies the torque most, i.e. first gear) by the low range gear ratio and the axle ratio.

By comparison, the new Wrangler Rubicon with a manual transmission has a first gear ratio of 4.46, a 4-to-1 transfer case, and 4.10 axle ratios. This equates to an enormous crawl ratio of 73!

Low End Torque

But crawl ratio, by itself, means very little without mentioning engine torque. You need to know what torque you’re actually multiplying by the crawl ratio to really understand how well your vehicle will handle the rough stuff. The crawl ratio of 27 we calculated above for the XJ is perfectly sufficient because the 4.0-liter produces nearly 200 lb-ft of torque at idle. And we know that torque at the wheels is simply the crawl ratio multiplied by engine torque. So, for the XJ, at idle in low range:

That’s a lot of torque at the wheels. That’s good, because not having to rev the engine to produce torque means the Jeep can travel nice and slowly over the rocks. If my XJ had the anemic 2.5-liter inline four, however, the same crawl ratio of 27 would yield much lower torque at the wheels and would make accelerating up rocks a rather pitiful experience. This is why four cylinder XJs came with 4.10 differential gears.

So, torque at the wheels is good, but it doesn’t tell the whole story. Tires also play a big role in gearing, too.

Tires

Going from skinny 30 inch tires to knobby 37s is great for ground clearance and traction, but it can do a number on a vehicle’s acceleration. Why? By rearranging Newton’s second law, we know that the acceleration of a car is equal to the net force acting on the car, divided by the mass of the car:

The reason why your car moves forward at all is because the ground is actually “pushing” the car forward by reacting to your wheel’s force against the ground. This is Newton’s Third Law: The force that the tire produces on the road is greeted by an equal and opposite force of the road onto the tire:

As shown in the image above, your axle produces a torque, τwheel, on your wheel. As we know, this torque is simply the engine torque times the crawl ratio. To determine the force the tire imparts on the road, FTR, we need to recall that torque is equal to a force times a distance. Think of this like your wrench: if you produce a force on a long wrench, it will produce more torque than imparting that same force on a short wrench.

The torque produced at the wheel, then, results in a force at the ground equal to the torque divided by the tire radius. This means bigger tires yield less force. And since mass is remaining unchanged, Newton’s Second Law (see rearranged equation above) says our acceleration will drop. This is why you want to regear when you have bigger tires: you want to increase τwheel to keep the force, Frt high enough to provide decent acceleration.

It should also be noted that the principles mentioned above are highly simplified and don’t account for increased moments of inertia of the larger tires. But larger tires do indeed have higher moments of inertia, meaning they require more torque to rotate. We won’t delve into this, but it provides yet another reason why re-gearing is so crucial.

Having More Control While Going Slowly

Another huge benefit of proper gearing besides simply getting more force to the ground is the ability to traverse obstacles more slowly and in a more controlled manner. Engines tend to produce maximum power high in their rev range (which makes sense, as power = torque x rpm). In order to provide your vehicle with lots of torque to traverse steep grades at low vehicle speeds, you want your engine to be able to spin fast while your wheels spin slowly. This keeps your engine near peak power while your vehicle is at a low, controlled speed.

This is the benefit of a big crawl ratio: it not only multiplies your engine torque, but it allows your engine to actually produce more power by keeping it high in the rev range at low vehicle speeds. This power can then go through many gear reductions to ultimately produce lots of torque at the wheels.

Having enough power to slowly traverse obstacles is one thing, but even if you have enough power at idle, you may be limited in how slowly you can physically drive before stalling the engine. And driving slowly off-road can be the difference between navigating a complex obstacle and shearing an axle shaft. Low speed limits are especially a problem for vehicles with a manual transmissions where your wheels are rigidly coupled with your engine. The engine has a certain minimum idle speed, usually around 600-800 rpm. This idle speed, ωEngine, is directly related to your minimum wheel RPM by the following equation:

This means that a high crawl ratio yields a low minimum rotational wheel speed. This makes sense: if you have really short gearing, your wheels will spin really slowly compared to your crankshaft. And a low rotational tire speed means a low vehicle speed, because vehicle speed is related to tire RPM by the tire radius, r:

So, if you have enormous tires, your minimum driving speed will be pretty high, that is, unless you regear and bump up that crawl ratio.

Having too high of a crawl speed can cause trouble when you’re in tight, hairy spots. Of course, there are ways to drive more slowly with a manual if you aren’t geared properly, but you’d either have to use the starter motor to move the car, or allow the tires or clutch to slip. Not exactly great options when there’s a 100 foot cliff on either side.

This “minimum crawl speed” isn’t so much of an issue for an automatic, since you can drive as slowly as you want without the engine stalling thanks to some good ol’ torque converter slippage. This will keep the engine idling even if your wheels aren’t spinning at all, though there will quite a bit of oil shearing, so it tends to generate considerable heat in the transmission. A well-sized transmission cooler can handle that, though. In fact, when the torque converter is slipping and shearing fluid, it will actually multiply engine torque by up to a factor of two. And more torque equals more better.

On-Road Driveability

Another thing to consider when gearing a car is how it will affect on-road driving. Shorter gearing will allow for for more torque at the wheels, and thus better acceleration, but it may limit top speed. Having a high crawl ratio (i.e. short gearing) means your tires will spin very slowly while your engine RPM is very high. This can lead to low top speeds, unless you size your tire properly. Recall that vehicle velocity is simply tire radius times tire RPM. So even with a huge crawl ratio, larger tires can bring your engine speeds down and make highway driving work just fine.

Tall gearing tends to allow for better fuel economy, but increases minimum crawl speed and does a number on acceleration. Tall gearing doesn’t necessarily equate to low highway RPMs and good fuel economy, though. Often times, people throw enormous tires onto their Jeeps and don’t bother to regear. The bigger tires reduce the thrust that moves the car forward, and when that forward force cannot overcome drag, the transmission will have to downshift to provide more torque to the wheels. This results in poor fuel economy and loud highway driving.

The sweet spot is a crawl ratio that gives the best of all worlds: short enough to provide good acceleration and low crawl speed, but tall enough to allow the engine to keep its RPMs down on highway speeds. Understanding the balance between gearing and tire size is the key to off-road success!